Академический Документы

Профессиональный Документы

Культура Документы

Ms For Repair and Welding Jointscoating and Painting

Загружено:

mansih457Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ms For Repair and Welding Jointscoating and Painting

Загружено:

mansih457Авторское право:

Доступные форматы

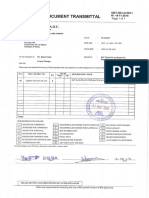

SOHAR REFINERY IMPROVEMENT PROJECT

SRIP

Method Statement for Painting/Coating

of Welding Joints and Damage Areas

Document No: BEC-OFD0137-MS-015, REV.1

BEC Project Number : OFD0137

DPJV Contract Number :120476 / JI-02022

Package Number : 2 & 6

8/4/2015

Issued for Approval

SSA

SJ

GVA

8/4/2015

Issued for Approval

SSA

SJ

GVA

Rev.

Date

Originator

Checker

Approver

Description

Bahwan Engineering Co LLC, PO Box 703, PC 112, Sultanate of Oman

Tel: +968 24597510, Fax: +968 24597511 www.bahwanengineering.com

DPJV

Sohar Refinery Improvement Project SRIP

Doc Ref :BEC-OFD0137-MS-008, Rev-1

Method statement for

Painting/Coating of Welding Joints

and Damage Areas

INDEX

1.0

Purpose

2.0

Scope

3.0

References

4.0

Abbreviations

5.0

Manpower

6.0

Equipment

7.0

Measuring Instruments

8.0

Sequence of activities

9.0

Inspection

10.0

Safety precautions

11.0

Attachment

Page No: 2 OF 9

Project No: OFD0137

Sohar Refinery Improvement Project SRIP

Doc Ref :BEC-OFD0137-MS-008, Rev-1

Method statement for

Painting/Coating of Welding Joints

and Damage Areas

Project No: OFD0137

1. OBJECTIVE

ThepurposeofthisMethodStatementistoestablish,monitorandcontrolallactivitiesinvolvedfor

repairofpaintedpipesandspoolsdamageareasduringtransportation,handling,erectionetc.and

fieldweldjointsofundergroundandabovegroundpipingfor(packagenumber2&6)inorderto

meetprojectspecification,referencecodesandstandards.

2. SCOPE

Thismethodstatementcoversminimumrequirementsforsurfacepreparation,Coating/paintingto

bedoneforSoharRefineryImprovementProject(SRIP)

3. REFERENCES

S00013A0102:GeneralSpecificationforExternalCoatingofUndergroundPiping

S00053A0001:Specificationforsurfacepreparation,PaintingandLettering

SSPCSP1:SolventCleaningMethod

SSPC:SurfacePreparationofSteelStructurePaintingCouncil

ISO8504:Preparationsteelsubstratebeforeapplicationofpaintsandrelatedproducts

SurfacepreparationMethods.Part13

ISO2808:PaintandVarnishDeterminationoffilmthickness

NACESP0274:HighVoltageElectricalInspectionofPipelineCoatingsPriorto

Installation.

PaintManufacturersTechnicalDataSheet

MaterialApprovalSheetforPaintsandAbrasives

Page No: 3 OF 9

Sohar Refinery Improvement Project SRIP

Doc Ref :BEC-OFD0137-MS-008, Rev-1

Method statement for

Painting/Coating of Welding Joints

and Damage Areas

Project No: OFD0137

4. ABBREVATIONS

HSE

QA/QC

DFT

NDFT

FBE

WFT

CURE

MSDS

CQP

ASTM

ISO

Health&SafetyandEnvironment

Qualityassurance/Qualitycontrol

DryFilmThickness

NominalDryFilmThickness

FusionBondEpoxy

WetFilmThickness

Theprocessofhardeningofappliedpaint.

MaterialSafetyDataSheet

ContractorsQualityPlan

AmericanSocietyforTestingandMaterials

InternationalOrganizationforStandards

5. MANPOWER

1.

2.

3.

4.

5.

6.

7.

8.

