Академический Документы

Профессиональный Документы

Культура Документы

Sieve Analysis

Загружено:

Bibhuti B. BhardwajАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sieve Analysis

Загружено:

Bibhuti B. BhardwajАвторское право:

Доступные форматы

Transportation Engineering Laboratory, IITG

EXPERIMENT NO.

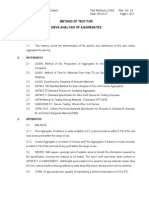

NAME OF THE EXPERIMENT: SIEVE ANALYSIS

AIM OF THE EXPERIMENT: To determine the particle size distribution of

fine, coarse and all-in-aggregates by sieving.

TEST DESCRIPTION:

A representative weighed sample is poured into the top sieve which has

the largest screen openings. Each lower sieve in the column has smaller

openings than the one above. At the base is a round pan, called the

receiver. The column is shaked, usually for some fixed amount of time.

After the shaking is complete the material on each sieve is weighed. The

weight of the sample of each sieve is then divided by the total weight to

give a percentage retained on each sieve. The size of the average particle

on each sieve is then analyzed to get a cut-off point or specific size range,

which is then captured on a screen. The results of this test are used to

describe the properties of the aggregate and to see if it is appropriate for

various civil engineering purposes such as selecting the appropriate

aggregate for concrete mixes and asphalt mixes as well as sizing of water

production well screens. The results of this test are provided in graphical

form to identify the type of gradation of the aggregate.

APPARATUS REQUIRED FOR THE TEST:

A balance which is having accuracy in measuring of 0.1% of the

weight of the sample.

Sieves: Sieves of the following sizesTable 1: IS Sieves for sieve analysis of aggregates for concrete

Type

Square hole, perforated

plate

Fine mesh, wire cloth

Sieve Designations

19 mm, 13.2 mm, 9.5 mm, 4.75 mm

2.36 mm, 1.18 mm, 600 micron, 300 ,

150 , 75

Page 1 of 3

Transportation Engineering Laboratory, IITG

Mechanical sieve shaker

An oven capable of maintaining temperature at 1050-1150 C

Sample: The weight of sample available should not be less than the

weight given in table 2. The sample for sieving is prepared from the

larger sample by quartering or by means of a sample divider.

Fig. 1 Stack of sieves

Fig.2 Sieve Analysis

Fig.3

Sieve shaker

RELEVANT CODES:

ASTM C136-06-1999: Standard test method for sieve analysis of fine and

coarse aggregates; American Society for Testing & Materials

IS 2386 (Part I)-1963 Methods of Test for aggregates for Concrete; Particle

size and shape; Bureau of Indian Standards

PROCEDURE:

1. A sample of suitable quantity is taken and is dried either by drying at room

temperature or by heating at a temperature of 100 to 110 C before weighing and

sieving.

2. The dry sample should be weighed and sieved successively on the appropriate sieves

starting with the largest at the top and smallest at the bottom.

3. Sieving is done either manually or mechanically.

4. The material retained on each sieve shall be weighed on completion of sieving.

Page 2 of 3

Transportation Engineering Laboratory, IITG

5. The percentage of the total weight of soil passing through each sieve can be calculated

on the basis of total weight of sample taken and weight of the aggregates retained on

each sieve.

PRECAUTIONS:

The sieves should be placed in the decreasing order of their openings

from top to bottom.

A pan should be placed underneath the nest of sieves to collect the

aggregate that passes through the smallest.

Use safety shoes, mask & aprons at the time of test.

Thoroughly clean & dry the sieves before testing.

After test sieve should be clean by a soft brush.

