Академический Документы

Профессиональный Документы

Культура Документы

50 190 RC e 03100

Загружено:

ThirukkumaranBalasubramanianОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

50 190 RC e 03100

Загружено:

ThirukkumaranBalasubramanianАвторское право:

Доступные форматы

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas

Ltd

Snamprogett

i

ABB Lummus Malta

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-65-X-O-19VA 01

CTR Job No.

CTR Doc. No.

310300

50 190-RC-E-03100

Plant

MELLITAH PLANT

Location

Sh.

GSPLAJ

of

P1

P2

P3

Rev.

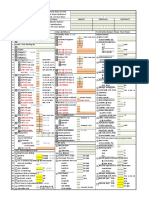

VESSEL DATA SHEET

1

SERVICE

INLET GAS SLUG CATCHER K.O. DRUM

Rev.

ITEM

50-190-VA-001 (*) (10)

DESIGN DATA

DESIGN CODE

DESIGN TEMPERATURE

ASME STAMP

OPERATING TEMPERATURE

MIN / NORM / MAX

14/29

OPERATING PRESSURE

MIN / NORM / MAX

41.9

bar (g)

MAX ALLOWABLE WORKING PRESSURE

DESIGN EXTERNAL PRESSURE

70

MIN DESIGN METAL TEMPERATURE

10

FLUID TYPE

11

(19)

DESIGN INTERNAL PRESSURE

88

bar (g)

bar (g)

-29 (14)

bar

AT A TEMPERATURE OF

AT A PRESSURE OF

C

88

bar (g)

RAW GAS (HC+WATER+CO2+H2S)

LETHAL FLUID

(15)

H2 PARTIAL PRESSURE

CAUSTIC FLUID

12 FLUID DENSITY AT OPERATING CONDITION

13

MIN / NORM / MAX

INTERNAL PAINTING

14

THERMAL INSULATION

15

ELEV. ABOVE GROUND

bar (a)

650

kg/m

EXTERNAL PAINTING

I

MIN.

mm

PP

INSULATION THICKNESS

HEADS TYPE

16

hemispherical

mm

X

PWHT

(16)

MATERIALS

17

SHELL

(16)

18

INTERNALS

(16)

19

FLANGES

SUPPORTS

20

NOZZLE NECK FROM PIPE

INTERNAL BOLTING

21

NOZZLE NECK FROM PLATE

(18)

CS (NACE)

STUD BOLTS

SS 316L (NACE)

NUTS

GASKETS

22

23 CORROSION ALLOW.

mm

24 CLADDING THK.

mm

25 INTERNAL LINING THK.

mm

26

SHELL

HEAD

LOADS AT SUPPORT BASE

27

ERECTION

28

29

N-m

30

31

OPERATING

JOINT EFFIC.

SHELL

HEAD

X RAY EXAM.

HYDROSTATIC TEST PRESSURE

TEST

bar (g)

WIND

EARTHQUAKE

VOLUME

EMPTY MASS

kg

TO BE TESTED BY

32

NOTES

33

THERMAL INSULATION (LINE 14): I = HOT INSULATION ; F = COLD INSULATION ; PP = PERSONAL PROTECTION

34

PWHT (LINE 15) = POST WELD HEAT TREATMENT

35

36

(*) Identical data sheet for 50-190-VA-002

37

38

39

40

41

42

P3

04-may-04 Approved for design

M. Comignani

F.Lagan

G. La Mantia

P2

26-feb-03 Approved for design

A.Bellina

F.Lagan

G. La Mantia

P1

22-nov-02 Issued for approval

M.Comignani

F.Lagan

G. La Mantia

Prep.

Check.

Appr.

Rev.

Description

Date

Form code: DAT.CR.PV.1300

Sh. 01

A. Maddaloni

T. M. Said

PMS Review

AGBV Appr.

Rev. 2.01

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for which it has

been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas

Ltd

Snamprogett

i

Plant

AGBV Doc. No.

0177/NC/02

G-65-X-O-19VA 01

CTR Job No.

CTR Doc. No.

310300

50 190-RC-E-03100

MELLITAH PLANT

Location

ABB Lummus Malta

AGBV Job No.

Sh.

