Академический Документы

Профессиональный Документы

Культура Документы

Article 1437035604

Загружено:

berangketrИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Article 1437035604

Загружено:

berangketrАвторское право:

Доступные форматы

International Journal of TechnoChem Research

ISSN:395-4248

www.technochemsai.com

Vol.01, No.02, pp 70-78, 2015

Numerical Analysis of Piled Raft Foundation using Fem

with Interaction Effects

Naveen kumar.D

Mtech structural engineering SASTRA University. India

Abstract : In modern construction, a piled-raft foundation is a composite construction which consists

of piles and raft is one of the alternatives over conventional pile or raft foundations. It is used not only

for reducing the settlement of soil, but also can handle large eccentric loading. The analysis of piled

raft foundation is very tough and the design of piled raft with soil interaction effect is one of the

major problem as the behavior of a structure is highly affected not only by the response of the

superstructure, but also by the behaviour of the foundation and the soil as well. In this study, the piled

raft foundation is analyzed using ANSYS (2D analysis), a popular finite element software to study the

load displacement response in a sand medium of various relative densities (loose, medium dense and

dense) with interaction effects.

Three different pile spacing - 3d, 4d and 5d were considered for the study (where d is the pile

diameter) with three different pile configuration (3x3, 4x4 and 5x5) with an objective of finding the

optimum number of piles and pile spacing for various relative densities of sand. The results show that

the ultimate load and settlement corresponding to ultimate load increases with the relative density.

Lesser settlement is observed when the frictional angle of the sand is increased and increases when the

number of piles are increasing. The rate of settlement decreases with the increase in relative density of

the soil. The load settlement response of medium and dense sand is almost identical. The performance

of a 4 x 4 pile group is observed to optimum.

Key Words: eccentric loading, pile raft foundation, ANSYS, settlement, relative density.

Introduction

The piled raft foundation is a composite structure which consist of three bearing parts the piles, mat

and underground soil. The overall load from the superstructure is partly carried by the mat through the effect of

subsoil and the remaining load only carried by the piles under the effect of negative skin friction (1). The piled

raft foundation is mainly used to reduce the settlement particularly the differential settlement. It is an

economical design without affecting the safety criteria. The behavior of piled raft foundation mainly depends on

the complex soil structure interaction effects and an understanding of these effects is necessary for the reliable

design of such foundation (2).

In a pile foundation the contribution of pile cap that functions as a raft is completely neglected. It is

used only for the supporting the structure. The piles alone carry the loads and transmit the load to the deep

stratum. On the other hand, in a raft foundation the total building load is carried only by the raft demanding a

very thick raft, which thereby increases the cost of the foundation as well as it undergoes a large settlement.

Piled raft foundation is therefore a best alternative for carrying more load and also containing settlement to a

smaller degree (3). It also allows shorter length of piles and lesser thickness of raft in the design, thereby proving

highly economical.

The present study highlights the change in the load carrying capacity and their corresponding

settlements for the various combination of spacing between the piles and the number of piles in different

Naveen kumar.D /Int.J. TechnoChem Res. 2015,1(2),pp 70-78.

71

relative densities of sand loose, medium dense and dense (4). Finite element analysis using ANSYS 12.0 is

used to evaluate the effect of some parameters such as the spacing between the piles and the number of piles on

the load settlement behavior of the piled raft foundation. The analysis is done for three different spacing and

three different group of piles.

It is necessary to consider the effect of various interactions which are present within the piled raft

foundation: pile-pile interaction, pile-raft interaction, and raft-raft interaction. These effects are generally

ignored in most of the common structural analyses, so it might seriously underestimate Piled raft foundations

have the capacity to provide economical foundation systems (5). Piled raft foundations are most suitable for

foundations of high rise buildings in weak soil also. The analysis of piled raft foundation is very tough and time

consuming, so computers are often used. When a large number of piles or a large size of raft is involved, then

more computing time is need for the analysis. The only disadvantage is that all the elements in the mat

foundation should be square shaped and to be equal size (6).

Increasing the thickness of raft gradually decreases the total and differential settlement but increases the

induced bending moment. There is a limit for thickness of the raft that reduces the differential settlement. But

this option does not fulfill economical design concepts and very sensitive. Rising the length of the pile

gradually decreases the total and differential settlements but does not decreases the induced bending moments.

The maximum carrying moment of soft clay are higher than that of silty sand and stiff clay (7).

The ultimate settlements are affected only lesser amount by the type of soil. Ultimate Moment carrying

capacity is a function of type of Soil, Diameter of piles, Pile configuration and Amount of concrete (8). Provide

larger inner pile diameters with smaller outer pile diameter will give better results. Pile length does not have

more impact on the maximum load carrying capacity. If the pile diameter increases then the maximum load

carrying capacity increases gradually (9).

