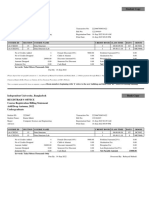

Академический Документы

Профессиональный Документы

Культура Документы

Mbe900 A I Manual

Загружено:

Jesus Vega HummerОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mbe900 A I Manual

Загружено:

Jesus Vega HummerАвторское право:

Доступные форматы

ATTENTION

This document is a guideline for qualified personnel. It is intended to be used by equipment

manufacturers and contains Detroit Diesel Corporation's preliminary recommendations for the

ancillary systems supporting the Detroit Diesel engines covered by this document. the equipment

manufacturer is responsible for developing, designing, manufacturing and installing these

systems, including component qualification. The equipment manufacturer is also responsible for

furnishing equipment users complete service and safety information for these systems. Detroit

Diesel Corporation makes no representations or warranties regarding the information contained in

installation of these ancillary systems, or the preparation or distribution to equipment users. The

information in this manual is incomplete and is subject to change without notice.

Viton is a registered trademark of Dupont Dow Elastomers L.L.C. All other trademarks are the

property of their respective owners.

MBE 900 APPLICATION AND INSTALLATION

MBE 900 APPLICATION AND INSTALLATION

ABSTRACT

This manual discusses the proper application and installation of the Detroit Diesel MBE 900

engine. This manual contains the following information:

General information on safety precautions and on accessing installation drawings

Specific component and accessory information on various production models

Information on the electrical, fuel, exhaust, lubrication, cooling, and air inlet systems

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

ABSTRACT

ii

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

TABLE OF CONTENTS

1

INTRODUCTION .................................................................................................................

1-1

SAFETY PRECAUTIONS ...................................................................................................

2.1

STANDS ..........................................................................................................................

2.2

GLASSES .......................................................................................................................

2.3

WELDING .......................................................................................................................

2.4

WORK PLACE ...............................................................................................................

2.5

CLOTHING ......................................................................................................................

2.6

ELECTRIC TOOLS .........................................................................................................

2.7

AIR ..................................................................................................................................

2.8

FLUIDS AND PRESSURE ..............................................................................................

2.9

BATTERIES .....................................................................................................................

2.10

FIRE ................................................................................................................................

2.11

FLUOROELASTOMER ..................................................................................................

2-1

2-1

2-1

2-2

2-3

2-4

2-4

2-5

2-5

2-6

2-6

2-7

ENGINE AND ACCESSORY IDENTIFICATION ................................................................

ENGINE DESCRIPTION .................................................................................................

MAJOR COMPONENT LOCATIONS FOR MBE 900 EGR ON-HIGHWAY ENGINES ...

MAJOR COMPONENT LOCATIONS FOR OM 900 OFF-HIGHWAY ENGINES ............

ENGINE IDENTIFICATION .............................................................................................

EMISSION LABELS ........................................................................................................

3-1

3-3

3-5

3-8

3-12

3-13

AIR INLET SYSTEM ...........................................................................................................

4.1

AIR INLET SYSTEM DESCRIPTION ..............................................................................

4.1.1

MBE 900 ON-HIGHWAY ENGINES ............................................................................

4.1.2

ENGINE AIR INLET CONNECTION FOR MBE EGR ENGINES ...............................

4.2

INSTALLATION REQUIREMENTS .................................................................................

4.2.1

DRY PAPER ELEMENT AIR CLEANERS ..................................................................

4.2.1.1

MEDIUM-DUTY USE AIR CLEANER ...................................................................

4.2.1.2

HEAVY-DUTY USE AIR CLEANER .....................................................................

4.2.1.3

EXTRA HEAVY-DUTY USE .................................................................................

4.2.1.4

FOAM TYPE AIR CLEANERS ..............................................................................

4.2.1.5

OIL BATH AIR CLEANERS ..................................................................................

4.2.1.6

AUXILIARY PRECLEANERS ................................................................................

4.2.1.7

INLET SCREENS .................................................................................................

4.2.1.8

RAIN CAPS AND INLET HOODS ........................................................................

4.2.1.9

WATER DRAINS ...................................................................................................

4.2.1.10 INLET SILENCERS ..............................................................................................

4.2.1.11 AIR CLEANER SELECTION ................................................................................

4.2.2

RESTRICTION INDICATOR .......................................................................................

4.2.3

PIPEWORK ................................................................................................................

4.2.3.1

PIPEWORK MATERIAL SPECIFICATIONS .........................................................

4.2.3.2

DIFFUSERS .........................................................................................................

4.2.4

HOSE CONNECTIONS ..............................................................................................

4-1

4-3

4-4

4-6

4-8

4-8

4-9

4-10

4-11

4-12

4-12

4-13

4-13

4-14

4-14

4-14

4-15

4-15

4-17

4-17

4-17

4-18

3.1

3.2

3.3

3.4

3.5

4

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

iii

TABLE OF CONTENTS

4.3

DESIGN GUIDELINES ....................................................................................................

4.3.1

MAXIMUM AIR INLET FLOW ....................................................................................

4.3.2

AIR INLET SYSTEM RESTRICTION .........................................................................

4.3.3

INLET LOCATION .......................................................................................................

4.3.4

CHARGE AIR COOLER ............................................................................................

4.3.4.1

RESTRICTION AND TEMPERATURE REQUIREMENTS ...................................

4.3.4.2

CLEANLINESS .....................................................................................................

4.3.4.3

LEAKAGE .............................................................................................................

4.3.4.4

SIZE ......................................................................................................................

4.3.4.5

COOLING AIR FLOW RESTRICTION .................................................................

4.3.4.6

MATERIAL ............................................................................................................

4.3.4.7

HEADER TANKS ..................................................................................................

4.3.4.8

LOCATION ............................................................................................................

4.3.4.9

FAN SYSTEMS .....................................................................................................

4.3.4.10 SHUTTERS ..........................................................................................................

4.3.4.11 WINTERFRONTS .................................................................................................

4.4

TESTING REQUIREMENTS ...........................................................................................

4.4.1

INSTRUMENTATION ..................................................................................................

4.4.1.1

TEMPERATURE MEASUREMENT ......................................................................

4.4.1.2

PRESSURE MEASUREMENT .............................................................................

4.4.1.3

LOCATION ............................................................................................................

4.4.2

INLET SYSTEM RESTRICTION ................................................................................

