Академический Документы

Профессиональный Документы

Культура Документы

Screw RoHS PDF

Загружено:

Anonymous PYEzEEVzОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Screw RoHS PDF

Загружено:

Anonymous PYEzEEVzАвторское право:

Доступные форматы

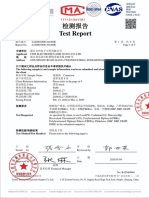

Test Report.

No. SHAEC1510636101

Date: 06 Jun 2015 .

Page 1 of 4.

WENZHOU SHI LONGWAN JINGZHI BIAOZHUNJIAN CHANG .

NO.212 LUSHAN RD.WENZHOU INDUSTRY PARK ZHEJIANG

.

.

The following sample(s) was/were submitted and identified on behalf of the clients as : SCREW .

SGS Job No. :

SP15-018237 - SH .

Date of Sample Received : .

04 Jun 2015.

Testing Period : .

04 Jun 2015 - 06 Jun 2015 .

Test Requested : .

Selected test(s) as requested by client. .

Test Method : .

Please refer to next page(s). .

Test Results :.

Please refer to next page(s). .

Conclusion :.

Based on the performed tests on submitted sample(s), the results of Lead,

Mercury, Cadmium, Hexavalent chromium comply with the limits as set by RoHS

Directive 2011/65/EU Annex II; recasting 2002/95/EC. .

Signed for and on behalf of

SGS-CSTC Standards Technical Services (Shanghai) Co., Ltd..

Marry Ma.

Approved Signatory .

Test Report.

No. SHAEC1510636101

Date: 06 Jun 2015 .

Page 2 of 4.

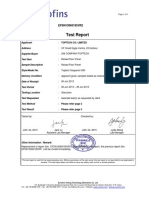

Test Results :.

Test Part Description : .

Specimen No..

SN1.

SGS Sample ID.

SHA15-106361.001

Description.

Silver-blue metal screw .

Remarks :.

(1) 1 mg/kg = 1 ppm = 0.0001% .

(2) MDL = Method Detection Limit .

(3) ND = Not Detected ( < MDL ) .

(4) "-" = Not Regulated .

RoHS Directive 2011/65/EU.

Test Method : . (1) With reference to IEC 62321-5:2013, determination of Cadmium by ICP-OES.

(2) With reference to IEC 62321-5:2013, determination of Lead by AAS.

(3) With reference to IEC 62321-4:2013, determination of Mercury by ICP-OES.

(4) With reference to IEC 62321:2008, determination of Hexavalent Chromium by spot test /

Colorimetric Method using UV-Vis. .

Test Item(s).

Limit.

Unit.

MDL.

001.

Cadmium (Cd) .

100

mg/kg.

ND

Lead (Pb).

1000

mg/kg.

ND

Mercury (Hg).

1000

mg/kg.

ND

Negative

Hexavalent Chromium (Cr(VI)) .

Notes :.

(1) The maximum permissible limit is quoted from directive 2011/65/EU, Annex II

(2) Spot-test:

Negative = Absence of Cr(VI) coating, Positive = Presence of Cr(VI) coating;

(The tested sample should be further verified by boiling-water-extraction method if the spot test result

is Negative or cannot be confirmed.)

Boiling-water-extraction:

Negative = Absence of Cr(VI) coating

Positive = Presence of Cr(VI) coating; the detected concentration in boiling-water-extraction solution is

equal or greater than 0.02 mg/kg with 50 cm sample surface area.

Information on storage conditions and production date of the tested sample is unavailable and thus

Cr(VI) results represent status of the sample at the time of testing. .

Test Report.

No. SHAEC1510636101

Date: 06 Jun 2015 .

Page 3 of 4.

ATTACHMENTS

RoHS Testing Flow Chart

1) Name of the person who made testing: Bob Zhang / Sunny Qin/Zengzhen Zhu

2) Name of the person in charge of testing: Summer Jin/Jan Shi/Stone Chen

3) These samples were dissolved totally by pre-conditioning method according to below flow chart.

