Академический Документы

Профессиональный Документы

Культура Документы

Cost Control Measure

Загружено:

Syed Safiur RahmanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cost Control Measure

Загружено:

Syed Safiur RahmanАвторское право:

Доступные форматы

NINL

POWER PLANT

Cost CONTROL

measures

NINL

POWER PLANT

AREAS IDENTIFED FOR COST CONTROL

Reduction in specific LDO consumption in

Boilers

Reduction in specific heat consumption in Boilers

Scrap despatch

Reduction in Acid/Alkali Consumption

Improvement in output of STG

Retrival of solar oil from GTG effluent

Reduction of LDO consumption of GTG

Mixing of spent solar oil with LDO

2

POWER PLANT

NINL

In Rs Lakhs

Savings w.r.t.

Budget Norms

SN

Heads

Reduction in

specific LDO

1

consumption in

Boilers

Budget

norm

Dept.

Actual Production/Consumption data Expected

Proposal

as per

Actual

Dept

Proposal

Ltr/ T steam

1.16

0.400

Mcal/T Steam

Reduction of

Sp Heat

2

consumption in

boilers

785

765

Steam Generation (tons)

799458

LDO cons. (kl)

57.64

Reduction of Sp Heat

consumption in boilers

0.072

Steam Generation (tons)

BF Gas consumption

(KNm3)

CO Gas consumption

(KNm3)

LDO Cons. (kl)

Total Heat cons. (Mcal)

Specific Heat cons.

(Mcal/ton)

Scrap

Despatch

304

435

145

-113

--

799458

332276

90787

57.64

64010986

0

801

POWER PLANT

NINL

Savings w.r.t.

Budget Norms

SN

Heads

Reduction in

Acid/Alkali

consumption

4a

Reduction in Acid

consumption

4b

Reduction in Alkali

consumption

Improvement in Out

put of STG

Actual

Expecte

Budget

Dept.

Production/Consumption d as per

norm Proposal

data

Dept Actual

Propos

al

kg/t of DM Water

DM water

consumption

237757

Acid consumption 111809

0.485

0.472

Specific acid

consumption

0.470

1.65

Alkali consumption 83191

0.348

0.283

Exit enthalpy of

Steam (Kcal/kg)

625

619

Specific alkali

consumption

0.350

Will be realised after

overhauling of STGs

--

0.08

POWER PLANT

NINL

Savings w.r.t.

Budget Norms

SN

Heads

Retrieval of

spent solar oil

from effluent

Budget

norm

Dept.

Proposal

Actual

Production/Consumption Expected

as per

data

Actual

Dept

Proposal

solar oil recovered

(kl/day)

Solar Oil recovered

(kl)

55.0

0.0

GT Runnung Days

137

LDO cons. (kl)

Solar Oil cons. In

Boilers (kl)

0.6

kl/month

Reduction of

LDO

38

Consumption in

17 KL/Month

KL/Month

GTG

Mixing of Spent

Solar Oil with

LDO

Kl/year

0

140 KL /year

24.7

16.5

266

126

9.9

348

35

104.4

636

456

TOTAL (Rs Lakhs)

POWER PLANT

NINL

STATUS OF COST CONTROL MEASURES & SAVINGS TILL jan2012

(RS LAKHS)

SN

1

2

3

4

5

6

Heads

Reduction in specific LDO

consumption in Boilers

Reduction of Sp Heat consumption in

boilers

Scrap etc. despatch

Reduction in Acid/Alkali

consmuption

Improvement in Out put of STG

Retrieval of spent solar oil from

effluent

Savings w.r.t. Budget

Norms

Expected as

per Dept

Actual

Proposal

303.2

404.9

144.7

-113.1

--

4.0

1.65

0.08

--

--

24.7

6

16.5

POWER PLANT

N I NMISCELLENEOUS

L

COST CONTROL

MESURES

Reduction of Job Contract

Restricted use of Vehicles

Reduction of Telephone expenditure

Judicious use of Impress

expenditure

Indenting only essential spares &

consumables

7

NINL

POWER PLANT

Reward ceremony of SRUJANI of power Plant

was held on 12-12-11

No of suggestions received till date

No of suggestions accepted

No of suggestions rejected

No of suggestions implemented

No of suggestions for cost saving/waste

reduction

No of suggestions for system

improvement

No of suggestions for improvement in

safety

Approximate savings from implemented

suggestions

38

28

10

9

9

15

4

8

250000/

yr

NINL

POWER PLANT

Qc teams and savings

No of Teams working

No of projects completed by SHAKTI QC

10

No of projects completed by BIJLEE QC

06

No of projects completed by KIRAN QC

02

No of projects completed by URJA QC

01

No of projects completed by AKSHYA QC

02

No of projects under progress

Estimated annual Savings of the projects

Completed

Rs 150 lakhs

9

NINL

POWER PLANT

FUTURE COST SAVING PLAN

STGs vacuum improvement

Boiler-3 Air Pre-heater

Replacement

Scrap Disposal ( MS scrap

& Used oil)