ConstructionManager

HSEAdvisor

QCInspector

PaintingSupervisor

PaintingForeman

Spoolcoordinator

Painters

Helpers

6. EQUIPMENTS

ForBlastingAirCompressor,BlastingPots,BlastingHoseswithNozzels,Blasting

Masks,ApronsandGoggles,DeadmanHandle,highpressurepump&accessories,Air

Receivers&AirFilters,power/pnumaticoperatedhandtools,wirebrush,etc.

ForPaintingAirCompressor,SprayPaintingMachine,SprayGuns,Pressure

regulators,HosePipes,PneumaticPaintAgitator,Rollers,Brush,etc.

7. MEASURINGINSTRUMENTS

Page No: 4 OF 9

Sohar Refinery Improvement Project SRIP

Doc Ref :BEC-OFD0137-MS-008, Rev-1

Method statement for

Painting/Coating of Welding Joints

and Damage Areas

Project No: OFD0137

ThemeasuringInstrumentsusedfortheInspectionforthesurfacepreparationand

paintingmeasurementsshallbeverifiedbytheCoatingInspectorforcalibrationstatusof

therecordsandduedateofcalibrations.

ThefollowingInstrumentsshallbeused:

WhirlingHygrometer

Humiditymeter/DewPointorRHCalculator

MagneticMetalTemperatureGauge

Thermometers

AnchorProfileMicrometer

WFT/CombGauge

CoatingThicknessGauge/DFTGauge

PinholeDetectorHighVoltageHolidayDetector

Testextape

8. SEQUENCEOFACTIVITIES

MeasurementofweatherconditionsandrecordedduringSurfacepreparationand

Coating/painting

SteelTemperature30Cabovedewpoint

RelativeHumidityBelow85%

Cleaning,Blasting,Coating/Paintingshallnotbecarriedoutinunsuitableconditionslike

Airbornedustorsand,rain,fog,mistorwhenthereisfreemoistureonthesurface.

Environmentalconditionsshallbeverifiedandrecordedpriortosurfacepreparationand.

Coating/Painting

Whenthereislikelihoodthatweatherconditionswillchangein2hrs,suchthattheabove

conditionsapply.

MaterialSelectionforsurfacepreparationandCoating/Paintingshallbeandapprovedby

DPJV

BlastingAbrasiveGritshallbeapprovedbyDPJV

Page No: 5 OF 9

Sohar Refinery Improvement Project SRIP

Doc Ref :BEC-OFD0137-MS-008, Rev-1

Method statement for

Painting/Coating of Welding Joints

and Damage Areas

Project No: OFD0137

CopperSlagforCarbonssteelPipesandfittingsandGarnetforSSandAlloySteel

Pipesandfittingsshallbeused

TheAbrasivematerialusedforblastingshallbevisuallyinspected.Thematerialshallbe

freefrommoistureduetocondensation,rainwater,oil,grease,soilandstonesingress

andsaltsetc.

Physicalandchemicalanalysisandparticlesizecertificateshallbemadeavailablefrom

abrasivesupplierforeachbatch.

PaintCoatingMaterial:

ThetypeofCoating/Paintmaterialshallbeselectedaspercontractorrequirementand

submittedforapproval.

ThepaintingmaterialsshallbeusedaspertheapprovedMaterialApprovalSheet.

TheCoatingmaterialshallbeinspectedforthetype,BatchNo.,MfgandExp.Dates,and

recorded.

AllPaintsandThinnersshallbestoredinaclosedcontainerasperManufacturers

recommendationsspecifiedinMSDS.

PaintMaterialshallbeconsumedonfirstinfirstoutbasis,

MSDSshallbeavailableforallpaintproducts.

SurfacePreparation:

Damagespotsandholidaysintheprimerand/orintermediatecoatshallbethoroughly

cleanedpriortotouchuppriming.

Areasrequiredtobereprimedshallbereblastedorpowertoolcleanedforareas

originallyabrasiveblasted.

Reprimingshallbedonewiththesameprimerasoriginallyapplied.Wherethisisnot

feasible,theprimerusedshallbecompatibleandbesuitablefortheoperating

temperature.

Page No: 6 OF 9

Sohar Refinery Improvement Project SRIP

Doc Ref :BEC-OFD0137-MS-008, Rev-1

Method statement for

Painting/Coating of Welding Joints

and Damage Areas

Project No: OFD0137

Alldamagescausedduetohandling,transportationanderectionshallbemarked.