GSPLAJ

of

P1

P2

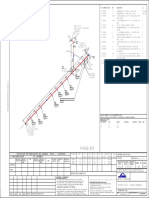

VESSEL DATA SHEET

1

2

SERVICE

GAS INLET

OUTLET

6

7

Rev.

LIST OF CONNECTIONS

ITEM

PSV

DIAMETER

RATING

FACING

26"

600#

RTJ

30"

600#

RTJ

LIQUID OUTLET

4"

600#

RTJ

SAFETY VALVE

6"

600#

RTJ

NPS

TYPE

UC

UTILITY CONNECTION

2"

600#

RTJ

DRAIN

3"

600#

RTJ

10

VENT

2"

600#

RTJ

11

MANHOLE (7)

20"

600#

RTJ

12

L1 (17)

LEVEL BRIDLE

2"

600#

RTJ

13

L2 (17)

LEVEL BRIDLE

2"

600#

RTJ

14

LS1 (17)

LEVEL SWITCH

1 1/2"

600#

RTJ

15

LS2 (17)

LEVEL SWITCH

1 1/2"

600#

RTJ

16

LS3 (17)

LEVEL SWITCH

1 1/2"

600#

RTJ

17

LS4 (17)

LEVEL SWITCH

1 1/2"

600#

RTJ

THK.

POSITION

PROJEC.

mm

mm

mm

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

P3

Rev.

NOTES

NPS (LINE 3): NOMINAL PIPE SIZE: NOMINAL DIAMETER WHEN U.S. STD's ARE USED

43

44

45

46

47

48

49

Form code: DAT.CR.PV.1300

Sh. 02

Rev. 2.01

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for which it has

been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

P3

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Snamprogetti

ABB Lummus Malta

Plant

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-65-X-O-19VA 01

CTR Job No.

CTR Doc. No.

310300

50 190-RC-E-03100

MELLITAH PLANT

Location

GSPLAJ

Sh.

of

P1

P2

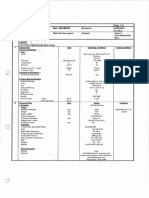

VESSEL DATA SHEET: Notes

1

(1)

High efficiency distributor to be considered. Inlet nozzle size to be confirmed by Vendor

(2)

Bottom arrangement of the Vane Pack downcomer by Vendor. Gas by-pass through the downcomer is to be avoided

(3)

Vane Pack type. Basis of design are on sheet 4. All dimensions and lay-out of Vane Pack shall be by Vendor. Vendor to advise if perforated plates must

4

(4)

Basis of design for inlet distributor are on sheet 5 (Schoepentoeter or equivalent)

(5)

Vane Pack Vendor to confirm these distances

(6)

Sizes to be reviewed after inlet distributor and Vane Pack selection

(7)

Inlet distributor and Vane Pack to be dismantable and removable through manhole

(8)

Deleted

10

(9)

Deleted

11

(10) Design case: year 2 summer

12

(11) Max pressure drop =0,1 bar (Schoepentoeter + Vane Pack)

13

(12) Vessel internals to be designed to withstand for short periods of time (8 hrs) twice the design flowrate. Lower performances are accepted in these periods

14

(13) Deleted

15

(14) Minimum temperature during depressurization is

16

(15)

17

(16) Raw gas does not contain free water, However presence of water is envisaged during turnaround and maintenance, therefore the equipment

P3

-13 C

Lethal service due to presence of H2S

shall be considered in wet H2S service. All materials shall be in accordance to Spec. G-50-S-Z-0001 00 and to NACE MR 0175

19

(17) Instrument connection sizes to be confirmed by instrument and mechanical departments

20

(18) Vendor design of vessel internals (distributor and vane pack) shall be submitted to process department for review and approval, prior to issue

21

22

Rev.

be installed. Gas outlet nozzle size to be confirmed by Vendor

18

P3

Rev.

the purchase order

(19) Alternative design condition during steam out: 155C at 0,1 bar (g)

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Form code: DAT.CR.PV.1300

Sh. 03

Rev. 2.01

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for which it has

been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Snamprogetti

ABB Lummus Malta

Plant

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-65-X-O-19VA 01

CTR Job No.

CTR Doc. No.

310300

50 190-RC-E-03100

MELLITAH PLANT

Location

Sh.

