Академический Документы

Профессиональный Документы

Культура Документы

Space4000 PDF

Загружено:

Krum KashavarovОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Space4000 PDF

Загружено:

Krum KashavarovАвторское право:

Доступные форматы

ELECTRONIC CONTROL SYSTEMS

AN INTRODUCTION TO

THE NEW SPACE 4000

CONTROL SYSTEM

Issue 1.1

SPACE 4000

1:1

ELECTRONIC CONTROL SYSTEMS

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent, or

incorrect operation of the equipment or from misuse of the equipment.

Every effort has been made to ensure the accuracy the contents of this Manual, however the manufactures,

publishers and author accept no liability for any loss, damage or injury caused by any errors in or omissions

from the information contained within this document.

The contents of this Manual are believed to be correct at the time of printing. In the interests of a commitment

to a policy of continuous development and improvement , the manufacturer reserves the right to change the

specification of the products or their performance or the contents of this Manual, without notice.

All rights reserved. No part of this Manual may be stored, reproduced or transmitted in any form or by any

means, electronically or mechanically including photocopying, recording or by any information retrieval

system, without permission in writing from the publisher.

Copyright HIAB AB February 2003

HIAB AB

SE-824 83

Hudiksvall

Sweden

Telephone +46 (0) 650 91000

FAX:

+46 (0) 650 12174

Author: CLM

Date of Issue: February 2003

1:2

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

Contents

What is space 4000?. .................................................................... 5

Functions. ................................................................................................... 6

Components................................................................................... 7

User Interface Front. ................................................................................... 7

Buttons and Leds. ....................................................................................... 7

Buttons and Leds (cont.)............................................................................. 9

User Interface Rear........................................................................ 10

Connections. ............................................................................................... 11

4000 Standard Bottom. ................................................................. 12

Connections. ............................................................................................... 12

4000 Radio Receiver...................................................................... 14

Connections. ............................................................................................... 14

4000 Radio Receiver Connections (cont). .................................................. 15

4000 Relay Box. ............................................................................. 16

Connections. ............................................................................................... 16

4000 Relay box Connections (cont)............................................................ 17

4000 Relay box Connections (cont)............................................................ 18

Extended Box. ....................................................................... 19

Connections. ............................................................................................... 19

Extended box connections (cont). .............................................................. 20

Column Box. .................................................................................. 21

Connections . .............................................................................................. 21

Column box connections (cont). ................................................................. 22

Controls....................................................................................................... 23

HiDrive controller. ......................................................................... 23

Controls....................................................................................................... 23

Connection drawing. ..................................................................... 25

Maintenance and adjustments. .................................................... 26

Terminal programs...................................................................................... 26

Using the new program............................................................................... 26

Changing system type. ............................................................................... 29

Crane Config File. ....................................................................................... 30

Parameters and Variables............................................................. 31

Understanding Parameters. ........................................................................ 31

Channels. ....................................................................................... 32

Understanding Channels. ........................................................................... 32

Channels list. .............................................................................................. 32

Channels list (cont). .................................................................................... 33

Issue 1.1

SPACE 4000

1:3

ELECTRONIC CONTROL SYSTEMS

Contents

Parameters list .............................................................................. 34

1. OLP function. .......................................................................................... 34

2. MSC-function. ......................................................................................... 35

3. Analog inputs. ......................................................................................... 36

4. Remote control. ...................................................................................... 37

5. Lever position sensors. ........................................................................... 38

6. Pressure sensors. ................................................................................... 39

7. Digital inputs. .......................................................................................... 40

8. Stability. .................................................................................................. 41

9. Digital outputs. ........................................................................................ 42

10. Service. ................................................................................................. 42

11. PLC. ...................................................................................................... 43

12. Various.................................................................................................. 44

13. Counters and Timers. ........................................................................... 46

14. Errors. ................................................................................................... 48

Variables......................................................................................... 55

1. OLP function. .......................................................................................... 55

2. MSC-function. ......................................................................................... 56

3. Analog inputs. ......................................................................................... 56

4. Remote control. ...................................................................................... 57

5. Lever position sensors. ........................................................................... 58

6. Pressure sensors. ................................................................................... 59

7. Digital inputs. .......................................................................................... 59

8. Stability. .................................................................................................. 61

9. Digital outputs ......................................................................................... 61

11. PLC ....................................................................................................... 61

10. Service. ................................................................................................. 61

12. Various.................................................................................................. 62

Notes. ............................................................................................. 66

Notes. ............................................................................................. 67

1:4

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

What is space 4000?

SPACE 4000 has been developed to work in conjunction with the new HIAB V80R remote control valve

and shares many of the now proven components developed for the SPACE 3000 system. Use of these

components has also allowed the use of CAN based communication in SPACE 4000.

Further development of the SPACE 3000 standard box allows this box to be used, for both the 3000 and

4000 systems only the User Interface is different. This means that in the future the 3000 standard box will be

withdrawn and replaced by the 4000 standard box removing the need to hold two different boxes in your spare

parts stock. SPACE 4000 will also share the same column and extended boxes as SPACE 3000.

New for the 4000 system is the User Interface, Radio Receiver/Output box, a new Relay box and a new hand

controller unit. Although named the 4000 Relay box it will be possible to use this box with any of the current

CAN-based control systems produced by HIAB.

The new hand controller shares the same housing as the RadioDrive unit, it is however completely new inside

and is not interchangable with the RadioDrive hand controller. The controller has 3 operating groups making it

possible to control up to 18 proportional functions. A digital display window giving information about possible

problems has also been added. Additional buttons now allow you to control relay operated functions easily

from the hand controller.

SPACE 4000 is also equipped to run PLC programs to help with some of the more difficult operational

requirements that customers can be faced with.

Issue 1.1

SPACE 4000

1:5

ELECTRONIC CONTROL SYSTEMS

Functions

The following functions are available in SPACE 4000

OLP

Overload protection on inner and other boom with pre-warning

OLP WINCH

Overload protection on winch with pre-warning, if winch with pre-warning

ADC

Automatic Duty Control raises capacity when crane is in hook mode, normal capacity if in tool mode. Sensed

with spool sensor on lever 6 or function winch.

OLP RELEASE

Override of OLP

ADO

Automatic dumping of oil when crane not in use

SLEWING SECTOR

Lowered capacity in sector

CONTROL PLATFORM

Crane movement restricted over platform

MANUAL EXTENSION

Lowered capacity when manual extension is in use

HORN

Sounds when button pressed or when 90% / OLP is detected (pre-warning, time and level settable).

MSC

Manual Speed Control, EXTENDED BOX and MSC valve block must be fitted

ADS

Automatic damping on slewing, EXTENDED BOX, ADS sensors and ADS valve block must be fitted

ASC

Automatic Speed Control, load dependent speed

EXTERNAL DUMP

External dump if EXTENDED BOX fitted.

DIAGNOSTICS

service indicator, errors ..

1:6

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

Components

User Interface Front

Buttons and Leds

1.ON/OFF BUTTON & LED

Button for switching on/off the system. If button pressed and held for more then 2s when system is on the

lamp test is activated, as long as the button is pressed all red leds light, when released all red leds continue to

light for 3 seconds then all green leds light for 3 seconds

LED green

Steady

Blinking

Off

Issue 1.1

= system on

= system on and STOP button pressed in (PSBM oil 1 function)

= system off

SPACE 4000

1:7

ELECTRONIC CONTROL SYSTEMS

Buttons and Leds (cont.)