6+

(Cr test method excluded)

Sample Preparation

Sample Measurement

Cr6

Pb/Cd/Hg

Acid digestion with

microwave/ hotplate

Nonmetallic

material

Filtration

Positive

Adding digestion

reagent

Solution

Metallic

material

Spot test

Residue

1) Alkali Fusion /

Dry Ashing

2) Acid to dissolve

ICP-OES/AAS

DATA

Negative

Heating to 90~95

for extraction

Filtration and pH

adjustment

Adding 1,5diphenylcarbazide

for color

development

UV-Vis

Boiling water

extraction

Adding 1,5diphenylcarbazide for

color development

A red color indicates

6+

the presence of Cr .

If necessary, confirm

with UV-Vis.

DATA

DATA

Test Report.

No. SHAEC1510636101

Date: 06 Jun 2015 .

Sample photo: .

SHAEC1510636101

SHA15-106361.001 .

SGS authenticate the photo on original report only .

*** End of Report *** .

Page 4 of 4.

Вам также может понравиться

- Worksheet #1 Balancing Chemical EquationsДокумент4 страницыWorksheet #1 Balancing Chemical EquationsMazanda YalinduaОценок пока нет

- TRL176Документ42 страницыTRL176Munir Olguín Majluf100% (1)

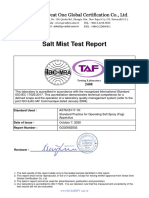

- Salt Spray Test Report - SampleДокумент8 страницSalt Spray Test Report - SamplearvindОценок пока нет

- Luna FixaДокумент6 страницLuna Fixatravellerfellow100% (3)

- RUSAL Encyclopedia Full Engl FINALДокумент117 страницRUSAL Encyclopedia Full Engl FINALSeffds LmlmqsdmlОценок пока нет

- Elements, CMPDS, Mix Ws PDFДокумент4 страницыElements, CMPDS, Mix Ws PDFDean JezerОценок пока нет

- Boric Acid Flotation PDFДокумент25 страницBoric Acid Flotation PDFLevent ErgunОценок пока нет

- (B0638) Zhuyao Zhang, R. A. Farrar-Atlas of Continuous Cooling Transformation (CCT) Diagrams Applicable To Low Carbon Low Alloy Weld Metals (Matsci-Maney Materials Science (1995)Документ101 страница(B0638) Zhuyao Zhang, R. A. Farrar-Atlas of Continuous Cooling Transformation (CCT) Diagrams Applicable To Low Carbon Low Alloy Weld Metals (Matsci-Maney Materials Science (1995)Jayanta MondalОценок пока нет

- Test ReportДокумент15 страницTest Reportthien dinh ba0% (1)

- Alternate RF Planning For Coverage DeficiancyДокумент11 страницAlternate RF Planning For Coverage DeficiancyAdnan HaiderОценок пока нет

- CE Test ReportДокумент14 страницCE Test ReportCamilo WispОценок пока нет

- Guideline for selecting accelerated corrosion testsДокумент37 страницGuideline for selecting accelerated corrosion testswarit01100% (1)

- Failure Analysis ReportДокумент14 страницFailure Analysis ReportpramodkumarОценок пока нет

- Copper Block ROHS PDFДокумент4 страницыCopper Block ROHS PDFAnonymous PYEzEEVzОценок пока нет

- Test Report: 7/F., Shekoutechnology Main Building, Industrial 7Th Road, Shekou, Shenzhen, ChinaДокумент5 страницTest Report: 7/F., Shekoutechnology Main Building, Industrial 7Th Road, Shekou, Shenzhen, ChinaGianluca TedescoОценок пока нет

- Certificate of Absorbent RoHSДокумент2 страницыCertificate of Absorbent RoHSprismatama.kreasindoОценок пока нет

- Certificación FDA "Aneer Copitas Menstruales"Документ2 страницыCertificación FDA "Aneer Copitas Menstruales"Francisco Aguilera RodríguezОценок пока нет