Total Savings

15

lakhs/mont

h

10

lakhs/mont

h

10

lakhs/Year

310

lakhs/Year

10

Thank You

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Chlorine Gas: Per Gallon of Water Treated, Possibly The Safest Form of Residual DisinfectionДокумент17 страницChlorine Gas: Per Gallon of Water Treated, Possibly The Safest Form of Residual DisinfectionSyed Safiur RahmanОценок пока нет

- Question Paper BoilerДокумент12 страницQuestion Paper BoilerSyed Safiur RahmanОценок пока нет

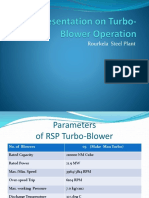

- Turbo-Blower Operation - PPSXДокумент12 страницTurbo-Blower Operation - PPSXSyed Safiur Rahman100% (1)

- How To Improve The Vacuum of STG-2Документ6 страницHow To Improve The Vacuum of STG-2Syed Safiur RahmanОценок пока нет

- SSS Clutch PrincipleДокумент2 страницыSSS Clutch PrincipleSyed Safiur RahmanОценок пока нет

- Chlorine Gas: Per Gallon of Water Treated, Possibly The Safest Form of Residual DisinfectionДокумент17 страницChlorine Gas: Per Gallon of Water Treated, Possibly The Safest Form of Residual DisinfectionSyed Safiur RahmanОценок пока нет

- Cooling Water System LectureДокумент81 страницаCooling Water System LectureSyed Safiur RahmanОценок пока нет

- Turbo Blower OperationДокумент12 страницTurbo Blower OperationSyed Safiur RahmanОценок пока нет

- Information Regarding Present Indian Power ScenarioДокумент3 страницыInformation Regarding Present Indian Power ScenarioSyed Safiur RahmanОценок пока нет

- Cooling Water System LectureДокумент81 страницаCooling Water System LectureSyed Safiur RahmanОценок пока нет

- Cooling Water System LectureДокумент81 страницаCooling Water System LectureSyed Safiur RahmanОценок пока нет

- Gas SafetyДокумент28 страницGas SafetySyed Safiur RahmanОценок пока нет

- Project 1Документ7 страницProject 1Syed Safiur RahmanОценок пока нет

- Cooling Water System LectureДокумент81 страницаCooling Water System LectureSyed Safiur RahmanОценок пока нет

- Cost Control MeasureДокумент11 страницCost Control MeasureSyed Safiur RahmanОценок пока нет

- Quality ToolsДокумент50 страницQuality ToolsSyed Safiur RahmanОценок пока нет

- Productivity For Global CompetitivenessДокумент47 страницProductivity For Global CompetitivenessSyed Safiur RahmanОценок пока нет

- Low Intensity Flame Scanner in Boiler1Документ10 страницLow Intensity Flame Scanner in Boiler1Syed Safiur RahmanОценок пока нет

- Productivity For Global CompetitivenessДокумент47 страницProductivity For Global CompetitivenessSyed Safiur RahmanОценок пока нет

- Cost Control MeasureДокумент11 страницCost Control MeasureSyed Safiur RahmanОценок пока нет

- Water ChemistryДокумент17 страницWater ChemistrySyed Safiur RahmanОценок пока нет

- Water ChemistryДокумент17 страницWater ChemistrySyed Safiur RahmanОценок пока нет

- Quality ToolsДокумент50 страницQuality ToolsSyed Safiur RahmanОценок пока нет

- How To Improve The Vacuum of STG-2: Power & Blowing Station - 2Документ6 страницHow To Improve The Vacuum of STG-2: Power & Blowing Station - 2Syed Safiur RahmanОценок пока нет

- How To Improve The Vacuum of STG-2Документ6 страницHow To Improve The Vacuum of STG-2Syed Safiur RahmanОценок пока нет

- How To Improve The Vacuum of STG-2Документ6 страницHow To Improve The Vacuum of STG-2Syed Safiur RahmanОценок пока нет