Page 3 of 3

Вам также может понравиться

- PDFДокумент16 страницPDFBibhuti B. BhardwajОценок пока нет

- NEXUS 2104brownsgasДокумент8 страницNEXUS 2104brownsgaswxcvbnnbvcxwОценок пока нет

- Soil Tests-Brief Method StatementДокумент7 страницSoil Tests-Brief Method StatementDr Wong Kim YuenОценок пока нет

- CE 121 LAB #2 Density, Specific Gravity, and Absorption of Fine and Coarse AggregatesДокумент14 страницCE 121 LAB #2 Density, Specific Gravity, and Absorption of Fine and Coarse AggregatesAngel Umali Gacutan100% (2)

- Cec 204 PracticalДокумент35 страницCec 204 PracticalPratibha Singh50% (2)

- Dynamic Cone Penetration TestДокумент3 страницыDynamic Cone Penetration TestBibhuti B. Bhardwaj0% (2)

- CE 121 LAB #3 Bulk Density (Unit Weight), Void Content, and Total Evaporable Moisture Content of AggregatesДокумент12 страницCE 121 LAB #3 Bulk Density (Unit Weight), Void Content, and Total Evaporable Moisture Content of AggregatesAngel Umali Gacutan50% (2)

- Textile Nonwoven TestingДокумент10 страницTextile Nonwoven TestingSandeep Yadav100% (1)

- 00016341Документ12 страниц00016341Ridip DuttaОценок пока нет

- Things Your Screw Designer Never-FinalДокумент6 страницThings Your Screw Designer Never-FinalRajesh Kumar100% (2)

- Sieve Analysis of 40mm Aggregate For ConcreteДокумент137 страницSieve Analysis of 40mm Aggregate For ConcreteV Venkata Narayana92% (12)

- Stripping Test of AggregatesДокумент2 страницыStripping Test of AggregatesBibhuti B. Bhardwaj100% (2)

- Soils Aggregates (Manual)Документ71 страницаSoils Aggregates (Manual)Liezel GñiloОценок пока нет

- Various Tests On TilesДокумент18 страницVarious Tests On TilesAzaz Ahmed73% (11)

- Elongation Index TestДокумент2 страницыElongation Index TestBibhuti B. Bhardwaj60% (5)

- 00024098Документ20 страниц00024098Ridip DuttaОценок пока нет

- D6857Документ5 страницD6857DannyChaconОценок пока нет

- PDFДокумент12 страницPDFBibhuti B. BhardwajОценок пока нет

- Report On Bituminous MixДокумент75 страницReport On Bituminous MixBibhuti B. BhardwajОценок пока нет

- Commissioning and Decommissioning of Installations For Dry Chlorine Gas and LiquidДокумент18 страницCommissioning and Decommissioning of Installations For Dry Chlorine Gas and LiquidKimberly ConleyОценок пока нет

- CE 121 LAB 2 Density Specific Gravity and Absorption of Fine and Coarse AggregatesДокумент14 страницCE 121 LAB 2 Density Specific Gravity and Absorption of Fine and Coarse AggregatesNatsu RefilОценок пока нет

- Flakiness Index TestДокумент3 страницыFlakiness Index TestBibhuti B. Bhardwaj0% (1)

- Sieve Analysis ReportДокумент15 страницSieve Analysis ReportTjia Tjie100% (1)

- CHEM 135 Exam 2 F15 KeyДокумент7 страницCHEM 135 Exam 2 F15 KeyMikeОценок пока нет

- Mapua University: Experiment No. 3AДокумент10 страницMapua University: Experiment No. 3AGeojanni PangibitanОценок пока нет

- Measurement of Drawbar Pull of Earth-Moving Machinery: Method ForДокумент14 страницMeasurement of Drawbar Pull of Earth-Moving Machinery: Method ForBibhuti B. BhardwajОценок пока нет

- AADE/Fluids Management Group: Advances in Deepwater FluidsДокумент15 страницAADE/Fluids Management Group: Advances in Deepwater FluidsBarry TrettОценок пока нет

- Cell Metabolism - Cell Homeostasis and Stress ResponseДокумент218 страницCell Metabolism - Cell Homeostasis and Stress ResponseguadialvarezОценок пока нет

- Multi Stage BlowersДокумент12 страницMulti Stage BlowersicingrockОценок пока нет

