Академический Документы

Профессиональный Документы

Культура Документы

Blest Plastic To Fuel Web

Загружено:

arnabjyoti dasОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Blest Plastic To Fuel Web

Загружено:

arnabjyoti dasАвторское право:

Доступные форматы

Blest Plastic-to-Fuel Project Report

Results and Recommendations for a Northern Climate

This publication may be obtained from:

Cold Climate Innovation

Yukon Research Centre, Yukon College

520 College Drive

PO Box 2799

Whitehorse, Yukon

Y1A 5K4

t. 867.668.9995

1.800.661.0504

www.yukoncollege.yk.ca/research

Recommended citation:

Cold Climate Innovation, 2014. Blest Plastic-to-Fuel Project Report - Results and Recommendations

for a Northern Climate. Yukon Research Centre, Yukon College, 16 p.

Front cover photograph: Blest B-240/NVG 200 plastic-to-fuel processing machine.

Printed in Whitehorse, Yukon, 2014 by Arctic Star Printing Inc., 204 Strickland St.

Blest Plastic to Fuel

EXECUTIVE SUMMARY

The Blest B-240 plastic-to-fuel machine has met or exceeded our expectations. Several

important factors were considered during this project including environmental, economical, and

operational factors. The machine is also adaptable to many different installation possibilities.

From an environmental standpoint, the machine is more efficient and has lower emissions

than traditional recycling. The CO2 emissions from the machine are just 186 g per kg of plastic

processed, compared with as much as 3500 g per kg processed using traditional recycling

methods. The machine meets environmental regulations in Yukon as well as other jurisdictions

that have much stricter emissions standards (e.g., Japan, Iceland, Slovakia, Palau, Oregon,

California, New York, Georgia and British Columbia). This machine also helps to deal with plastic

that is currently unsellable due to Chinas new Green Fence Policy, which limits what grades of

plastics can be exported.

Results of the emissions testing have indicated that there are no concerns with the emissions

from the machine.

Table of emissions results.

Parameter

Result

Expected result

CO2

186 g/kg plastic

250 g/kg plastic

methane

10 ppm

25 ppm

TVOCs

<1 ppm (undetectable)

1 ppm

NOx

<4 ppm

<10 ppm

SOx

<5 ppm

<15 ppm

Note: TVOC = total volatile organic compounds; NOx = nitrogen oxides; SOx = sulfur oxides

Economical investigations have successfully demonstrated that the Blest B-240 turns waste

plastic that has a negative economic value (i.e., shipping costs exceed value of product) into a

high-profit product. The B-240(NVG 220) machine is capable of producing 1 L of fuel at a cost as

low as $0.31 per litre; larger machines produce the fuel at $0.14 per litre. Gasoline and diesel

equivalents can be produced with the installation of an optional inline distillation unit, which

allows these fuels to be used anywhere gasoline and diesel are used.

The operations of the machine are simple and can be taught to users in 2 to 3 hours. Operation

of the machine can also be accomplished through remote access via a secure Internet

connection. The machine operated well in a variety of temperature conditions, as well as with a

variety of feedstock.

The plastic types that can be processed include:

#2 Poly Ethylene (e.g., HDPE, UHMWPE, etc.)

#3 Poly Vinyl Chloride (when processed with the new optional pre-processor)

#4 Low Density Poly Ethylene

#5 Poly Propylene (e.g., PP, HDPP, UHMWPP, etc.)

#6 Poly Styrene (e.g., PS, EPS, HDPS, HIPS, etc.)*

ABS (With an optional off-gas filter)

Blest Plastic to Fuel

*When processing #6 Polystyrene, styrene monomer can be produced and sold to manufacturers

to make new polystyrene products. This is currently feasible with a larger model of the machine

(NVG 1000) as the B-240(NVG 220) does not process enough to satisfy chemical brokers

minimum sales requirements.

#1 PETE plastic is considered a high-value product and can generally be recycled by traditional

methods.

#7 OTHER plastics are a mix of resins and may include a combination of resins such as Nylon and

Polyethylene making recycling by any method difficult.

In communities with populations as low as 200 people, benefits from the installation of such a

machine could be realized. In particular, remote and arctic communities would see the greatest

benefits where fuel costs are high due to barged or flown-in fuel, and where there are waste

disposal problems such as open-burning in landfills. Many organizations (e.g., private recycling

companies, NGOs, etc.) are also considering this technology as a means of processing marinesourced plastic that may be unrecyclable due to the accumulated salt concentrations in the

plastic. The Blest plastic-to-fuel machine is also ideally suited for use in an industrial setting

where waste plastic from manufacturing or processing can be directly used as the feedstock.

A mobile or travelling scenario for the Blest B-240 was explored, however, minimal operational

staff requirements and high transportation and standby labour costs suggest that a stationary

installation of the machine is more suitable. However, one machine has been mounted on a

truck that travelled extensively in India and Nepal as an environmental demonstration project.

This environmental demonstration project was not intended to be economically feasible, so

labour costs were not a consideration.

Blest Plastic to Fuel

TABLE OF CONTENTS

Executive Summary............................................................................................................................................ i

Introduction. ...................................................................................................................................................... 1

Blest Models. ....................................................................................................................................................... 2

Additional Options............................................................................................................................................. 2

Peripherals. ......................................................................................................................................................... 3

Cost Analyses....................................................................................................................................................... 3

Maintenance Costs............................................................................................................................................ 4

Environmental Analyses. ............................................................................................................................... 4

Off-Gas Testing.................................................................................................................................................... 5

Fuel Testing. ........................................................................................................................................................ 5

Water. ............................................................................................................................................................ 5

Copper corrosion.......................................................................................................................................... 5

Pour/plug points........................................................................................................................................... 6

Flash point..................................................................................................................................................... 6

Sulphur........................................................................................................................................................... 6

Output Contaminant Testing ........................................................................................................................... 7

Contaminant testing.................................................................................................................................... 7

Fuel volatiles testing.................................................................................................................................... 7

Internal Combustion Engine Testing. .............................................................................................................. 8

Processing Expanded Polystyrene (EPS)..................................................................................................8

EPS Foam Quality............................................................................................................................................... 8

Comparing Recycling to Plastic-to-Fuel Processing. .......................................................................9

Energy Usage ..................................................................................................................................................... 9

CO2 Emissions. ....................................................................................................................................................9

Remote Access.................................................................................................................................................... 10

Recommendations for Remote Access.........................................................................................................10

Containerization.............................................................................................................................................. 10

Power supply............................................................................................................................................... 11

Glass glycol tubes....................................................................................................................................... 11

Glycol reservoir........................................................................................................................................... 11

Glycol chiller................................................................................................................................................ 11

Load cell scale............................................................................................................................................. 11

Off take tank. .............................................................................................................................................. 11

Reactor and buffer tank hangers.............................................................................................................11

Levelling....................................................................................................................................................... 11

Molten plastic in reactor........................................................................................................................... 12

Blest Plastic to Fuel

Community Size and Feasibility................................................................................................................. 12

Population Considerations. ............................................................................................................................ 13

