Академический Документы

Профессиональный Документы

Культура Документы

GE12TI Gen-Pack Diesel Engine Specs

Загружено:

setiajaya2012Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GE12TI Gen-Pack Diesel Engine Specs

Загружено:

setiajaya2012Авторское право:

Доступные форматы

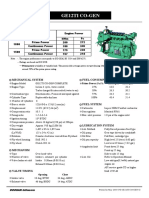

GE12TI GEN-PACK

POWER RATING

Engine

Type of

Speed

rev/min

Operation

1800

1500

Engine Power

kWm

Ps

Prime Power

200

272

Standby Power

220

299

Prime Power

175

238

Standby Power

192

262

Note : -. The engine performance corresponds to ISO 3046, BS 5514 and DIN 6271.

* Without cooling fan, inter cooler inlet water temperature 32

-. Ratings are based on ISO 8528.

Prime power available at variable load. The permissible average power out put (during 24h period) shell not

exceed 70% of the prime power rating. No overload is permitted.

Standby power available in the event of a main power network failure. No overload is permitted.

MECHANICAL SYSTEM

FUEL CONSUMPTION

Combustion type

Cylinder Type

Number of cylinders

Bore x stroke

In-line 4 cycle, water cooled

Prime (Nm3/hr)

Turbo charged & intercooled (water to air)

25%

Stoichiometric, Premixed and spark ignited

50%

Replaceable dry liner

75%

6

100%

123(4.84) x 155(6.1) mm(in.)

Standby (Nm3/hr)

Displacement

Compression ratio

Firing order

Ignition timing

Compression pressure

Dry weight

Dimension

(LxWxH)

Rotation

Fly wheel housing

Fly wheel

11.051 (674.5) lit.(in3)

10.5 : 1

1-5-3-6-2-4

13 BTDC

Above 16 kg/cm2(228 psi) at 200rpm

Approx. 1,010 kg (2,227 lb)

1,672 x 1,039 x 1,435 mm

(66 x 41 x 57 in.)

Counter clockwise viewed from Flywheel

SAE NO.1

Clutch NO.14

Engine Type

MECHANISM

Over head valve

Intake 1, exhaust 1 per cylinder

Intake 0.30mm (0.0118 in.)

Exhaust 0.30mm (0.0118 in.)

Type

Number of valve

Valve lashes at cold

VALVE TIMING

Intake valve

Exhaust valve

Opening

18 deg. BTDC

46 deg. BBDC

DOOSAN Infracore

Close

34 deg. ABDC

14 deg. ATDC

25%

50%

75%

100%

15.6

27.0

38.4

47.8

1,800 rpm

20.4

30.2

41.1

51.4

1,800 rpm

29.0

36.6

43.7

55.4

FUEL SYSTEM

Carburetor

Gas regulator

Max. inlet pressure

1,500 rpm

16.8

26.3

34.3

43.4

1,500 rpm

Impco 200M Varifuel carburetor

Maxitrol RV61

1.0 psi at the engine inlet

LUBRICATION SYSTEM

Lub. Method

Oil pump

Oil filter

Oil pan capacity

Lub. Oil

Fully forced pressure feed type

Gear type driven by crankshaft

Full flow, cartridge type

High level 25 liters ( 6.60 gal.)

Low level 19 liters ( 5.02 gal.)

Refer to Operation Manual

Low ash type(0.5wt%) natural gas

engine oil

API service grade CD or higher

SAE 15W-40

Printed in February 2011 PS-GE12TI GEN-PACK-D

GE12TI GEN-PACK

COOLING SYSTEM

Cooling method

Water capacity

(engine only)

Pressure system

Water pump

Cooling fan

Loss power of fan

Thermostat

Fresh water forced circulation

21 liters ( 5.55 gal.)

ENGINEERING DATA

Water flow

Heat rejection to coolant

Max. 0.5 kg/cm ( 7.1 psi)

Centrifugal type driven by belt

Blower, 755mm diameter, 7 blades

Plastic

9.5PS (7kW) Eng. Speed 1,500 rpm

15PS (11kW) Eng. Speed 1,800 rpm

Heat rejection to CAC

Intercooler water flow

15.7 m3/min @1,800 rpm

Exhaust gas flow

23.0 m3/min @1,500 rpm

Exhaust gas temp.