4.4.3

MAXIMUM TEMPERATURE RISE--AMBIENT TO TURBOCHARGER INLET ..........

4.4.4

AIR-TO-AIR SYSTEM EVALUATION TESTS .............................................................

4.4.4.1

MAXIMUM TEMPERATURE RISE--AMBIENT TO INTAKE MANIFOLD ..............

4.4.4.2

CHARGE AIR COOLER SYSTEM RESTRICTION ..............................................

4.5

TEST ...............................................................................................................................

4-18

4-19

4-19

4-19

4-20

4-21

4-21

4-22

4-22

4-22

4-22

4-23

4-23

4-23

4-23

4-24

4-24

4-24

4-24

4-25

4-28

4-28

4-29

4-29

4-29

4-30

4-30

EXHAUST SYSTEM ...........................................................................................................

5.1

EXHAUST SYSTEM DESCRIPTION ..............................................................................

5.1.1

TURBOCHARGER .....................................................................................................

5.2

INSTALLATION REQUIREMENTS .................................................................................

5.2.1

BACK PRESSURE .....................................................................................................

5.2.2

NOISE .........................................................................................................................

5.2.3

FLEXIBLE FITTINGS ..................................................................................................

5.2.4

MATERIAL SPECIFICATIONS FOR PIPEWORK .......................................................

5.2.5

MANIFOLDING OF ENGINES INTO A COMMON EXHAUST SYSTEM ...................

5.3

DESIGN REQUIREMENTS ...........................................................................................

5.3.1

OUTLET LOCATION ...................................................................................................

5.3.2

DRAINAGE .................................................................................................................

5.3.3

MUFFLER LOCATION ................................................................................................

5.3.4

SYSTEM INSULATION ...............................................................................................

5.4

TESTING REQUIREMENTS ...........................................................................................

5.4.1

MEASUREMENT OF EXHAUST BACK PRESSURE ................................................

5.4.2

MEASUREMENT OF EXHAUST TEMPERATURE ....................................................

5-1

5-2

5-4

5-4

5-5

5-6

5-6

5-6

5-6

5-7

5-7

5-7

5-8

5-8

5-8

5-9

5-11

EXHAUST GAS RECIRCULATION ....................................................................................

SYSTEM DESCRIPTION ................................................................................................

6-1

6-3

6.1

iv

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

6.2

6.3

6.4

6.5

7

EGR COOLER ................................................................................................................

EGR VALVE ....................................................................................................................

REED VALVES ................................................................................................................

EGR MIXER ....................................................................................................................

6-5

6-5

6-6

6-6

COOLING SYSTEM ...........................................................................................................

7.1

COOLING SYSTEM DESCRIPTION ..............................................................................

7.2

JACKET WATER COOLING SYSTEM ............................................................................

7.3

THERMOSTAT ................................................................................................................

7.3.1

ENGINE VENTING ....................................................................................................

7.4

WATER PUMP ...............................................................................................................

7.5

TYPES OF COOLING SYSTEMS ...................................................................................

7.5.1

RAPID WARM-UP COOLING SYSTEM ....................................................................

7.5.2

CONVENTIONAL COOLING SYSTEM ......................................................................

7.5.3

AUXILIARY AIR-COOLED COOLER CORES ............................................................

7.5.4

COOLANT HEATERS .................................................................................................

7.6

AIR-TO-AIR CHARGE COOLING ...................................................................................

7.6.1

CHARGE AIR COOLER .............................................................................................

7.7

COOLING SYSTEM PERFORMANCE REQUIREMENTS .............................................

7.7.1

SYSTEM FILL .............................................................................................................

7.7.2

SYSTEM DRAIN .........................................................................................................

7.7.3

DEAERATION .............................................................................................................

7.7.4

SYSTEM COOLANT CAPACITY ................................................................................

7.7.5

DRAWDOWN CAPACITY ...........................................................................................

7.7.6

CORE CONSTRUCTION ............................................................................................

7.7.7

WATER PUMP INLET PRESSURE/MAXIMUM STATIC HEAD ..................................

7.7.8

COOLANT FLOW RATE/EXTERNAL PRESSURE DROP .........................................

7.7.9

MINIMUM COOLANT TEMPERATURE .....................................................................

7.7.10 SYSTEM PRESSURIZATION .....................................................................................

7.7.11 COOLANTS ................................................................................................................

7.8

CHARGE AIR COOLING REQUIREMENTS ..................................................................

7.8.1

COOLING CAPABILITY ..............................................................................................

7.8.2

MAXIMUM PRESSURE LOSS ...................................................................................

7.8.3

CLEANLINESS ...........................................................................................................

7.8.4

LEAKAGE ...................................................................................................................

7.9

END PRODUCT QUESTIONNAIRE ...............................................................................

7.10

COOLING SYSTEM DESIGN CONSIDERATIONS ........................................................

7.10.1 COOLING SYSTEM REQUIREMENTS .....................................................................

7.10.1.1 ENGINE OPERATING TEMPERATURE ..............................................................

7.10.2 ENGINE PERFORMANCE .........................................................................................

7.10.2.1 ENGINE HEAT REJECTION ................................................................................

7.10.2.2 COOLANT FLOW .................................................................................................

7.10.2.3 HEAT TRANSFER CAPABILITIES .......................................................................

7.10.3 ENVIRONMENTAL AND OPERATING CONDITIONS ...............................................

7.10.3.1 AMBIENT TEMPERATURE ..................................................................................

7.10.3.2 ALTITUDE .............................................................................................................

7.10.3.3 SPACE CONSTRAINTS .......................................................................................

7-1

7-3

7-3

7-7

7-8

7-8

7-8

7-8

7-10

7-10

7-10

7-11

7-12

7-13

7-13

7-13

7-13

7-14

7-15

7-15

7-15

7-15

7-16

7-16

7-16

7-16

7-16

7-17

7-17

7-17

7-17

7-17

7-17

7-18

7-18

7-18

7-18

7-18

7-19

7-20

7-20

7-20

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

TABLE OF CONTENTS

7.10.3.4 NOISE LIMITS ......................................................................................................

7.10.3.5 TILT OPERATIONS OR INSTALLATIONS ............................................................

7.10.4 SYSTEM COMPONENTS ..........................................................................................

7.10.4.1 ADDITIONAL HEAT LOADS TO COOLANT .........................................................

7.10.4.2 ADDITIONAL HEAT LOADS TO AIR ....................................................................

7.10.4.3 COOLANT TYPE ..................................................................................................

7.10.4.4 PLUMBING ..........................................................................................................