GSPLAJ

of

P1

P2

P3

Rev.

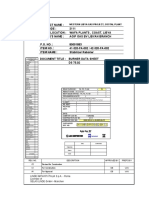

VESSEL DATA SHEET: Vane Pack

Rev.

1

2

3

4

5

6

7

8

VANE PACK SPECIFICA TION

This specification covers the basic requirements of a vertical type tw o stage VANE PACK w ith horizontal gas flow (refer to sketch on page

5) to be installed on top of 50-190-VA-001 and 50-190-VA-002.

9

10

FOREWORD

Performances of VANE PACK have to be as defined here below and are related to a high pressure system, e.g. w et natural gas.

11

12

13

14

15

PURPOSE

The Gas slug catcher K.O. drum carries out a tw o phase separation prior to sending the raw gas to the next Gas sw eetening section. A

VANE PACK has to be installed to catch the maximum amount of droplet as small in size as possible.

DESIGN CONDITIONS

Refer to the tables below for the outlet conditions of gas/liquid/w ater. Refer to relevant data for drum internal geometry.

16

17

18

19

Sulphur = 12

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Vapor outlet stream

composition is as follow s

(molar %)

Year 2 summer production

H/C liquid outlet stream

composition is as follow s

(molar %)

Year 2 summer production

H2O

0.017

N2

4.589

CO2

Design Data 15.702

H2S

1.289

Temperature (C)

C1

70.080

Pressure

(

bar

g)

C2

4.460

C3Density at T (kg/m3)

1.802

IC4Viscosity (cP) 0.396

Surface Tension0.664

(N/m)

NC4

IC5Flow Rate at conditions

0.292

(Ton/h)

NC5

0.285

m3/h (actual design)

NC6

0.250

MW

NC7

0.130

NC8

0.038

NC9

0.004867

NC10

0.000531

NC11

5.05 E -05

C12+

0.000

H2O

0.0096

N2

0.4285

CO2 HC liquid expected

7.5080

H2S

1.4749

C1

14.1581

C2

4.1034

650

C3

4.7313

IC4 0.19

2.2257

NC4 0.0125

5.0117

IC5 13 (design)

4.6795

NC5 20 (design)

5.5879

NC6 73.0

13.6800

NC7

17.9728

NC8

12.7357

NC9

4.2863

NC10

1.1082

NC11

0.2468

C12+ &

0.0556

MERCAPTANS

Outlet Wet Gas

28.9

41.9

44.81

0.012

506

11301 - 12430

23.45

GUA RANTEES

100% of removal

larger or equal to

Maximum

VANE PACK +

and outlet nozzle = 50 mbar @ design temperature. Maximum entrainment: 0.1 USgal/MMSCF ( 14.1 liters/MMNm 3)

Mercaptans

ppmw

of liquid droplets

50 microns.

pressure drop:

perforated plate

NOTES

Supplier to maintain separation performances from 110% to 40% of the indicated flow rates. Retrocondensation is expected. Supplier may

be asked to review design in accordance w ith Gas Distributor design finalization. Entrained solid particles: hydrates formation may occur.

VANE PACK design shall take into account the risk of plugging w ith hydrates.

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Form code: DAT.CR.PV.1300

Sh. 04

Rev. 2.01

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for which it has

been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas

Ltd

Snamprogett

i

ABB Lummus Malta

Plant

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-65-X-O-19VA 01

CTR Job No.

CTR Doc. No.

310300

50 190-RC-E-03100

MELLITAH PLANT

Location

GSPLAJ

VESSEL DATA SHEET: Sketch

Sh.

of

(All dimensions in mm, unless indicated otherwise)

P1

P2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Form code: DAT.CR.PV.1300

=

Sh. 05

Rev. 2.01

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for which it has

been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

P2

P3

Rev.

Rev.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas

Ltd

Snamprogett

i

ABB Lummus Malta

Plant

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-65-X-O-19VA 01

CTR Job No.

CTR Doc. No.

310300

50 190-RC-E-03100

MELLITAH PLANT

Location

Sh.

GSPLAJ

of

P1

P2

P3

Rev.

VESSEL DATA SHEET: DISTRIBUTOR

Rev.