- New Sensors and Processing ChainОт EverandNew Sensors and Processing ChainJean-Hugh ThomasОценок пока нет

- PDFДокумент14 страницPDFBibhuti B. Bhardwaj100% (1)

- Sampling & Testing Procedures 01aug2009Документ12 страницSampling & Testing Procedures 01aug2009akclams77Оценок пока нет

- Sieve Analysis ProcedureДокумент0 страницSieve Analysis ProcedureAbdul Raheem U LОценок пока нет

- Astm A529 1975Документ4 страницыAstm A529 1975dharlanuctcomОценок пока нет

- Abrasion Resistance MartindaleДокумент3 страницыAbrasion Resistance MartindaleGreeshma100% (1)

- CEN 12566-3 European Standard enДокумент45 страницCEN 12566-3 European Standard enDebreteni Florin100% (1)

- KashipurДокумент18 страницKashipurakankshaawasthi304Оценок пока нет

- ASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricДокумент14 страницASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricSinan Chen100% (1)

- Exercrse: Triaxia1 Shear ofДокумент7 страницExercrse: Triaxia1 Shear ofTantanОценок пока нет

- Me136p Exp5 Sieve Analysis of AggregatesДокумент9 страницMe136p Exp5 Sieve Analysis of AggregatesJohn Henry SalvadoОценок пока нет

- CE 121 LX1 - BendicioДокумент12 страницCE 121 LX1 - BendicioArfil BendicioОценок пока нет

- Experiment No# 1 Standard Test Method For Sieve Analysis of Coarse Aggregates From Different Sources. ScopeДокумент12 страницExperiment No# 1 Standard Test Method For Sieve Analysis of Coarse Aggregates From Different Sources. Scopeirfan Ullah Lab EngineerОценок пока нет

- Act Lab ManualДокумент46 страницAct Lab ManualAJAYОценок пока нет

- Screenshot 2022-10-17 at 18.52.41Документ41 страницаScreenshot 2022-10-17 at 18.52.41Rod VincentОценок пока нет

- Department of Building Technology: College of Architecture and PlanningДокумент11 страницDepartment of Building Technology: College of Architecture and PlanningZach EffahОценок пока нет

- Triaxial Test: Xzdetermination of Shear Parameters by Triaxail TestДокумент8 страницTriaxial Test: Xzdetermination of Shear Parameters by Triaxail TestTenzinKesangОценок пока нет

- Sieve Analysis and Finess ModulusДокумент20 страницSieve Analysis and Finess ModulusGeomanjeriОценок пока нет

- Aggregate Crushing ValueДокумент8 страницAggregate Crushing ValueEngineeri TadiyosОценок пока нет

- Lab Report - Copy EditedДокумент24 страницыLab Report - Copy EditedSaksham ShekhawatОценок пока нет

- Laboratory Manual: Name: Roll No.: Semester: Academic YearДокумент58 страницLaboratory Manual: Name: Roll No.: Semester: Academic YearDipankar NathОценок пока нет

- Sourav Kabiraj - Professional Practice, Law & Ethics Ca1Документ12 страницSourav Kabiraj - Professional Practice, Law & Ethics Ca1souravkabiraj.ce.2817Оценок пока нет

- Flakiness Index, Elongation, Aggregate Crushing ValueДокумент6 страницFlakiness Index, Elongation, Aggregate Crushing ValueAshadi HamdanОценок пока нет

- 3.sieve AnalysisДокумент24 страницы3.sieve AnalysisTapas DasОценок пока нет

- Basic Equipment in Material Testing - SubilДокумент6 страницBasic Equipment in Material Testing - Subiljohn ian subilОценок пока нет

- Test 09Документ6 страницTest 09Ateafac Anastasia NjuafacОценок пока нет

- REPORTДокумент10 страницREPORTMUHAMMAD ZEESHANОценок пока нет

- Highway Materials and Construction Practice: UNIT-4Документ54 страницыHighway Materials and Construction Practice: UNIT-4RawandAlbarodyОценок пока нет