7.10.4.5 AUXILIARY COOLANT FLOW PATH CIRCUITRY ...............................................

7.10.4.6 WATER PUMPS ....................................................................................................

7.11

CHARGE AIR COOLING DESIGN GUIDELINES ...........................................................

7.11.1 SIZE ............................................................................................................................

7.11.2 COOLING AIR FLOW RESTRICTION ........................................................................

7.11.3 MATERIAL ..................................................................................................................

7.11.4 HEADER TANKS ........................................................................................................

7.11.5 LOCATION ..................................................................................................................

7.11.6 PIPEWORK ................................................................................................................

7.12

HEAT EXCHANGER SELECTION ..................................................................................

7.13

FAN SYSTEM RECOMMENDATIONS AND FAN SELECTION ......................................

7.13.1 BLOWER VS SUCTION FANS ...................................................................................

7.13.1.1 FAN PERFORMANCE ..........................................................................................

7.13.1.2 FAN POSITION .....................................................................................................

7.13.1.3 FAN SHROUDS ....................................................................................................

7.13.1.4 FAN SYSTEM ASSEMBLIES ...............................................................................

7.13.1.5 FAN DRIVES ........................................................................................................

7.13.1.6 BAFFLES TO PREVENT AIR RECIRCULATION ................................................

7.13.1.7 SHUTTERS ..........................................................................................................

7.13.1.8 WINTERFRONTS .................................................................................................

7.14

RADIATOR COMPONENT DESIGN ...............................................................................

7.14.1 DOWN FLOW AND CROSS FLOW RADIATORS ......................................................

7.14.1.1 HORIZONTAL RADIATOR ....................................................................................

7.14.1.2 RAPID WARM-UP DEAERATION TANK - DOWN FLOW RADIATOR .................

7.14.1.3 REMOTE MOUNTED RADIATORS/HEAT EXCHANGER ....................................

7.14.1.4 INTEGRAL TOP TANK .........................................................................................

7.14.1.5 REMOTE TANK ....................................................................................................

7.14.1.6 RADIATOR BOTTOM TANK .................................................................................

7.14.1.7 COOLANT PRESSURE CONTROL CAPS AND RELIEF VALVES ......................

7.14.1.8 THERMOSTAT ......................................................................................................

7.14.1.9 COOLANT SENSOR DEVICES ...........................................................................

7.14.1.10 COOLANT RECOVERY SYSTEM ........................................................................

7.14.2 COLD WEATHER OPERATING OPTIMIZATION .......................................................

7.14.2.1 ENGINE ................................................................................................................

7.14.2.2 VEHICLE ..............................................................................................................

7.14.2.3 COOLING SYSTEM .............................................................................................

7.14.2.4 HEATER CIRCUIT ................................................................................................

7.14.3 COOLANT HEATERS .................................................................................................

7.14.4 MULTI-DUTY CYCLE .................................................................................................

7.14.5 OTHER CONSIDERATIONS ......................................................................................

vi

7-20

7-20

7-20

7-21

7-21

7-22

7-22

7-23

7-23

7-24

7-24

7-25

7-25

7-25

7-25

7-25

7-26

7-27

7-28

7-29

7-31

7-32

7-32

7-33

7-33

7-33

7-33

7-34

7-34

7-34

7-35

7-35

7-36

7-39

7-40

7-42

7-44

7-44

7-46

7-51

7-51

7-51

7-51

7-52

7-52

7-52

7-52

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

7.15

DIAGNOSTICS AND TROUBLESHOOTING ..................................................................

7.15.1 ENGINE OVERHEAT ..................................................................................................

7.15.1.1 TROUBLESHOOTING FOR ENGINE OVERHEAT ..............................................

7.15.2 COLD RUNNING ENGINE (OVERCOOLING) ...........................................................

7.15.3 POOR CAB HEATER PERFORMANCE .....................................................................

7.16

MAINTENANCE ..............................................................................................................

7-53

7-53

7-53

7-55

7-55

7-57

FUEL SYSTEM ...................................................................................................................

8.1

FUEL SYSTEM DESCRIPTION ......................................................................................

8.2

FUEL SYSTEM EQUIPMENT/INSTALLATION GUIDELINES ........................................

8.2.1

FUEL TANK ................................................................................................................

8.2.1.1

MATERIAL ............................................................................................................

8.2.1.2

DESIGN ................................................................................................................

8.2.1.3

CAPACITY ............................................................................................................

8.2.1.4

POSITION .............................................................................................................

8.2.2

REMOTE FUEL FILTER .............................................................................................

8.2.3

FUEL FILTER CONFIGURATION ...............................................................................

8.2.4

FUEL LINES ...............................................................................................................

8.2.4.1

DESIGN ................................................................................................................

8.2.4.2

MATERIAL ............................................................................................................

8.2.4.3

SIZE ......................................................................................................................

8.2.5

OPTIONAL DEVICES .................................................................................................

8.2.5.1

FUEL COOLER ....................................................................................................

8.2.5.2

FUEL WATER SEPARATOR .................................................................................

8.3

FUEL SELECTION ..........................................................................................................

8-1

8-2

8-4

8-4

8-4

8-4

8-5

8-6

8-7

8-7

8-8

8-8

8-9

8-9

8-9

8-9

8-9

8-9

LUBRICATION SYSTEM ...................................................................................................

9.1

LUBRICATION SYSTEM DESCRIPTION .......................................................................

9.2

LUBRICATION OIL SELECTION ....................................................................................

9.3

LUBRICATION FILTER ...................................................................................................

9.4

ENGINE COMPONENT OIL SUPPLY REQUIREMENTS ...............................................

9.4.1

TURBOCHARGER LUBRICATION ............................................................................

9.4.2

AIR COMPRESSOR LUBRICATION ..........................................................................

9.5

INSTALLATION REQUIREMENTS .................................................................................

9.5.1

SUPPLEMENTAL FILTRATION SYSTEMS ................................................................

9.5.1.1

REMOTE MOUNT SUPPLEMENTAL OIL FILTERS ............................................

9.5.2

OIL SAMPLING VALVE ..............................................................................................

9.5.3

MECHANICAL OIL PRESSURE GAUGES ................................................................

9.6

COMPONENT OPTIONS ................................................................................................

9.6.1

OIL CHECKS AND FILLS ...........................................................................................