Factors Affecting Operations. .................................................................................................................. 13

Humidity of Feedstock. ................................................................................................................................... 13

Calibration for moisture............................................................................................................................ 14

Plastic Types...................................................................................................................................................... 14

Calibration for plastic type. ...................................................................................................................... 14

Fuel Output Quality......................................................................................................................................... 14

Adjustments for fuel output quality........................................................................................................14

Feedstock. ......................................................................................................................................................... 14

Ambient Temperatures. .................................................................................................................................. 14

Ambient temperatures encountered.......................................................................................................14

Cold temperature operating guidelines .................................................................................................15

Fuel Output....................................................................................................................................................... 15

Troubleshooting/Repairs............................................................................................................................ 15

Bibliography. ..................................................................................................................................................... 16

Introduction

INTRODUCTION

Plastic accounts for >12% of all materials deposited in landfills, placing an ever-increasing burden

on the environment. Furthermore, initiatives such as Chinas Green Fence Policy, which limits the

ability to dispose of plastic products, has resulted in a growing requirement for initiatives that

will reduce the environmental impact of plastic.

Thermal depolymerization is a process that uses pyrolysis for the reduction of complex materials

(in this case plastic) into light crude oil and essentially mimics natural geological processes.

Under pressure and heat, long-chain polymers of hydrogen, oxygen and carbon decompose

into short-chain petroleum hydrocarbons which can then be used for heating or transport

applications. One of the leading global proponents for utilizing pyrolysis technology to address

the plastics issue is Blest, a Japanese company established by inventor Akinori Ito. Motivated by

declining conventional oil reserves and increasing plastic pollution, Ito sought to adapt existing

pyrolysis technology to create community-scale, plastic-to-fuel processors. To date, Blest is

developing and manufacturing a wide range of plastic-to-fuel machines and are increasing their

global distribution network.

Following the recommendations of a 2011 feasibility study conducted by Rising Sun Innovations,

a Blest B-240 plastic-to-fuel machine was procured in 2012 under the partnership of Canadian

Northern Economic Development Agency (CanNor), Yukon Research Centre and Cold Climate

Innovation. The purpose of the procurement was to house the B-240 in a Whitehorse recycling

centre (P&M Recycling), in order to determine if it was economically and environmentally viable

to up-cycle plastic to fuel, rather than follow traditional recycling methods. It was envisaged

that this process would not only reduce the burden on local landfills, or remove the necessity to

transport plastics out of territory and ultimately overseas, but would also have the potential to

generate locally produced fuels that have an intrinsic commercial value.

The initial phase of the project concluded

with the successful installation and

operation of the Blest B-240 machine.

Phase 2 of the project included a detailed

analysis of the fuel produced by different

types of plastic, an assessment of

emissions produced by the machine and

internal combustion engine, and finally an

assessment with recommendations as to

the feasibility of deploying the machine to

remote northern communities. This report

summarizes the work completed to date,

details the findings of the fuel analysis,

and makes recommendations as to which

Blest machine is most suitable depending

on community size. It is envisaged that

this report will better prepare individuals

and communities to assess the economic

and environmental viability of moving

from conventional plastic recycling to upcycling, which produces usable fuel.

Blest Plastic to Fuel

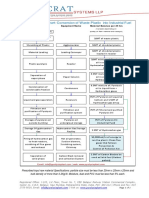

BLEST MODELS

Blest manufactures several capacities of machines to suit different feedstock amounts. The

size of a machine purchased should match the amount of plastic available. A table providing

different machine sizes and their corresponding estimated annual fuel production and Return on

Investment (ROI) is provided below.

Table of Blest models.

Machine

size

Maximum

community

size

(no. of people)

Amount of plastic

per year

(kg)

Potential annual

fuel production

(litres)

ROI

(min. in years)

NVG 220

200 - 1400

80 300

80 300

NVG 1000

6300

365 000

365 000

NVG 2000

13,000

730 000

730 000

2.25

NVG 4000

26,000

1 460 000

1 460 000

NVG 6000

38,000

2 190 000

2 190 000

1.75

NVG 8000

52,000

2 920 000

2 920 000

1.5

20 tonnes

126,000

7 300 000

7 300 000

1.25

ADDITIONAL OPTIONS

As well as different sizes of machines, different options are available depending on what the

feedstock is and the desired output of fuel is.

1. Film option:

a. Processes film and low-density plastics

2. Refiner option:

a. Inline

i. Produces diesel and gasoline

ii. Uses no extra electricity

iii. Uses no extra labour

b. BOR 20/50

i. Produces gasoline, diesel, kerosene, #2 oil

ii. Uses 1 kWh extra per litre

iii. Extra labour needed

3. PVC option:

a. Processes PVC plastic

b. Outputs salt and oil

c. Extra energy required

Cost Analyses

4. Cold weather kit:

a. Allows operation below specified temperatures

b. Extra energy required

5. Heavy moisture option:

a. Reduces moisture content in very wet materials

b. Extra energy required

PERIPHERALS

As well as the machine sizing to feedstock and machine options, the peripherals need to be sized

to match the needs of the feedstock.

The peripherals include:

Shredder: Takes large materials down in size for the granulator (conveyor to granulator).

Granulator: Reduces the size of material so it will feed properly into the machine

(conveyor from granulator to hopper/feed system).

Fuel storage: Appropriate sizes and types of containers.

COST ANALYSES

Various cost analyses were performed in order to define variables such as cost per litre of

product, cost at different throughputs, as well as general maintenance costs. Results are

provided in the tables below.

Table of average cost per litre of product.

Test #

Kg

processed

Litres

produced

kWh used*

Labour

Cost/litre

64

63

64

24.1

0.504

42

47

54

17.98

0.52

82

79

77

30.22

0.499

75

77

75

29.46

0.5

87

88

82

33.66

0.494

88

88

84

33.66

0.494

92

91

92

34.81

0.497

30

25

32

9.57

0.504

55

56

55

21.43

0.536

10

57

54

56

20.66

0.507

11

43

34

40

13

0.523

12

14

10

18

3.83

0.599

Average cost per litre = $0.515

* This did not account for granulator power (estimated at ~$0.01/litre).

Blest Plastic to Fuel

Temperature

Energy usage per

kg input

Energy cost

@ $0.12/kWh

Labour/litre @

20 kg/hr throughput

on granulator

Labour/litre @

50 kg/hr throughput

on granulator

Labour/litre on

machine @ $18/hr

Cost/litre 20kg/hr

throughput*

Cost/litre 50 kg/hr

throughput*

Cost/litre 150 kg/hr

throughput*

Table of cost calculations at different throughputs.

-1C

0.89 1.1

kWh

$0.11 $0.13

$0.75

$0.30

$0.09

~$0.99

~$0.52

~$0.31

0C

0.92 1.2

kWh

$0.11 $0.14

$0.75

$0.30

$0.09

~$0.995

~$0.525

~$0.31

+20C

0.98 1

kWh

$0.12

$0.75

$0.30

$0.09

~$0.99

~$0.52

~$0.31

* Throughput on granulator is the main labour cost, thus the main consideration on cost per litre.