2.RELEASE BUTTON AND LED

Button for:

1.

switching on OLP release if crane has OLP

2.

switching on Dump valve/valves if not OLP, if dump valve 2 present it is also switched on, connected

to a relay or extended box (switched off after 10 minutes and when a crane function is used dump

valve 2 is always switched off)

Green LED

Steady = Dump valve on (PSBM oil 2 function)

off

= Dump valve off (PSBM oil 2 function)

Red LED

Steady red

= OLP

Blinking red

= Release button pushed and allowed to run crane (OLP case)

Steady green = Dump valve2 on (if dump valve 2 present)

3.HORN BUTTON

Button for switching on the horn if present

4.REMOTE CONTROL BUTTON

Button to activate remote control. Press and release to activate, repeat to de-activate.

Steady Green

= Remote control on

Blinking Green = Stop button pressed in

Blinking Red

= Radio Interference

5.STAB SECTOR LED

LED to show that crane is in a stability sector

LED green

Steady

= Crane is in sector and crane capacity is lowered

Off

= Crane is not in sector

6.SERVICE/ERROR LED

LED to show that system has error or time to service crane

LED green/red

Steady green

= Time to service the crane, x seconds after start-up

Steady red

= System has error/errors

Flashing red

= CAN communication error

1:8

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

Buttons and Leds (cont.)

7.IB/OB_PRESS BAR LEDs

LEDs to show pressure in inner/other boom cylinder in percentage of actual OLP limit

LEDs 90% & 100% red, 50% & 70% red/green

-Sequence

50%

= LED 1 steady green

70%

= LED 1 & 2 steady green

90%

= LED 1-3 blinking red

100%

= LED 1-4 steady red

All flashing red = Flashes for 5 seconds when system is switched off and the inner boom is high

Sweep LEDs

= LEDs sweep when OLP in corresponding cylinder and release

activated and release allowed

Note 1, if no outer boom pressure sensor present, pressure and sweep function on other boom

LEDs are inactivated. (Example some M-link cranes)

8.WINCH LED

LED to show 90% or OLP in winch

LED red

Blinking

= Winch has 90% of nominal load

Steady

= Winch has 100% of nominal load OLP

Flashing

= Flashes for 5 seconds when system switch off and inner boom high

9.ADC LED

LED to show if crane is working with hook or tool capacity, if system type ADC not selected always off

LED green

Steady

= Crane is working with hook(added) capacity

Off

= Crane is working with normal capacity

10.MAN EXT LED

LED to show that crane is working with Manual extension logic (Switch on/off with hand controller)

LED green

Steady

= Manual extension logic on

Off

= Manual extension logic off

11.STOP BUTTON

Total stop button, overrides all other controls. Press in to prohibit all crane functions, turn clockwise to release.

Issue 1.1

SPACE 4000

1:9

ELECTRONIC CONTROL SYSTEMS

User Interface Rear

Visually the back of the SPACE 4000 User Interface is the same as SPACE 3000.

Two x 7 connector plinths for the CAN connection cabling. NOTE: If no connections are made to the CAN out

plinth (P2) a bridge wire must be placed between P2.5 & P2.6. Failure to do this will result in error code E3

being displayed.

One x 5 position jumper field, used to tell the 4000 standard box the number of the interface in the system.

As with SPACE 3000 it is possible to use upto 4 user interfaces in the SPACE 4000 system.

1:10

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

Connections

Plinth

Description

P1.............................. CAN (From/to Standard bottom)

P1.1........................... 0V

P1.2........................... 24V

P1.3........................... CAN H

P1.4........................... CAN L

P1.5........................... Emergency stop out

P1.6........................... Emergency stop in

P1.7........................... on/off of the system

P2.............................. CAN (From/to Cover 2, Extended box)

P2.1........................... 0V

P2.2........................... 24V

P2.3........................... CAN H

P2.4........................... CAN L

P2.5........................... Emergency stop out

P2.6........................... Emergency stop in

P2.7........................... on/off of the system

One x 5 position jumper field, used to tell the 4000 standard box the number of the interface in the

system. As with SPACE 3000 it is possible to use upto 4 user interfaces in the SPACE 4000 system.

Note: Jumper field named nc is not used, strapping has no effect.

Issue 1.1

SPACE 4000

1:11

ELECTRONIC CONTROL SYSTEMS

4000 Standard Bottom

SPACE 4000 ST

Connections

Plinth

Description

P1 ..............................................SPOOL SENSORS 1-4

P1.1 ...........................................0V

P1.2 ...........................................24V

P1.3 ...........................................signal from spool sensor 1 (0-5V)

P1.4 ...........................................signal from spool sensor 2 (0-5V)

P1.5 ...........................................signal from spool sensor 3 (0-5V)

P1.6 ...........................................signal from spool sensor 4 (0-5V)

P2 ..............................................SPOOL SENSORS 5-6

P2.1 ...........................................0V

P2.2 ...........................................24V

P2.3 ...........................................signal from spool sensor 5 (0-5V)

P2.4 ...........................................signal from spool sensor 6 (0-5V)

P3 ..............................................TERMINAL

P3.1 ...........................................0V

P3.2 ...........................................24V

P3.3 ...........................................Data out

P3.4 ...........................................Data in

1:12

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

Plinth

Description

P4 .................................... SWITCH FOR INDICATOR ON PLATFORM

P4.1 ................................. 0V

P4.2 ................................. 24V

P4.3 ................................. Signal 24V from on platform Indicator (0/24V)

P5 .................................... Column box

P5.1 ................................. 0V

P5.2 ................................. 24V

P5.3 ................................. Signal from IB pressure sensor (4-20mA)

P5.4 ................................. Signal from OB pressure sensor (4-20mA)

P5.5 ................................. Signal from OB tilt indicator (4-20mA)

P5.6 ................................. Signal from IB tilt indicator (4-20mA)

P5.7 ................................. Signal from winch indicator (4-20mA)

P5.8 ................................. Signal from second IB tilt indicator (control platform)(0/24V)

P5.9 ................................. Signal from Extension out indicator(0/24V)

P6 .................................... SLEWING SECTOR 1

P6.1 ................................. 0V

P6.2 ................................ 24V

P6.3 ................................. Signal from slew sect_1 Indicator (positive) (0/24V)

P6.4 ................................. Signal from slew sect_1 Indicator (negative) (0/24V)

P6.5 ................................. Signal from slew sect_2 Indicator (positive) (0/24V)

P6.6 ................................. Signal from slew sect_2 Indicator (negative) (0/24V)

P7 .................................... CAN (From/to Cover 1)

P7.1 ................................. 0V

P7.2 ................................. 24V

P7.3 ................................. CAN H

P7.4 ................................. CAN L

P7.5 ................................. Emergency stop out

P7.6 ................................. Emergency stop in

P7.7 ................................. on/off

P8 .................................... HORN

P8.1 ................................. 0V

P8.2 ................................ HORN (24V, 2A)

P9 .................................... DUMP VALVE 1

P9.1 ................................. 0V

P9.2 ................................. To dump valve

P10 .................................. POWER IN

P10.1 ............................... 0V truck

P10.2 ............................... 24V truck (15-35V, 10A)

Note: P10

0V and 24V on this plinth dont have the same potential as the other plinths in the system

because there is a filtering unit between them.

One x 5 position jumper field, used to tell the 4000 standard box the number of the interfaces in the system.

As with SPACE 3000 it is possible to use upto 4 user interfaces in the SPACE 4000 system.

Note: Jumper field named nc is not used, strapping has no effect.