- 692489003 电镀RoHS报告 20220818Документ4 страницы692489003 电镀RoHS报告 20220818Toan Cao0% (1)

- Ingress Protection-IP66-IEC60529Документ12 страницIngress Protection-IP66-IEC60529tushar2.khandelwalОценок пока нет

- Test Report: Applicant AddressДокумент7 страницTest Report: Applicant AddressEnzo AscañoОценок пока нет

- Bai Yun-2Документ8 страницBai Yun-2Hamada Shoukry MohammedОценок пока нет

- Test Report: Applicant AddressДокумент9 страницTest Report: Applicant AddressEnzo AscañoОценок пока нет

- Test Report: July 12, 2022Документ8 страницTest Report: July 12, 2022sudipОценок пока нет

- Toptech GWI LEED IEQ CR 4.3 EurofinsДокумент5 страницToptech GWI LEED IEQ CR 4.3 EurofinsSuki LiuОценок пока нет

- 蓝色PVC手套EU食品检测EN1186Документ5 страниц蓝色PVC手套EU食品检测EN1186GIANNIОценок пока нет

- 692489003 材料RoHS报告 20221118Документ4 страницы692489003 材料RoHS报告 20221118Toan CaoОценок пока нет

- RoHS Compliant Test ReportДокумент3 страницыRoHS Compliant Test Reportanon_413476106Оценок пока нет

- HYP Corner Bead - SIRIMДокумент5 страницHYP Corner Bead - SIRIMSusana KhoОценок пока нет

- Guidelines For Testing Fresh Self-Compacting Concrete: Principal Author: G. DE SCHUTTERДокумент24 страницыGuidelines For Testing Fresh Self-Compacting Concrete: Principal Author: G. DE SCHUTTERGeorge CarmelОценок пока нет

- Test Report: 6/F East, Heping Building, Heping Road, Luohu, Shenzhen, ChinaДокумент17 страницTest Report: 6/F East, Heping Building, Heping Road, Luohu, Shenzhen, ChinaJosé FerreiraОценок пока нет

- Epdm Rosh報告Документ8 страницEpdm Rosh報告Cary LuОценок пока нет

- REACHДокумент16 страницREACHTranVinhОценок пока нет

- 14 00247 (En)Документ6 страниц14 00247 (En)cccc80cccccОценок пока нет

- UntitledДокумент21 страницаUntitledአንዋርጀማልОценок пока нет

- Nexxt Solutions LSZH Rohs CertificateДокумент8 страницNexxt Solutions LSZH Rohs CertificatenormОценок пока нет

- Casestry Lab Report 2022Документ19 страницCasestry Lab Report 2022Team QuestInОценок пока нет

- M 12-D I L E F S S: 1.0 Scope and ApplicationДокумент14 страницM 12-D I L E F S S: 1.0 Scope and ApplicationLili YiyoОценок пока нет

- Specific Compounds Test Report - Asbestos - PSBДокумент3 страницыSpecific Compounds Test Report - Asbestos - PSBbuzzpavanОценок пока нет

- Spout-PE europeДокумент7 страницSpout-PE europealejo781Оценок пока нет

- XNB-58 Protec-195 TC 20RSx20RS-195gsm Dark RedДокумент5 страницXNB-58 Protec-195 TC 20RSx20RS-195gsm Dark RedashrafbookОценок пока нет

- RoHS Compliant Polyethylene FoamДокумент6 страницRoHS Compliant Polyethylene FoamkingsleyОценок пока нет

- SGS REACH 219項測試報告 - unlockedДокумент17 страницSGS REACH 219項測試報告 - unlockedCary LuОценок пока нет

- Articol Stancu Vijan 2022Документ7 страницArticol Stancu Vijan 2022Cristina StancuОценок пока нет