This cost includes electrical costs for the granulator.

Ambient air temperatures were recorded using a Hobo U30 Data Logger. The minimum recorded

ambient room temperature between 1/21/2013 and 10/31/2013 was -2.073C. The maximum

ambient room temperature in the same time period was +28.593C.

Temperature had little effect on the energy consumption of the machine. In fact, the lowest

energy usage was observed at -1C ambient temperature. The insulation on the machine is

therefore effective at retaining the heat. Furthermore, the reduced energy consumption could

be due to lower usage of the chiller at theses temperatures since the ambient temperature

around the condenser is adequate to chill the pyrolysis gas.

The largest cost is associated with the initial granulating process of the plastic. This cost could

be reduced by installing a shredder before the granulator, as the granulation process is time

consuming. At 150 kg/hr throughput, the cost per litre is reduced to $0.31/litre.

MAINTENANCE COSTS

There are two main components included in the maintenance cost:

1. Cleaning and inspection of the machine: 1 day every 3 months = $960/year @ $30/hr.

This has very little impact on fuel cost. If the machine was running at full output, this

amounts to $0.016/litre

2. Sharpening of the granulator blades: 3 to 4 times/year = $120 = 2/10 of a cent increase

to fuel price.

ENVIRONMENTAL ANALYSES

Yukon Environment was consulted on the project, and since there is no significant waste or

emissions associated with the process, there are no permitting requirements.

Janine Kostelnik, Environment Yukon

it has been determined that the Plastic to Fuel pilot project, is not an

Environmental Analyses

activity that is captured under the Environment Act, or any of the

regulations (Air Emissions, Solid Waste, Special Waste). As such,

we are not able to require emissions testing or any other operational

requirements related to the unit.

However, testing has been completed on all the outputs of the Blest machine. This testing was

completed to the lowest detectable limits available. Four main tests were performed:

1. Off-gas testing was completed in Japan on an identical machine.

2. Fuel-testing was completed by Polaris Laboratories in Calgary, AB.

3. Fuel testing for contaminants was completed by CH2M Hill Applied Sciences Laboratories

in Corvallis, OR.

4. Carbon char contaminant testing was performed by CH2M Hill Applied Sciences

Laboratories in Corvallis, OR.

OFF-GAS TESTING

Off-gas emissions testing was completed by JFE Techno Research Co. Ltd. The samples were

collected in Tetra Teflon coated bags in accordance with JIS standards and tested with MS/GC

methods. Testing was conducted with a standard off-gas filter at 164.9 l/h off-gas output. Results

are as follows:

CO2 emissions amount to 186 g per kg of plastic input.

Methane (CH4) levels were negligible at 10 ppm.

No combustion NOX was produced, and only barely detectable amounts of thermal NOx

were produced.

Table of emissions results.

Emission

Volume

carbon dioxide

6.70%

oxygen

3.61%

CH4

<1 ppm

Polaris Laboratories in Edmonton, as well as

Econo-Tech Labs in Vancouver tested the fuel

produced by the Blest B-240.

C2H4

<1 ppm

C2H6

<1 ppm

The following results were obtained:

C3H8

<1 ppm

C2H9

<1 ppm

FUEL TESTING

Water

The water test measured the total dissolved

water content of the fuel. Early results from

i-C4H10

<1 ppm

testing of the fuel indicated high water content

n-C4H10

<1 ppm

and were likely due to PET contamination in the

cis-2-C4H8

<1 ppm

feedstock. Elimination of the PET resulted in a

reduction in the water content to 0.005%; this

nitrogen oxide

<4 ppm

is well below requirements and specifications

sulphur oxide

<5 ppm

for diesel fuel of 0.02%. This test clearly

demonstrates the need to carefully sort the plastic feedstock prior to processing in the machine.

Copper corrosion

This test indicates if the fuel is corrosive to copper. Testing resulted in a 1a rating. The maximum

Blest Plastic to Fuel

rating set out by ASTM International standards is 3 and therefore the fuel is considered to not be

corrosive to copper.

Pour/plug points

Pour and plug points indicate usability in cold weather conditions. The pour point is -9 to -12C;

below this temperature the fuel will not flow readily. The plug point is -5 to -8C; below this

temperature the fuel will plug a filter. These results were expected, as the fuel produced is a

crude oil. With further refining, the fuel would have a lower pour/plug point. Results indicate

that the fuel is best used indoors or with a heated tank unless it is refined.

Flash point

The flash point measures the minimum temperature at which the fuel vaporizes to form an

ignitable mixture in air. The test results produced a Pensky-Marten flash point of 52C; this is

identical to diesel fuel.

Sulphur

Sulphur concentrations were measured on several samples. One sample indicated a higher-thanexpected sulphur content of 32 ppm; 15 ppm was the expected result. However, one sample had

a measured concentration of sulphur of 12ppm. The higher result was determined to originate

from a run of plastic that had a pipe dope on the threads. Upon examination of the MSDS,

there was a sulphur compound listed on the pipe dope.

1B

1A

1A

pour point

<-5c

-17

-9

-12

plug point

<-5c

-12c

-5

-8

flash point

~52

min. 52

~55

sulphur

<15 ppm

0.01%

12

bacteria

and mold

ash content

0.01%

7

0

100 ppm

-0.01%

viscosity

0.00%

0.00%

1.6

lubricity

<520

monomer

>99.7

305

375

334

99.71

99.88

* Failed result; high-water content due to accidental processing of #1PETE and nylon.

Notes: blank cells = not tested; HDPE = high-density polyethylene; PS = polysterene;

EPS = expanded polysterene; PP = polypropelene

6

Result 6

(PP)

<3

Result 5

(clean, white

EPS)

copper

corrosion

Result 4

(dirty, mixed

PS)

>0.2%*

water

Result 3

(mixed plastic)

<0.02%

Analysis

Result 2

(HDPE)

Desired

result

Result 1

(mixed plastic)

Table of fuel testing results.

Environmental Analyses

Testing has indicated that feedstock types affect the quality of the fuel output. Plastics that

are not recommended can affect fuel quality such as PET#1 which produces water. Plastic type

#4 LDPE was not tested because this would require a film option on the machine, which was

not available at the time of purchase of the test pilot machine. The low density of LDPE causes

feeding problems without the film option.

OUTPUT CONTAMINANT TESTING

Contaminant testing

Fuel testing for concentrations of various contaminants and volatiles were measured by CH2M

Hill Applied Science Laboratories. The results are provided in the following tables.

Table of contaminant testing results.

Contaminant

Concentration (ppm)

Detection limit

arsenic

0.03

below detection limit

barium

0.017

below detection limit

cadmium

0.008

none detected

chromium

13.3

from pipe dope

lead

0.35

from pipe dope

mercury

0.000

undetected

selenium

0.029

undetected

silver

0.092

undetected

With the exception of chromium and lead, all values were either none detected (U) or below the

detection limit (J). The higher chromium and lead values were found to be due to a test sample

consisting of well pipe caps from a natural gas facility. These pipe caps had a thread dope applied

on the plastic; the MSDS indicated chromium and lead constituents in the thread dope.