9.6.2

OIL SUMPS ................................................................................................................

9.6.2.1

INSTALLATION REQUIREMENTS FOR OIL SUMPS ..........................................

9.6.3

OIL IMMERSION HEATERS .......................................................................................

9.6.4

ENGINE OIL LEVEL SENSOR ...................................................................................

9.7

OPERATION AND MAINTENANCE ................................................................................

9.7.1

FIRST TIME START ....................................................................................................

9.7.2

OIL LEVEL MEASUREMENTS ..................................................................................

9.7.3

USED OIL ANALYSIS .................................................................................................

9-1

9-3

9-6

9-6

9-7

9-7

9-7

9-8

9-8

9-8

9-10

9-10

9-10

9-10

9-11

9-11

9-11

9-11

9-12

9-12

9-12

9-12

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

vii

TABLE OF CONTENTS

9.7.4

OIL DRAIN INTERVALS .............................................................................................

9.8

OIL FILTER CONFIGURATION .......................................................................................

9.9

OIL CENTRIFUGE ..........................................................................................................

9-12

9-12

9-12

10

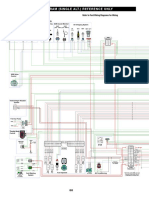

ELECTRICAL SYSTEM ......................................................................................................

10.1

ELECTRICAL SYSTEM DESCRIPTION .........................................................................

10.2

INSTALLATION GUIDELINES .........................................................................................

10.2.1 BATTERY ....................................................................................................................

10.2.1.1 FILLER CAP BATTERIES .....................................................................................

10.2.1.2 SEMI-MAINTENANCE FREE BATTERIES ..........................................................

10.2.1.3 MAINTENANCE-FREE BATTERIES ....................................................................

10.2.1.4 DEEP CYCLE BATTERIES ..................................................................................

10.2.1.5 BATTERY CAPACITY ...........................................................................................

10.2.1.6 BATTERY MOUNTING AND LOCATION ..............................................................

10.2.2 CRANKING MOTOR ...................................................................................................

10.2.3 ALTERNATOR .............................................................................................................

10.2.3.1 ALTERNATOR MOUNTING ..................................................................................

10.2.4 GROUNDING REQUIREMENTS ................................................................................

10.2.5 WIRING ......................................................................................................................

10.2.5.1 GUIDELINES FOR ELECTRICAL WIRING ..........................................................

10.2.5.2 CABLE LOSS TEST PROCEDURE .....................................................................

10.2.5.3 MEASURING CIRCUIT RESISTANCE .................................................................

10.2.5.4 CALCULATING CIRCUIT RESISTANCE ..............................................................

10-1

10-2

10-3

10-3

10-3

10-3

10-3

10-3

10-4

10-4

10-7

10-9

10-11

10-11

10-12

10-12

10-13

10-14

10-15

11

MOUNTING SYSTEM .........................................................................................................

11.1

MOUNTING SYSTEM DESCRIPTION ...........................................................................

11.1.1 THREE-POINT MOUNTING .......................................................................................

11.1.2 FOUR-POINT MOUNTING .........................................................................................

11.2

SOLID MOUNTING SYSTEMS .......................................................................................

11.3

FLEXIBLE MOUNTING SYSTEMS .................................................................................

11.3.1 FLEXIBLE MOUNT SELECTION ...............................................................................

11.3.1.1 METHOD A ...........................................................................................................

11.3.1.2 METHOD B ...........................................................................................................

11.4

INSTALLATION CHECK LIST .........................................................................................

11.5

ENGINE SUPPORT ........................................................................................................

11-1

11-2

11-3

11-4

11-5

11-6

11-6

11-7

11-8

11-9

11-10

12

TORSIONAL ANALYSIS ....................................................................................................

12.1

OVERVIEW .....................................................................................................................

12.2

MASS ELASTIC ..............................................................................................................

12-1

12-2

12-2

13

ENGINE ELECTRONIC CONTROLS .................................................................................

13.1

OVERVIEW .....................................................................................................................

13.2

PLD-MR ENGINE-RESIDENT CONTROL UNIT .........................................................

13.3

VEHICLE CONTROL UNIT ON-HIGHWAY ................................................................

13.3.1 GRID HEATER ............................................................................................................

13.3.1.1 WIRING THE GRID HEATER ...............................................................................

13.4

ADM2 ..............................................................................................................................

13.4.1 GRID HEATER ............................................................................................................

13.4.1.1 WIRING THE GRID HEATER ...............................................................................

13-1

13-2

13-3

13-4

13-6

13-6

13-7

13-9

13-9

viii

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

13.5

13.6

13.7

VEHICLE INTERFACE HARNESS .................................................................................

ENGINE HARNESS .......................................................................................................

SYSTEM SENSORS .......................................................................................................

13-10

13-12

13-14

14

TECHNICAL DATA .............................................................................................................

14-1

15

INSTALLATION DRAWINGS ..............................................................................................

MBE 906 EGR ENGINE INSTALLATION DRAWINGS ...................................................

MBE 904 EGR ENGINE INSTALLATION DRAWINGS ...................................................

OM 904 NON-EGR ENGINE INSTALLATION DRAWINGS ............................................

OM 906 NON-EGR ENGINE INSTALLATION DRAWINGS ............................................

15-1

15-2

15-10

15-18

15-26

16

OPTIONS ............................................................................................................................

16-1

17

17.1

17.2

17.3

17.4

EFFECTS OF ENVIRONMENTAL CONDITIONS ..............................................................

OVERVIEW .....................................................................................................................

AIR INLET TEMPERATURE ...........................................................................................

EXHAUST BACK PRESSURE ........................................................................................

ALTITUDE .......................................................................................................................

17-1

17-2

17-2

17-3

17-3

18.1

18.2

18.3

18.4

ENGINE BRAKE SYSTEMS ..............................................................................................

OVERVIEW .....................................................................................................................

CONSTANT-THROTTLE VALVES ...................................................................................

EXHAUST BRAKE ..........................................................................................................

COMBINING CONSTANT-THROTTLE VALVE AND EXHAUST BRAKE ........................

18-1

18-2

18-2

18-3

18-3

15.1

15.2

15.3

15.4

18

APPENDIX A:

ABBREVIATIONS / ACRONYMS .........................................................................

A-1

GLOSSARY .....................................................................................................................................