Defects/Damagesobservedshallberepairedtoachievethepropertyoftheoriginal

painting/coating.

Theareastoberepairedshallbecleanedandfreefromoil,grease,dustanddirt.Iftraces

ofcontaminationsarenoticed,thentheareashallbedegreased(SSPCSP1)andwashed

withcleanwater.

Afterallowingtheareatodry,alltheexposedsteelsurfaceshallbemechanicallycleaned

usingpowerwirebrushed,needlegunsasperthestandardISO85043.

Amaximumwidthof25mmareasurroundingthedefectsshallberoughenedusing

emerypaper.Theedgesoftheedgesofcoatingadjacenttothedamagedareashallbe

featheredtoafinetaperedinterface.

Whereshopcoatinghasbeendamagedinhandling,alldamagedandblisteredcoating

shallberemovedbyhandorpowertoolcleaning.Edgesofthebreaksshallbefeathered

andthespecifiednumberofprimerandfinishedcoatsapplied.Repairofcoatingis

subjecttoinspectionbyclient.

PAINTAPPLICATION:

Afterremovingofdustandrougheningthesurroundingarea,thesamepaintsystemof

thesamepaintmanufacturer,whichwasusedtocarryouttheoriginalpainting,shallbe

mixeduniformlyandappliedontheabradedareausingrollersorbrushestoachievea

requiredtotalDFTaspertherequirementofthespecificpaintsystemand/or

specification.

Areaofslightlydamagedgalvanizingshallbetreatedwithtwocoatsofapprovedzinc

richepoxyprimerinlinewiththerequirementsofthepaintcoatingschedules.

Itshallbeensuredthatthepaintusediswithinitsshelflifeandovercoatingintervalis

maintainedasperthemanufacturersrecommendations.

Subsequentcoatsofpaintshallbeappliedwithnecessarydryingtimeandovercoating

intervalsasperpaintmanufacturersrecommendations.

TheDFTshallbecheckedonallrepairedareas,afterdrying,usingaDFTgauge.Ifthe

achievedtotalDFTislessthanthespecifiedrequirement,andadditionalcoatshallbe

appliedtoachievetherequiredtotalDFT.

PaintsystemtobeappliedshallbeaspertheRespectiveapprovedMaterialApproval

Sheet.

Page No: 7 OF 9

Sohar Refinery Improvement Project SRIP

Doc Ref :BEC-OFD0137-MS-008, Rev-1

Method statement for

Painting/Coating of Welding Joints

and Damage Areas

Project No: OFD0137

UndergroundpipingshallbecoatedaccordingtospecificationS00013A0102

Rev.R1C2.

AbovegroundpipingshallbepaintedaccordingtoSpecificationS00053A0001Rev.

4.

AllPaintandCoatingmaterialshallbestoredaspermanufacturersrecommendations.

Shelfliveandpotlifeshallberegularlymonitored.

TherespectivepaintsystemshallbeselectedandappliedasperspecificationS000

53A0001Rev.4.Attachment1.0

Paintswhicharesuppliedastwocomponentsinseparatecontainers,shallbemixedjust

beforeuseandshallbeappliedwithinthetimelimits(potlife)specifiedbythe

manufacturer.

Productsfromdifferentmanufacturersshallnotbeusedinthesamecoatingsystem.

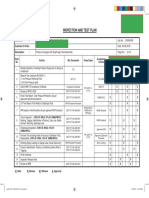

9. INSPECTION

Theappliedcoatingshallbeofuniformcolor,freeofanydefects detrimentaltoits

quality, free of deleterious defects such as runs, sags wrinkles discontinuities and

contamination.

Allinspectionshallbecarriedoutinaccordancewithapprovedinspectionandtestplan

Theresultsofallmeasurementshallberecordedintheinspectionreport.

WetFilmthickness(WFT)spotchecksshallbecarriedoutduringthecourseofpainting

operationtoensurethatfilmthicknessismaintained.Thisshallbedoneaccordingtothe

proceduredescribedinISO2808,methodNo.1ACombGauge

TheDFToftheappliedpaintshallbecheckedwithcalibratedDFTGauge.