1

2

Gas inlet conditions are shown in the herebelow table

3

4

5

6

7

8

9

Design Data

Temperature (C)

Pressure ( bar g)

Density at T (kg/m3)

10

11

12

Outlet Wet Gas

28.9

41.9

44.81

HC liquid expected

650

13

14

15

16

17

18

19

PRELIMINARY SCHOEPENTOETER DESIGN

Sizing data (To be confirmed by Vendor)

20

21

22

23

24

25

AVAILABLE SPACE

mm

3500

26

VANE ANGLE

ALFA

RAD

0.1396263

27

EDGE ANGLE

BETA

RAD

0.1046826

28

VESSEL ID

mm

3600

29

FEED NOZZLE ND

d1

mm

660.4

30

LENGHT OF STRAIGHT PART OF VANE

Lv

mm

100

31

NUMBER OF VANES PER SIDE Nv

Nv

31

32

VANE RADIUS

Rv

mm

100

33

VANE MATERIAL THICKNESS

mm

34

WIDTH OF VANE ENTRANCE OPENING

W vo

mm

21.321727

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Form code: DAT.CR.PV.1300

=

Sh. 05

Rev. 2.01

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for which it has

been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

Вам также может понравиться

- S-Stamp Calculation Nozzle ShellДокумент4 страницыS-Stamp Calculation Nozzle ShellmukeshОценок пока нет

- Balaji S - Static Equipment Design - 7 Years - Resume - NEWДокумент5 страницBalaji S - Static Equipment Design - 7 Years - Resume - NEWkanchanabalajiОценок пока нет

- Shell Entrance Area Calculation-R0Документ2 страницыShell Entrance Area Calculation-R0nagtummalaОценок пока нет

- Data Sheet For Absorber Reflux Drum (GTPT-V-250-003)Документ4 страницыData Sheet For Absorber Reflux Drum (GTPT-V-250-003)Mohamed hamza souissiОценок пока нет

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleДокумент25 страницPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidОценок пока нет

- Pipe Size Flange Rating Operating Condition: E F SFДокумент4 страницыPipe Size Flange Rating Operating Condition: E F SFvivekpec100% (1)

- TEMA Shell Bundle Entrance and Exit AreasДокумент3 страницыTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaОценок пока нет

- TQ - Air Fin Cooler (CS) - ModificationДокумент6 страницTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaОценок пока нет

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterДокумент2 страницыHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc Nguyen100% (1)

- Mechanical Data SheetДокумент7 страницMechanical Data SheetktejankarОценок пока нет

- Design Procedure For Aes He PDFДокумент30 страницDesign Procedure For Aes He PDFRyan Goh Chuang HongОценок пока нет

- Sphere Design and Thickness Calculation (Div 2)Документ6 страницSphere Design and Thickness Calculation (Div 2)Asad KhanОценок пока нет

- VERIFICATIONДокумент3 страницыVERIFICATIONshaishavОценок пока нет

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Документ4 страницы15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanОценок пока нет

- U-Tube Heat Exchanger Design: Tubes SpecДокумент8 страницU-Tube Heat Exchanger Design: Tubes SpecVipul SharmaОценок пока нет

- Nozzle Calculations 01Документ32 страницыNozzle Calculations 01Rohith V VОценок пока нет

- ENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)Документ4 страницыENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)m khaeronОценок пока нет

- Tema ChecklistДокумент2 страницыTema ChecklistAdrian Stoicescu100% (1)

- Datasheet For Gate Valves: ProjectДокумент3 страницыDatasheet For Gate Valves: ProjectbecpavanОценок пока нет

- Shell and Tube HE CalculationДокумент16 страницShell and Tube HE CalculationPradip ShindeОценок пока нет

- Ligament Efficiency and Thickness of The Support PlateДокумент10 страницLigament Efficiency and Thickness of The Support PlatePankajDhobleОценок пока нет

- TEMA Sheet Heat Exchanger Specification SheetДокумент3 страницыTEMA Sheet Heat Exchanger Specification SheetSonNguyenОценок пока нет

- Condensate Tank - For 250Документ3 страницыCondensate Tank - For 250Sakthi VelОценок пока нет

- Atmospheric Tank Design CalculationДокумент2 страницыAtmospheric Tank Design CalculationmusaveerОценок пока нет