Issue 1.1

SPACE 4000

1:13

ELECTRONIC CONTROL SYSTEMS

4000 Radio Receiver

Connections

Plinth

Description

P1 ...................................CAN in

P1.1 ................................0V

P1.2 ................................24V

P1.3 ................................CAN H

P1.4 ................................CAN L

P1.5 ................................Emergency stop out

P1.6 ................................Emergency stop in

P1.7 ................................On/off

P2 ...................................CAN out

P2.1 ................................0V

P2.2 ................................24V

P2.3 ................................CAN H

P2.4 ................................CAN L

P2.5 ................................Emergency stop out

P2.6 ................................Emergency stop in

P2.7 ................................On/off

1:14

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

4000 Radio Receiver Connections (cont)

Plinth

Description

P3 .................................. Output 1-2

P3.1 ............................... 0V

P3.2 ............................... Output Valve 1-1

P3.3 ............................... Output Valve 2-1

P3.4 ............................... Output Valve 2-2

P3.5 ............................... Output Valve 1-2

P3.6 ............................... 0V

Plinth

Description

P7A............................... Output 9-10

P7A.1............................ 0V

P7A.2............................ Output Valve 9-1

P7A.3............................ Output Valve 10-1

P7B .............................. Output 9-10

P7B.1............................ Output Valve 10-2

P7B.2............................ Output Valve 9-2

P7B.3............................ 0V

P8 ................................. Output 11-12

P8.1 .............................. 0V

P8.2 .............................. Output Valve 11-1

P8.3 .............................. Output Valve 12-1

P8.4 .............................. Output Valve 12-2

P8.5 .............................. Output Valve 11-2

P8.6 .............................. 0V

P4 .................................. Output 3-4

P4.1 ............................... 0V

P4.2 ............................... Output Valve 3-1

P4.3 ............................... Output Valve 4-1

P4.4 ............................... Output Valve 4-2

P4.5 ............................... Output Valve 3-2

P4.6 ............................... 0V

P5 .................................. Output 5-6

P5.1 ............................... 0V

P5.2 ............................... Output Valve 5-1

P5.3 ............................... Output Valve 6-1

P5.4 ............................... Output Valve 6-2

P5.5 ............................... Output Valve 5-2

P5.6 ............................... 0V

P9 ................................. External Antenna

P9.1 .............................. 0V

P9.2 .............................. Antenna signal

P6 .................................. Output 7-8

P6.1 ............................... 0V

P6.2 ............................... Output Valve 7-1

P6.3 ............................... Output Valve 8-1

P6.4 ............................... Output Valve 8-2

P6.5 ............................... Output Valve 7-2

P6.6 ............................... 0V

JUMPER FIELD

LEDS

Issue 1.1

Red

Green

Yellow

Green

b1-b3, is used to set the address in the system.

ext_ant, is used to set internal or external antenna

Error

Data

Squelch

Power

= error, radio signal corrupted

= Radio data is ok

= Carrier detected

= power to the system

SPACE 4000

1:15

ELECTRONIC CONTROL SYSTEMS

4000 Relay Box

1 2

Connections

Plinth

Description

P1 ............................................. CAN in

P1.1 .......................................... 0V

P1.2 .......................................... 24V

P1.3 .......................................... CAN H

P1.4 .......................................... CAN L

P1.5 .......................................... Emergency stop out

P1.6 .......................................... Emergency stop in

P1.7 .......................................... On/off

1:16

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

4000 Relay box Connections (cont)

Plinth

Description

P2 ............................................. CAN out

P-1 ............................................ 0V

P-2 ............................................ 24V

P-3 ............................................ CAN H

P-4 ............................................ CAN L

P-5 ............................................ Emergency stop out

P-6 ............................................ Emergency stop in

P-7 ............................................ On/off

P3 ............................................. Relay 1

P-1 ............................................ 0V Truck

P-2 ............................................ Relay 1 out, 24V 2A (potential as 24V Truck)

LED .......................................... Steady green when power on plinth

P4 ............................................. Relay 2

P-1 ............................................ 0V Truck

P-2 ............................................ Relay 2 out, 24V 2A (potential as 24V Truck)

LED .......................................... Steady green when power on plinth

P5 ............................................. Relay 3

P-1 ............................................ 0V Truck

P-2 ............................................ Relay 3 out, 24V 2A (potential as 24V Truck)

LED .......................................... Steady green when power on plinth

P6 ............................................. Relay 4

P-1 ............................................ 0V Truck

P-2 ............................................ Relay 4 out, 24V 2A (potential as 24V Truck)

LED .......................................... Steady green when power on plinth

P7 ............................................. Relay 5

P-1 ............................................ 0V Truck

P-2 ............................................ Relay 5 out, 24V 2A (potential as 24V Truck)

LED .......................................... Steady green when power on plinth

P8 ............................................. Relay 6

P-1 ............................................ 0V Truck

P-2 ............................................ Relay 6 out, 24V 2A (potential as 24V Truck)

LED .......................................... Steady green when power on plinth

Issue 1.1

SPACE 4000

1:17

ELECTRONIC CONTROL SYSTEMS

4000 Relay box Connections (cont)

Plinth

Description

P9 ................................... Relay 7

P-1.................................. 0V Truck

P-2.................................. Relay 7 out, 24V 2A (potential as 24V Truck)

LED ................................ Steady green when power on plint

P10 ................................. Relay 8

P-1.................................. 0V Truck

P-2.................................. Relay 8 out, 24V 2A (potential as 24V Truck)

LED ................................ Steady green when power on plinth

P11 ................................. IN

P-1.................................. 0V Truck

P-2.................................. 24V Truck

P12 ................................. IN

P-1.................................. 0V Truck

P-2.................................. 24V Truck

CAN Led

Flashing Red

Flickering Green

Flashing Green

= CAN protocol missing or strapping error

= SPACE system switched On, emergency stop Out.

= SPACE system switched On, emergency stop In.

Status Led

Steady Green

Flashing Red

= Relays Ok, external and CAN supplies present.

= Relay malfunction. All relay outputs are disabled.

Jumper field

b1-b4, to set the address in the system of the relay box, relay behaviour and

action is set via terminal in SPACE box. Up to 4 relay boxes can be used.

NOTE !

1:18

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

Extended Box

SPACE 4000 EX

Connections

Plinth

Description

P1 ............................ ADS VALVE

P1.1 .........................0V, not same potential as other 0V.

P1.2 .........................24V (24V 1A)

P2 ............................ADS PRESSURE 1

P2.1 .........................24V

P2.2 .........................signal from pressure sensor (4-20mA)

P3 ............................ADS PRESSURE 2

P3.1 .........................24V

P3.2 .........................signal from pressure sensor (4-20mA)

Issue 1.1

SPACE 4000

1:19

ELECTRONIC CONTROL SYSTEMS

Extended box connections (cont)

Plinth

Description

P4 .................................EXTRA SENSOR INPUT

P4.1 ..............................0V

P4.2 .............................24V

P4.3 ..............................signal from extra Indicator (0/24V)

P5 .................................SPOOL SENSORS 7-8

P5.1 ..............................0V

P5.2 ..............................24V

P5.3 ..............................signal from spool sensor 7 (0-5V)

P5.4 ..............................signal from spool sensor 8 (0-5V)

P6 .................................CAN (From/to Cover 2)

P6.1 ..............................0V

P6.2 ..............................24V

P6.3 ..............................CAN H

P6.4 ..............................CAN L

P6.5 ..............................Emergency stop out

P6.6 ..............................Emergency stop in

P7 .................................CAN (From/to extra boxes)

P7.1 ..............................0V

P7.2 ..............................24V

P7.3 ..............................CAN H

P7.4 ..............................CAN L

P7.5 ..............................Emergency stop out

P7.6 ..............................Emergency stop in

P7.7 ..............................On/off of the system

P8 .................................DUMP VALVE 2

P8.1 ..............................0V

P8.2 ..............................24V (24V, 2A)

P9 .................................MSC

P9.1 ..............................0V

P9.2 ..............................24V (24V, 2A)

P10 ...............................EXTRA SENSOR INPUT

P10.1 ............................0V

P10.2 ............................24V

P-10.3 ...........................signal from extra Indicator (0/24V)

P11 ...............................EXTRA DUMP VALVE

P11.1 ............................Relay contact

P11.2 ............................Relay contact

Note.