- The Basic Principles of Sieve Analysis: Fig. 1: Particle Size Determination MethodsДокумент8 страницThe Basic Principles of Sieve Analysis: Fig. 1: Particle Size Determination MethodsPpiSpanyolОценок пока нет

- LedumowesomejinabovuviДокумент3 страницыLedumowesomejinabovuviDarylОценок пока нет

- Tensile of CubeДокумент4 страницыTensile of Cubeindrajit sodhaОценок пока нет

- Practical 01 and 02Документ10 страницPractical 01 and 02RAJ MODAKОценок пока нет

- Water Pipeline DesignДокумент16 страницWater Pipeline DesignrendaninОценок пока нет

- Dry Sieve Test UNIДокумент2 страницыDry Sieve Test UNIosbo1611Оценок пока нет

- CHE 509 - Lecture 1Документ18 страницCHE 509 - Lecture 1Jane Eilyza AballaОценок пока нет

- Construction Materials 1 4 TangnaДокумент12 страницConstruction Materials 1 4 TangnaPaul Vincent RamosОценок пока нет

- University of MisanДокумент9 страницUniversity of MisanoОценок пока нет

- Highway Practical NdiiДокумент18 страницHighway Practical NdiiMuniru QudusОценок пока нет

- A Presentation On Fabric ThicknessДокумент10 страницA Presentation On Fabric ThicknessSubhradeep HazraОценок пока нет

- Vanes Hear Test 11Документ5 страницVanes Hear Test 11Rahsaan KirtonОценок пока нет

- Construction Fabrics: Test Procedure ForДокумент9 страницConstruction Fabrics: Test Procedure ForSaeedreza ZahОценок пока нет

- CMT 3Документ7 страницCMT 3Anthony AlarillaОценок пока нет

- Transportation LabДокумент32 страницыTransportation LabBiplob GhoshОценок пока нет

- 7.0 Particle Size Analysis 26.04.2020Документ3 страницы7.0 Particle Size Analysis 26.04.2020Mabvuto Banda the son of the Consuming fireОценок пока нет

- Exp 4Документ4 страницыExp 4sju65Оценок пока нет

- Oel TransДокумент19 страницOel Transrazaain4305302Оценок пока нет

- ENCE 361 Soil Mechanics: Grain Size AnalysisДокумент68 страницENCE 361 Soil Mechanics: Grain Size AnalysisamokhtaОценок пока нет

- Argillaceous Swellingxocks - Methods For Laboratory TestingДокумент16 страницArgillaceous Swellingxocks - Methods For Laboratory Testingvenkatraman20Оценок пока нет

- Air PermeabilityДокумент2 страницыAir Permeabilityjyoti1234321Оценок пока нет

- Aggregate Impact ValueДокумент5 страницAggregate Impact Valueonline researchОценок пока нет

- The Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsОт EverandThe Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsОценок пока нет

- MerlinДокумент4 страницыMerlinBibhuti B. BhardwajОценок пока нет

- CBR TestДокумент5 страницCBR TestBibhuti B. BhardwajОценок пока нет

- Specific Gravity of Coarse and Fine AggregateДокумент5 страницSpecific Gravity of Coarse and Fine AggregateBibhuti B. BhardwajОценок пока нет

- Agularity Number TestДокумент3 страницыAgularity Number TestBibhuti B. BhardwajОценок пока нет

- Preservation and Storage of Earth-Moving Machinery: Methods ForДокумент10 страницPreservation and Storage of Earth-Moving Machinery: Methods ForBibhuti B. BhardwajОценок пока нет

- PDFДокумент8 страницPDFBibhuti B. BhardwajОценок пока нет

- Experiment No. Name of The Experiment: Aggregate Impact Test AIM OF THE EXPERIMENT: To Determine The Aggregate Impact Value ofДокумент4 страницыExperiment No. Name of The Experiment: Aggregate Impact Test AIM OF THE EXPERIMENT: To Determine The Aggregate Impact Value ofBibhuti B. BhardwajОценок пока нет