Thedryfilmthicknessofthecompletedcoatingsystemshallbeequaltoorgreaterthan

thespecifiedNominalDryFilmThickness(NDFT).

Thedryfilmthicknessoftheindividualcoatinglayersshallbeequaltoorabove80%of

thespecifiednominaldryfilmthickness.ThenumberofreadingsbelowNDFTshallbe

lessthan20%ofthetotalnumberofDFTreadingstaken.

Ifcoatingisperformedovertheexistingpaintlayers,theDFToftheexistingcoating

shallbemeasuredbeforeapplicationofthenextlayerofcoatingsothatthethicknessof

thenewlayerofcoatingcanbedetermined.

Afterfullcuringofthetopcoat,holidaytestingshallbecarriedoutusinghighvoltage

holidaydetectormethodinaccordancewithNACESP0274,toensurethetopcoatis

freefromcoatingbreakdownsandholidays.Theresultofsuchtestshallbedocumented.

Coating / Painting activity including holiday / pinhole detection, Painting / Coating

InspectionReportshallbeissuedbytheQCInspector(Painting)

HighVoltageHolidayDetection:

Page No: 8 OF 9

Sohar Refinery Improvement Project SRIP

Doc Ref :BEC-OFD0137-MS-008, Rev-1

Method statement for

Painting/Coating of Welding Joints

and Damage Areas

Project No: OFD0137

Afterfullcuringofthetopcoat,holidaytestingshallbecarriedoutusingHighVoltage

HolidayDetectormethodinaccordancewithNACESP0274,toensurethetopcoatis

freefromcoatingbreakdownsandholidays.Theresultofsuchtestshallbedocumented.

10.0

SAFETYPRECAUTIONS

11.0

AllpeopleworkingforsurfacepreparationandpaintingworkshallwearfullPPEand

faceshieldswhereevernecessary.

Allotherequipmentpresentintheworkareashallbeprotectedbycovering,during

surfacepreparationandpaintingoperations.

Fixedscaffoldingorstagingshallbeusedwhererequiredforsurfacepreparationand

paintingandshallcomplywiththesafetyregulations

When painting is carried out in enclosed spaces, as adequate ventilation shall be

provided

Allpotentialsourcesofignitionsshallbestrictlycontrolled

Storageofchemicalsshallbeaspermanufacturersrecommendations

Disposalofwasteshallbemadeasperwastemanagementsystem.

ATTACHMENT

JHA

Page No: 9 OF 9

Вам также может понравиться

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkДокумент38 страницMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTОценок пока нет

- Obite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureДокумент22 страницыObite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureeetuaОценок пока нет

- (WPQL) : Welder / Welding Operation Performance Qualified ListДокумент2 страницы(WPQL) : Welder / Welding Operation Performance Qualified ListTrương Đông HưngОценок пока нет

- Inspection, Flushing & Testing of Piping-21Документ6 страницInspection, Flushing & Testing of Piping-21Saurabh Kumar VermaОценок пока нет

- Tdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)Документ1 страницаTdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)mОценок пока нет

- G. Std. ITP For Pipeline Job PDFДокумент4 страницыG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGWОценок пока нет

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionДокумент1 страницаPunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoОценок пока нет

- Inspection and Test Plan for Pressure GaugesДокумент1 страницаInspection and Test Plan for Pressure GaugesVenkatesh PethurajОценок пока нет

- Material Test Report Welder Qualification Butt Weld PipeДокумент2 страницыMaterial Test Report Welder Qualification Butt Weld PipeSyed Mahmud Habibur RahmanОценок пока нет

- Work Procedure For Pouring and Waterproofing of Chemical Storage ShelterДокумент41 страницаWork Procedure For Pouring and Waterproofing of Chemical Storage ShelterResearcherОценок пока нет

- KOC-CGCC-BRANTON-GC15 Test Package DocumentsДокумент13 страницKOC-CGCC-BRANTON-GC15 Test Package DocumentsVISHNUPRASAD ARAKKAL MOHANDASОценок пока нет