Methodology

Two dimensional plane strain analysis using finite element software ANSYS to find the ultimate load

carrying capacity and settlement of a piled raft foundation. It is one of the non-linear analysis and in this project

only deals with vertical loads. Here, pile and mat are taken as linear and isotropic while the soil-raft interface

and soil-pile interface are treated as non-linear. Drucker-Prager model is used for representing the soil.

The following properties are taken for the analysis of pile and mat, i) Youngs modulus (E), ii)

Poissons ratio () and iii) Density for pile and raft (10). Soil is treated as elasto - plastic and having the linear

material properties and properties that describe non-linear behaviour are material cohesion strength (c), angle of

internal friction () and flow angle () are explained. For the design of piles, mat and underground soil,

PLANE 82 is used as the type of element and the behavior of the element is taken as plane strain behaviour.

The interface behaviour is designed as non- linear behaviour. The Contact elements CONTA 172 and

TARGET 169 at soil-pile interface and soil-raft interface for soil and raft respectively provides complete

analysis. On the boundary conditions, nodes which present in the bottom of the soil zone is fixed against

movement in both vertical and horizontal directions on the other way the zone away from pile raft (the vertical

surface of underground soil at the boundary) is restricted only against the horizontal movements. The

horizontal boundary (H) is fixed at 5 times the width of the piled raft cluster (5D) and the vertical boundary (V)

is fixed at 3 times the width of the piled raft cluster (3D).

The load is applied on the center of the upper raft surface for the analysis. After giving all the inputs the

model can be solved for the given boundary and loading conditions. The results will be in the form of contour

diagram for the study on the settlement behaviour until failure under various loads. The nodal solutions and the

contour graphs describe the results of the analysis indicating the load-settlement response of the structure.

This process should be tried for various combinations of spacing of pile (3d, 4d and 5d), where d is the

pile diameter and for various number of piles (3x3, 4x4 and 5x5) in square configuration in different relative

densities of sand (loose sand, medium sand and dense sand) by changing the material properties. The results for

the various combinations are compared for the optimum results.

Values Of The Parameters

A brief summary of the parameters selected for the study are given below:

Pile diameter=0.5 m

Naveen kumar.D /Int.J. TechnoChem Res. 2015,1(2),pp 70-78.

72

Pile length=5 m

Pile spacing: 3 d, 4 d and 5 d , where d diameter of the pile

Number of piles: 9, 16 and 25

Configuration : square - 3x3, 4x4 & 5x5

Thickness of the raft= 0.5m

Type of Soil: loose sand , medium sand and dense sand

Material Properties

The properties of the piles, raft and soil are given below in tables 5.1 and 5.2. The pile and raft is made

up of concrete. Hence, properties of concrete are used to model the pile and raft. The pile and raft show linear

isotropic behaviour.

Table 1 Properties of the Materials

Description

E (kPa)

(kg/m)

Piled &raft

2.5*10^7

0.15

2500

Soil

2*10^4

0.2

2000

The Drucker Prager model is used to model soil for non-linear behaviour.The soil selected for the study

is sand. A minimal cohesion for all the relative densities selected in this study.

Table 2 Properies of Soil

Description

c

Loose sand

5 kPa

15

6

Medium sand

5 kPa

30

6

Dense sand

5 kPa

42

10

Three different relative densities loose, medium dense and dense are modelled by varying the angle of

internal friction and by assigning an appropriate dilatancy (i.e.) flow angle.

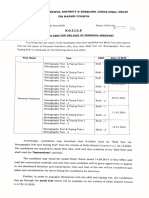

Figure 1:Ansys Model of 4x4 Pile Group

Naveen kumar.D /Int.J. TechnoChem Res. 2015,1(2),pp 70-78.

73

Figure 2: Meshed Model of 4x4 Pile Group

Figure 3: Contour Diagram of 4x4 Pile Group

Results and Discussions

1.Load Vs Settlement

The response of the piled raft foundation system for various load, with different spacing of piles and

number of piles are studied with special interest on its load settlement behaviour. For the constant value of 5

loads the settlements are calculated for various combinations.

Case (i): 9 piles (3x3)

This is for 9 pile groups. The procedure is done for 3 different spacing and for three different types of

soils. From the table the settlement increases with the increase in spacing between the piles and decreases with

the increases in angle of internal friction

Table 3: Load Vs Displacement for 9 Piles

Load

(kN)

100

300

500

700

900

15

2.96

11.46

23.11

46.56

75.45

3d spacing

30

42

2.08

1.96

10.57

9.15

17.23

14.19

21.22

18.95

29.53

24.62

15

3.38

15.62

35.16

45.17

53.49

4d spacing

30

2.15

14.54

27.56

38.90

46.26

42

2.03

13.45

22.86

32.03

40.79

15

3.84

16.32

37.24

60.40

86.65

5d spacing

30

2.32

12.65

24.14

36.73

51.30

42

2.11

11.87

21.24

30.96

40.90

Case (ii) 16 piles (4x4):

Here the number of piles changes from 9 to 16. The spacing and the relative density of the soil of

various combinations are continued by the same way of 9 piles. The same way of increase in the

settlement like 9 pile group.