27.0 m3/min @1,800 rpm

545 C @1,500 rpm

566 C @1,800 rpm

Radiator air flow

270 m3/min @1,500 rpm, 0.7kPa

Full open temp. 85C

ELECTRICAL SYSTEM

Charging generator

Voltage regulator

Starting motor

Battery Voltage

Battery Capacity

24V x 45A alternator

Built-in type IC regulator

24V x 7.0kW

24V

150 AH (recommended)

Ignition controller

12 or 24V DC

(min 8V DC at start, 32V DC max)

360 m3/min @1,800 rpm, 1.0kPa

Max. permissible restrictions

220 mmH2O initial

-.Intake system

635 mmH2O final

600 mmH2O max.

-.Exhaust system

Altitude Capability

IGNITION SYSTEM

46.5 kcal/sec @1,800 rpm

1.8 kcal/sec @1,500 rpm

3.1 kcal/sec @1,800 rpm

284 liters/min @1,500 rpm

390 liters/min @1,800 rpm

13.0 m3/min @1,500 rpm

Air flow

Wax pellet type

Opening temp. 71C

260 liters/min @1,500 rpm

310 liters/min @1,800 rpm

39.0 kcal/sec @1,500 rpm

1,000 m

CONVERSION TABLE

Ignition controller

NGK IFR7B-D, 0.4mm air gap

Champion RC78PYP, 0.38mm air gap

Altronic CD 1 unit (12 or 24V DC)

in. = mm x 0.0394

PS = kW x 1.3596

psi = kg/cm2 x 14.2233

in3 = lit. x 61.02

lb/ft = N.m x 0.737

U.S. gal = lit. x 0.264

kW = 0.2388 kcal/s

lb/PS.h = g/kW.h x 0.00162

Ignition coil

Altronic 501 061 blue epoxy individual

hp = PS x 0.98635

cfm = m3/min x 35.336

coil

lb = kg x 2.20462

Nm3= SCF 0.0283

Magnetic pick-up sensor and trigger

Kg/hr = Nm3/hr 0.732 (natural gas)

wheel and Hall-effect

Btu/ft3= MJ/m3 26.8392 (natural gas)

kPa = 101.97 mmH2O = 0.01 bar

Spark plug

Trigger system

( 0.75 ~ -0.25mm air gap)

DOOSAN Infracore

Printed in February 2011 PS-GE12TI GEN-PACK-D

GE12TI GEN-PACK

Dimensions : Engine

Dimensions : Gen-pack

Doosan Infracore Co., Ltd.

21st Floor, Doosan Tower, 18-12, Euljiro 6-ga,

Jung-gu, Seoul, Korea

TEL : +82-2-3398-8400 / Fax : +82-2-3398-8509

E-mail : enginesales@doosan.com

Web site : www.doosaninfracore.com

Specifications are subject to change without prior notice

DOOSAN Infracore

Printed in February 2011 PS-GE12TI GEN-PACK-D

Вам также может понравиться

- Ge12ti Co Gen-GДокумент2 страницыGe12ti Co Gen-GTilok DasОценок пока нет

- VOLTAR P086TI G-DRIVE SpecificationsДокумент186 страницVOLTAR P086TI G-DRIVE SpecificationsSilver SilverОценок пока нет

- PU158TI E1G Motor IndustrialДокумент2 страницыPU158TI E1G Motor IndustrialANGEL UQUILLASОценок пока нет

- P086ti 1Документ2 страницыP086ti 1Serhan AysanОценок пока нет

- Ge12ti 950106-01168 PBДокумент268 страницGe12ti 950106-01168 PBKeron TrotzОценок пока нет

- Ariel Corporation - Arielcorp - Com3Документ1 страницаAriel Corporation - Arielcorp - Com3Anwar Sadat100% (1)