- Working ITPДокумент4 страницыWorking ITPStephen BoodooОценок пока нет

- Method of Statement For RadiationДокумент4 страницыMethod of Statement For RadiationFiras AlbaweiОценок пока нет

- Bus Duct Inspection Test PlanДокумент2 страницыBus Duct Inspection Test PlankamlОценок пока нет

- Swiss International LLCДокумент4 страницыSwiss International LLCBurning TrainОценок пока нет

- A-Method Statement Painting and Touch-Up Painting For Furnace-CДокумент20 страницA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngОценок пока нет

- Oil Pantriting ProcedureДокумент5 страницOil Pantriting ProcedureSERT-QA/QC- BUZОценок пока нет

- Site Inspection Test PlanДокумент24 страницыSite Inspection Test Planprabu palaniswamyОценок пока нет

- Duqm Refinery Project EPC Package 2 Utilities and Offsites Contract No CNT-1100-1000-007 INSPECTION RELEASE NOTEДокумент2 страницыDuqm Refinery Project EPC Package 2 Utilities and Offsites Contract No CNT-1100-1000-007 INSPECTION RELEASE NOTEDadaso Baburao JamdarОценок пока нет

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Документ7 страниц13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- Nde Map & Nde Procedure (Sudah Di Revisi)Документ4 страницыNde Map & Nde Procedure (Sudah Di Revisi)Hardika SambilangОценок пока нет

- ITP Plan - FF PDFДокумент7 страницITP Plan - FF PDFAltaf KhanОценок пока нет

- Construction Steel Erection PlansДокумент10 страницConstruction Steel Erection PlansTran KhuynhОценок пока нет

- S0442 GPS L XXX SP 0005 - 0 - Specification For Piping Fabrication and InstallationДокумент42 страницыS0442 GPS L XXX SP 0005 - 0 - Specification For Piping Fabrication and InstallationThành TrịnhОценок пока нет

- Itp - 002 - Duct Installation - IfrДокумент3 страницыItp - 002 - Duct Installation - IfrMari BelajarОценок пока нет

- ITP Heat ExchangerДокумент1 страницаITP Heat Exchangersarmad009Оценок пока нет

- B Qac Pro 210 39161 AДокумент12 страницB Qac Pro 210 39161 AZaidiОценок пока нет

- Excavation and Fill Method Statement SummaryДокумент12 страницExcavation and Fill Method Statement Summary한상호Оценок пока нет

- Tasnee HDPE - LDPE Plant Project: Method Statement For Earthworks: Excavation and BackfillingДокумент10 страницTasnee HDPE - LDPE Plant Project: Method Statement For Earthworks: Excavation and BackfillingFarhanОценок пока нет

- Radiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0Документ13 страницRadiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0BCE DeОценок пока нет

- O252-PI-SP-0126 - C04 - Specification For PaintingДокумент26 страницO252-PI-SP-0126 - C04 - Specification For PaintingBestun AhmedОценок пока нет

- Inspection and Test Plan FOR Coating (02260 ITP-COA-001) : Petronas Rapid Project (Package 3)Документ9 страницInspection and Test Plan FOR Coating (02260 ITP-COA-001) : Petronas Rapid Project (Package 3)Namta GeorgeОценок пока нет

- Al-Uqlah Central Processing Facility Water Level & Settlement TableДокумент12 страницAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaОценок пока нет

- WP 11 Corrosion Protection Tape CoatingДокумент3 страницыWP 11 Corrosion Protection Tape CoatingKarthikОценок пока нет

- 04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Документ8 страниц04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Sherif YehiaОценок пока нет

- Itp For InsulationДокумент14 страницItp For InsulationHytham El-NoubyОценок пока нет

- Rotating Itp 1Документ4 страницыRotating Itp 1abdul aziz100% (1)

- Procedure for holiday testingДокумент2 страницыProcedure for holiday testingSaptarshi MandalОценок пока нет

- Xyz Company: PurposeДокумент3 страницыXyz Company: PurposeAnonymous 3eHGEDbxОценок пока нет

- 3 Steel Structure Installation CLДокумент2 страницы3 Steel Structure Installation CLwhah11Оценок пока нет