Fuel volatiles testing

Testing for fuel volatiles was performed by gas spectrometry and mass spectrometer analyses.

Results are provided in the following table.

Table of fuel volatiles testing results.

Volatile compound

Fuel sample

Carbon char sample

vinyl chloride

undetectable

undetectable

1,1-dichloroethene

undetectable

undetectable

2-butonone

undetectable

undetectable

chloroform

undetectable

undetectable

1,2-dichloroethane

undetectable

undetectable

carbon tetrachloride

undetectable

undetectable

benzene

undetectable

undetectable

trichloroethene

undetectable

undetectable

tetrachloroethene

undetectable

undetectable

Blest Plastic to Fuel

Table of fuel volatiles testing results, continued.

Volatile compound

Fuel sample

Carbon char sample

chlorobenzene

undetectable

undetectable

1,4-dichlorobenzene

undetectable

undetectable

hexachlorobutadiene

undetectable

undetectable

INTERNAL COMBUSTION ENGINE TESTING

The fuel was tested on an engine-driven generator (generator type: ME-531A /2kW 120V; fuel

consumption: 0.946 litre/hr). Results of this test are as follows:

Table of internal combustion engine testing.

baseline

diesel

running

on plastic

fuel

O2 (%)

CO

(ppm)

NO

(ppm)

NOx

(ppm)

NO2

(ppm)

SO2

(ppm)

CO2

(ppm)

21

129

10

1.4

19.8

77

11

This test demonstrated that the emissions from the engine were similar to, or lower than

running on regular diesel fuel.

PROCESSING EXPANDED POLYSTYRENE (EPS)

Due to the low specific gravity of EPS, the machine cannot handle this material unless it is

densified. A densifier for EPS costs ~$6,000 to $24,000 depending on size requirements.

Densified EPS can be processed in the machine to produce styrene monomers. The value

of these monomers fluctuates and can be up to $1,800/tonne ($1.80/litre). Shipping costs

are $100/tonne, making these monomers potentially the most valuable recyclable material.

However, chemical brokers were contacted and required a minimum quantity of 90 barrels.

This would take 3 months of production to fulfill this order with the current machine; however,

an NVG 5000 machine could produce 90 barrels in 4 days. This limits the usefulness of styrene

monomer production to the larger centres that have ready access to shipping terminals.

Markets for the monomers are primarily polysterene (PS) manufacturers located in large centres.

The manufacturers that would most likely buy the product are foam extruders that make

insulation materials for the construction industry. Some of these manufacturers are located in

Edmonton, Vancouver and Anchorage.

Styrene monomers rapidly degrade into dimers and trimers without the addition of chilling,

circulation and stabilizers. Unstabilized monomers would need to be shipped out within 2 to 3

weeks to reduce storage costs associated with chilling, circulation and stabilization.

EPS FOAM QUALITY

Unlike traditional EPS recycling, the machine will handle any quality of foam. Dirty or coloured

foam should not affect the quality of the monomers produced. This is a benefit that allows the

Comparing Recycling to Plastic-to-Fuel Processing

processing of foam that is currently not accepted by traditional recyclers. The styrene monomers

produced could then be utilized to make new EPS of equal or greater quality. This is unlike

traditional EPS recycling that downgrades the product into a less useful and less recyclable form.

COMPARING RECYCLING TO PLASTIC-TO-FUEL PROCESSING

Recycling of plastic requires sorting, granulating, washing and pelletizing the resin in order to

use it as feedstock for new plastic. In the broadest sense, this is putting the plastic back into the

production loop.

Realistically, the plastic is also down-cycled in the process. This is something that occurs when

the plastic resins produced are of a lower quality than the original material. For example,

different resins of plastic can be mixed together and the new hybrid product is of a lower quality

than the original plastic.

In order to achieve the highest quality possible in the new plastic, careful sorting of the resins is

necessary in order to reduce contamination. As well, due to Chinas Green Fence policy, mixed

plastics that are uneconomical to recycle are now being landfilled or incinerated in a waste-toenergy plant. The cost of this disposal is being charged to the shipper of these uneconomical

plastics (i.e., #3 to#7) at a rate of up to $237/tonne.

We are now only accepting HDPE (#2) and PETE (#1). Do not send us any

mixed plastics anymore, we will have to charge you a disposal fee of

$237/tonne if you do recycling buyer, Vancouver.

Since Chinas green fence policy, 1/3 of our plastic recycling is going to

the landfill as we have no markets for it unnamed Vancouver area recycling

company that is considering a plastic-to-fuel machine to deal with this waste.

With the plastic-to-fuel process, the plastic is being up-cycled. Up-cycling is a process where the

material is made into a product of greater quality and/or lower environmental consequence.

Furthermore, up-cycling often results in an increase in the monetary value of the product. Upcycling is considered an important aspect of a zero-waste initiative.

The fuel produced could be used as a feedstock to make synthetic plastic of greater quality

compared with the original feedstock. However, it is important to note that the goal of this pilot

project is to reduce the import of fossil fuels and thus to produce fuels that could be used locally

as heating fuel.

ENERGY USAGE

Localized processing of materials reduces energy usage by about 25% compared to outsourcing

the processing elsewhere.

CO2 EMISSIONS

In addition to a reduction in energy consumption, CO2 emissions are dramatically reduced

making the process a carbon-reducing technology that is certified by the United Nations

Environment Program.

A comparison of the energy usage and CO2 emissions from conventional recycling methods

versus plastic to fuel is presented in the following tables.

Blest Plastic to Fuel

Table of energy usage comparing conventional recycling vs. plastic to fuel.

Recycling

Plastic to fuel

4735 btu/kg energy used to recycle plastic

3412 btu/kg plastic to fuel energy used

1852 btu/kg transport of plastic to Vancouver

-3704 btu displaced fuel shipment

1852 btu/l oil shipped to Yukon

7576 produce virgin plastic

1852 btu/l empty oil truck returning south

1852 transport new plastic to Yukon as products

1852 btu/kg transport recycled plastic to Yukon

as products

Total energy consumption:

Total energy consumption:

12,143 btu/kg

9,136 btu/kg

to recycle plastic and import fuel

to convert plastic to fuel and produce new plastic

Table of CO2 emissions of recycling vs. plastic to fuel.

Recycling

Plastic to fuel

3.500 kg/kg plastic

0.186 kg/kg plastic

REMOTE ACCESS

Fully operational remote monitoring and control of the B-240 was installed and tested. Full

functionality has been obtained with the remote access. This was beyond what was expected,

as we understood the remote access would be monitoring only and not actual operation of the

unit.

The Soft Got software and secure LogmeIn application allow the machine functions to be

operated through a secure Internet connection.

This feature is coupled with an independently connected wireless security camera that allows

critical components on the machine to be monitored visually.

RECOMMENDATIONS FOR REMOTE ACCESS

Install the remote-access feature as it allows greater ease in troubleshooting and

supervision.