- AL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCДокумент5 страницAL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCCaptainToniesОценок пока нет

- Technical Data Sheet For Control ValveДокумент5 страницTechnical Data Sheet For Control Valvealinor_tnОценок пока нет

- Etank Full ReportДокумент108 страницEtank Full ReportFaizal SattuОценок пока нет

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Документ4 страницыSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRIОценок пока нет

- Air Receiver DesignДокумент3 страницыAir Receiver DesigngksakthiОценок пока нет

- Appendix 1Документ22 страницыAppendix 1HudaFiHayyat0% (1)

- TBE-Pressure Vessel Standard TemplateДокумент4 страницыTBE-Pressure Vessel Standard TemplateSiva baalanОценок пока нет

- Air Blowe DatasheetДокумент1 страницаAir Blowe DatasheetMoein PОценок пока нет

- MP Condensate Flash VesselДокумент4 страницыMP Condensate Flash VesselGanesh BhardwajОценок пока нет

- PTB E4.18.5 Fixed TubesheetДокумент83 страницыPTB E4.18.5 Fixed TubesheetNicolaSaviliОценок пока нет

- 682 E4 DatasheetsДокумент4 страницы682 E4 DatasheetsHammad SafeerОценок пока нет

- Superheated Steam SeparatorДокумент4 страницыSuperheated Steam SeparatorGanesh BhardwajОценок пока нет

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureДокумент7 страницPipe Thickness Calculation For Straight Pipe Under Internal PressureMakhdoom Ibad HashmiОценок пока нет

- TBE Inlet Separator V 2100 FLNG2Документ6 страницTBE Inlet Separator V 2100 FLNG2halipzramlyzОценок пока нет

- Nozzle & FlangeДокумент14 страницNozzle & FlangeRaghОценок пока нет

- Technical Part 1 2 PDFДокумент301 страницаTechnical Part 1 2 PDFKumar Kousik Mondal50% (2)

- Support RingДокумент13 страницSupport RingvamsiОценок пока нет

- 7-12-0017 Rev 5Документ2 страницы7-12-0017 Rev 5cynideОценок пока нет

- Bolt Torque Calculations 1 PDFДокумент1 страницаBolt Torque Calculations 1 PDFshazanОценок пока нет

- External Template UG-29 UG-80 - 81 Calculation - Rev.0Документ5 страницExternal Template UG-29 UG-80 - 81 Calculation - Rev.0souren1975100% (1)

- Mechanical Tender CNG PDFДокумент161 страницаMechanical Tender CNG PDFAWANI SRIVASTAVAОценок пока нет

- Thickness Calculation of Pressure Vessel ShellДокумент16 страницThickness Calculation of Pressure Vessel ShellClaudia BonocoreОценок пока нет

- Vertical Vessel Adequacy CheckДокумент15 страницVertical Vessel Adequacy CheckTifano KhristiyantoОценок пока нет

- API 660 Vs TEMAДокумент5 страницAPI 660 Vs TEMAALONSO GOMEZОценок пока нет

- API 650 Baseplate DesignДокумент3 страницыAPI 650 Baseplate DesignmjlazoОценок пока нет

- Calculation of Heat and Mass BalanceДокумент16 страницCalculation of Heat and Mass BalanceHEMANTОценок пока нет

- Mechanical Design Calculation: DocumentДокумент146 страницMechanical Design Calculation: DocumentvikramОценок пока нет

- ASME VIII CalculationДокумент15 страницASME VIII CalculationJoao Osmar Correa100% (1)

- Data Sheet Fuel Gas Filter Rev 0Документ22 страницыData Sheet Fuel Gas Filter Rev 0Bowo Edhi WibowoОценок пока нет

- STD - Pressure Vessel DrawingДокумент138 страницSTD - Pressure Vessel DrawingChetan PatelОценок пока нет

- Anex 1Документ59 страницAnex 1rotatic_engineerОценок пока нет

- IsometricsДокумент4 страницыIsometricsMuhammedHafisОценок пока нет

- 315 Me DS 083 D3Документ6 страниц315 Me DS 083 D3mihailspiridonОценок пока нет

- L028 Me Dat 01 00122 001 00Документ8 страницL028 Me Dat 01 00122 001 00sivasan10006098Оценок пока нет