1:20

Jumper fields are not used in the Extended Box,

strapping has no effect on the system.

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

Column Box

Connections

Plinth

Description

P1 ............................SPACE3000/4000

P1.1 .........................0V

P1.2 .........................24V

P1.3 .........................Signal from IB pressure sensor (4-20mA)

P1.4 .........................Signal from OB pressure sensor (4-20mA)

P1.5 .........................Signal from OB tilt indicator (4-20mA)

P1.6 .........................Signal from IB tilt indicator (4-20mA)

P1.7 .........................Signal from winch indicator (4-20mA)

P1.8 .........................Signal from second tilt indicator(ib)/indicators(ib&ob) (control platform)(0/

24V)

P1.9 .........................Signal from Extension out indicator/ second tilt indicator(ob) (0/24V)

P2 ............................To sensors 1

P2.1 .........................0V

P2.2 .........................24V

P2.3 .........................Connection to winch signal (4-20mA)

P2.4*........................0V

P2.5*........................24V

P2.6*........................Connection to extension out/OB fixed platform indicator (0/24V)

*See note.1

Issue 1.1

SPACE 4000

1:21

ELECTRONIC CONTROL SYSTEMS

Column box connections

(cont)

Plinth

Description

P3 .................................................To sensors 2

P3.1 ..............................................0V

P3.2 ..............................................24V

P3.3 ..............................................Connection to IB fixed platform tilt indicator (0/24V)

P3.4*.............................................0V

P3.5*.............................................24V,from P-3

P3.6*.............................................Connection to OB fixed platform tilt indicator (0/24V)

*See note 1.

P4 .................................................To sensors 3

P4.1 ..............................................24V

P4.2 ..............................................Connection to IB pressure sensor (4-20mA)

P4.3 ..............................................24V

P4.4 ..............................................Connection to OB pressure sensor (4-20mA)

P4.5 ..............................................24V

P4.6 ..............................................Connection to OB tilt indicator (4-20mA)

P4.7 ..............................................24V

P4.8 ..............................................Connection to IB tilt indicator (4-20mA)

Note 1

Connection is made in this way if an Extension Out sensor is fitted. If no sensor is fitted connect

as shown in illustration on previous page.

1:22

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

HiDrive controller

Controls

In addition to the normal six proportional control levers the HiDrive hand controller incorporates the following

devices:

1. Visual identity.

The thin blue line around the lever control plan label identifies the hand controller as

HiDrive and not RadioDrive.

2.Channel change button.

Used when it is necessary to change channels because of interference from outside sources. Press and

hold down the horn button (5), press the channel button and release. The new channel number will be

displayed in the LED window (8) until the horn button is released.

3.OLP release button.

Press and hold button whilst operating a function that will reduce the cranes loading. Warning Leds

will display in sweeping sequence on user interface during release operation. The Dump 2 cannot be

activated with this button, this function must be activated with the button on the User Interface.

Issue 1.1

SPACE 4000

1:23

ELECTRONIC CONTROL SYSTEMS

5. Horn button. The horn button has three functions:

(a) To activate the remote controller, release stop button and press and release the horn button once.

(b) Once the hand controller is activated the horn button can be used to sound the crane horn.

(c) Part of radio channel change and Manual Ext sequence. See items 2&10

6. Group switch

The group toggle switch allows the operator to select the group of functions to be controlled by the

proportional levers. The function groups can be individually set to an operators own requirements.

7. Speed selector switch

During normal crane operation this switch is set towards the leopard symbol. When the switch is

moved to the snail symbol the crane speed is reduced to 50%

8. Digital display window

This window currently displays the following information:

(a) When the hand controller is switched on the selected radio channel is displayed for

approx. 2 secs

(b) Two alternating red dots flash to indicate the controller is activated.

(c) When the horn button is pressed to activate the hand controller and a fault is detected on a lever

for example; lever not centred, the letter E is displayed for 2 secs followed by L x.

(x=lever number. Slew lever=1)

(d) When the horn button is pressed to activate the hand controller and a fault is detected on a button,

the letter E is displayed for 2 secs followed by x (x=button number. Horn button=1)

(e) The letter L in the window indicates that battery voltage is low in the hand controller battery.

Recharge or change the battery.

9. Relay control buttons

These three buttons can be set to operate various functions controlled by the SPACE 4000

relay box. They have an on/off function and can be set for both holding and non-holding modes of

operation. No function labels are fitted because the functions will be set by the dealers.

10. Manual extensions

To activate the Manual Extension logic press the Horn (5) and release (3) buttons together. The Leds

on the User Interface will work in the usual way for this function. Press the buttons in the same way to

de-activate the function.

1:24

SPACE 4000

Issue 1.1

Issue 1.1

5A

6A

6

5

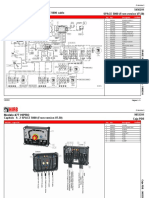

4

3

2

1

1

7

4A

4B

3A

3B

RADIO RECIVER

1

2 34 56 2 34 56 1 2 34 56

SPACE 4000

6B

5B

3B

V-80

4B

2B

1B

DUMP

VALVE

Cable 1A connect to 1A on the positioner.

Cable 2A connect to 2A on the positioner.

ETC.

5B

6B

TO WARNING

LAMP IN CABIN

24V

IGNITION/

TNDNING

WARNING INTERFACE

PLACED IN CABIN

HIGH INNER BOOM

WARNING KIT "OPTION"

2A

2B

1A

1B

COMPUTER

TO COLUMN BOX

HORN

6

5

4

3

2

1

SPACE 4000 ST

1 2 3 456 78 9 1 2 3 4

1 2 3 456 7

7 6 5 4 32 1 7 6 5 4 32 1

SLEWINGSECTOR

SPACE 4000 UI

LOCK/COVER

1

7

6

4

6

4

1 2

4

RELAY BOX

5 extra relay out puts

2

1

REMOTE ON

90%

OLP

Connection drawing

24V MAIN POWER

WARNING LAMP

ELECTRONIC CONTROL SYSTEMS

1:25

ELECTRONIC CONTROL SYSTEMS

Maintenance and adjustments

Terminal programs

In general you will recognise most of the terminal program from the original SPACE 3000 program. However,

new terminal programs have been developed for both Windows and DOS based terminal units, the aim of this

section is to highlight some of the more important changes. The new programs work on both SPACE 3000

and SPACE 4000.

For Windows you must use the program named S3000 Win.exe version 2.00 (or later), for DOS use

SPC4000.exe version 1.00 (or later). The currently available interface units all work with SPACE 4000 and no

new units are required.

Using the new program

The Main Menu screen in the new program has a new button in the bottom Lefthand corner named CAN.

Click on this button and the screen below is revealed.