- My Home RichДокумент3 страницыMy Home Richj.saiyathОценок пока нет

- Comba ReportДокумент51 страницаComba Reportculeros1Оценок пока нет

- Test Report: 收件日期 (Sample Receiving Date)Документ4 страницыTest Report: 收件日期 (Sample Receiving Date)Htun SoeОценок пока нет

- ARMSTRONG - VEYTAUX-SPC Tile EN14372 DOTPДокумент5 страницARMSTRONG - VEYTAUX-SPC Tile EN14372 DOTPngnnduc.hauОценок пока нет

- Test Report Summary for Toy Safety StandardsДокумент11 страницTest Report Summary for Toy Safety StandardsAshir ShahbazОценок пока нет

- Water-Extractable Chloride in Aggregate (Soxhlet Method) : Provisional Standard Test Method ForДокумент3 страницыWater-Extractable Chloride in Aggregate (Soxhlet Method) : Provisional Standard Test Method ForOscar Gutiérrez-JuncoОценок пока нет

- MARISEAL 300 Potable Water Certification From SingaporeДокумент6 страницMARISEAL 300 Potable Water Certification From SingaporeVirender KumarОценок пока нет

- EN Square Skin Sensitization Test LIM 3946 & LIM 2012 SeriesДокумент14 страницEN Square Skin Sensitization Test LIM 3946 & LIM 2012 SeriessilvanaОценок пока нет

- US Environmental Protection Agency Office of Pesticide ProgramsДокумент20 страницUS Environmental Protection Agency Office of Pesticide Programsanandhra2010Оценок пока нет

- Test Report No. 54S071437/4/LGJ: Dated 26 Mar 2007Документ3 страницыTest Report No. 54S071437/4/LGJ: Dated 26 Mar 2007mayurghule19Оценок пока нет

- Test Report: Client InformationДокумент19 страницTest Report: Client Informationho muzОценок пока нет

- Test Report: Client InformationДокумент19 страницTest Report: Client Informationho muz0% (1)

- Luxury Vinyl Tile antimicrobial test reportДокумент3 страницыLuxury Vinyl Tile antimicrobial test reportIvonne Elisa Reyes LopezОценок пока нет

- Leak Test Report for Tank 25Документ7 страницLeak Test Report for Tank 25Sibgathullah MohammedОценок пока нет

- TLDD 2007 1AAG Q02 2001 A1 Non Destructive Examination Procedures (NDE) PTДокумент12 страницTLDD 2007 1AAG Q02 2001 A1 Non Destructive Examination Procedures (NDE) PTThân KhaОценок пока нет

- SVHC Test Report for Fiberglass Sample Analyzes 138 SubstancesДокумент25 страницSVHC Test Report for Fiberglass Sample Analyzes 138 Substancesbdy3372Оценок пока нет

- Approval of LPT ProcedureДокумент14 страницApproval of LPT ProcedureimranОценок пока нет

- Water-Extractable Chloride in Aggregate (Soxhlet Method) : Standard Test Method ForДокумент5 страницWater-Extractable Chloride in Aggregate (Soxhlet Method) : Standard Test Method Foryohanna riveraОценок пока нет

- SIRIM Eco Label (Dri-Floor EP1550)Документ3 страницыSIRIM Eco Label (Dri-Floor EP1550)胡大威Оценок пока нет

- Hilti CFS SP Smoke TestДокумент11 страницHilti CFS SP Smoke Testnasbardi2Оценок пока нет

- 油性上光涂料 CC 25062019 PDFДокумент17 страниц油性上光涂料 CC 25062019 PDFNguyễn Tiến DũngОценок пока нет

- B05 e PDFДокумент6 страницB05 e PDFAnonymous PYEzEEVzОценок пока нет

- Conduits PDFДокумент12 страницConduits PDFAnonymous PYEzEEVzОценок пока нет

- SpecДокумент1 страницаSpecAnonymous PYEzEEVzОценок пока нет

- SpecДокумент1 страницаSpecAnonymous PYEzEEVzОценок пока нет

- Gi PVC Conduit PDFДокумент1 страницаGi PVC Conduit PDFAnonymous PYEzEEVzОценок пока нет