G-1

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

ix

TABLE OF CONTENTS

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

LIST OF FIGURES

Figure 3-1

Figure 3-2

Figure 3-3

Figure 3-4

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-8

Figure 3-9

Figure 3-10

Figure 3-11

Figure 3-12

Figure 3-13

Figure 3-14

Figure 3-15

Figure 4-1

Figure 4-2

Figure 4-3

Figure 4-4

Figure 4-5

Figure 4-6

Figure 4-7

Figure 4-8

Figure 4-9

Figure 4-10

Figure 4-11

Figure 4-12

Figure 4-13

Figure 4-14

Figure 4-15

Figure 4-16

Figure 4-17

Figure 5-1

Figure 5-2

Figure 5-3

Figure 5-4

Figure 6-1

Figure 6-2

Figure 6-3

Figure 6-4

Figure 7-1

Figure 7-2

Figure 7-3

Typical MBE Six-Cylinder Engine with EGR ......................................................

Typical OM 900 Offhighway Six Cylinder Engine ............................................

Typical OM 900 Offhighway Four Cylinder Engine ..........................................

Right Front View of MBE 900 EGR Engine .......................................................

Right Rear View of the MBE 900 EGR Engine .................................................

Left Rear View of the MBE 900 EGR Engine ....................................................

Front View of a Typical 6Cylinder OM 900 Off-highway Engine ......................

Side View of a Typical 6cylinder OM 900 Off-highway Engine ........................

Front View of 4Cylinder OM 900 Off-highway Engine ....................................

Rear View of Typical 4Cylinder OM 900 Off-highway Engine .........................

Location of Engine Identification .......................................................................

Engine Identification Number Laser Etching .....................................................

Serial Number ...................................................................................................

Emission Label, 6-Cylinder ...............................................................................

Emission Label, 4-Cylinder ...............................................................................

Air Intake System Schematic ............................................................................

Intake Manifold and Related Parts for OM 900 .................................................

Air Inlet Elbow Flange Geometry ......................................................................

Clamp for Air Inlet Elbow ...................................................................................

Medium-duty Air Cleaner ..................................................................................

Heavy-duty Air Cleaner .....................................................................................

Extra Heavy-duty Air Cleaner ............................................................................

Precleaner Centrifugal Action ...........................................................................

Rain Cap and Inlet Hood ...................................................................................

Altitude vs. Inlet Restriction ..............................................................................

Diffuser Configurations ......................................................................................

Air Inlet System Calculation ..............................................................................

Typical Radiator-mounted Charge Air Cooling System .....................................

Static Pressure Tap ...........................................................................................

Piezometer Ring ................................................................................................

Typical Instrumentation Location .......................................................................

Air Inlet Data Sheet for Air-to-Air Charge Cooled Engine .................................

Exhaust System Schematic ..............................................................................

Wastegated Turbocharger Assembly ................................................................

Piezometer Ring ................................................................................................

Static Pressure Tap ...........................................................................................

Airflow Diagram Through Engine With EGR System .......................................

EGR System .....................................................................................................

MBE 900 Six-Cylinder Engine with EGR ...........................................................

Exhaust Inlet with Reed Valves .........................................................................

Thermostats Closed ..........................................................................................

Thermostats Open ............................................................................................

Coolant Expansion ............................................................................................

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

3-3

3-4

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-12

3-13

3-14

3-14

4-4

4-5

4-6

4-6

4-9

4-10

4-11

4-13

4-14

4-16

4-17

4-19

4-20

4-25

4-27

4-28

4-31

5-3

5-4

5-9

5-11

6-3

6-4

6-5

6-6

7-4

7-5

7-6

xi

TABLE OF CONTENTS

Figure 7-4

Figure 7-5

Figure 7-6

Figure 7-7

Figure 7-8

Figure 7-9

Figure 7-10

Figure 7-11

Figure 7-12

Figure 7-13

Figure 7-14

Figure 7-15

Figure 7-16

Figure 7-17

Figure 7-18

Figure 7-19

Figure 7-20

Figure 7-21

Figure 7-22

Figure 7-23

Figure 7-24

Figure 7-25

Figure 8-1

Figure 8-2

Figure 8-3

Figure 9-1

Figure 9-2

Figure 9-3

Figure 9-4

Figure 9-5

Figure 9-6

Figure 10-1

Figure 10-2

Figure 10-3

Figure 10-4

Figure 10-5

Figure 10-6

Figure 11-1

Figure 11-2

Figure 11-3

Figure 11-4

Figure 11-5

Figure 13-1

Figure 13-2

Figure 13-3

Figure 13-4

xii

Thermostat and Related Parts 6-Cylinder OM 900 Engine ............................

Rapid Warm-up Cooling System - Remote Tank, Cross Flow and Down Flow

Radiators ..........................................................................................................

Rapid Warm-up with Integral Top Tank .............................................................

Typical Radiator-mounted Charge Air Cooling System .....................................

Typical Charge Air Cooler .................................................................................

Percent Increases in Volume for Water and Antifreeze Solution .......................

Blower vs. Suction Fans ....................................................................................

Fan Shroud Types .............................................................................................

Down Flow Radiator and Cross Flow Radiator .................................................

Rapid Warm-up Down Flow Radiator Top Tank ................................................

Remote Surge Tank Design for Rapid Warm-up Cooling System .....................

Down Flow Radiator Inlet Tank Deaeration Line Boss Position .........................

Coolant Inlet/Outlet Locations ...........................................................................

Radiator Outlet Contour ....................................................................................

Pressure Control Cap Pressure Valve Open ................................................

Pressure Control Cap Vacuum Valve Open ..................................................

Nominal Settings For Coolant Temperature Control Devices 181 ...............

Cooling System Design (Warm-up -- Closed Thermostat) ................................

Cooling System Design (Stabilized Temperature -- Open Thermostat) ............

Cooling System Design (Cool-down -- Closed Thermostat) .............................

Acceptable Top Tank Design .............................................................................

Unacceptable Top Tank Design .........................................................................

Schematic Diagram of the Fuel System ............................................................

Properly Designed Fuel Tank ............................................................................

Remote Fuel Filter .............................................................................................

Typical MBE 900 Lubrication System Schematic ..............................................

Typical MBE 900 Lubrication System ................................................................

Vertical Oil Filter ................................................................................................

Engine Oil Drain Plug, Oil Pan ..........................................................................

Remote Mount Bypass Filter Options ...............................................................