Naveen kumar.D /Int.J. TechnoChem Res. 2015,1(2),pp 70-78.

74

Table 4: Load Vs Displacement for 16 Piles

Load

(kN)

100

300

500

700

900

15

3.21

14.25

31.51

52.38

77.58

3d spacing

30

2.31

11.27

21.29

32.04

38.54

42

2.11

10.95

18.73

27.18

34.15

15

4.28

15.08

33.76

56.54

81.23

4d spacing

30

3.56

12.94

24.10

36.47

48.15

42

3.22

12.65

22.09

30.61

39.37

15

4.17

16.14

35.12

60.02

85.68

5d spacing

30

3.63

14.53

27.09

40.43

53.59

42

3.34

12.73

26.34

35.97

42.84

Case (iii) 25 piles (5x5):

In this test instead of 16 piles 25 piles are used. The remaining procedure is almost similar. For this also

three different spacing and three different soil conditions are used.it is observed that when the number of piles

increases the settlement also increases.

Table 5: Load Vs Displacement for 25 Piles

Load

(kN)

100

300

500

700

900

15

3.42

13.98

30.51

54.30

70.78

3d spacing

30

2.51

12.43

22.81

32.23

37.59

42

2.14

12.21

18.13

25.16

33.37

15

5.84

15.48

33.08

57.19

87.35

4d spacing

30

4.67

14.39

26.24

39.11

53.27

42

4.55

14.18

24.53

35.23

47.97

15

8.24

17.25

36.05

61.78

92.18

5d spacing

30

7.12

16.98

28.71

41.04

55.28

42

6.97

16.82

26.42

38.71

52.93

2. Ultimate Load And Ultimate Settlement

The maximum load which can be carried by the structure is called its ultimate load and the

corresponding settlement corresponding to the ultimate load is called the ultimate settlement. Here the effect of

ultimate load is analysed for the different combination of pile raft foundation. The ultimate load is calculated

from the load settlement graph using the above tabulated values

Case (i): 9 number of piles

For a 3 x 3 pile group the ultimate load increases when there is some increase in pile spacing. There is

minimal change in the case of loose sand which can be attributed to load compacting the surrounding soil rather

than carrying it. But in dense though on increasing the spacing from 3 d to 4 d the change is not appreciable

(only 4 %), there is considerable increase in the ultimate load by 19 % on increasing the spacing from 4 d to 5

d. the ultimate settlement increases with the increase in ultimate load for all the spacing and number of piles of

all types of soils and vice versa

Figure 4: Ultimate Load Vs Spacing Between Piles for 3x3 Piles

Naveen kumar.D /Int.J. TechnoChem Res. 2015,1(2),pp 70-78.

75

Case (ii) 16 number of piles:

Figure shows the ultimate load variance with the pile spacing for the 4 x 4 pile group. The ultimate load

increases when the spacing increases to 4 d but on increasing the spacing to 5 d, even though the spacing is

increased, the ultimate load decreases.

Figure 5: Ultimate Load Vs Spacing Between Piles for 4x4 Piles

Case (iii): 25 number of piles:

Figure 6.17 shows the ultimate load behaviour of 5 x 5 pile group for the various spacing. The ultimate

load starts to decrease with the increase in spacing and the trend is similar in all relative densities of sand.

Figure 6: Ultimate Load Vs Spacing Between Piles for 5x5 Piles

3.Normal Load Vs Ultimate Load And Normal Settlement Vs Ultimate Settlement

The ratio of P/Pu and /u is one of the major factor to determine the load response criteria. From the

ultimate load it is seen that16 group of piles show some good results when compared to 9 and 25 number of

piles since that combination consist of higher ultimate load with lesser settlements. Hence we are discussing the

behaviour of 16 number of piles alone

Case (i):3d spacing

The figure represents the behaviour of 4x4 piles of 3d spacing and this is very similar to that of 3x3

piles. For loose soil the curve is concave and for medium and dense the curve is convex.

Naveen kumar.D /Int.J. TechnoChem Res. 2015,1(2),pp 70-78.

76

Figure 7: P/Pu Vs /u For 4x4 Pile-3d Spacing

Case (ii): 4d spacing

The figure 6.23 shows the normalized load settlement behaviour for the pile of 4 x 4 of 4 d spacing. It

is also similar to that of 3 x 3 pile group. For all the types of sand the curve is concave behaviour and there is no

sudden change.

Figure 8: P/Pu Vs /u for 4x4 Pile-4d Spacing

Case (iii): 5d spacing

Figure 6.24 shows the trend of 4 x 4 piles of 5 d spacing. This is also similar to the graph of 3 x 3 piles

of 5d spacing. All the curves are convex in nature but the magnitude varies for the relative densities. For loose

soil the curve extends upto the value of P/Pu is 2.2 but for medium it is reduced to 1.4 and for dense sand it is

decreased to 0.9

Naveen kumar.D /Int.J. TechnoChem Res. 2015,1(2),pp 70-78.