- SA04C2-00-MET-MS-00007 MS Excavation and BackfillingДокумент47 страницSA04C2-00-MET-MS-00007 MS Excavation and BackfillingABAID ULLAHОценок пока нет

- Inspected by QCP Approval 1-APC 1-Employer (APC) 2 - DAR 2 - Engineer (DAR) 3 - Contractor (NEGEMCO) 4 - Vendor 5 - Third PartyДокумент6 страницInspected by QCP Approval 1-APC 1-Employer (APC) 2 - DAR 2 - Engineer (DAR) 3 - Contractor (NEGEMCO) 4 - Vendor 5 - Third PartyAhmad DagamsehОценок пока нет

- Inspectable MaterialsДокумент2 страницыInspectable MaterialsMohamed RedaОценок пока нет

- 0610.1 - Shell and Tube Heat ExchangersДокумент30 страниц0610.1 - Shell and Tube Heat Exchangersvenkatrangan2003Оценок пока нет

- 08572-Trht-Egcb-Qc-Aq-012 Itp - Pipeline Construction Rev1 PDFДокумент33 страницы08572-Trht-Egcb-Qc-Aq-012 Itp - Pipeline Construction Rev1 PDFbelhaskaОценок пока нет

- Method Statement for Pipe Handling and StorageДокумент14 страницMethod Statement for Pipe Handling and StorageShambu S VtkОценок пока нет

- Weld Repairs:: 1) Production Repairs 2) In-Service RepairsДокумент4 страницыWeld Repairs:: 1) Production Repairs 2) In-Service RepairsEhsan KhanОценок пока нет

- Heat Shrink ProcedureДокумент7 страницHeat Shrink ProcedureBabar Manzoor GhauriОценок пока нет

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportДокумент12 страницSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- Saka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderДокумент19 страницSaka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderriandiОценок пока нет

- Baking register tracks electrode usageДокумент3 страницыBaking register tracks electrode usageShivam TiwariОценок пока нет

- UG PIPING COATINGДокумент10 страницUG PIPING COATINGcloud23Оценок пока нет

- Painting SpecificationДокумент19 страницPainting SpecificationArunkumar Rackan0% (1)

- MIP17-MS-2012 Method Statement For Fabrication and Installation of PipingДокумент23 страницыMIP17-MS-2012 Method Statement For Fabrication and Installation of PipingAmeerHamzaWarraichОценок пока нет

- EN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete ConstructionДокумент32 страницыEN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete Construction章宇Оценок пока нет

- NDT Request (Template)Документ4 страницыNDT Request (Template)Bethel NdifonОценок пока нет

- SRIP Above Ground Piping Installation Method StatementДокумент15 страницSRIP Above Ground Piping Installation Method Statementmansih457Оценок пока нет

- Method Statement For Under Ground Metallic Piping InstallationДокумент13 страницMethod Statement For Under Ground Metallic Piping Installationmansih457100% (1)

- Welding control system method statementДокумент14 страницWelding control system method statementmansih457100% (1)

- Format. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Документ3 страницыFormat. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Raja KrsОценок пока нет

- Copper Sulfate Product InformationДокумент2 страницыCopper Sulfate Product Informationmansih457Оценок пока нет

- QCP For SURFACE PREPARATION & COATING (PCS-1)Документ22 страницыQCP For SURFACE PREPARATION & COATING (PCS-1)mansih457Оценок пока нет

- Method Statement For 32'' Pipeline Hydro Static TestingДокумент50 страницMethod Statement For 32'' Pipeline Hydro Static Testingmansih457Оценок пока нет

- TR 949Документ8 страницTR 949mansih457Оценок пока нет

- Qa-Qc Multi Inspector CV (Welding-Painting-Ndt)Документ7 страницQa-Qc Multi Inspector CV (Welding-Painting-Ndt)mansih457Оценок пока нет

- Mcdelivery Menu 974 enДокумент1 страницаMcdelivery Menu 974 enmansih457Оценок пока нет

- Comments Resolution Sheet (CRS) : No. QP Comments Contractor ResponseДокумент4 страницыComments Resolution Sheet (CRS) : No. QP Comments Contractor Responsemansih457Оценок пока нет