The CAN menu. All boxes connected to the CAN bus are shown here. Clicking on the file button lets you load

parameter settings for the box selected in the CAN modules window only. The counter button will give you

access to information about how the box has been used. The most useful button however is Init.

1:26

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

Clicking the Init button will reveal the screen shown above. Click on the Address button and you will move

to the screen shown below. SPACE 4000 can only be operated with 1 HiDrive hand controller unit, so if you

change the hand controller you must go to this window and enter the serial number of the new unit.

Clicking the Channels button on the Init menu reveals the menu above. With this menu you can change

the channels of the SPACE 4000 receiver box. This means that you can tell the DA outputs which remote

lever and group they should listen to for their comands. This is the same as using V-Type for RadioDrive or

strapping the DA modules in Combirive. There is of course a difference with SPACE 4000, you will see 12

outputs displayed.

Issue 1.1

SPACE 4000

1:27

ELECTRONIC CONTROL SYSTEMS

Remember, if you make changes in the SPACE 4000 receiver you must tell the SPACE standard bottom.

To do this, from the Main Menu select Init, from the Init menu select Remote and the screen above will be

displayed. Make the selectons you require and click OK. To access this screen you must have REM in the

system type.

If we now return to the CAN menu and in the CAN Module window select Relay box 1 and click Init, the

screen above is displayed. In this screen you can set the SPACE 4000 relay box. The function/Group windows

are self explanatory, however some new teminology appears in the type windows. New terminology has been

applied to replace latch, toggle, etc. In the future these functions will be named Holding and Non-Holding. This

maybe best described as:

Press and hold relay button to operate function = non-Holding

Press and release relay button function operates, press and release again function off = Holding

Where the letters EM appear against a type, this indicates that the function will listen to the emergency stop

and switch off if the emergency stop button is pressed in.

NonHldEM =

NonHld =

Lamppole =

Blackout =

HldEM =

HldEMMem =

Hld=

Wrklight =

1:28

Non-Holding relay, listening to emergency stop.

Non-Holding relay not listening to emergency stop.

This relay assigned to lamp pole

This relay assigned to Blackout function. (Military applications only)

Holding relay listening to emergency stop.

Holding relay, listening to emergency stop with memory function. Will

reactivate automatically when emergency stop is released.

Holding relay not listening to emergency stop.

This relay assigned to worklight.

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

Changing system type

A new screen has been introduced to the terminal program to make changing the system type easier. To access

this screen if you have a Service level password, in the Main Menu click on Diagnostic in the display box and

press the page down (PgDn) key on terminal, Factory display will appear (greyed out). Now click on parameters

and the first screen shown below appears, click on the System type button to take you to the next screen. If you

have Diagnostic access simply press Page Down on your keyboard to change the display level.

Once you arrive at the screen shown above you can either click on the tick box to the left of the screen, or

enter the system type number directly into the New System Type window. To complete the operation you must

enter a protected parameter password into the password window, click on the Change System Type button

and a window appears confirming the changes have been made.

Issue 1.1

SPACE 4000

1:29

ELECTRONIC CONTROL SYSTEMS

Crane Config File

When starting a crane and clicking on the Init button you may see the screen below appear. As explained in

the pop-up window, this is an information screen only and has no affect on the performance of the crane. It is

designed to be completed by the dealer after the insatllation of the crane.

To access the Crane Config screen click OK in the pop-up window and the screen below appears.

Click Crane Config.

Now fill in the appropriate boxes and click OK

1:30

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

Parameters and Variables

Understanding Parameters

In the following description the name variable is used for program variables that change according to the

state of the crane.

The name parameter is used for program variables that are constants for the SPACE 4000 program (there

are of course no real constants, because the user can change them with the service-terminal). The SPACE

4000 program is adapted to different crane types and working conditions with the parameters.

All the variables and parameters in this description can be monitored and eventually changed (see below) with

the VARS and PARS selections of the SPACE 4000 terminal. When a variable is chosen on the terminal its

value is shown on the screen, and the value changes as the value of the variable changes. When a parameter

is chosen, the terminal shows its present value and prompts the user for a new value.

All the parameters belongs to one of three access-levels (level S, Service, level D, Diagnostic or level F,

Factory), and so do the users password (required when the service-terminal is started). To be able to change

a parameter, the users access-level has to be at least the same as the parameters access-level. During

the initiating of the system, some parameters are automatically changed by the terminal, even if the users

access-level not would allow the user to manually change the parameter.

All parameters and variables also belong to one of three display-levels (S, D or F). You must have the same

or higher display-level selected in the terminal programs main menu, otherwise the parameter/variable is not

shown under the parameter/variable menus.

This description classes the variables and parameters in the same way as the SPACE 4000 terminal, and the

classes are:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

OLP

ASC / MSC

Analog inputs

Remote Control

Levers

Pressures

Digital inputs

Stability

Digital outputs

Service

PLC

Various

Counters and Timers (special menu)

Errors (special menu)

PLC operands (for PLC programs)

Note. All the parameters and variables will be shown on the terminal, even if the system-type of the actual

control does not include all the options. For example if you have a crane without winch, the variables and

parameters for the winch will still be shown on the terminal (but they have no meaning for the system).

Issue 1.1

SPACE 4000

1:31

ELECTRONIC CONTROL SYSTEMS

Channels

Understanding Channels

Parameters with the extension _chan allocated to them require a channel number to be entered to activate a

feature. The list below shows the channel normal channel number allocation. It is important to note that there

are two different types of inputs to SPACE: Digital = 0v or 24v and Analog = variable voltage input. When

connecting an accessory to SPACE 4000 the list below shows what type of signal can be connected to a

plinth. See the example below.

A Military customer has requested you to supply crane with SPACE 4000 and they want the blackout feature

with a keyswitch to operate it. Blackout is activated by a 0v=off, 24v=on signal so you know you are dealing

with a digital input. By looking at the parameter information you can see that the limits given for this feature

are channel numbers 1-36. However reference to the channel list shows that only 8 of the 36 channel

inputs will support a digital input. For the purpose of this example you will not have an Extended box, so this

reduces your choice to 4 possible channels (23-26 inclusive). The crane is not fitted with a platform or manual

extensions so this leaves plinth P4 in the standard bottom available. Connect the keyswitch 24v signal to

plinth P4:3 and and enter channel number 24 into the parameter blackout_chan. SPACE 4000 now knows

that when a signal is received at plinth 4:3 it must execute the blackout function.

Remember it is only possible to assign 1 function to a plinth terminal, and the channel number for the terminal

is fixed as shown in the following list.

Channels list

Channel

Terminal

-1

1:32

Normally used for

Input not in use

P1:3

Analog input: Spool sensor 1

P1:4

Analog input: Spool sensor 2

P1:5

Analog input: Spool sensor 3

P1:6

Analog input: Spool sensor 4

P2:3

Analog input: Spool sensor 5

P2:4

Analog input: Spool sensor 6

EXT-P5:3

Extended box analog input: Spool sensor 7

EXT-P5:4

Extended box analog input: Spool sensor 8

P5:8

Analog input: Second Inner Boom Tilt Indicator (for platform logic)

P5:7

Analog input: Winch Indicators

10

P5:6

Analog input: Inner Boom Tilt Indicator

11

P5:5

Analog input: Outer Boom Tilt indicator

12

P5:4

Analog input: Outer Boom Pressure Sensor

13

P5:3

Analog input: Inner Boom Pressure Sensor

14

P6:3

Digital input: Slewing sector 0 Positive Indicator

15

P6:4

Digital input: Slewing sector 0 Negative Indicator

16

P2:5

Analog input: Spool sensor 9

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

Channels list (cont.)