77

Figure 9: P/Pu Vs /u for 4x4 Pile-5d Spacing

From the figures 6.22 to 6.24, for 4x4 piles t the curves for all spacing is different but it is very similar

to that of 3 x 3 pile. The behaviour is almost same but the magnitude only changes in gradual manner

Discussions

On spacing between the piles

When the pile spacing alters then the load carrying capacity also varies. For the 3x3 pile group the

ultimate load is increased by 4% when the spacing between the piles increased to 4d and 5d.for 4x4 pile group

the ultimate load is increased by 10% when the spacing is increased to 4d but decreased by 12% when the

spacing increased to 5d.for 5x5 pile group the ultimate load decreased by 2% when the spacing increased to 4d

and 5d.

Regarding settlement when we changes the spacing there is much change in the settlement also. If we

alters the spacing to 4d and 5d there is nearly 40% increase in the settlement.

On number of piles

If the number of piles increases there is some increment in the load carrying capacity as well as the

reduction in settlement. When the number of piles increases from 9 to 16 the ultimate load increases by 4% and

settlement decreases by 4% and if the number of piles changes from 16 to 25 the ultimate load increases by 5%

and the settlement reduces by 8%

On soil conditions

When the soil turns from loose to medium the load carrying capacity increases by 43% and the

settlement decreases by 5%.in similar way when soil moves from medium to dense the load carrying capacity

increases by 17% and settlement decreases by 1%

From the overall analysis the graphs are linear only for the lesser number of piles and for the lesser

spacing. The medium and dense sand shows some similarity and give normal results. The loose sand give some

dissimilarity and abrupt values. When compared with 3x3 and 5x5 piles 4x4 shows some good results and it

carry maximum ultimate load with the lesser settlements. So it provides optimistic values

Conclusions

From the analysis the following results are obtained. The solutions are completely analytical in nature

and may have some small practical variations depending on the nature of the structure and the loading pattern /

type of load.

Pile spacing affects greatly the maximum settlement, the ultimate settlement and the load carrying

capacity of the piles

The spacing between the piles should be within the permissible range that depend upon the loading

conditions also. If the load acts at the centre of the mat structure then we have to provide lesser pile

spacing.

Naveen kumar.D /Int.J. TechnoChem Res. 2015,1(2),pp 70-78.

78

Increasing the number of piles decreases the total and ultimate settlement and increases the load carrying

capacity upto certain limit that depend upon the loading condition

The number of piles also depend upon the loading conditions. But the cost of construction will increase if

the number of piles increased. So the optimum number of piles should be used.

From this analysis 16 number of piles is more optimised when compared to 9 and 25 number of piles

because it produces the combination of higher load carrying capacity with the lesser settlements.

The soil type is also one of the major factor that affect load settlement behaviour. Dense sand produces

better results when compared to the loose and medium sand.

References:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

El-Mossallamy, Y., Innovative Application Of Piled Raft Foundation to Optimize the Design of HighRise Buildings and Bridge Foundations, 10th International Conference On Piling And Deep

Foundations, Amsterdam, 2006

Shukla, S. J, Desai, A. K. and Solanki C. H., Behavioural Study of Piled Raft Foundation in Layered

Soil Deposits, International Journal of Applied Engineering Research, 2011.

Sayed, Sayed M and Reda M. Bakeer., Efficiency Formula for Pile Groups, Journal of Geotechnical

Engineering, 1992.

Chow. Y. K, Yong K.Y and Shen W.Y., "Analysis of Piled Raft Foundations Using a Variational

Approach", International Journal of Geomechanics, 2001.

Poulos. H. G., Methods of analysis of piled raft foundations, International Society of Soil Mechanics

and Geotechnical Engineering, 2001, 21, 67-72

Chaudhari.R.R and Dr. Kadam K.N., Effect of Piled Raft Design on High-Rise Building Considering

Soil Structure Interaction. International journal of scientific & technology research, 2013, 2(6), 55 - 64

Ta, L.D., An approximation for analysis of raft and piled raft foundations, Computers and Geotechnics,

1997

Nguyen, Dang Dinh Chung, Dong-Soo Kim and Seong-Bae Jo., Parametric study for optimal design of

large piled raft foundations on san, Computers and Geotechnics, 2014.

Srilakshmi.G, and Darshan Moudgalya N S., Analysis of piled raft foundation using finite element

method, International journal of scientific & technology research, 2013, 2(3),234-241.

Katzenbach. R, Bachmann. G, Boled-mekasha. G, Ramm. H., Combined pile raft foundations (cprf): an

appropriate solution for the foundations of high-rise buildings, Slovak journal of civil engineering,

2005, 19 29.