Install more cameras, as they are inexpensive and easy to deploy/operate (i.e., 1 on load

cell/extruder, 1 on off take tank, 1 on conveyor hopper, and 1 in general area).

The camera utilized allows for video recording to a memory card as well as installation

of a speaker to enable 2-way communication between the operator and a remote

supervisor. This would allow low-skill operators to be completing everyday tasks and a

high-skilled supervisor to be overseeing the operation on multiple machines

CONTAINERIZATION

If the machine would be set up as a mobile unit in a trailer or container to travel between

various communities, some changes would be required. Containerization of the machine would

10

Containerization

require some redesign of the components. The items that would need to be addressed and their

corresponding solutions are as follows:

Power supply

Issue: the need for an adequate power supply at remote sites

Solution 1: install a 3-phase generator utilizing 30% of fuel produced (cost of ~$18,000)

Solution 2: install decontactor 3-phase, 200-amp plug (requires 3-phase power at each

site; cost of ~$3000 to $20,000)

Glass glycol tubes

Issue: the fragile Pyrex glass could be damaged

Solution: replace Pyrex glass with stainless steel and sight glass (cost of ~$0 if installed at

factory)

Glycol reservoir

Issue: loose-fitting lid that is designed for stationary use; movement could result in

spillage

Solution: weld on spill-proof top and vent tube/filler cap (cost of ~$0 if installed at

factory)

Glycol chiller

Issue: loose-fitting lid that is designed for stationary use; movement could result in

spillage

Solution: replace with closed-loop refrigeration unit such as is used in commercial

refrigerators (cost of ~$4000)

Load cell scale

Issue: sensitive equipment

Solution: remove and secure during transport; recalibrate upon setup

Off take tank

Issue: full of fuel

Solution: empty before transport

Reactor and buffer tank hangers

Issue: transport could put strain on fittings

Solution: add shock absorbers to limit lateral movement (cost of ~$400)

Levelling

Issue: machine designed to be operated on a level surface

Solution: install levelling devices to container/trailer (cost of ~$9000)

11

Blest Plastic to Fuel

Molten plastic in reactor

Issue: splashing during transport

Solution: add a sensor to lock levelling devices and lock brakes when reactor is above

75C (plastic will be solid below this temperature); this will prevent movement of the

system when it is unsafe to do so (cost of ~$5000)

Some of these modifications could be fitted on a new machine from the factory or retrofitted at

a later date. All of the above modifications are easy to implement.

As the scalability of the machine allows operation in small communities, it is recommended that

rather than one mobile machine, several stationary machines should be utilized. This would

reduce labour costs, as an operator does not need to travel with the machine. The operator of a

mobile machine would need to stay in the area for day-to-day operations, but these operations

only take 1 to 2 hours per day. If a local operator would be used, their work would be so

infrequent that re-training would be necessary with every visit.

Remote communities that are accessible by ship or road, but having no facilities with which

to house the machine would benefit from the unit being set up (all peripherals installed) in a

shipping container so the operation is turn-key and ready to operate at the install site.

COMMUNITY SIZE AND FEASIBILITY

The national average for disposal of plastic is 58 kg per person per year. A production analysis

was estimated for Yukon communities and is summarized in the following table.

Table of production analysis for Yukon communities.

Community

Population

Average plastic

recycling in kg per

capita/annum*

Days of production

per

community/annum

Beaver Creek

100

5800

26

Burwash Landing

90

5220

24

Carmacks

519

30 102

136

Dawson City

2010

116 580

116 (NVG 1000)

Carcross/Tagish

437

25 346

115

Faro

390

22 620

102

Haines Junction

864

50 112

228

Mayo

487

28 246

128

Old Crow

249

14 442

65

Pelly Crossing

348

20 184

92

Ross River

378

21 924

100

Teslin

459

26 622

121

Watson Lake

1,495

86 710

365

Whitehorse

28,033

1 625 914

325 (NVG 5000)

Notes: NVG 220 sized unless otherwise stated

NVG 1000 processes 1000 kg/day

NVG 5000 processes 5000 kg/day

12

Factors Affecting Operations

A mobile version of the machine would be best mounted on a truck or a trailer unless it

is destined for a barge-in/fly-in community, where an install in an existing warehouse or a

container is recommended.

The biggest challenges of mobile units are:

Having trained operators in each community, as well as keeping those trained operators

current on the operation of the machine when it is only needed in the community 15 to

20 days out of the year. However, this issue may be resolved by having supervision from

a central location whereby instant communication to assist in operations can be set up

over secure Internet connections.

Keeping the feedstock consistent and within the accepted parameters. This will require

careful sorting of the feedstock by facility staff.

POPULATION CONSIDERATIONS

The Blest machine would be feasible to operate in a remote community with a population of 200

or more, unless there is another source of plastic such as beach clean-up operations. This would

provide a reasonable payback period on the machine as well as provide local employment and

a local source of fuel. Additionally, less waste will need to be dealt with through incineration or

landfilling processes. The Return on Investment (ROI) is a simple calculation, but does not take

into account disposal costs as these vary by community.

Table of ROI based on community population.

Minimum

days of

operation

per year*

Potential

output of

fuel

(litres/year)

Size of

machine

Value of fuel

(@ $1.20/

litre)

Simple ROI

(years)

200

52

11,600

NVG 220

$13,920

21.5

500

131

42,500

NVG 220

$51,000

5.88

1000

263

85,000

NVG 220

$102,000

2.94

1800

104

153,000

NVG 1000

$183,600

3.26

2,300

133

195,500

NVG 1000

$234,600

2.55

6,700

194

569,500

NVG 2000

$683,400

1.46

20000

232

1,700,000

NVG 5000

$2,040,000

0.98

Community

population

* Assuming ~128 pounds plastic/person/year

FACTORS AFFECTING OPERATIONS

Numerous factors associated with the operations of the machine were observed and recorded.

These factors are outlined below.

HUMIDITY OF FEEDSTOCK

Humidity (moisture) levels in the feedstock can have an effect on the energy consumption of

the machine. This is due to the need for the moisture to be processed off the plastic during

processing. Three settings are available on the machine:

Normal: for up to 2% moisture

Medium: 2% to 5%

High: 5% to 10%

13

Blest Plastic to Fuel

Eight random samples of plastic were tested and found to have between 0% and 2.8% moisture

content.

Calibration for moisture

Proper calibration was achieved with pre-programmed options.

PLASTIC TYPES

The Blest machine is designed to accept polypropylene, polyethylene and polystyrene types of

plastics. These are better known as #2, #4, #5 and #6 resin codes. Within these parameters, the

Blest machine functioned as expected. Issues were identified when non-acceptable plastic types

were processed. These included:

Nylon: The Nylon containing plastics, which is found in some brands of juice containers

(#5 and #7 resin code) produced whitish grease, which caused a buildup in the

condenser. This causes the machine to back up and stop producing fuel.

PETE: The PETE (found in #1 resin code) sublimates into a solid at temperatures

below the operating temperatures of the machine. This accumulates as a grey semisolid material in the buffer tank. When PETE is processed it produces 50% H2O that

accumulates in the extruder as well as in the fuel. This eventually stops the machine

from accepting plastic in the extruder.