- Gas SafetyДокумент28 страницGas SafetySyed Safiur RahmanОценок пока нет

- WPT PresentationДокумент23 страницыWPT PresentationSyed Safiur RahmanОценок пока нет

- Water ChemistryДокумент17 страницWater ChemistrySyed Safiur RahmanОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- English Class Vii PDFДокумент101 страницаEnglish Class Vii PDFpannapurohitОценок пока нет

- Matters Signified by The Sublord of 11th Cusp in KP SystemДокумент2 страницыMatters Signified by The Sublord of 11th Cusp in KP SystemHarry HartОценок пока нет

- Yoga SadhguruДокумент6 страницYoga Sadhgurucosti.sorescuОценок пока нет

- GB GW01 14 04 02Документ2 страницыGB GW01 14 04 02Muhammad LukmanОценок пока нет

- Bravo MRI II Operation ManualДокумент45 страницBravo MRI II Operation ManualLuis100% (1)

- Kelas ChondrichtyesДокумент15 страницKelas ChondrichtyesanitagustinawatiОценок пока нет

- CulvertsДокумент18 страницCulvertsAmmar A. Ali100% (1)

- Rachel Joyce - A Snow Garden and Other Stories PDFДокумент118 страницRachel Joyce - A Snow Garden and Other Stories PDFИгорь ЯковлевОценок пока нет

- Clinical Biomechanics: Leigh W. Marshall, Stuart M. McgillДокумент4 страницыClinical Biomechanics: Leigh W. Marshall, Stuart M. McgillMichael JunОценок пока нет

- Joby Aviation - Analyst Day PresentationДокумент100 страницJoby Aviation - Analyst Day PresentationIan TanОценок пока нет

- Etoricoxib - Martindale 39thДокумент2 страницыEtoricoxib - Martindale 39thCachimbo PrintОценок пока нет

- Contoh CV / Daftar Riwayat HidupДокумент2 страницыContoh CV / Daftar Riwayat HiduprusmansyahОценок пока нет

- Theoretical CyclesДокумент49 страницTheoretical CyclesMariaEzzaSyUyОценок пока нет

- Case 445Документ4 страницыCase 445ForomaquinasОценок пока нет

- TM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 1Документ294 страницыTM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 1AdvocateОценок пока нет

- Concrete Super Structure ReportДокумент43 страницыConcrete Super Structure ReportLivian TeddyОценок пока нет

- Coding Decoding Sheet - 01 1678021709186Документ9 страницCoding Decoding Sheet - 01 1678021709186Sumit VermaОценок пока нет

- Wcdma Idle Mode (Ericsson)Документ29 страницWcdma Idle Mode (Ericsson)Hosein ShahbaziОценок пока нет

- Tabla9 1Документ1 страницаTabla9 1everquinОценок пока нет

- 23001864Документ15 страниц23001864vinodsrawat33.asiОценок пока нет

- FBC MNCS Service-, Error-, Infocodes ENДокумент23 страницыFBC MNCS Service-, Error-, Infocodes ENDragos Stoian100% (1)

- Asme Code Sec Ix Ma Appe 2004Документ3 страницыAsme Code Sec Ix Ma Appe 2004Guillermo CamachoОценок пока нет

- Entero SequencesДокумент12 страницEntero SequencesKelvin SueyzyОценок пока нет

- Badminton ReviewerДокумент10 страницBadminton ReviewerHailsey WinterОценок пока нет

- Chillers VoltasДокумент4 страницыChillers Voltasanil shuklaОценок пока нет

- Chap 4 - Basic Principles of ElectricityДокумент31 страницаChap 4 - Basic Principles of ElectricityAdiseshuMiddeОценок пока нет

- Tokyo Guidelines 2018Документ115 страницTokyo Guidelines 2018Alik Razi100% (1)

- Harmonic Analysis of Separately Excited DC Motor Drives Fed by Single Phase Controlled Rectifier and PWM RectifierДокумент112 страницHarmonic Analysis of Separately Excited DC Motor Drives Fed by Single Phase Controlled Rectifier and PWM RectifierGautam Umapathy0% (1)

- Preview: Proquest Dissertations and Theses 2002 Proquest Dissertations & Theses Full TextДокумент24 страницыPreview: Proquest Dissertations and Theses 2002 Proquest Dissertations & Theses Full TextFelipe AguilarОценок пока нет

- Addtional List Dissertation 040117Документ6 страницAddtional List Dissertation 040117Sagar Kansara100% (2)