Oil Sampling Valve Attachment Point ................................................................

Engine Electrical System ..................................................................................

Battery Retainers ..............................................................................................

Typical Cranking Motor Mounting ......................................................................

Typical Cranking Motor Cross-section ...............................................................

Typical Alternator and Related Parts Location ..................................................

Cable Resistance ..............................................................................................

Threepoint Mounting with Rear Bracket .........................................................

Fourpoint Mounting with Front and Rear Bracket Sets ..................................

Transmissibility ..................................................................................................

Distance of Rear Mounts for Zero Bending Moments .......................................

Bending Moment for Fixed Mounting System ...................................................

PLD-MR Control Unit on Engine .......................................................................

The Vehicle Control Unit ...................................................................................

NAFTA Architecture ...........................................................................................

VCU Grid Heater Wiring ....................................................................................

7-7

7-9

7-10

7-11

7-12

7-14

7-28

7-32

7-34

7-36

7-39

7-40

7-41

7-41

7-43

7-43

7-45

7-46

7-47

7-48

7-50

7-50

8-3

8-5

8-7

9-4

9-5

9-6

9-7

9-9

9-10

10-2

10-5

10-7

10-8

10-10

10-14

11-3

11-4

11-8

11-10

11-11

13-3

13-4

13-5

13-6

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

Figure 13-5

Figure 13-6

Figure 13-7

Figure 13-8

Figure 13-9

Figure 13-10

Figure 13-11

Figure 13-12

Figure 16-1

Figure 16-2

Figure 16-3

Figure 16-4

Figure 16-5

Figure 16-6

Figure 16-7

Figure 16-8

Figure 16-9

Figure 16-10

Figure 16-11

Figure 16-12

Figure 16-13

Figure 16-14

Figure 16-15

Figure 16-16

Figure 16-17

Figure 16-18

Figure 16-19

Figure 16-20

Figure 16-21

Figure 16-22

Figure 16-23

Figure 16-24

Figure 16-25

Figure 16-26

Figure 16-27

Figure 16-28

Figure 16-29

Figure 16-30

Figure 16-31

Figure 16-32

Figure 16-33

Figure 16-34

Figure 16-35

Figure 16-36

Figure 16-37

Figure 16-38

Figure 16-39

The ADM2 .........................................................................................................

NAFTA Architecture ..........................................................................................

ADM2 Grid Heater Wiring .................................................................................

Typical MBE 900 On-highway Vehicle Interface Harness .................................

Typical OM 900 Off-highway Vehicle Interface Harness ...................................

A Typical OM 900 6Cylinder Non-EGR Engine Harness .................................

Typical On-highway MBE 900 Six-cylinder Engine Harness EGR Engine ...

Engine Sensor Harness and Sensor Location, MBE 900 .................................

SK11947 Series 900 Air Compressor (1 of 3) .................................................

SK11947 Series 900 Air Compressor (2 of 3) .................................................

SK11947 Series 900 Air Compressor (3 of 3) .................................................

SK-11951 Series 906 Exhaust Brake (1 of 4) ...................................................

SK-11951 Series 906 Exhaust Brake (2 of 4) ...................................................

SK-11951 Series 906 Exhaust Brake (3 of 4) ...................................................

SK-11951 Series 906 Exhaust Brake (4 of 4) ...................................................

SK-11958 Series 900 Flywheel SAE 2 (1 of 3) .................................................

SK-11958 Series 900 Flywheel SAE 2 (2 of 3) .................................................

SK-11958 Series 900 Flywheel SAE 2 (3 of 3) .................................................

SK-11975 Series 900 SAE 2 Flywheel Housing (1 of 4) ...................................

SK-11975 Series 900 SAE 2 Flywheel Housing (2 of 4) ...................................

SK-11975 Series 900 SAE 2 Flywheel Housing (3 of 4) ...................................

SK-11975 Series 900 SAE 2 Flywheel Housing (4 of 4) ...................................

SK-11978 Series 904 Oil Pan, Flat Rear Sump (1 of 3) ....................................

SK-11978 Series 904 Oil Pan, Flat Rear Sump (2 of 3) ....................................

SK-11978 Series 904 Oil Pan, Flat Rear Sump (3 of 3) ....................................

SK-12006 Series 906 Oil Pan, Rear Sump (1 of 3) ...........................................

SK-12006 Series 906 Oil Pan, Rear Sump (2 of 3) ...........................................

SK-12006 Series 906 Oil Pan, Rear Sump (3 of 3) ...........................................

SK-12205 Series 900 SAE 3 Flywheel Housing (1 of 4) ...................................

SK-12205 Series 900 SAE 3 Flywheel Housing (2 of 4) ...................................

SK-12205 Series 900 SAE 3 Flywheel Housing (3 of 4) ...................................

SK-12205 Series 900 SAE 3 Flywheel Housing (4 of 4) ...................................

SK-12206 Series 906 Exhaust Brake (1 of 4) ...................................................

SK-12206 Series 906 Exhaust Brake (2 of 4) ...................................................

SK-12206 Series 906 Exhaust Brake (3 of 4) ...................................................

SK-12206 Series 906 Exhaust Brake (4 of 4) ...................................................

SK-12207 Series 900 Flywheel SAE 2 (1 of 3) .................................................

SK-12207 Series 900 Flywheel SAE 2 (2 of 3) .................................................

SK-12207 Series 900 Flywheel SAE 2 (3 of 3) .................................................

SK-12208 Series 906 Remote Fuel Filter Connections (1 of 3) ........................

SK-12208 Series 906 Remote Fuel Filter Connections (2 of 3) ........................

SK-12208 Series 906 Remote Fuel Filter Connections (3 of 3) ........................

SK-12210 Series 904 Oil Pan, Front Sump (1 of 3) ..........................................

SK-12210 Series 904 Oil Pan, Front Sump (2 of 3) ..........................................

SK-12210 Series 904 Oil Pan, Front Sump (3 of 3) ..........................................

SK-1221 Series 906 Oil Pan, Front Sump (1 of 3) ............................................

SK-1221 Series 906 Oil Pan, Front Sump (2 of 3) ............................................