Calibration for plastic type

Within the normal range of feedstock encountered, the pre-set calibrations were adequate to

process all of the acceptable plastics.

FUEL OUTPUT QUALITY

The quality of fuel output can be optimized by various temperature adjustments as well as

feedstock.

Adjustments for fuel output quality

It was observed that at temperatures above 450C, the fuel darkened considerably. This is due

to the heavy oil components having a higher temperature needed for cracking. When the

adjustments were kept at 430C, the fuel output had a light, golden-yellow colour.

FEEDSTOCK

Proper sorting of the plastic is necessary in order to minimize downtime with the machine.

This includes removal of all PETE #1 and other #7 resins. Primarily we are targeting #4, #5 and

#6 resins, as well as some #2 resins that are not accepted in the recycling markets (e.g., oil

containers and pharmaceutical containers).

AMBIENT TEMPERATURES

A data logger was used to monitor ambient temperatures and correlate this to energy usage by

the machine. It was expected that the energy usage would increase with decreases in ambient

temperatures; however, this was found to have a minimal effect. At -1C, we actually observed

some of the highest efficiencies at 0.89 kWh + 1 kg plastic to 1 litre fuel. Efficiencies ranged from

0.89 kWh to 1.2 kWh/kg/litre

14

Troubleshooting/Repairs

Ambient temperatures encountered

The coldest temperature encountered in the facility was -1.76C. The warmest temperature

encountered was +26.9C.

Cold temperature operating guidelines

Feedstock

To optimize production in cold temperatures:

1. Ensure snow/ice is removed as much as possible from the plastic before processing.

2. If available, keep the plastic in a heated space to melt the ice/snow before processing.

FUEL OUTPUT

The unrefined fuel generated by this machine will start to gel at -20C. If ambient temperatures

colder than 0C are encountered in the area, a cold-weather optimizing kit is recommended

by Blest. This involves the installation of heating coils on the various parts of the off-take tank.

These heating coils can be purchased locally and installed on site.

Fuel output is maximized when proper feedstock is used in the machine. Shutdown for

maintenance is necessary when unacceptable resins are processed.

TROUBLESHOOTING/REPAIRS

Some changes and modifications were performed to enhance the operation of the machine.

These included:

Vibrator on the storage chamber: this eliminated bridging problems that were

encountered with some types of plastics.

Centre core on the screw auger: this facilitated transport of fine material.

Extruder feed cone: this facilitated processing of low specific gravity materials.

Reprogramming conveyor stops: this allowed the machine to turn off when the hopper

was empty of plastic.

Reprogramming scale stops: this allowed the machine to turn off in the event of a

backup in the extruder.

Nitrogen purge valve: this reduced nitrogen consumption during shutdown periods.

Condenser trap: this allowed easier cleaning of the condenser residues.

Deluxe off-gas filter: this reduced odours that were detected during start-up of the

operation. Pyrite gasses are reduced to 10 ppm from 50 ppm.

One item is still to be installed:

Rheostat to slow feed auger: this would allow better processing of low specific gravity

materials. This part is currently being shipped from Japan.

15

Blest Plastic to Fuel

BIBLIOGRAPHY

Bury, D., 2011. Plastics Recovery in Canadian EPR. Plastics Recycling Update; http://www.

duncanburyconsulting.ca/_documents/Plastics%20Recycling%20Update%20PRU_

Feb11Bury.pdf; [accessed November, 2013].

Government of Yukon, 2009. Communities. Government of Yukon; http://www.gov.yk.ca/

aboutyukon/communities.html; [accessed November, 2013].

Guilford, G., 2013. A lot of US plastic isnt actually being recycled since China put up its Green

Fence. Quartz; http://qz.com/122003/plastic-recycling-china-green-fence/#122003/plasticrecycling-china-green-fence; [accessed November, 2013].

Sheehan, J., Camobreco, V., Duffield, J., Graboski, M. and Shapouri, H., 2000. An Overview of

Biodiesel and Petroleum Diesel Life Cycles. National Energy Renewables Laboratory (NREL);

http://www.nrel.gov/docs/legosti/fy98/24772.pdf; [accessed November, 2013].

The Cambridge-MIT Institute, 2005. The ImpEE (Improving Engineering Education) Project:

Recycling of Plastics. University of Cambridge; http://www-g.eng.cam.ac.uk/impee/topics/

RecyclePlastics/files/Recycling%20Plastic%20v3%20PDF.pdf; [accessed November, 2013].

United States Environmental Protection Agency (US EPA), Office of Solid Waste and Emergency

Response (OSWER), Office of Resource Conservation and Recovery, 2010. Waste Reduction

Model. United States Environmental Protection Agency (US EPA); http://www.epa.gov/

climatechange/wycd/waste/downloads/plastics-chapter10-28-10.pdf; [accessed November,

2013].

Yamashitak, K., Kumagai, K., Noguchi, M., Yamamoto, N., Ni, Y., Mizukoshi, A. and Yanagisawa, Y.,

2007. VOC emissions from waste plastics during melting processes. The 6th International

Conference on Indoor Air Quality, Ventilation & Energy Conservation in Buildings, IAQVEC

2007, Oct. 28 - 31 2007, Sendai, Japan; http://www.inive.org/members_area/medias/pdf/

Inive/IAQVEC2007/Yamashita.pdf; [accessed November, 2013].

16

Вам также может понравиться

- ANZ Plastic Waste ManagementДокумент19 страницANZ Plastic Waste ManagementGustavosalazarmОценок пока нет

- Vishwaniketan Institute of Management, Entrepreneurship and Engineering Technology KHALAPUR-410202Документ12 страницVishwaniketan Institute of Management, Entrepreneurship and Engineering Technology KHALAPUR-410202piyush sapkalОценок пока нет

- Ecp 101Документ12 страницEcp 101onejako12Оценок пока нет

- RUDRA ENVIORNMENTAL SOLUTION (INDIA) LTD. Established On29th July 2009. SinceДокумент6 страницRUDRA ENVIORNMENTAL SOLUTION (INDIA) LTD. Established On29th July 2009. SinceAbhay ThakurОценок пока нет

- Biogas Re Powerplant 42013 GasДокумент55 страницBiogas Re Powerplant 42013 GaszmahfudzОценок пока нет

- Plastic Waste ManagementДокумент20 страницPlastic Waste Managementhappy2009yОценок пока нет

- Cage Culture of FishesДокумент31 страницаCage Culture of FishesEd DanОценок пока нет

- FYP PropsalДокумент17 страницFYP PropsalusamaОценок пока нет

- 2014 Energy and Exergy Analyses of Solar Drying System of Red SeaweedДокумент9 страниц2014 Energy and Exergy Analyses of Solar Drying System of Red SeaweedasifzardaniОценок пока нет

- Sewage Sludge Management in Germany PDFДокумент104 страницыSewage Sludge Management in Germany PDFKenaia AdeleyeОценок пока нет

