Академический Документы

Профессиональный Документы

Культура Документы

What Is BIW - PDF

Загружено:

Avneet Maan0 оценок0% нашли этот документ полезным (0 голосов)

19 просмотров2 страницыОригинальное название

What is BIW _.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

19 просмотров2 страницыWhat Is BIW - PDF

Загружено:

Avneet MaanАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

ana hati BIW ?

What is BIW ?

BIW-Body in White

In the Automotive Industry BIW (Body in White) is the common terminology used to mention the car sheet

metal welded structure (body shell).

In today's situation, automotive BIW is made of steel (various steel grade material -DP, DD, HDP etc) as well

as_made of aluminium alloy (e.g. AUD A8)

‘Sub assemblies like Under body, Body side Left Hand Side/Right Hand Side, Front End, Roof etc. get welded

together by various metal joining process e.g. resistance spot welding, Laser welding, MIG welding to make

welded metal shell (Without Door, Trunk-lid / Tailgate) , Fender, Bonnet Center) called Body in White.

Automotive car shell made before painting is called Body in White.

BIW joinery decides the exterior and interior look of any car.

All the Interior Parts(Commonly used in Automotive) ¢.g Dashboard, Trim (Door Trim, Pillar Trims, Roof liner,

Seats are mounted on the BIW shell with the help of various brackets or nuts mounted on the BIW.

Exterior (Commonly used term in car industry) components e.g. Front Bumper, Rear Bumper, Fender LH/RH,

Side Mirrors are mounted on the BIW shell with the help of various brackets or mounting systems

In car industry outer look defines the style, BIW sheet metal part shell defines overall car style,

In automotive industry Do you know who is linked with BIW?

Following professionals are linked

1) Product Designer! Styling Engineer-

Who designs car profiles via sketch, prepares clay mode.

Who makes concept vehicles for auto show display.

Who makes concepts and present to Top Executives who design product strategy.

2) BIW product designer- R&D Engineers

+ Who design the sheet metal individual components as per the styling data,

+ Who brings the styling to realty via designing individual components in details,

+ Who decide the product specification

+ Who decides no of spots as per the geometry and strength requirement

3) BIW process engineer-

+ Who plans the BIW weld shop layout

+ Who decide the assembly sequence of sheet metal in discussion with die designer

+ Who decides no of stations required to join BIW panel /sub assemblies.

+ Who decides no of equipment as per the JPH (jobs per hour) requirement

4) Die Designer! Too! designer-

+ Who decides the no of tools and process to make the sheet metal.

+ Who design the die for sheet metal component

5) BIW Fixture designer Engineer

+ Who works with product designer, process planner and die designer

+ Who decides or help product designer to decide the PLP.

+ Who designs spot welding fixture,

+ Who works with process planner to finalize the cycle time.

epsitiwwelcingstareblogspotin'2011/0 hwhatis-biv.himl 1

ana hati BIW ?

6) Body Shop Engineer

+ Who weld the panels/sub assembles to form sub assemblies/assemblies

7) Paint shop Engineer

+ Who is responsible to get the BIW painted as per the requirement

8) TCF Engineer

+ Who is responsible for assembly of other aggregates on BIW in TCF lines.

which are these aggregates -Seat, Interior trim, Engine, Exhaust System, Axle, Fender, Head lamp, tail lap

and all wiring harness.

eputtiwelaingxture Blogspotin’20110thwhatis-biv hem

Вам также может понравиться

- Properties of Material1Документ1 страницаProperties of Material1Avneet MaanОценок пока нет

- Dimensional Engineering Part1Документ10 страницDimensional Engineering Part1Avneet MaanОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Properties of Material3Документ1 страницаProperties of Material3Avneet MaanОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Properties of Material2Документ1 страницаProperties of Material2Avneet MaanОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- MTechDesignEngineering Jan2017Документ2 страницыMTechDesignEngineering Jan2017Avneet MaanОценок пока нет

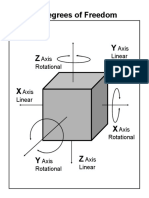

- Six Degree of FreedomДокумент1 страницаSix Degree of FreedomAvneet MaanОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- BДокумент1 страницаBAvneet MaanОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- MPДокумент1 страницаMPAvneet MaanОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Manuf ProcДокумент1 страницаManuf ProcAvneet MaanОценок пока нет

- Definition FSCДокумент1 страницаDefinition FSCAvneet MaanОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

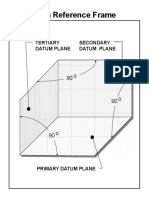

- Datum FsДокумент1 страницаDatum FsAvneet MaanОценок пока нет

- MTechDesignEngineering Jan2017Документ2 страницыMTechDesignEngineering Jan2017Avneet MaanОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Datum QuizДокумент1 страницаDatum QuizAvneet MaanОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Datum Reference Frame: Tertiary Datum Plane Secondary Datum PlaneДокумент1 страницаDatum Reference Frame: Tertiary Datum Plane Secondary Datum PlaneAvneet MaanОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Dimensional Engineering Part3Документ10 страницDimensional Engineering Part3Avneet MaanОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Dimensional Engineering Part2Документ10 страницDimensional Engineering Part2Avneet MaanОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- DN101.6 Inspection Port Installation DrawingДокумент1 страницаDN101.6 Inspection Port Installation DrawingAvneet MaanОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- Pitch and angle measurement documentДокумент1 страницаPitch and angle measurement documentAvneet MaanОценок пока нет

- D W G 1Документ1 страницаD W G 1Avneet MaanОценок пока нет

- A AaaaaaaaaaaaaaaaaaaaaaaaДокумент1 страницаA AaaaaaaaaaaaaaaaaaaaaaaaAvneet MaanОценок пока нет

- Dimensional Engineering PDFДокумент71 страницаDimensional Engineering PDFAvneet MaanОценок пока нет

- CBD 2516Документ1 страницаCBD 2516Avneet MaanОценок пока нет

- Good Knowledge of Powertrain Development Process and SystemsДокумент1 страницаGood Knowledge of Powertrain Development Process and SystemsAvneet MaanОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Mahindra Truxo 25Документ1 страницаMahindra Truxo 25Avneet MaanОценок пока нет

- A0Y2U4 - Attachment 99999Документ1 страницаA0Y2U4 - Attachment 99999Avneet MaanОценок пока нет

- A0Y2U4 - Attachment 99999999999999Документ1 страницаA0Y2U4 - Attachment 99999999999999Avneet MaanОценок пока нет

- What Is BIW - 11111111111111Документ1 страницаWhat Is BIW - 11111111111111Avneet MaanОценок пока нет

- A0Y2U4 - Attachment 99Документ1 страницаA0Y2U4 - Attachment 99Avneet MaanОценок пока нет

- What Is BIW - PDFДокумент2 страницыWhat Is BIW - PDFAvneet MaanОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)