- Volume3A MechДокумент321 страницаVolume3A MechAdeel JamilОценок пока нет

- DS-21-J-0026 - 2 TPCDR Approved PDFДокумент40 страницDS-21-J-0026 - 2 TPCDR Approved PDFsumant.c.singh1694Оценок пока нет

- Job Description-Mechanical EngineerДокумент1 страницаJob Description-Mechanical EngineerThirukkumaranBalasubramanianОценок пока нет

- PALL FILTER - Process Data SheetДокумент2 страницыPALL FILTER - Process Data SheetThirukkumaranBalasubramanianОценок пока нет

- Job Description-Process EngineerДокумент1 страницаJob Description-Process EngineerThirukkumaranBalasubramanianОценок пока нет

- CEIL Engineering FinHR Advt 202324 02Документ6 страницCEIL Engineering FinHR Advt 202324 02ThirukkumaranBalasubramanianОценок пока нет

- Job Description-Piping EngineerДокумент1 страницаJob Description-Piping EngineerThirukkumaranBalasubramanianОценок пока нет

- DS 7502Документ4 страницыDS 7502ThirukkumaranBalasubramanianОценок пока нет

- Final Report TOTAL EP MYANMARДокумент24 страницыFinal Report TOTAL EP MYANMARThirukkumaranBalasubramanianОценок пока нет

- A Guide To Failure Analysis For The Oil and Gas IndustryДокумент6 страницA Guide To Failure Analysis For The Oil and Gas IndustryThirukkumaranBalasubramanian100% (1)

- D2-001-AM Part 1Документ118 страницD2-001-AM Part 1ThirukkumaranBalasubramanianОценок пока нет

- INITIAL RISK REVIEW - WAFA Cold CutДокумент6 страницINITIAL RISK REVIEW - WAFA Cold CutThirukkumaranBalasubramanianОценок пока нет

- Cold CuttingДокумент2 страницыCold CuttingThirukkumaranBalasubramanianОценок пока нет

- Installation PlanДокумент28 страницInstallation PlanThirukkumaranBalasubramanianОценок пока нет

- Execution of Tie-Ins Without A Plant ShutdownДокумент3 страницыExecution of Tie-Ins Without A Plant ShutdownThirukkumaranBalasubramanianОценок пока нет

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureДокумент583 страницыMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanian0% (1)

- Mellitah Oil & Gas BVДокумент12 страницMellitah Oil & Gas BVThirukkumaranBalasubramanianОценок пока нет

- Mellitah Oil & Gas BV: Field Bending OF LinepipeДокумент4 страницыMellitah Oil & Gas BV: Field Bending OF LinepipeThirukkumaranBalasubramanianОценок пока нет

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureДокумент19 страницMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanianОценок пока нет

- JERES-D-001 Design Criteria For Pressure VesselsДокумент37 страницJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianОценок пока нет

- Aspee Hi-Tech: Knapsack SprayerДокумент2 страницыAspee Hi-Tech: Knapsack SprayerThirukkumaranBalasubramanianОценок пока нет

- A4 Piping Vibration Risks and Integrity Assessment ARTICLEДокумент5 страницA4 Piping Vibration Risks and Integrity Assessment ARTICLEDavid SmithОценок пока нет

- DataSheet 105723Документ2 страницыDataSheet 105723ThirukkumaranBalasubramanianОценок пока нет

- Reference ListДокумент28 страницReference ListThirukkumaranBalasubramanianОценок пока нет

- Ce I Fire Box HeaterДокумент4 страницыCe I Fire Box HeaterThirukkumaranBalasubramanianОценок пока нет

- Heating of Pipelines DEH SmallДокумент2 страницыHeating of Pipelines DEH SmallThirukkumaranBalasubramanianОценок пока нет

- Failure Analysis ReportДокумент24 страницыFailure Analysis ReportThirukkumaranBalasubramanianОценок пока нет

- Failure Analysis ReportДокумент24 страницыFailure Analysis ReportThirukkumaranBalasubramanianОценок пока нет

- Inspection Plan 61-300-HA-101A PDFДокумент4 страницыInspection Plan 61-300-HA-101A PDFThirukkumaranBalasubramanianОценок пока нет