- Environmental and Economic Analysis of Emerging Plastics Conversion TechnologiesДокумент70 страницEnvironmental and Economic Analysis of Emerging Plastics Conversion TechnologiesHenry JeyssonОценок пока нет

- Acknowledgement: Dr. V. K. JANARDHANAN, For The Facilities Rendered For The Progress of Our ProjectДокумент23 страницыAcknowledgement: Dr. V. K. JANARDHANAN, For The Facilities Rendered For The Progress of Our ProjectAkashPrakash100% (1)

- Tyre Pyrolysis Plant CalculationsДокумент2 страницыTyre Pyrolysis Plant CalculationsTarun GuptaОценок пока нет

- Pyrolysis 2014017017 ChelseaДокумент24 страницыPyrolysis 2014017017 ChelseaerkiruthirajОценок пока нет

- 9 4 Sludge DryingДокумент17 страниц9 4 Sludge Dryingkosmc123Оценок пока нет

- 10.1.1.686.8585 Life Cycle BHD BiodieselДокумент6 страниц10.1.1.686.8585 Life Cycle BHD BiodieselphimentОценок пока нет

- Tyre Pyrolysis Plant: EquipmentsДокумент18 страницTyre Pyrolysis Plant: EquipmentsSanthosh KtiОценок пока нет

- Executive Summary: NACES 2015 - Plant DesignДокумент2 страницыExecutive Summary: NACES 2015 - Plant DesignVentrue LeongОценок пока нет

- 1bottles Group Production of Bisphenol-AДокумент112 страниц1bottles Group Production of Bisphenol-AJames BelciñaОценок пока нет

- Approved CNG KitsДокумент1 страницаApproved CNG KitsAbdullah TahirОценок пока нет

- Running A Biogas Programme PDFДокумент199 страницRunning A Biogas Programme PDFparamjeetОценок пока нет

- Ahsan Agro RAS Catfish - High DensityДокумент1 страницаAhsan Agro RAS Catfish - High DensityFortaengineering FortaenviroОценок пока нет

- Brochure Movialsa Gasification Plant EnglishДокумент0 страницBrochure Movialsa Gasification Plant EnglishApri ApriyantoОценок пока нет

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupДокумент2 страницыWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilОценок пока нет

- Chances For BioLNG Article Versie 41Документ9 страницChances For BioLNG Article Versie 41HemalJagodageОценок пока нет

- 5.01 Biomass and Biofuels - IntroductionДокумент9 страниц5.01 Biomass and Biofuels - IntroductionRhita RayОценок пока нет

- Waste Energy Plastic 3Документ3 страницыWaste Energy Plastic 3Jorge Alejandro DelaVega Lozano100% (2)

- Incineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987От EverandIncineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987Robert B. DeanОценок пока нет

- Methane ManureДокумент151 страницаMethane ManuretdamgacıОценок пока нет

- Biotech New Normal Agribusiness Final v2Документ36 страницBiotech New Normal Agribusiness Final v2Bidur Prasad ChaulagainОценок пока нет

- Zero Waste Approach From Scrap Tyre Recycling Major Project ReportДокумент10 страницZero Waste Approach From Scrap Tyre Recycling Major Project Reportsinghsanjeev0Оценок пока нет

- Extraction of Methane From Biogas - FinalДокумент23 страницыExtraction of Methane From Biogas - FinaldhanushОценок пока нет

- Biogas Production by Co-Digestion of Cassava Peels With UreaДокумент3 страницыBiogas Production by Co-Digestion of Cassava Peels With UreaInnovative Research PublicationsОценок пока нет

- Bioplastics: Centre T Hnol M LL R D University D Lhi IndiДокумент13 страницBioplastics: Centre T Hnol M LL R D University D Lhi IndiTino RodriguezОценок пока нет

- 12 Things To Consider While Selecting Pyrolysis Plant SupplierДокумент1 страница12 Things To Consider While Selecting Pyrolysis Plant SupplierdaresavioОценок пока нет

- Approaches To Incinerator Selection and DesignДокумент83 страницыApproaches To Incinerator Selection and DesignAbu Izzan Al BunyОценок пока нет

- Appendix A - Co-Digestion ModelДокумент107 страницAppendix A - Co-Digestion ModelAnonymous MVHQ97KEoPОценок пока нет

- Design, Construction and Maintenance of A Biogas GeneratorДокумент23 страницыDesign, Construction and Maintenance of A Biogas GeneratorOxfamОценок пока нет

- Iso 13690 1999 FR PDFДокумент8 страницIso 13690 1999 FR PDFAlfonso RecioОценок пока нет

- Plastic Tyre PyrolysisДокумент1 страницаPlastic Tyre PyrolysisDharamОценок пока нет

- Study On The Thermal Pyrolysis of Medical Waste (Plastic Syringe) For The Production of Useful Liquid Fuels PDFДокумент53 страницыStudy On The Thermal Pyrolysis of Medical Waste (Plastic Syringe) For The Production of Useful Liquid Fuels PDFraihonaОценок пока нет

- Biogas Compressor Project PDFДокумент72 страницыBiogas Compressor Project PDFJavier LerinОценок пока нет

- Activated Carbon - Granular (: Coconut Shell Charcoal Base) Specification of The ProductДокумент1 страницаActivated Carbon - Granular (: Coconut Shell Charcoal Base) Specification of The ProductkumarОценок пока нет

- Evaluation of Biochar Production Systems: ERG 211 - Renewable Energy and Green Technology Experiment Cycle IiДокумент11 страницEvaluation of Biochar Production Systems: ERG 211 - Renewable Energy and Green Technology Experiment Cycle IiDr. Kiruthika RajamanickamОценок пока нет

- Machines ManufacturerДокумент6 страницMachines ManufacturerArasan ArasanОценок пока нет

- Pyrolysis Plant BrochureДокумент7 страницPyrolysis Plant BrochureManojj NatarrajanОценок пока нет

- Project Report For Pyrolysis of Scrap Tire (A Waste To Energy Project)Документ17 страницProject Report For Pyrolysis of Scrap Tire (A Waste To Energy Project)Qazi AhmedОценок пока нет

- Polyethylene Demand & SupplyДокумент4 страницыPolyethylene Demand & Supplysadam_madas2050% (2)

- Biogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Документ17 страницBiogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Madhav Mohan100% (1)

- 1.0 Project Background: WWW - Gam-Rd - Co.inДокумент17 страниц1.0 Project Background: WWW - Gam-Rd - Co.inljsflj alsfjoiОценок пока нет

- Subjectiveandobjectivefoodtech Contents1Документ8 страницSubjectiveandobjectivefoodtech Contents1Tulasi0% (1)

- PlasticsEurope Eco-Profile VCM PVCДокумент48 страницPlasticsEurope Eco-Profile VCM PVCABC100% (1)

- Biomass Power Plants Final2Документ34 страницыBiomass Power Plants Final2Abdulhadi EliasОценок пока нет

- Reactor Designforthe Conversionof Waste Plasticinto Fuel Oiland GasДокумент84 страницыReactor Designforthe Conversionof Waste Plasticinto Fuel Oiland GasMeetu KaurОценок пока нет