17

EXT-P4:3

Extended box analog input: On Platform indicator

18

EXT-P10:3

Extended box analog input: Extra sensor

19

plc_anin[0] = PLC OW4

20

plc_anin[1] = PLC OW5

21

plc_anin[2] = PLC OW6

22

plc_anin[3] = PLC OW7

23

P5:9

Digital input: Extensions out indicator

24

P4:3

Digital input: Manual Extension / On Platform indicator

25

P6:5

Digital input: Slewing sector 1 Positive Indicator

26

P6:6

Digital input: Slewing sector 1 Negative Indicator

27

EXT-P5:5

Extended box digital input: Extra indicator

28

EXT-P5:6

Extended box digital input: Extra indicator

29

plc_digin.0 = PLC O8

30

plc_digin.1 = PLC O9

31

plc_digin.2 = PLC O10

32

plc_digin.3 = PLC O11

33

plc_digin.4 = PLC O12

34

plc_digin.5 = PLC O13

35

plc_digin.6 = PLC O14

36

plc_digin.7 = PLC O15

Issue 1.1

SPACE 4000

1:33

ELECTRONIC CONTROL SYSTEMS

Parameters list

1. OLP function

end_pos_spd

parameter access:F display:F limits:0..255 default:50

The speed at which (% lever deflection) the inner or outer booms can be driven down if they

were driven up when the OLP was activated (a big load lifted or cylinder end position).

end_pos_time

parameter access:D display:D limits:20..100 default:20

How long (number of sample intervals) the inner or outer booms can be driven down if they

were driven up when the OLP was activated (a large load lifted or cylinder end position).

mlink_mode

parameter access:D display:D limits:0..1 default:0

If the crane has a mechanical link (mlink_mode = 1) or not (mlink_mode = 0). Note that the

ib_tilt_chan parameter also has to be set for the mechanical link logic to work. If ib_tilt_chan is

set, but mlink_mode = 0, the ib_tilt signal is used for high inner boom warning only.

olp_lim

parameter access:S display:S limits:50..150 default:100

The default OLP limit pressure (in % of the working pressure ??_p_lim) for the two different

OLP-systems (Inner Boom and Outer Boom). The final OLP limit pressure will vary depending

on MSC, MultiMode, errors, cabin area and so on.

Note!

This parameter will always default to 100 % when the power is switched on.

olp_rel_lim

parameter access:F display:F limits:100..120 default:108

Sets the limit (relative to the current inner and outer boom OLP limits) over which the OLP

Release function is disabled the second time the OLP Release is used during the same OLP

situation.

olp_rel_time

parameter access:F display:F limits:0..255 default:200

The number of sample intervals (50 ms) the OLP-release mode is active when the release

switch is activated and a forbidden function is driven. Note! The OLP Release time is halved

(run with double speed) when the MSC is not active.

olp_rel_wait

parameter access:F display:F limits:0..65565 default:30

The number of seconds the OLP-release mode is inhibited after the previous OLP-release.

w_top_n

parameter access:D display:D limits:0..255 default:22

w_top_p

parameter access:D display:D limits:0..255 default:12

These parameters contains a bit pattern that describes which functions should be stopped in

the negative (w_top_n) and positive (w_top_p) directions when the winchs top-switch indicator

is activated.

1:34

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

2. MSC-function

Manual Speed Control or ASC function: Automatic Speed Control

asc_old_fact

parameter access:F display:F limits:1..12800 default:32

An ageing factor for the ?b_p_asc pressure signals. When ?b_p_filt increases, ?b_p_asc

follows without delay, but when ?b_p_filt decreases, ?b_p_asc decreases with asc_old_fact *

1/128 % per sample interval. (The default value 32 gives an ageing factor of 5% per second).

asc_rel_mode

parameter access:S display:S limits:0..1 default:0

A non-zero value in this parameter means that the MSC/ASC should be automatically

deactivated when the pressure drops below the MSC/ASC-pressures. If the parameter is zero,

the MSC/ASC is not deactivated before the user releases all the levers.

ib_asc_lim[2]]

parameter access:F display:F limits:0..128 default:80,100

ob_asc_lim[2]

parameter access:F display:F limits:0..128 default:80,100

MSC: ?b_asc_lim[0] is the pressures (% of ib_olp_lim and ob_olp_lim) at which the MSCsystem should be activated.

ASC: the pressures (% of ib_olp_lim and ob_olp_lim) at which the ASC-reduction starts

(speeds start to reduce) and has reached its maximum value (speed reached the minimum

value). asc_lim[0] < asc_lim[1].

ib_asc_olp_add

parameter access:F display:F limits:0..20 default:10

ob_asc_olp_add

parameter access:F display:F limits:0..20 default:10

How many %-units the OLP pressure limit (ib_olp_lim and ob_olp_lim) shall increase when

MSC or ASC is selected (system type MSC or ASC).

ib_asc_spd_p[FUNCS] parameter access:F display:F limits:0..100

ob_asc_spd_p[FUNCS] parameter access:F display:F limits:0..100

defaults:

100, 42, 42, 100, 100,100,100,100

Max speed in positive directions [%] when the inner boom or outer boom MSC or ASC is active.

If both ?SC-systems are active at the same time, the lower of the max speeds are used.

ib_asc_spd_n[FUNCS] parameter access:F display:F limits:0..100

ob_asc_spd_n[FUNCS] parameter access:F display:F limits:0..100

defaults::

100, 52, 52, 100, 100,100,100,100

Max speed in negative directions [%] when the inner boom or outer boom MSC or ASC is

active. If both ?SC-systems are active at the same time, the lower of the max speeds are used.

mm_ib_olp_add[2] parameter access:F display:F limits-20..20 default:0,0

mm_ob_olp_add[2] parameter access:F display:F limits-20..20 default:0,0

How many %-units the OLP pressure limit (ib_olp_lim and ob_olp_lim) shall in/decrease in the

different MultiModes. The first value is for Hook Mode and the second for Winch Mode (in Tool

Mode the OLP limits are not changed)

mm_off_lift[2]

parameter access:F display:F limits: 0..4 default:0,1

How many lifts must be performed before the multimode returns to Hook Mode from Tool Mode

and Winch Mode.

mm_off_time[2]

parameter access:F display: F limits: 60..240 default:60,60

How many seconds must elapse before the multimode returns to Hook Mode from Tool Mode

and Winch Mode.

Issue 1.1

SPACE 4000

1:35

ELECTRONIC CONTROL SYSTEMS

msc_act_mode

parameter access:S display:S limits:0..2 default:0

This parameter describes how the MSC is activated:

0: Auto

The MSC is automatically activated always when the (inner or outer boom)

pressure reaches the MSC-limit. Levers that are deflected more than the MSClimit, are hydraulically forced back to the MSC-limit.

1: Non-limitingThe MSC is automatically activated only if no lever needs to be forced back (no

function is being driven too fast). Otherwise the MSC is not activated until all

levers are centred.

2: Zero-pos. The MSC is activated only when all levers are centred. This means that when

the crane load increases, you will first get an OLP at the crane nominal capacity

(100%). When you centre the levers, the MSC will be activated (also limiting the

valve spool strokes) and the crane capacity will increase with ??_msc_olp_add

%.

unload_der

parameter access:F display:F limits:-100..0 default:-10

If the inner boom pressure calculation (ib_p_der)

ib_p_der) is more negative than this parameter while a

ib_p_der

ASC is active, the ASC will not be released until all remote levers have been centred.

3. Analog inputs

Note!