- PDFДокумент8 страницPDFBibhuti B. BhardwajОценок пока нет

- PDFДокумент16 страницPDFBibhuti B. BhardwajОценок пока нет

- PDFДокумент12 страницPDFBibhuti B. BhardwajОценок пока нет

- PDFДокумент12 страницPDFBibhuti B. BhardwajОценок пока нет

- PDFДокумент8 страницPDFBibhuti B. BhardwajОценок пока нет

- PDFДокумент10 страницPDFBibhuti B. BhardwajОценок пока нет

- PDFДокумент10 страницPDFBibhuti B. BhardwajОценок пока нет

- 00021826Документ8 страниц00021826Ridip DuttaОценок пока нет

- 00016614Документ12 страниц00016614Ridip DuttaОценок пока нет

- File 1120201401025350 PDFДокумент197 страницFile 1120201401025350 PDFBibhuti B. BhardwajОценок пока нет

- MillingДокумент24 страницыMillingBibhuti B. BhardwajОценок пока нет

- The Inhibitive Effect of Ficus Thonningii Leaves Extract in 1m HCL Solution As Corrosion Inhibitors On Mild SteelДокумент8 страницThe Inhibitive Effect of Ficus Thonningii Leaves Extract in 1m HCL Solution As Corrosion Inhibitors On Mild SteelInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Masteremaco 2525pdfДокумент2 страницыMasteremaco 2525pdfapi-283891975Оценок пока нет

- APPLIED CHEMISTRY Lab ManualДокумент50 страницAPPLIED CHEMISTRY Lab ManualHarshit RajОценок пока нет

- Chapter 1 - Matter in Our SurroundingsДокумент22 страницыChapter 1 - Matter in Our SurroundingsTara SinghОценок пока нет

- Catalog Biocraft Electronic Test InstrumentДокумент2 страницыCatalog Biocraft Electronic Test InstrumentHmmОценок пока нет

- Hydrogen DetectionДокумент7 страницHydrogen DetectionWahyuning LestariОценок пока нет

- Comparison of Post and Pre CombustionДокумент12 страницComparison of Post and Pre CombustionMuhammad AtifОценок пока нет

- Factors Affecting Workability of ConcreteДокумент6 страницFactors Affecting Workability of ConcreteNick GeneseОценок пока нет

- Applied Energy: J.R. Monte, M. Brienzo, A.M.F. MilagresДокумент6 страницApplied Energy: J.R. Monte, M. Brienzo, A.M.F. MilagresArif HidayatОценок пока нет

- SediGraph 5120 BrochureДокумент8 страницSediGraph 5120 Brochurerajeevup2004100% (1)

- Basic Principles and Calculations in Chemical Engineering - Solutions ManualДокумент454 страницыBasic Principles and Calculations in Chemical Engineering - Solutions ManualAnnette Garcia86% (21)

- Mid Term Igcse Physics Grade 10 Sem 1 2014 Soal - RevisiДокумент10 страницMid Term Igcse Physics Grade 10 Sem 1 2014 Soal - RevisiJoshuaUntungОценок пока нет

- Research PaperДокумент7 страницResearch PaperJafarОценок пока нет

- Chapter 15 Fluid and Chemical BalanceДокумент47 страницChapter 15 Fluid and Chemical BalanceIntan FirmallahОценок пока нет

- Ba 10aДокумент4 страницыBa 10aFrancis LoboОценок пока нет

- Curriculam Vitae: - Since Aug 2011 To Till DateДокумент6 страницCurriculam Vitae: - Since Aug 2011 To Till DatechetanmaleОценок пока нет

- Project Report On Manures and Chemical Fertilizers ManuresДокумент3 страницыProject Report On Manures and Chemical Fertilizers ManuresJayveersinh Jadeja0% (1)

- GE ES Module4Документ9 страницGE ES Module4EnzuОценок пока нет

- 32 Vaporization TNДокумент4 страницы32 Vaporization TNAjeng FadillahОценок пока нет