- PERKINS ENGINE Identification Serial Number 38Документ1 страницаPERKINS ENGINE Identification Serial Number 38wilsonОценок пока нет

- MANДокумент12 страницMANNirwana GroupОценок пока нет

- 6-Cylinder Diesel Engine For Power Generation.: MAN NutzfahrzeugeДокумент4 страницы6-Cylinder Diesel Engine For Power Generation.: MAN NutzfahrzeugeMuhammad rizkiОценок пока нет

- MCOT Tank Operating ProcedureДокумент18 страницMCOT Tank Operating ProcedureLembang ApangОценок пока нет

- Perkins M215C and M185C 1006 SeriesДокумент2 страницыPerkins M215C and M185C 1006 SeriesDamian Cid Morales100% (1)

- 5-650kva 60HZ en PDFДокумент26 страниц5-650kva 60HZ en PDFAndrésRozoОценок пока нет

- C18 Industrial Engine SN WJH-WRH Part Book PDFДокумент200 страницC18 Industrial Engine SN WJH-WRH Part Book PDFMuhammad Taupik KurrahmanОценок пока нет

- Yangdong Not EnabledДокумент4 страницыYangdong Not EnabledalawiОценок пока нет

- Deutz 413fw SpecsДокумент2 страницыDeutz 413fw SpecsBouchekouf OussamaОценок пока нет

- Generator Set Control PanelsДокумент4 страницыGenerator Set Control Panelslusoegyi 1919Оценок пока нет

- Enerpac Hydratight Powergen CapabilitiesДокумент81 страницаEnerpac Hydratight Powergen CapabilitiesAhmed El TayebОценок пока нет

- Komatsu GD535-5 Motor Grader SpecsДокумент20 страницKomatsu GD535-5 Motor Grader SpecsFiras MaitigОценок пока нет

- 403d 15g EngineДокумент4 страницы403d 15g EngineIqra khanОценок пока нет

- Series: 973 - 1327 KWM (Gross) at 1500 RPMДокумент18 страницSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudОценок пока нет

- PSI HD 14.6L Natural Gas or Propane EngineДокумент1 страницаPSI HD 14.6L Natural Gas or Propane EngineWilliam AlvaradoОценок пока нет

- 3516 516de4a 50HZ 6300Документ6 страниц3516 516de4a 50HZ 6300sinliongОценок пока нет

- Thermal Oil Centrifugal Pump Technical ManualДокумент25 страницThermal Oil Centrifugal Pump Technical ManualbeqsОценок пока нет

- New Dme Catalog PDFДокумент72 страницыNew Dme Catalog PDFBrandon TrocОценок пока нет

- GD705A-5 Adjusting ValveДокумент3 страницыGD705A-5 Adjusting ValveSurya FaniОценок пока нет

- Series 60 Spec Sheet CollectionДокумент6 страницSeries 60 Spec Sheet CollectionAngel NaranjoОценок пока нет

- Generator LogДокумент4 страницыGenerator LogFELIXENGIPLASCOMОценок пока нет

- Injection Pump Specification ©Документ4 страницыInjection Pump Specification ©Mr CupuОценок пока нет

- C4.4 NRP Maintenance SchedДокумент3 страницыC4.4 NRP Maintenance SchedDerrick AramОценок пока нет

- Especificaciones ISME420 30 Diesel Engine For VehicleДокумент1 страницаEspecificaciones ISME420 30 Diesel Engine For VehicleVICTOR TIMANAОценок пока нет

- Parts Manual - WGD185Документ8 страницParts Manual - WGD185Francisco Fernandez-Davila SainzОценок пока нет

- Msi Ms-7120 Rev 1b SCHДокумент28 страницMsi Ms-7120 Rev 1b SCHalexgrtОценок пока нет

- EMS98R3 User GuideДокумент22 страницыEMS98R3 User GuideAnas BasarahОценок пока нет

- 65 99898-8091Документ73 страницы65 99898-8091Juan Carlos Guarneros MorenoОценок пока нет