The anin_max[]-, anin_min[]- and anin[]

anin[]-arrays are not function-related, but the indexes

refer to the channel number of the analog inputs (0..18, see the table in the beginning of this

description)

anin_max[19]

defaults:

parameter access:F display:F limits:0..255

240,240,240,240,240,240,240,240,

255,240,240,240,240,240,255,255,

255,255,255

Max permitted value on the analog input. A input that exceeds this value, is considered faulty

(shorted to +24V or +5V).

anin_min[19]

defaults:

parameter access:F display:F limits:0..255

16, 16, 16, 16, 16, 16, 16, 16,

0, 16, 16, 16, 16, 16, 0, 0,

0, 0, 0

Min permitted value on the analog input. A input that is below this value, is considered faulty

(open or grounded).

1:36

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

4. Remote control

func_k[FUNCS]

parameter access:D display:D limits:0..100 defaults:100

An amplification coefficient 0..100 %, with which the solenoid current outputs for each crane

function multiplies its control data.

give_oil[REMS]

parameter access:D display:D limits:0..255 defaults:0

This parameter is used to activate the dump valve for remote channels that are not assigned to

any crane function. The 4 high bits (16 = group 1, 32 = group 2, 64 = group 3 and 128 = group

4) indicates that the channel needs oil in the corresponding remote control group(s).

ramp_time

parameter access:F display:F limits:0..48 default:10

How many sample intervals (50 ms) the supervision of the lever- (spool-) sensors should be

inhibited when the max permitted speed is changed during remote control.

rem_chan[FUNCS] parameter access:F display:F limits:0..255

defaults:

16, 17, 18, 19, 20, 20, 21, 255

Remote control channel 0..7 for each function. The four highest bits of the value (decimal

16, 32, 64 and 128) indicates to which remote control group (s) the function belongs. 255 if a

function is not remote controlled.

rem_a_ramp[FUNCS] parameter access:F display:F limits:1..100

defaults:

4, 4, 4, 4, 4, 20, 20, 20

The ramp (%-units / sample interval) when the max allowed remote control speed is increasing

(as when deactivating ASC, if asc_release_mode is on). The slowest ramp you can get is 20

%/sec (1 %/sample). A parameter value of 100 means no ramp (100 %/sample).

rem_r_ramp[FUNCS] parameter access:F display:F limits:1..100

defaults:

4, 20, 20, 20, 100, 20, 20, 20

The ramp (%-units / sample interval) when the max allowed remote control speed is decreasing

(as when activating ASC/OLP). The slowest ramp you can get is 20 %/sec (1 %/sample). A

parameter value of 100 means no ramp (100 %/sample).

micro_factor[3]

parameter access:D display:D limits:0..100 default: 53, 33, 20

The micro-speeds of the remote control system. This parameter does not actually change the

speed, it just tells the SPACE-system the speed that are used by the remote control system, so

that the lever supervision can work correctly.

Issue 1.1

SPACE 4000

1:37

ELECTRONIC CONTROL SYSTEMS

5. Lever position sensors

func_dir[FUNCS]

parameter access:D display:D limits:0..1 defaults:0

0 if the function has normal lever directions (positive direction = lever up). 1 for functions with

reversed lever directions (positive direction = lever down).

lev_ad_chan[FUNCS] parameter access:F display:F limits:-1..22 defaults:0,1,2,3,4,4,5,-1

anin-channel (0..22) for each functions lever position sensor. -1 if the function does not have a

sensor.

lev_db

parameter access:S display:S limits:0..50 default:33

The dead band [%] of the valve, that is, how much the lever has to be moved, before it is

opened.

lev_n_range[FUNCS] parameter access:F display:F limits:-120..120 default:75

How much the analog input value differs from lev_offs[] when the valve is fully open in the

negative direction.

lev_p_range[FUNCS] parameter access:F display:F limits:-120..120 default:-75

How much the analog input value differs from lev_offs[] when the valve is fully open in the

positive direction.

lev_offs[FUNCS]

parameter access:F display:F limits:76..178 default:128

The analog input value when the lever is centred.

lev_rem_add

parameter access:F display:F limits:0..48 default:35

MSC: how much [%-units] the signal from the lever-sensors (variable lever

lever) may exceed the

MSC max speeds (??_asc_spd_? parameters) when the MSC is active (valve stroke limited

with the hydraulic MSC system).

ASC: how much [%-units] the signal from the lever-sensors (variable lever

lever) may exceed the

remote control signal (variable rem_out) when the remote control is in use. If lever > rem_out +

lev_rem_add for a longer time than lev_rem_time samples, the oil is dumped.

lev_rem_time

parameter access:F display:F limits:0..40 default:25

MSC: When the msc_act_mode is in Auto-mode (0), the spool-position supervision (see

lev_rem_add) is by-passed for this time (sample intervals, 50ms), when the MSC is activated

(gives time for the hydraulic MSC-system to force back the valves to allowed speeds).

ASC: When comparing lever-sensor signals to the remote control signals (see lev_rem_add

above), the dumping of the oil is delayed lev_rem_time sample intervals (to compensate for

delays in remote control transmission, valve movement, analog input sampling/filtering etc.).

lev_zero_range

parameter access:F display:F limits:0..50 default:25

How much (in % of full stroke) the lever-transducer-inputs may vary from the centred position

for the control to accept the lever as centred (used to supervise that the levers are not moved

manually when the remote control is connected).

1:38

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

oil_need_n[FUNCS] parameter access:D display:D limits:0..100 default:100

oil_need_p[FUNCS] parameter access:D display:D limits:0..100 default:100

The amount of pump-flow [l/min] each crane function needs for full speed (lever

lever = 100%) in the

negative resp. positive directions.

win_sel_gr

parameter access: F display: F no limits default: 241

With this parameter you tell the system in which remote control group/manual mode the Winch

function should exist. The bits 0x10, 0x20, 0x40 and 0x80 corresponds to the remote control

groups 1, 2, 3 and 4, and the bit 0x01 is for the manual mode. The parameter should be used

when the crane is equipped with a selector valve for the winch.

For example, if you have a selector valve on the winch and the valve is connected so that

the oil goes to the winch when the valve is off, and to the tool 2 functions when the valve is

activated. The valve is connected so that it is activated when the remote control group 2 is

selected and inactivated otherwise, the rem_chan-parameters are set so that the winch is

controlled with lever 5 in group 1, and the tool 2 with the same lever in group 2. The solenoid

outputs for these functions are set to work on lever 5 in group 1 and 2, the spool sensor for

the tool 2 function is set to the same as for the winch: -> set win_sel_gr

_sel_gr to 209 -> the winch

function is unconnected when group 2 is selected -> the spool sensor will be used for the Tool

2 instead.

6. Pressure sensors

The system has connections for two pressure sensors, inner boom and outer boom. Both sensors have

a collection of parameters and variables which are named ib_p_?? and ob_p_??.

The pressure signals are calculated and filtrated in the following way:

- first the analog input values are converted to absolute pressures:

??_p_mom = (anin[??_p_chan] - 44) * ??_p_p_range / 180

- the relative pressure is calculated: ??_p_r = 100 * ??_p_mom / (??_p_lim * (100 + ??_p_lim_corr)

/ 100)

- the relative pressure signal (??_p_r) is filtered (average of the 20 latest values) and stored in ??_p_

filt

- the peak pressure (??_p_asc) is a peak value decaying according to the asc_old_fact parameter

der_zero_lev

parameter access:F display:F limits:1..111 default:50

The minimum speed the functions must be moving (%, read from lever[]) before the pressure

sensor supervision is activated (the pressure must not be constant for a longer time than der_

zero_time). The supervision can be disconnected by setting this parameter to 111 (because

the max value for lever[] is 110).

der_zero_time

parameter access:F display:F limits:10..3600 default:1800

The time (seconds) in which the pressure values may be constant when the corresponding

function is moving over a min speed (der_zero_lev). If the pressure value is constant longer,

the sensor is considered faulty.