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

13-7

13-8

13-9

13-10

13-11

13-12

13-13

13-14

16-3

16-4

16-5

16-6

16-7

16-8

16-9

16-10

16-11

16-12

16-13

16-14

16-15

16-16

16-17

16-18

16-19

16-20

16-21

16-22

16-23

16-24

16-25

16-26

16-27

16-28

16-29

16-30

16-31

16-32

16-33

16-34

16-35

16-36

16-37

16-38

16-39

16-40

16-41

xiii

TABLE OF CONTENTS

Figure 16-40

Figure 16-41

Figure 16-42

Figure 16-43

Figure 16-44

Figure 16-45

Figure 16-46

Figure 16-47

Figure 16-48

Figure 16-49

Figure 16-50

Figure 16-51

Figure 16-52

Figure 16-53

Figure 16-54

Figure 16-55

Figure 16-56

Figure 16-57

Figure 16-58

Figure 16-59

Figure 16-60

Figure 17-1

Figure 17-2

Figure 18-1

xiv

SK-1221 Series 906 Oil Pan, Front Sump (3 of 3) ............................................

SK-12212 Series 904 Oil Pan, Front Sump (1 of 4) ..........................................

SK-12212 Series 904 Oil Pan, Front Sump (2 of 4) ..........................................

SK-12212 Series 904 Oil Pan, Front Sump (3 of 4) ..........................................

SK-12212 Series 904 Oil Pan, Front Sump (4 of 4) ..........................................

SK-12213 Series 906 Oil Pan, Front Sump (1 of 4) ..........................................

SK-12213 Series 906 Oil Pan, Front Sump (2 of 4) ..........................................

SK-12213 Series 906 Oil Pan, Front Sump (3 of 4) ..........................................

SK-12213 Series 906 Oil Pan, Front Sump (4 of 4) ..........................................

SK-12214 Series 906 Dipstick (1 of 3) ..............................................................

SK-12214 Series 906 Dipstick (2 of 3) ..............................................................

SK-12214 Series 906 Dipstick (3 of 3) ..............................................................

SK-12215 Series 904 Dipstick (1 of 3) ..............................................................

SK-12215 Series 904 Dipstick (2 of 3) ..............................................................

SK-12215 Series 904 Dipstick (3 of 3) ..............................................................

SK-12226 Series 900 Accessory Mounting Location (1 of 3) ...........................

SK-12226 Series 900 Accessory Mounting Location (2 of 3) ...........................

SK-12226 Series 900 Accessory Mounting Location (3 of 3) ...........................

SK-12227 Series 906 Oil Pan (1 of 3) ...............................................................

SK-12227 Series 906 Oil Pan (2 of 3) ...............................................................

SK-12227 Series 906 Oil Pan (3 of 3) ...............................................................

The Effects of Air Inlet Temperature ..................................................................

The Effects of Exhaust Back Pressure on Engine Power ..................................

Constant Throttle Valve .....................................................................................

16-42

16-43

16-44

16-45

16-46

16-47

16-48

16-49

16-50

16-51

16-52

16-53

16-54

16-55

16-56

16-57

16-58

16-59

16-60

16-61

16-62

17-2

17-3

18-2

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

LIST OF TABLES

Table 2-1

Table 4-1

Table 4-2

Table 4-3

Table 4-4

Table 4-5

Table 4-6

Table 7-1

Table 7-2

Table 7-3

Table 7-4

Table 7-5

Table 7-6

Table 10-1

Table 10-2

The Correct Type of Fire Extinguisher ...............................................................

General Requirements for Air Inlet Connection O-ring ......................................

Air Cleaner Applications ....................................................................................

Air Inlet Restriction ............................................................................................

Hose Specifications for the Inlet Side of the Turbocharger ...............................

Thermocouples .................................................................................................

Pressure Taps ...................................................................................................

Maximum Engine Coolant Out Temperature .....................................................

Heat Exchanger Materials, Construction, and Design Choices ........................

Installed Fan Performance Factors ....................................................................

Top Tank Component Guidelines Standpipe(s), Baffle, Vortex Baffle, Fill

Line and Connections, Vent Line, and Radiator Inlet .......................................

Top Tank Component Guidelines- Fill Neck, Fill Neck Vent Hole, and Coolant

Level Sensor ....................................................................................................

Component Design and Location Guidelines for the Remote Top Tank ............

Minimum Battery Capacity for Acceptable Engine Cranking .............................

Maximum Circuit Resistance .............................................................................

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

2-6

4-7

4-8

4-15

4-18

4-29

4-30

7-13

7-26

7-29

7-37

7-38

7-40

10-4

10-15

xv

TABLE OF CONTENTS

xvi

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

INTRODUCTION

MBE/OM 900 engines are water-cooled, four-stroke, direct-injection diesel engines. The

cylinders are arranged inline on both the 6-cylinder and 4-cylinder models. Each has a separate

fuel injection pump (unit pump) with a short injection line to the injection nozzle, which is located

in the center of the combustion chamber. The unit pumps are attached to the crankcase and are

driven from the camshaft. Each cylinder has two intake valves and one exhaust valve.

Charge-air cooling and an exhaust gas turbocharger are standard equipment on all MBE 900

engines.

The engine has a fully electronic control system, which regulates the fuel injection quantity and

timing using solenoid valves, allowing extremely low-emission operation.

Engine braking is controlled by either a pneumatically-operated (4cylinder engine) or

hydraulically-operated constant-throttle (optional) system (6-cylinder engine) and by an exhaust

brake on the turbocharger (optional).

The cylinder block has integrated oil and water channels. The upper section of the cylinder bore

is induction-hardened. The single-piece cylinder head is made of cast iron. The cylinder head

gasket is a three-layer, adjustment-free seal with Viton sealing elements.

The pistons are made of aluminum alloy with a shallow combustion chamber recess. The pistons

are cooled by oil spray nozzles.

The crankshaft is precision-forged with seven main bearings (five on the 4-cylinder engine), six

of which have custom-forged counterweights (four on the 4-cylinder engine), and a vibration

damper at the front end.

The camshaft is made of induction-hardened steel and has seven main bearings (five on the

4-cylinder engine). Each cylinder has cams for intake and exhaust valves and a unit pump.

The valves are controlled by mushroom tappets, pushrods, and rocker arms. The intake valves are

opened and closed by a valve-guided bridge.

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

1-1

INTRODUCTION

THIS PAGE INTENTIONALLY LEFT BLANK

1-2

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

SAFETY PRECAUTIONS

The following safety measures are essential when installing the MBE/OM 900 engine.

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

Always start and operate an engine in a well ventilated

area.

If operating an engine in an enclosed area, vent the

exhaust to the outside.