*****

www.technochemsai.com

Вам также может понравиться

- Effect of Varying Length and Diameter of Pile in Pile Raft FoundationДокумент7 страницEffect of Varying Length and Diameter of Pile in Pile Raft FoundationSatya kaliprasad vangaraОценок пока нет

- Irjet V4i4229 PDFДокумент8 страницIrjet V4i4229 PDFnithuОценок пока нет

- Recent Studies On Piled-Raft Foundation: State of Art: V.J.Sharma, S.A.Vasanvala, C.H.SolankiДокумент9 страницRecent Studies On Piled-Raft Foundation: State of Art: V.J.Sharma, S.A.Vasanvala, C.H.SolankiMặc Thế NhânОценок пока нет

- Study of Lateral Load Carrying Capacities of Piles in Layered Soils Using PLAXIS 3DДокумент6 страницStudy of Lateral Load Carrying Capacities of Piles in Layered Soils Using PLAXIS 3Dneerad mohan100% (1)

- Effect of Soil Nonlinearity On AnalysisДокумент9 страницEffect of Soil Nonlinearity On AnalysisArjun PaudelОценок пока нет

- Tie BeamДокумент8 страницTie BeamKarma Jamtsho100% (2)

- Performance of Single Pile and Group Piles in Piled Raft Analysis Based On The Elastic ApproachДокумент13 страницPerformance of Single Pile and Group Piles in Piled Raft Analysis Based On The Elastic ApproachAnshuman SinghОценок пока нет

- Parametric Study On The Behavior of Combined Pile Raft Foundation Founded On Multi-Layered Soil Using PLAXIS 3DДокумент9 страницParametric Study On The Behavior of Combined Pile Raft Foundation Founded On Multi-Layered Soil Using PLAXIS 3Djuan carlos molano toroОценок пока нет

- Axial - Loaded Pile PLAXIS 2dДокумент4 страницыAxial - Loaded Pile PLAXIS 2dMarko AdamovićОценок пока нет

- 3-D Numerical Analysis of Consolidation Effect On Piled Raft Foundation in Bangkok Subsoil ConditionДокумент7 страниц3-D Numerical Analysis of Consolidation Effect On Piled Raft Foundation in Bangkok Subsoil ConditionSitthiphat Eua-apiwatchОценок пока нет

- 32.three Dimensional Analysis of Piled-Raft Foundation in Clay SoilsДокумент12 страниц32.three Dimensional Analysis of Piled-Raft Foundation in Clay SoilsKho Yen LiangОценок пока нет

- 3-D Numerical Analysis of Consolidation Effect OnДокумент8 страниц3-D Numerical Analysis of Consolidation Effect OnMARIA PAULA TRILLEROS LOZANOОценок пока нет

- Load and Settlement Behaviors of Pile-Raft Foundation in Soft Soil of Post-ConsolidationДокумент5 страницLoad and Settlement Behaviors of Pile-Raft Foundation in Soft Soil of Post-ConsolidationBRAYAN GERARDO AREVALO MENDOZAОценок пока нет

- Effects of Soil Movement On Pile Group in Term of Negative Skin Friction (NSF) Using FEMДокумент14 страницEffects of Soil Movement On Pile Group in Term of Negative Skin Friction (NSF) Using FEMFoolad GharbОценок пока нет

- 1 Malviya Et Al - 2023 - Settlement and Load Sharing Behavior of Piled Raft Foundation A ReviewДокумент28 страниц1 Malviya Et Al - 2023 - Settlement and Load Sharing Behavior of Piled Raft Foundation A ReviewDinesh Kumar MalviyaОценок пока нет

- Theme - N 9Документ5 страницTheme - N 9Satya kaliprasad vangaraОценок пока нет

- Soil Pile Interaction Pallavi Neelima ICETCE-14Документ8 страницSoil Pile Interaction Pallavi Neelima ICETCE-14Gizeth AguilarОценок пока нет

- 03 Johnson SimulatingДокумент6 страниц03 Johnson SimulatingGanesh RaviОценок пока нет

- Journal Study - of - Ultimate - Bearing CapДокумент12 страницJournal Study - of - Ultimate - Bearing Capel.salumbidesОценок пока нет

- Effect of Soil Subgrade Reaction On Raft FoundationДокумент14 страницEffect of Soil Subgrade Reaction On Raft FoundationAshique AkbarОценок пока нет

- Advanced Design of Foundation For Vibrating EquipmentsДокумент11 страницAdvanced Design of Foundation For Vibrating EquipmentsAndre BuranelliОценок пока нет

- 32.three Dimensional Analysis of Piled-Raft Foundation in Clay SoilsДокумент12 страниц32.three Dimensional Analysis of Piled-Raft Foundation in Clay SoilsAli RezayiОценок пока нет

- Parametric Study For Optimal Design of Large Piled Raft Foundations On SandДокумент15 страницParametric Study For Optimal Design of Large Piled Raft Foundations On SandRijoGeorgeОценок пока нет