- WPG80 16Документ4 страницыWPG80 16AlanОценок пока нет

- 6BT5.9-DM Non-Certified Ratings SSДокумент2 страницы6BT5.9-DM Non-Certified Ratings SStempro100% (1)

- COMAP IL-MRS11-16 Thong So Ky Thuat PDFДокумент2 страницыCOMAP IL-MRS11-16 Thong So Ky Thuat PDFthanhhai31Оценок пока нет

- (Approved) DX12 Tappet Replacement ManualДокумент34 страницы(Approved) DX12 Tappet Replacement ManualLuis Ramón Argüello Real100% (1)

- 3516 - 1825kVA PrimeДокумент6 страниц3516 - 1825kVA PrimeAdul Rahmat100% (1)

- Water PumpsДокумент119 страницWater PumpsLesly LeslyОценок пока нет

- ) Perational Vlaintena, Nce Manual: I UGRK SeriesДокумент22 страницы) Perational Vlaintena, Nce Manual: I UGRK Seriessharan kommiОценок пока нет

- NASON Kilopak SwitchesДокумент32 страницыNASON Kilopak Switchesmarcel321Оценок пока нет

- Crankshaft As 3849907 - Caterpillar d10tДокумент1 страницаCrankshaft As 3849907 - Caterpillar d10tgraha networkОценок пока нет

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Документ4 страницыDoosan Infracore Generator Engine: Ratings (KWM/PS)moisesОценок пока нет

- 4008TAG2 Electro Unit PN2199Документ2 страницы4008TAG2 Electro Unit PN2199RioОценок пока нет

- Ee6790 1Документ3 страницыEe6790 1Miguel RojasОценок пока нет

- SS Engine Lovol 1003TGДокумент1 страницаSS Engine Lovol 1003TGalfan nash100% (1)

- 6068hf485 AuxДокумент2 страницы6068hf485 AuxObdvietnam Service100% (1)

- Ronald George ResumeДокумент3 страницыRonald George ResumeRonald GeorgeОценок пока нет

- Motor P222FE PDFДокумент4 страницыMotor P222FE PDFMarco QuitoОценок пока нет

- J - Ponuda PDFДокумент8 страницJ - Ponuda PDFAjdin Herc AhmetovicОценок пока нет

- PGP PGM 500 600 Uk 845Документ36 страницPGP PGM 500 600 Uk 845Jorge Andres PozoОценок пока нет

- Flywheel PM3516 3516B Power Module NBR00001-UPДокумент2 страницыFlywheel PM3516 3516B Power Module NBR00001-UPFaresОценок пока нет

- FAW FD 336 CG 6x4 Ready Stock Truck SpecsДокумент1 страницаFAW FD 336 CG 6x4 Ready Stock Truck SpecsMiftahul Ihwan SiregarОценок пока нет

- Inspect, repair and dyno test Cummins QSK45C engineДокумент5 страницInspect, repair and dyno test Cummins QSK45C engineSACHIDHANANDHAM A100% (1)

- Gep13.5-2, Geph22-2, Geph17sp, Gep11sp-2Документ1 страницаGep13.5-2, Geph22-2, Geph17sp, Gep11sp-2Jorge Gustavo GoyecheaОценок пока нет

- Mcdonnell & Miller Service Parts CatalogДокумент76 страницMcdonnell & Miller Service Parts Catalogkamran shahОценок пока нет

- DP158LD: Doosan Infracore Generator EngineДокумент4 страницыDP158LD: Doosan Infracore Generator EnginemoisesОценок пока нет

- GE08TI GEN-PACK Specifications and DimensionsДокумент3 страницыGE08TI GEN-PACK Specifications and DimensionsGian Percy Lozano FloresОценок пока нет

- TLT 440Документ31 страницаTLT 440Mendung SimunjanОценок пока нет

- Everything You Need to Know About Lathe MachinesДокумент23 страницыEverything You Need to Know About Lathe MachinesNeeraj JithuОценок пока нет

- Bob Ackert's SIEG SC4 ManualДокумент40 страницBob Ackert's SIEG SC4 ManualStefanVerschaeve67% (3)