- BMP07 - Rev.0 (Purchase)Документ9 страницBMP07 - Rev.0 (Purchase)mansih457Оценок пока нет

- 11-Zinc Ribbon For HT CrossingsДокумент6 страниц11-Zinc Ribbon For HT Crossingsmansih457Оценок пока нет

- Debit Account Details: Inter Bank TransferДокумент1 страницаDebit Account Details: Inter Bank Transfermansih457Оценок пока нет

- CWI Sample QuestionsДокумент4 страницыCWI Sample Questionsmansih457Оценок пока нет

- CV (Sr. QA QC Engineer)Документ5 страницCV (Sr. QA QC Engineer)mansih457100% (1)

- EPC CONTRACT PROCUREMENT PLAN FOR BHARUCH JAMNAGAR GAS PIPELINEДокумент5 страницEPC CONTRACT PROCUREMENT PLAN FOR BHARUCH JAMNAGAR GAS PIPELINEmansih457100% (3)

- Bina-Kota Pipeline Project: Monthly Progress ReportДокумент2 страницыBina-Kota Pipeline Project: Monthly Progress Reportmansih457Оценок пока нет

- 12 - TR - U NitДокумент5 страниц12 - TR - U Nitmansih457Оценок пока нет

- De-watering and drying diagramДокумент1 страницаDe-watering and drying diagrammansih457Оценок пока нет

- Leave Status: Page 1 of 1Документ1 страницаLeave Status: Page 1 of 1mansih457Оценок пока нет

- Package Name CardДокумент1 страницаPackage Name Cardmansih457Оценок пока нет

- Inspection Request: Report #: RE/INRQ/ Date: 24-Sep-17 Page: 1 of 1Документ1 страницаInspection Request: Report #: RE/INRQ/ Date: 24-Sep-17 Page: 1 of 1mansih457Оценок пока нет

- Ba084709 002Документ1 страницаBa084709 002mansih457Оценок пока нет

- Step 3 Hydrotest Diagram Stage 1Документ1 страницаStep 3 Hydrotest Diagram Stage 1mansih457100% (1)

- Package: 22.1M TL-9 TO OC-12 Drawing No:-RE/WELDMAP/17BP0978-01-012 Rev-00Документ2 страницыPackage: 22.1M TL-9 TO OC-12 Drawing No:-RE/WELDMAP/17BP0978-01-012 Rev-00mansih457Оценок пока нет

- Hydrotest Schematic Diagram Stage-2 (From Valve Station-2 To Valve Station-1)Документ1 страницаHydrotest Schematic Diagram Stage-2 (From Valve Station-2 To Valve Station-1)mansih457100% (1)

- Step 1 Cleaning & Gauging Diagram Stage 1Документ1 страницаStep 1 Cleaning & Gauging Diagram Stage 1mansih457Оценок пока нет

- SS Ut GammaДокумент29 страницSS Ut Gammamansih457Оценок пока нет

- Appendix E Water CertificateДокумент1 страницаAppendix E Water Certificatemansih457Оценок пока нет

- Appendix D Scraper DrawingsДокумент4 страницыAppendix D Scraper Drawingsmansih457Оценок пока нет

- BA085010001 Pipeline Route PlanДокумент1 страницаBA085010001 Pipeline Route Planmansih457Оценок пока нет

- Epogen Safety Data Sheet 20130213 Rev 4Документ8 страницEpogen Safety Data Sheet 20130213 Rev 4Michael Marc Andico DeleonОценок пока нет

- Real Heat Engines and RefrigeratorsДокумент11 страницReal Heat Engines and RefrigeratorsMario MikulandraОценок пока нет

- Probing The Mott Physics in - (BEDT-TTF) 2X Salts Via Thermal ExpansionДокумент28 страницProbing The Mott Physics in - (BEDT-TTF) 2X Salts Via Thermal ExpansionFelipeSilveiraОценок пока нет

- Nebula Igo Gear-OilДокумент1 страницаNebula Igo Gear-OilDidi KurniadiОценок пока нет

- Nuclear Power: Pros, Cons and FutureДокумент4 страницыNuclear Power: Pros, Cons and FutureSamarthОценок пока нет