- 2009 - Review of Pyrolyisis Platform For Coproducing Bio-Oil and BiocharДокумент16 страниц2009 - Review of Pyrolyisis Platform For Coproducing Bio-Oil and BiocharapitbhuОценок пока нет

- Production of Plaster of Paris Using Solar EnergyДокумент4 страницыProduction of Plaster of Paris Using Solar EnergyesatjournalsОценок пока нет

- Design ManualДокумент41 страницаDesign ManualNikolas PapadopoulosОценок пока нет

- Polylactic Acid (PLA) - A Global Market Watch, 2011 - 2016 - BroucherДокумент4 страницыPolylactic Acid (PLA) - A Global Market Watch, 2011 - 2016 - BroucherAxis ResearchMindОценок пока нет

- Aiim - Part IIДокумент8 страницAiim - Part IIarnabjyoti dasОценок пока нет

- CHAP 6 - Vocab PDFДокумент7 страницCHAP 6 - Vocab PDFarnabjyoti dasОценок пока нет

- Session 6 - Leveraging Land - Bangalore Mysore Infrastructure Corridor ProjectДокумент41 страницаSession 6 - Leveraging Land - Bangalore Mysore Infrastructure Corridor Projectarnabjyoti dasОценок пока нет

- Chinese C C II - SCДокумент13 страницChinese C C II - SCarnabjyoti dasОценок пока нет

- MArketing ResearchДокумент19 страницMArketing Researcharnabjyoti dasОценок пока нет

- DocumentДокумент1 страницаDocumentarnabjyoti dasОценок пока нет

- Container Policy and CTOs 22april 2011Документ44 страницыContainer Policy and CTOs 22april 2011arnabjyoti dasОценок пока нет

- Indore City Bus TRNSPT Service - CIPR0003 (B)Документ33 страницыIndore City Bus TRNSPT Service - CIPR0003 (B)arnabjyoti dasОценок пока нет

- India Budget Analysis 2016 - EninconДокумент12 страницIndia Budget Analysis 2016 - Eninconarnabjyoti dasОценок пока нет

- MArketing ResearchДокумент19 страницMArketing Researcharnabjyoti dasОценок пока нет

- Introduction: What Is Macroeconomics All About?Документ21 страницаIntroduction: What Is Macroeconomics All About?arnabjyoti dasОценок пока нет

- Session 4 - National Income and Inflation - Part AДокумент21 страницаSession 4 - National Income and Inflation - Part Aarnabjyoti dasОценок пока нет

- Private Equity CareersДокумент21 страницаPrivate Equity Careersarnabjyoti dasОценок пока нет

- MacДокумент5 страницMacarnabjyoti dasОценок пока нет

- Process Flow Chart 10TPD Plant PDFДокумент1 страницаProcess Flow Chart 10TPD Plant PDFarnabjyoti dasОценок пока нет

- Sec2 8 PDFДокумент3 страницыSec2 8 PDFpolistaОценок пока нет

- Auto Report LogДокумент3 страницыAuto Report LogDaniel LermaОценок пока нет

- Ucbackup Faq - Commvault: GeneralДокумент8 страницUcbackup Faq - Commvault: GeneralhherОценок пока нет

- On Applied EthicsДокумент34 страницыOn Applied Ethicsamanpatel78667% (3)

- LISTA Nascar 2014Документ42 страницыLISTA Nascar 2014osmarxsОценок пока нет

- 19-2 Clericis LaicosДокумент3 страницы19-2 Clericis LaicosC C Bờm BờmОценок пока нет

- Ewellery Ndustry: Presentation OnДокумент26 страницEwellery Ndustry: Presentation Onharishgnr0% (1)

- Learner Guide HDB Resale Procedure and Financial Plan - V2Документ0 страницLearner Guide HDB Resale Procedure and Financial Plan - V2wangks1980Оценок пока нет

- SKF LGMT-2 Data SheetДокумент2 страницыSKF LGMT-2 Data SheetRahul SharmaОценок пока нет

- Land Degradetion NarmДокумент15 страницLand Degradetion NarmAbdikafar Adan AbdullahiОценок пока нет

- Deshidratador Serie MDQДокумент4 страницыDeshidratador Serie MDQDAIROОценок пока нет

- Eclipsecon MQTT Dashboard SessionДокумент82 страницыEclipsecon MQTT Dashboard Sessionoscar.diciomma8446Оценок пока нет

- Revenue Management Session 1: Introduction To Pricing OptimizationДокумент55 страницRevenue Management Session 1: Introduction To Pricing OptimizationDuc NguyenОценок пока нет

- Kuper ManualДокумент335 страницKuper Manualdonkey slap100% (1)

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Документ6 страницType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheОценок пока нет

- Global Review Solar Tower Technology PDFДокумент43 страницыGlobal Review Solar Tower Technology PDFmohit tailorОценок пока нет

- The Fundamentals of Investing PPT 2.4.4.G1Документ36 страницThe Fundamentals of Investing PPT 2.4.4.G1Lùh HùñçhòОценок пока нет

- 7933-Article Text-35363-1-10-20230724Документ8 страниц7933-Article Text-35363-1-10-20230724Ridho HidayatОценок пока нет

- Chapter 1.4Документ11 страницChapter 1.4Gie AndalОценок пока нет

- Catalogue of The Herbert Allen Collection of English PorcelainДокумент298 страницCatalogue of The Herbert Allen Collection of English PorcelainPuiu Vasile ChiojdoiuОценок пока нет

- Admission Notice: Weekend Masters Program (WMES)Документ4 страницыAdmission Notice: Weekend Masters Program (WMES)masud100% (1)

- Ss1169 - Telecom Frameworx l1TMFДокумент65 страницSs1169 - Telecom Frameworx l1TMFPrince SinghОценок пока нет

- TENDER DOSSIER - Odweyne Water PanДокумент15 страницTENDER DOSSIER - Odweyne Water PanMukhtar Case2022Оценок пока нет

- NYLJtuesday BДокумент28 страницNYLJtuesday BPhilip Scofield50% (2)

- List of Light Commercial LED CodesДокумент8 страницList of Light Commercial LED CodesRenan GonzalezОценок пока нет

- 3.1 Radiation in Class Exercises IIДокумент2 страницы3.1 Radiation in Class Exercises IIPabloОценок пока нет

- Musings On A Rodin CoilДокумент2 страницыMusings On A Rodin CoilWFSCAO100% (1)

- Software Testing Notes Prepared by Mrs. R. Swetha M.E Unit I - Introduction at The End of This Unit, The Student Will Be Able ToДокумент30 страницSoftware Testing Notes Prepared by Mrs. R. Swetha M.E Unit I - Introduction at The End of This Unit, The Student Will Be Able ToKabilan NarashimhanОценок пока нет

- POM 3.2 Marketing Management IIДокумент37 страницPOM 3.2 Marketing Management IIDhiraj SharmaОценок пока нет

- Giuliani Letter To Sen. GrahamДокумент4 страницыGiuliani Letter To Sen. GrahamFox News83% (12)