- Scholastica: Mock 1Документ14 страницScholastica: Mock 1Fatema KhatunОценок пока нет

- Training For Humans Guide: FAQ's How Many Sets/reps Should I Do Per Exercise?Документ28 страницTraining For Humans Guide: FAQ's How Many Sets/reps Should I Do Per Exercise?Paulo Pires100% (1)

- CV & Surat Lamaran KerjaДокумент2 страницыCV & Surat Lamaran KerjaAci Hiko RickoОценок пока нет

- Chhay Chihour - SS402 Mid-Term 2020 - E4.2Документ8 страницChhay Chihour - SS402 Mid-Term 2020 - E4.2Chi Hour100% (1)

- Economic Review English 17-18Документ239 страницEconomic Review English 17-18Shashank SinghОценок пока нет

- Tutorial 5 SolvedДокумент3 страницыTutorial 5 SolvedAshutoshKumarОценок пока нет

- Implementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorДокумент11 страницImplementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorChristie YohanaОценок пока нет

- Sandstorm Absorbent SkyscraperДокумент4 страницыSandstorm Absorbent SkyscraperPardisОценок пока нет

- Cyber Briefing Series - Paper 2 - FinalДокумент24 страницыCyber Briefing Series - Paper 2 - FinalMapacheYorkОценок пока нет

- Out PDFДокумент211 страницOut PDFAbraham RojasОценок пока нет

- 40 People vs. Rafanan, Jr.Документ10 страниц40 People vs. Rafanan, Jr.Simeon TutaanОценок пока нет

- PresentationДокумент27 страницPresentationMenuka WatankachhiОценок пока нет

- Clark SM 616 Service ManualДокумент20 страницClark SM 616 Service Manualenid100% (55)

- Eggermont 2019 ABRДокумент15 страницEggermont 2019 ABRSujeet PathakОценок пока нет

- 2014 - A - Levels Actual Grade A Essay by Harvey LeeДокумент3 страницы2014 - A - Levels Actual Grade A Essay by Harvey Leecherylhzy100% (1)

- Lecture 2 Effects of Operating Conditions in VCCДокумент9 страницLecture 2 Effects of Operating Conditions in VCCDeniell Joyce MarquezОценок пока нет

- How To Block HTTP DDoS Attack With Cisco ASA FirewallДокумент4 страницыHow To Block HTTP DDoS Attack With Cisco ASA Firewallabdel taibОценок пока нет

- Wholesale Terminal Markets - Relocation and RedevelopmentДокумент30 страницWholesale Terminal Markets - Relocation and RedevelopmentNeha Bhusri100% (1)

- Brand Strategy - in B2BДокумент6 страницBrand Strategy - in B2BKrishan SahuОценок пока нет

- Science 4 Diagnostic/Achievement TestДокумент5 страницScience 4 Diagnostic/Achievement TestGe PebresОценок пока нет

- Apple Change ManagementДокумент31 страницаApple Change ManagementimuffysОценок пока нет

- KsДокумент5 страницKsnurlatifahОценок пока нет

- 22 Khan S.Документ7 страниц22 Khan S.scholarlyreseachjОценок пока нет

- Algoritm BackTracking EnglezaДокумент6 страницAlgoritm BackTracking Englezaionutz_67Оценок пока нет

- What Are The Spacer Bars in RC Beams - QuoraДокумент3 страницыWhat Are The Spacer Bars in RC Beams - QuoradesignОценок пока нет

- How To Configure PowerMACS 4000 As A PROFINET IO Slave With Siemens S7Документ20 страницHow To Configure PowerMACS 4000 As A PROFINET IO Slave With Siemens S7kukaОценок пока нет

- 6GK74435DX040XE0 Datasheet enДокумент3 страницы6GK74435DX040XE0 Datasheet enLuis CortezОценок пока нет

- Configuring BGP On Cisco Routers Lab Guide 3.2Документ106 страницConfiguring BGP On Cisco Routers Lab Guide 3.2skuzurov67% (3)

- Rom 2 - 0-11 (En)Документ132 страницыRom 2 - 0-11 (En)Mara HerreraОценок пока нет

- Chapter - I Introduction and Design of The StudyДокумент72 страницыChapter - I Introduction and Design of The StudyramОценок пока нет