- 3D-Analysis of Soil-Foundation-Structure Interaction in Layered SoilДокумент14 страниц3D-Analysis of Soil-Foundation-Structure Interaction in Layered SoilThaung Myint OoОценок пока нет

- Elastoplastic Constitutive Modelling ofДокумент18 страницElastoplastic Constitutive Modelling ofJose Joaquin Lozano RadaОценок пока нет

- Iss25 Art3 - Simulation of Nail StructuresДокумент6 страницIss25 Art3 - Simulation of Nail StructuresAnonymous kBl0u3nОценок пока нет

- Three-Dimensional Analysis For The Effect of Piles Geometry and Arrangement On The Dynamic Response of Piled Raft FoundationДокумент15 страницThree-Dimensional Analysis For The Effect of Piles Geometry and Arrangement On The Dynamic Response of Piled Raft FoundationCuongvm92 VuОценок пока нет

- Numerical Analysis of Piled-Raft Foundation Under Vertical Load in Stone Column Improved SoilДокумент10 страницNumerical Analysis of Piled-Raft Foundation Under Vertical Load in Stone Column Improved SoilSeif EddineОценок пока нет

- Ijciet 08 10 096Документ8 страницIjciet 08 10 096aekockautОценок пока нет

- Analysis of Pile Group Subjected To Embankment Induced Soil MovementДокумент10 страницAnalysis of Pile Group Subjected To Embankment Induced Soil MovementSeif EddineОценок пока нет

- Behavior of Raft Foundation Resting On Improved Soft Soil With Conventional Granular PilesДокумент8 страницBehavior of Raft Foundation Resting On Improved Soft Soil With Conventional Granular PilesaОценок пока нет

- Settlement Evaluation of Soft Clay Reinforced With Stone Columns Using The Equivalent Secant ModulusДокумент7 страницSettlement Evaluation of Soft Clay Reinforced With Stone Columns Using The Equivalent Secant Modulusamir hossein KabiriОценок пока нет

- 3D Modeling of Piled Raft Foundation Sub PDFДокумент9 страниц3D Modeling of Piled Raft Foundation Sub PDFArmando Farfan NiñoОценок пока нет

- Effect of Groundwater Table On Pullout Capacity of Anchor in Frictional SoilДокумент7 страницEffect of Groundwater Table On Pullout Capacity of Anchor in Frictional SoilMD Anan MorshedОценок пока нет

- Soil Improvement by Using Bamboo ReinforcementДокумент7 страницSoil Improvement by Using Bamboo ReinforcementShah Mohammad IqbalОценок пока нет

- Ijciet 07 01 022Документ14 страницIjciet 07 01 022aekockautОценок пока нет

- Geotechnical Issues of Urban Infrastructure: Theme T 1Документ5 страницGeotechnical Issues of Urban Infrastructure: Theme T 1pradeepjoshi007Оценок пока нет

- Analysis of Load Transformation Behavior of Stepped Rigid PileДокумент5 страницAnalysis of Load Transformation Behavior of Stepped Rigid PileInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Civil - IJCE - Effect of Sand Densification Due To Pile Driving Faisal I - Shalabi Saudi ArabiaДокумент14 страницCivil - IJCE - Effect of Sand Densification Due To Pile Driving Faisal I - Shalabi Saudi Arabiaiaset123Оценок пока нет

- Study On Behaviour of Piled Raft Foundation by Numerical ModellingДокумент5 страницStudy On Behaviour of Piled Raft Foundation by Numerical ModellingANA MARIA RODRIGUEZ VASQUEZОценок пока нет

- Parametric Study On Performance of Piled Raft Foundation On Dense Sand Underlain by Soft ClayДокумент10 страницParametric Study On Performance of Piled Raft Foundation On Dense Sand Underlain by Soft ClayEswara PrasadОценок пока нет

- Optimal Skirt SpacingДокумент11 страницOptimal Skirt SpacingAcid Hadi100% (2)

- Bearing Capacity of Eccentrically Loaded FootingsДокумент18 страницBearing Capacity of Eccentrically Loaded FootingsAlaaGaballaОценок пока нет

- Influence of Under-Reamed Pile Groups Arrangement On Tensile Bearing Capacity Using FE MethodДокумент16 страницInfluence of Under-Reamed Pile Groups Arrangement On Tensile Bearing Capacity Using FE MethodBhaskar ReddyОценок пока нет

- Design of Table Top Structures With Soil - Structure InteractionДокумент11 страницDesign of Table Top Structures With Soil - Structure InteractionPraveen SutraveОценок пока нет

- 2017 Printable Calendar PDF 03Документ4 страницы2017 Printable Calendar PDF 03JPDGLОценок пока нет

- Numerical Simulation of Soil-Structure Interaction in Framed and Shear-Wall StructuresДокумент18 страницNumerical Simulation of Soil-Structure Interaction in Framed and Shear-Wall StructuresYorman LPОценок пока нет