- Optical Fiber LimitsДокумент7 страницOptical Fiber LimitsAnonymous PYEzEEVzОценок пока нет

- Re PeterДокумент12 страницRe PetersandeepОценок пока нет

- Horn Antennas Frequency Ranges and SpecificationsДокумент1 страницаHorn Antennas Frequency Ranges and SpecificationsAnonymous PYEzEEVzОценок пока нет

- Other Bulk Chemicals ProductionДокумент54 страницыOther Bulk Chemicals Productionmuhammad izzulОценок пока нет

- Oxidation-Reduction Worksheet AnswersДокумент2 страницыOxidation-Reduction Worksheet AnswersMary Ann DimacaliОценок пока нет

- Inorganic Chemistry 2nd Edition (Housecroft) - Copy - 1Документ169 страницInorganic Chemistry 2nd Edition (Housecroft) - Copy - 1firda noer ainiОценок пока нет

- Calorific values of fuelsДокумент2 страницыCalorific values of fuelsanon_181713663Оценок пока нет

- Carbide End Mill Feeds and Speeds TuffCut XR 177 MetricДокумент1 страницаCarbide End Mill Feeds and Speeds TuffCut XR 177 MetricIlham FadillahОценок пока нет

- Chemical Degradation of Trimethyl Phosphate As Surrogate For OrganophosporusДокумент11 страницChemical Degradation of Trimethyl Phosphate As Surrogate For OrganophosporusNura LailatussoimahОценок пока нет

- Cyanidation of GoldДокумент11 страницCyanidation of GoldBea Christine LedesmaОценок пока нет

- HSEB Chemistry SyllabusДокумент3 страницыHSEB Chemistry SyllabusprabeshjhaОценок пока нет

- Intermediate Chemistry Model PaperДокумент1 страницаIntermediate Chemistry Model PaperRK YeleswarapuОценок пока нет

- Carbonate Minerolgy PDFДокумент5 страницCarbonate Minerolgy PDFNadeesha MadugallaОценок пока нет

- Material Lab 2 Edit 2014Документ22 страницыMaterial Lab 2 Edit 2014Muhamad HafizОценок пока нет

- F 32 Alkr KG 4 PM0 Yfk Zta VДокумент70 страницF 32 Alkr KG 4 PM0 Yfk Zta VVaishnavi SahuОценок пока нет

- 1 Grade 11 Review AnswersДокумент9 страниц1 Grade 11 Review Answersapi-363234558Оценок пока нет

- Colorimetric Determination of Microgram Amounts of ThiolsДокумент3 страницыColorimetric Determination of Microgram Amounts of ThiolsAlexandru SavaОценок пока нет

- AS and A Level Chemistry: Transition GuideДокумент80 страницAS and A Level Chemistry: Transition GuideTedОценок пока нет

- Estimating Water HardnessДокумент4 страницыEstimating Water HardnessFarhan TaseenОценок пока нет

- Iso 12473 2017Документ13 страницIso 12473 2017testing castcoОценок пока нет

- Maintain inventory of chemicals and suppliesДокумент1 страницаMaintain inventory of chemicals and suppliesJuan Gilberto Terreros JimenezОценок пока нет

- Preparation of Double and Complex SaltsДокумент10 страницPreparation of Double and Complex SaltsSyamsul Maarif60% (5)

- Acids, Bases & Salts 4 QPДокумент8 страницAcids, Bases & Salts 4 QPkhalil rehmanОценок пока нет

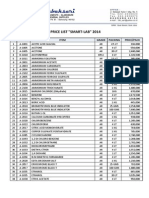

- Smart LabДокумент4 страницыSmart LabMuhamad AfidinОценок пока нет

- Aluminium AssignmentДокумент4 страницыAluminium AssignmentangellaОценок пока нет

- 10 Science Notes 03 Metals and Non Metals 1Документ9 страниц10 Science Notes 03 Metals and Non Metals 1varunОценок пока нет