Do not modify or tamper with the exhaust system or

emission control system.

2.1

STANDS

Use safety stands in conjunction with hydraulic jacks or hoists. Do not rely on either the jack or

the hoist to carry the load.

2.2

GLASSES

Select appropriate safety glasses for the job. Safety glasses must be worn when using tools

such as hammers, chisels, pullers and punches.

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

2-1

SAFETY PRECAUTIONS

2.3

WELDING

Use caution when welding.

To avoid injury from arc welding, gas welding, or cutting, wear

required safety equipment such as an arc welders face plate

or gas welders goggles, welding gloves, protective apron,

long sleeve shirt, head protection, and safety shoes. Always

perform welding or cutting operations in a well-ventilated

area. The gas in oxygen/acetylene cylinders used in gas

welding and cutting is under high pressure. If a cylinder

should fall due to careless handling, the gage end could

strike an obstruction and fracture, resulting in a gas leak

leading to fire or an explosion. If a cylinder should fall

resulting in the gage end breaking off, the sudden release

of cylinder pressure will turn the cylinder into a dangerous

projectile.Observe the following precautions when using

oxygen/acetylene gas cylinders:

Always wear required safety shoes.

Do not handle tanks in a careless manner or with greasy

gloves or slippery hands.

Use a chain, bracket, or other restraining device at all

times to prevent gas cylinders from falling.

Do not place gas cylinders on their sides, but stand

them upright when in use.

Do not drop, drag, roll, or strike a cylinder forcefully.

Always close valves completely when finished welding

or cutting.

2-2

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

NOTICE:

When welding, the following must be done to avoid damage to the

electronic controls or the engine:

Both the positive (+) and negative (-) battery leads must be

disconnected before welding.

Ground cable must be in close proximity to welding location

- engine must never be used as a grounding point.

Welding on the engine or engine mounted components is

NEVER recommended.

To avoid injury from fire, check for fuel or oil leaks before

welding or carrying an open flame near the engine.

2.4

WORK PLACE

Organize your work area and keep it clean.

To avoid injury from slipping and falling, immediately clean

up any spilled liquids.

Eliminate the possibility of a fall by:

Wiping up oil spills

Keeping tools and parts off the floor

A fall could result in a serious injury.

After installation of the engine is complete:

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

2-3

SAFETY PRECAUTIONS

To avoid injury from rotating belts and fans, do not remove

and discard safety guards.

Reinstall all safety devices, guards or shields

Check to be sure that all tools and equipment used to install the engine are removed

from the engine

2.5

CLOTHING

Wear work clothing that fits and is in good repair. Work shoes must be sturdy and rough-soled.

Bare feet, sandals or sneakers are not acceptable foot wear when installing an engine.

To avoid injury when working near or on an operating engine,

remove loose items of clothing, jewelry, tie back or contain

long hair that could be caught in any moving part causing

injury.

2.6

ELECTRIC TOOLS

Improper use of electrical equipment can cause severe injury.

To avoid injury from electrical shock, follow OEM furnished

operating instructions prior to usage.

2-4

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

2.7

AIR

Use proper shielding to protect everyone in the work area.

To avoid injury from flying debris when using compressed air,

wear adequate eye protection (face shield or safety goggles)

and do not exceed 40 psi (276 kPa) air pressure.

2.8

FLUIDS AND PRESSURE

Be extremely careful when dealing with fluids under pressure.

To avoid injury from the expulsion of hot coolant, never

remove the cooling system pressure cap while the engine is

at operating temperature. Remove the cap slowly to relieve

pressure. Wear adequate protective clothing (face shield or

safety goggles, rubber gloves, apron, and boots).

Fluids under pressure can have enough force to penetrate the skin.

To avoid injury from penetrating fluids, do not put your hands

in front of fluid under pressure. Fluids under pressure can

penetrate skin and clothing.

These fluids can infect a minor cut or opening in the skin. See a doctor at once, if injured by

escaping fluid. Serious infection or reaction can result without immediate medical treatment.

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

2-5

SAFETY PRECAUTIONS

2.9

BATTERIES

Electrical storage batteries give off highly flammable hydrogen gas when charging and continue

to do so for some time after receiving a steady charge.

To avoid injury from battery explosion or contact with battery

acid, work in a well-ventilated area, wear protective clothing,

and avoid sparks or flames near the battery. Always establish

correct polarity before connecting cables to the battery or

battery circuit. If you come in contact with battery acid:

Flush your skin with water.

Apply baking soda or lime to help neutralize the acid.

Flush your eyes with water.

Get medical attention immediately.

Always disconnect the battery cable before working on the Detroit Diesel Electronic Controls

system.

2.10

FIRE

Keep a charged fire extinguisher within reach. Be sure you have the correct type of extinguisher

for the situation. The correct fire extinguisher types for specific working environments are listed

in Table 2-1.

Fire Extinguisher

Work Environment

Type A

Wood, Paper, Textile and Rubbish

Type B

Flammable Liquids

Type C

Electrical Equipment

Table 2-1

2-6

The Correct Type of Fire Extinguisher

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

2.11

FLUOROELASTOMER

Fluoroelastomer (Viton) parts such as O-rings and seals are perfectly safe to handle under

normal design conditions.

To avoid injury from chemical burns, wear a face shield and

neoprene or PVC gloves when handling fluoroelastomer

O-rings or seals that have been degraded by excessive heat.

Discard gloves after handling degraded fluoroelastomer

parts.

A potential hazard may occur if these components are raised to a temperature above 600 F (316 C)

(in a fire for example). Fluoroelastomer will decompose (indicated by charring or the appearance

of a black, sticky mass) and produce hydrofluoric acid. This acid is extremely corrosive and, if

touched by bare skin, may cause severe burns (the symptoms could be delayed for several hours).

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

2-7

SAFETY PRECAUTIONS

THIS PAGE INTENTIONALLY LEFT BLANK

2-8

All information subject to change without notice.

7SA823 0308 Copyright 2003 DETROIT DIESEL CORPORATION

MBE 900 APPLICATION AND INSTALLATION

ENGINE AND ACCESSORY IDENTIFICATION

Section

Page

3.1

ENGINE DESCRIPTION .........................................................................

3.2

MAJOR COMPONENT LOCATIONS FOR MBE 900 EGR ON-HIGHWAY

ENGINES ................................................................................................

3.3

3-3

3-5