Issue 1.1

SPACE 4000

1:39

ELECTRONIC CONTROL SYSTEMS

frict_comp

parameter access:D display:D limits:-12..12 default:0

A compensation for friction in the cylinders. This value is subtracted from the filtrated

relative pressure values (??_p_filt) when the cylinder is moving in positive direction (positive

compensation) or negative direction (negative compensation).

ib_p_chan

parameter access:F display:F limits:-1..22 default:13

ob_p_chan

parameter access:F display:F limits:-1..22 default:12

The analog input channel (0..22) the pressure sensor is connected to. -1 if the function do not

have a sensor.

ib_p_lim

parameter access:F display:F limits:0..400 default:250

ob_p_lim

parameter access:F display:F limits:0..400 default:250

The working (100%-) pressure [bar] for the functions.

ib_p_lim_corr

parameter access:S display:S limits:-20..+3 default:0

ob_p_lim_corr

parameter access:S display:S limits:-20..+3 default:0

A person with access-level 1 can with this parameter adjust the ib_p_lim- and ob_p_lim-values.

ib_p_p_range

parameter access:F display:F limits:0..1024 default:400

ob_p_p_range

parameter access:F display:F limits:0..1024 default:400

The pressure range of the pressure sensor [bar], that is, the pressure that gives a 20 mA signal

current

stop_tool_1_load

parameter access:S display:S limits:0..255 default:200

When the inner boom pressure (ib_p_filt) is higher than this level, the positive direction of

TOOL_1 is stopped. Intended to used on cranes with the support legs on the TOOL_1-function.

stop_tool_2_load

parameter access:S display:S limits:0..255 default:200

When the inner boom pressure (ib_p_filt) is higher than this level, the positive direction of

TOOL_2 is stopped. Intended to used on cranes with the support legs on the TOOL_2-function.

7. Digital inputs

blackout_chan

parameter access:D display:D limits:-1..36 default:-1

The channel number to which a dark mode request switch is connected. When this parameter

is set to 1, the dark mode cant be activated and the lamps in the system works in the normal

way. When the parameter is set to a channel number, the lamps and the OLP and Prewarning

horn will be shut off as default; only when the input is read as 0, the lamps can work (this means

for example that when switching on the system, the covers remains dark until the input has been

read (and is 0) and the state has been transmitted to the covers.

ext_in_chan

parameter access:D display:D limits:-1..36 default:-1

The channel number (usually 19) for the crane extension in-indicator (used to give a higher

manual extension load when the crane extensions are out).

ib_tilt_chan

parameter access:S display:S limits:-1..36 default:-1

The channel number for the inner boom tilt indicator

lo_load_inp_chan

parameter access:D display:D limits:-1..36 default:-1

A digital input with which the crane capacity can be reduced

1:40

SPACE 4000

Issue 1.1

ELECTRONIC CONTROL SYSTEMS

lo_load_inp_load

parameter access:D display:D limits:0..100 default:50

The inner boom capacity is limited to this value [%] when the lo_load_inp_chan is set ( 1)

and the lo_load_inp -variable is off ( 1).

man_ext_load[2]

parameter access:D display:D limits:0..100 default:50,75

The inner boom capacity is limited to this value [%] when the manual extension mode is

selected in the PSB. The first value (should be lower) is used when the crane extensions are in

(ext_in_inp = 1) or no ext_in-indicator is connected (ext_in_chan = -1) and the second value

(higher) when the crane extensions are out (ext_in_inp = 0).

ob_tilt_chan

parameter access:F display:F limits:-1..36 default:11

The channel number for the outer boom tilt indicator

plc_tilt_chan[4]

parameter access:D display:D limits:-1..36 default:-1,-1,-1,-1

The channel numbers for the four extra tilt indicator for use by the PLC program

stand_ib_low_chan parameter access:D display:D limits:-1..36 default:-1

The channel number for the inner boom tilt indicator for the stand platform

stand_ob_low_chan parameter access:D display:D limits:-1..36 default:-1

The channel number for the outer boom tilt indicator for the stand platform

stand_on_chan

parameter access:D display:D limits:-1..36 default:-1

The channel number for the person on platform-indicator

win_box_type

parameter access:S display:S limits:0..1 default:0

Tells the system which type of winch box is used. 0 means the old Hiab box with connections

for 4 on/off indicators (wload, wend, wtop and wdis). 1 means the new winch box with analog

load sensor and on/off wend indicator.

win_chan

parameter access:F display:F limits:-1..22 default:-1

The channel to which the winch-box is connected

8. Stability

stab_n_chan[3]

parameter access:D display:D

limits:-1..36 default:-1,-1,-1

The channel number for the three slewing sector negative-side indicators

stab_p_chan[3]

parameter access:D display:D

limits:-1..36 default:-1,-1,-1

The channel number for the three slewing sector positive-side indicators

stab_olp[3]

parameter access:S display:S limits:0..100 default:60,100,100

The level (in %) to which the inner boom OLP-pressure limit shall reduce when the slewing is

inside an OLP_SECT restriction sector.

stab_sect_type[3]

parameter access:D display:D limits:0..2 default:0,0,0

This parameter sets the type of the three different slewing sectors

0 OLP_SECT

normal capacity reducing stability sector

1 STOP_SECT

end damping sector

2 STND_SECT

sector for stand platform

Issue 1.1

SPACE 4000

1:41

ELECTRONIC CONTROL SYSTEMS

stop_legs_load

parameter access:D display:D limits:0..100 default:40

The inner boom pressure level (%, ib_p_filt) at which the remote control channels for supportlegs up are disabled.

stop_legs_p[REMS] parameter access:D display:D limits:0..255 defaults: all 0

stop_legs_n[REMS] parameter access:D display:D limits:0..255 defaults: all 0

When the inner boom load (ib_p_filt) is higher than stop_legs_load the positive (stop_legs_p)

and/or negative (stop_legs_n) remote control directions will be stopped for the channels which

have a 1 in the bit corresponding to the current remote control group(s).

9. Digital outputs

olp_horn_on

parameter access:S display:S limits:0..10 default:3

How many times (1 second apart) the horn should beep when the crane (inner or outer boom)

load reaches the OLP level.

olp_horn_time

parameter access:S display:S limits:0..255 default:90

How long (in 600 Hz timer ticks) the OLP horn beeps should be.

prew_horn_on

parameter access:S display:S limits:0..10 default:1

How many times (1 second apart) the horn should beep when the crane (inner or outer boom)

load reaches the prewarning level.

prew_horn_time

parameter access:S display:S limits:0..255 default:30

How long (in 600 Hz timer ticks) the prewarning horn beeps should be.

remb_horn_on

parameter access:S display:S limits:0..10 default:2

How many times (1 second apart) the horn should beep when the remote control unit indicates

that its battery level is low.

remb_horn_time

parameter access:S display:S limits:0..255 default:60

How long (in 600 Hz timer ticks) the RCU battery warning horn beeps should be.

slr_horn_onparameter access:S display:S limits:0..10 default:1

How many times (1 second apart) the horn should beep when the crane slews into a capacity

restricting sector

slr_horn_time