- 12.elastic ConstantsДокумент18 страниц12.elastic ConstantsaderancОценок пока нет

- Collected By: Prof: Abdul Samad Mechanical Engineering Department. 2017Документ19 страницCollected By: Prof: Abdul Samad Mechanical Engineering Department. 2017Ans ahmedОценок пока нет

- Implantable Therapeutic Systems: Introduction of ImplantДокумент16 страницImplantable Therapeutic Systems: Introduction of ImplantUma MaheswararaoОценок пока нет

- Determination of Core Sample Absolute Permeability Using Gas Permeameter and Liquid Fluid Practicum ReportДокумент17 страницDetermination of Core Sample Absolute Permeability Using Gas Permeameter and Liquid Fluid Practicum ReportAqsal IlhamОценок пока нет

- 2 MS ElectrochemistryДокумент7 страниц2 MS ElectrochemistrysachinОценок пока нет

- SuperPur Product InformationДокумент1 страницаSuperPur Product InformationRamОценок пока нет

- Question Paper Applied Physics, Sem-1, BS-105Документ5 страницQuestion Paper Applied Physics, Sem-1, BS-105Kartik AgrawalОценок пока нет

- Sample Paper For ChemistryДокумент23 страницыSample Paper For ChemistryAmit joshiОценок пока нет

- General Installation Practices: Section EДокумент26 страницGeneral Installation Practices: Section EMohsen ArabifardОценок пока нет

- Band Theory 1Документ26 страницBand Theory 1Achmad AriebyoОценок пока нет

- 4-Procedure Pipe To SoilДокумент7 страниц4-Procedure Pipe To SoilKhanh DTОценок пока нет

- B.pharm. Class NotesДокумент817 страницB.pharm. Class NotesMukesh TiwariОценок пока нет

- Introduction to Computational Chemistry for Experimental Chemists... (Part 1/2Документ46 страницIntroduction to Computational Chemistry for Experimental Chemists... (Part 1/2Jennifer Carolina Rosales NoriegaОценок пока нет

- Hysys 8.8 - ManualДокумент606 страницHysys 8.8 - ManualCarlos Vaz88% (8)

- KapilДокумент69 страницKapilPraveen SrivastavaОценок пока нет

- Rubber: ASTM D412 Tensile Properties of Vulcanized Rubber and Thermoplastic ElastomersДокумент2 страницыRubber: ASTM D412 Tensile Properties of Vulcanized Rubber and Thermoplastic ElastomersPrabhakar KambleОценок пока нет

- Effectiveness of Liquid Oxygen BleachДокумент4 страницыEffectiveness of Liquid Oxygen BleachSingh GurleenОценок пока нет

- Heavy Oil Upgrading - A Key Solution For Heavy Oil Upstream and Midstream Operations - IVANHOE ENERGY PDFДокумент44 страницыHeavy Oil Upgrading - A Key Solution For Heavy Oil Upstream and Midstream Operations - IVANHOE ENERGY PDFGustavo Gonzalez ServaОценок пока нет

- Silver Clusters in Zeolites: Structure, Stability and PhotoactivityДокумент1 страницаSilver Clusters in Zeolites: Structure, Stability and PhotoactivityJan HermannОценок пока нет

- Construction & Material: Defects in Buildings & RemediesДокумент29 страницConstruction & Material: Defects in Buildings & RemedieskirtikaОценок пока нет

- Acid Cleaning For Nickel Alloys Pages From Handbook of Engineering Practice of Materials and Corrosion by Jung-Chul (Thomas) EunДокумент9 страницAcid Cleaning For Nickel Alloys Pages From Handbook of Engineering Practice of Materials and Corrosion by Jung-Chul (Thomas) EunMohammad TaherОценок пока нет

- HPLC ExperimentДокумент4 страницыHPLC ExperimentFrances PaulineОценок пока нет

- Stereoisomers Part 1Документ14 страницStereoisomers Part 1Mabelle DucusinОценок пока нет

- Properties of Matter PresentationДокумент9 страницProperties of Matter PresentationMica Ela MañoОценок пока нет

- Reservoir Drive Mechanisms PDFДокумент28 страницReservoir Drive Mechanisms PDFWassef MB100% (1)