- Numerical Analysis of PilesДокумент31 страницаNumerical Analysis of PilesIancu-Bogdan TeodoruОценок пока нет

- Analysis of Mat Foundation Using FeaДокумент15 страницAnalysis of Mat Foundation Using FeaShadin Asari ArabaniОценок пока нет

- Pile Supported Raft FoundationДокумент11 страницPile Supported Raft FoundationrzsoltОценок пока нет

- 1Документ8 страниц1Md RobinОценок пока нет

- Research Article: Analysis of Settlement of Group Pile Foundation in Linear Viscoelastic SoilДокумент12 страницResearch Article: Analysis of Settlement of Group Pile Foundation in Linear Viscoelastic SoilPhetole Pat RaseteloОценок пока нет

- The Application of Triaxial Testing To Flexible Pavement DesignДокумент17 страницThe Application of Triaxial Testing To Flexible Pavement DesignvictorОценок пока нет

- EJGE of The EdgeДокумент11 страницEJGE of The Edgechondroc11Оценок пока нет

- Identification and Quantification of Parameters Influencing The Behavior of Piled Raft Foundation in Layered SandДокумент10 страницIdentification and Quantification of Parameters Influencing The Behavior of Piled Raft Foundation in Layered SandEswara PrasadОценок пока нет

- CH 115Документ6 страницCH 115akshay kothiyalОценок пока нет

- Constitutive Modeling of Soils and RocksОт EverandConstitutive Modeling of Soils and RocksPierre-Yves HicherРейтинг: 5 из 5 звезд5/5 (1)

- Shallow Foundations: Discussions and Problem SolvingОт EverandShallow Foundations: Discussions and Problem SolvingРейтинг: 5 из 5 звезд5/5 (1)

- Perhitungan Sambungan Baut Profil SikuДокумент12 страницPerhitungan Sambungan Baut Profil Sikuberangketr100% (1)

- Member Subject Bending AS4100Документ4 страницыMember Subject Bending AS4100berangketrОценок пока нет

- Perhitungan Sambungan Las Profil SikuДокумент15 страницPerhitungan Sambungan Las Profil SikuberangketrОценок пока нет

- Loading Assesment Hopper Based On AS 3774Документ13 страницLoading Assesment Hopper Based On AS 3774berangketrОценок пока нет

- Concrete Floor Slabs On Grade Subjected To Heavy Loads PDFДокумент57 страницConcrete Floor Slabs On Grade Subjected To Heavy Loads PDFPn EkanayakaОценок пока нет

- Analisa Member Baja T-02-2005Документ12 страницAnalisa Member Baja T-02-2005berangketrОценок пока нет

- Stability Modelling With SLOPE/WДокумент246 страницStability Modelling With SLOPE/WMaya AwonОценок пока нет

- Lateral Loads ManualДокумент252 страницыLateral Loads ManualEmanuelRodriguezEleraОценок пока нет

- SketchДокумент2 страницыSketchberangketrОценок пока нет

- Modelling of Diaphrams in STAAD Pro PDFДокумент13 страницModelling of Diaphrams in STAAD Pro PDFragalwarОценок пока нет

- Paper Geotechical Modeling Short Couse by WoodДокумент357 страницPaper Geotechical Modeling Short Couse by WoodChainun TaidamrongОценок пока нет

- JHS Square PileДокумент1 страницаJHS Square PileberangketrОценок пока нет

- Numerical Modeling PVDДокумент12 страницNumerical Modeling PVDberangketrОценок пока нет

- Stability Modelling With SLOPE/WДокумент246 страницStability Modelling With SLOPE/WMaya AwonОценок пока нет

- Brosur Spun Pile Wika 2011Документ2 страницыBrosur Spun Pile Wika 2011Angga Wahyudi Fajarianto80% (5)

- Sheet Pile Baja (JFESP)Документ15 страницSheet Pile Baja (JFESP)berangketrОценок пока нет

- BH-1 D610 30m.apo - NotepadДокумент13 страницBH-1 D610 30m.apo - NotepadberangketrОценок пока нет

- Methods of Analysis of Piled Raft Foundations - H.G. PoulosДокумент46 страницMethods of Analysis of Piled Raft Foundations - H.G. PoulosMuhammad Yunus100% (10)

- Methods of Analysis of Piled Raft Foundations - H.G. PoulosДокумент46 страницMethods of Analysis of Piled Raft Foundations - H.G. PoulosMuhammad Yunus100% (10)

- Methods of Analysis of Piled Raft Foundations - H.G. PoulosДокумент46 страницMethods of Analysis of Piled Raft Foundations - H.G. PoulosMuhammad Yunus100% (10)

- ASTM A 252 98 Standard Specification For Welded and Seamless Steel Pipe Piles PDFДокумент7 страницASTM A 252 98 Standard Specification For Welded and Seamless Steel Pipe Piles PDFberangketr100% (1)