- Rochester AdjustmentДокумент36 страницRochester Adjustmentrobotrmu100% (2)

- Envision WareДокумент36 страницEnvision WareBhanu Singh SainiОценок пока нет

- Selector Valve Technical Data Sheet for SEVO P-SVP0200 to P-SVP0600Документ1 страницаSelector Valve Technical Data Sheet for SEVO P-SVP0200 to P-SVP0600Ronald Urizar100% (1)

- Engine repair manual termsДокумент5 страницEngine repair manual termsHenry SilvaОценок пока нет

- Pelumas Pertamina LubricantsДокумент6 страницPelumas Pertamina LubricantsGiovan PratamaОценок пока нет

- HC 95Документ20 страницHC 95Kenny Huisa100% (1)

- DESMI Portable Centrifugal Pump: SA50-T (50-135/14) HATZ 1B20/30Документ14 страницDESMI Portable Centrifugal Pump: SA50-T (50-135/14) HATZ 1B20/30Kamran AleemОценок пока нет

- Bel252 252xl Technical Reference Mar09Документ59 страницBel252 252xl Technical Reference Mar09christineОценок пока нет

- Synchronous MotorДокумент33 страницыSynchronous MotorMizanur RahmanОценок пока нет

- Operating and Maintenance Manual For Launching-And Retrieval System of Freefall Lifeboat Type: FFAДокумент22 страницыOperating and Maintenance Manual For Launching-And Retrieval System of Freefall Lifeboat Type: FFAGoga100% (2)

- 312C & 312C L Excavators FDS00301-UP (MACHINE) POWERED BY 3064 Engine (SEBP3833 - 38) - DocumentationДокумент3 страницы312C & 312C L Excavators FDS00301-UP (MACHINE) POWERED BY 3064 Engine (SEBP3833 - 38) - DocumentationRaul RodriguezОценок пока нет

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 06-16 - Crankcase Side CoverДокумент5 страницD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 06-16 - Crankcase Side CoverMANUALESОценок пока нет

- Catálogo de Peças ALCO PDFДокумент550 страницCatálogo de Peças ALCO PDFLucas Lima100% (1)

- Separately Excited Electronic Motor Speed Controller: Model 1268 SepexДокумент5 страницSeparately Excited Electronic Motor Speed Controller: Model 1268 Sepexpavli999Оценок пока нет

- 020 611 PDFДокумент168 страниц020 611 PDFDipak PrajapatiОценок пока нет

- Invoice Omniparts 031404 04 0489Документ12 страницInvoice Omniparts 031404 04 0489Paula Andrea Gómez NuñezОценок пока нет

- A - C Control System - Autoo PDFДокумент4 страницыA - C Control System - Autoo PDFANH LÊОценок пока нет

- Kwu Governing SystemДокумент25 страницKwu Governing SystemLakshmi Narayan100% (2)

- Uenr2534uenr2534-02 Sis PDFДокумент15 страницUenr2534uenr2534-02 Sis PDFDiego zapataОценок пока нет

- Manual 820-Pp AsДокумент12 страницManual 820-Pp AsjabalpuramitОценок пока нет

- Parts Manual: 140G Motor GraderДокумент1 053 страницыParts Manual: 140G Motor GraderPëerawích Fang100% (6)

- Bolens TractorДокумент16 страницBolens TractorJocelyn DuteauОценок пока нет

- Gearabc A1 PDFДокумент19 страницGearabc A1 PDFjinriОценок пока нет

- UTB 650 Service Manual SmallДокумент201 страницаUTB 650 Service Manual Smallrom100% (3)

- Chapter 7 Engine Fuel and Fuel MeteringДокумент76 страницChapter 7 Engine Fuel and Fuel MeteringRobertОценок пока нет

- Vienna Superautomatica Parts DiagramДокумент8 страницVienna Superautomatica Parts DiagramGheorghe Mihalcovici0% (1)

- Swadro 38 42 46 TДокумент66 страницSwadro 38 42 46 TAleksandar KovačevićОценок пока нет