- Square PileДокумент2 страницыSquare PileberangketrОценок пока нет

- Seismik Retaining WallДокумент11 страницSeismik Retaining WallberangketrОценок пока нет

- Methods of Analysis of Piled Raft Foundations - H.G. PoulosДокумент46 страницMethods of Analysis of Piled Raft Foundations - H.G. PoulosMuhammad Yunus100% (10)

- Install and Configure GlusterFS On CentOS 7 Part2Документ5 страницInstall and Configure GlusterFS On CentOS 7 Part2kamakom78Оценок пока нет

- Windows 10Документ28 страницWindows 10Vibal PasumbalОценок пока нет

- Electronics 19 PDFДокумент25 страницElectronics 19 PDFgitanjali seciОценок пока нет

- Operation & Maintenance Manual d260 S3a-En Okt. 2014Документ166 страницOperation & Maintenance Manual d260 S3a-En Okt. 2014DrBollapu Sudarshan50% (2)

- Hydro Generator CoolingДокумент4 страницыHydro Generator CoolingHamedJamshidiОценок пока нет

- Free Space For Shanghair CompressorДокумент1 страницаFree Space For Shanghair CompressorAndri YansyahОценок пока нет

- Environmental Life Cycle AssessmentДокумент1 страницаEnvironmental Life Cycle Assessmentkayyappan1957Оценок пока нет

- Zipf's Law and Heaps LawДокумент10 страницZipf's Law and Heaps Lawadvita sharmaОценок пока нет

- Perform Cover Hole DrillingДокумент12 страницPerform Cover Hole Drillingjulianusginting00Оценок пока нет

- 78-00583 Profo Metpoint Ocv Compact 8p Int DisplayДокумент8 страниц78-00583 Profo Metpoint Ocv Compact 8p Int DisplayLinh NgoОценок пока нет

- Ip Nat Guide CiscoДокумент418 страницIp Nat Guide CiscoAnirudhaОценок пока нет

- UTDEC 2020: Sub: Skill Test/Typing Test For The Post of Personal AssistantДокумент2 страницыUTDEC 2020: Sub: Skill Test/Typing Test For The Post of Personal Assistantneekuj malikОценок пока нет

- The Hydraulic Pumping SystemДокумент12 страницThe Hydraulic Pumping SystemCarlos Lopez DominguezОценок пока нет

- Leuenberger 2010 TwoWheelVehiclesДокумент30 страницLeuenberger 2010 TwoWheelVehiclesSimon ErniОценок пока нет

- Honda Accord 2008-2010 v6 OemДокумент1 794 страницыHonda Accord 2008-2010 v6 OemAlbertoCòrdovaОценок пока нет

- The Truth About Fuelless Motors Popular Science 1928Документ3 страницыThe Truth About Fuelless Motors Popular Science 1928Celestial Shaman100% (2)

- B3Документ3 страницыB3Jericho MoralesОценок пока нет

- 3CP.1.3 PaperДокумент4 страницы3CP.1.3 PaperAlexander ChekalinОценок пока нет

- Applications of Statistics and Probability in Civil EngineeringДокумент9 страницApplications of Statistics and Probability in Civil EngineeringAlexis CruzОценок пока нет

- Manual - Submersible PumpДокумент4 страницыManual - Submersible PumpcodersriramОценок пока нет

- Don Honorio Ventura Technological State University: Dr. Enrique G. BakingДокумент1 страницаDon Honorio Ventura Technological State University: Dr. Enrique G. BakingJulianne DucutОценок пока нет

- Hemi Spherical Vs Ellipsoidal Vs Tori SphericalДокумент5 страницHemi Spherical Vs Ellipsoidal Vs Tori SphericalkingstonОценок пока нет

- 4 Leed Open SpaceДокумент6 страниц4 Leed Open SpaceswapnilupgadeОценок пока нет

- Unit: Pltu Bolok Area: UNIT #1 Equipment Standard Measurement Point Unit Minggu 1 Minggu 2 Minggu 3 Minggu 4 StatusДокумент18 страницUnit: Pltu Bolok Area: UNIT #1 Equipment Standard Measurement Point Unit Minggu 1 Minggu 2 Minggu 3 Minggu 4 StatusAchmad Zaki MubarokОценок пока нет

- Evolution of Quality in XeroxДокумент29 страницEvolution of Quality in XeroxJappreet SinghОценок пока нет

- Speed Breaker Electric GenerationДокумент72 страницыSpeed Breaker Electric Generationparas bhogulkarОценок пока нет

- AT&T Syntax MMXДокумент17 страницAT&T Syntax MMXakirank1Оценок пока нет

- 1 Starting Time Calculation 2Документ15 страниц1 Starting Time Calculation 2Sankalp MittalОценок пока нет

- FE107 Experimental ResultsДокумент11 страницFE107 Experimental ResultsEsapermana RiyanОценок пока нет