Академический Документы

Профессиональный Документы

Культура Документы

Shuttering Design and Cost Comparisons

Загружено:

Bala SubramanianАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Shuttering Design and Cost Comparisons

Загружено:

Bala SubramanianАвторское право:

Доступные форматы

International Journal of Recent Advances in Engineering & Technology (IJRAET)

_______________________________________________________________________________________________

Shuttering Design & Cost Comparisons

1

Rawal Meet Hemant, 2Bharakhada Mayank Prakash, 3Dhawde Akash Ankush

1

(U.G) Thakur College of Engg & Tech

(U.G) St. John College of Engg & Tech

3

(U.G) VIVA College of Engg & Tech

Abstract Shuttering is the most ignored aspect in Indian

Construction scenario. Formwork is carried out by the same

age old methods. But there is advancement in formwork

methods as well as types which require careful attention in

order to arrive at efficient, economic & durable formwork

design as well as formwork cost.

The temporary structure erected to support the concrete in

its required shape, till it hardens and becomes self

supporting is known as form-work or shuttering.

As the definition states that shuttering is a kind of mould

created temporarily for the purpose of pouring concrete in it

to have desirable geometrical structure. Also it helps in the

strength gain of concrete member as early curing is

permitted. From the stability point of view as well as from

architectural point of view, Shuttering

Index Termsshuttering design,

I. INTRODUCTION

In cities like Mumbai which have a considerable amount

of humid atmosphere, there are chances that the shuttering

may keep expanding and contracting due to change of

atmosphere and the shuttering plywood may bend

subjecting to bulging of sides of Column, Retaining Wall,

Footing, Beams, Chajjas, etc. It may cause bending of

beams and slabs which is unsafe from both structural

point of view and also from architectural point of view if

the plywood used for shuttering is not accounted for its

properties for moisture content during extreme humid

conditions and in monsoon season. If care is not taken in

design then it may create blunder. Even the stacking of

shuttering materials has an adverse effect on design of

shuttering as the designer design the ply for its maximum

available repetitions, but due to improper use of the

shuttering materials the design may fail after repetitive

improper use of the shuttering materials which also affects

the cost factor of project.

Shuttering counts for 50% of the total project cost. So for

the same purpose Cost Analysis of various systems of

shuttering in various construction practices and

depending on the type of project in hand, Cost Analysis

has immense effect on the overall economy of the project.

Cost Analysis of various types of systems gives an idea of

comparative costing of various systems in comparison to

the type of project. It may so happen that a shuttering

system used for an institutional or commercial project

may prove to be expensive for the use of it for residential

purpose and vice versa. From all the briefing above, it

concludes that both Design and Cost Analysis of

Shuttering system for a particular project has to be done

prior for going for a particular kind of shuttering system.

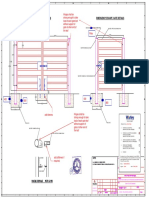

II. CASE STUDY

A. Dream Villa Bungalows at Goa

Shuttering Design of Conventional Timber Shuttering

along with Cuplock System as Staging was undertaken.

Project was just an assumption of G+2 Luxurious

Bungalows. Design done for new shuttering materials.

B. New building of Shri Bhagubhai Mafatlal

Shuttering System was Cuplock System along with timber

shuttering. Designing was done for this and checked.

Project was an Institutional Building G+7 floors and 3

Basements having floor plate area of 25000ft2(Approx).

Design Checked for existing shuttering materials.

III. UNITS

Use of MKS Units is done for designing of entire

formwork design

IV. MATERIAL SPECIFICATIONS

Marine Plywood as per IS 710: 2010, IS 1734: 1983

ISMB 100 & 150 as per IS-SP-6(1): 1964

Joint Putty as per IS-SP-6(1): 1964

MS Square Pipe as per IS 4923: 1972

Technical properties of Marine Plywood by Manufacturer

_______________________________________________________________________________________________

ISSN (Online): 2347 - 2812, Volume-4, Issue -3, 2016

85

International Journal of Recent Advances in Engineering & Technology (IJRAET)

_______________________________________________________________________________________________

(Pragati Hightech Products Pvt. Ltd.)

10. fy = yield stress of steel in MPa.

Wooden Joists or Beam Technical properties as per book

Design of Steel Structure (L.S.NEGI)

11. fcc = elastic critical stress in compression = 2*E/ 2

12. = slenderness ratio = l/r,

V. DESIGNING COMPONENTS

13. l = effective length of compression member

Slab & Beam Formwork Design

14. r = appropriate radius of gyration of member

a)

Materials used for Slab & Beam Shuttering.

i. Marine Plywood 2400mm*1200mm*12mm.

15. E = Elastic Modulus = 2*105 MPa, n = a factor

assumed as 1.4

ii. Wooden Runner Beam of 10mm*7.5mm*1600mm.

16. Permissible stress in axial compression as per Table

5.1( L.S.Negi, Design of Steel Structure) ac = 33 Mpa

iii. Vertical of 2m length, 48.3mm External Diameter,

2.6mm Wall thickness.

17. Load on each vertical (P permissible)

iv.

18. = ac (permissible)*Area (Area as per provided by

manufacturer)

ISMB 100 of 3200mm length.

v. Square Pipe 40mm*40mm C/S area, thickness of wall

2.6mm.

vi. Horizontal of 1.5m length, 48.3mm External

Diameter, 2.6mm Wall thickness.

vii. U-Head of 600mm/300mm adjustable. 32mm

diameter and 150mm*120mm*50mm*4/5mm.

viii. Base Plate of 300mm/600mm adjustable. 32mm

diameter, 120mm*120mm*4/5mm.

b)

Designing of Vertical of Cuplock System

1. Load Calculation.

2. Assuming the Spacing of Verticals @ 1.5m c/c & 1kg =

10N.

3. Dead Load of Concrete on Shuttering (w1) = Length

(m)*Breadth (m)* Height (m)* Density of Concrete (2500

kN/m3).

19. So, use Cuplock of 2m height, OD 48.3 at the

spacing of 1.5m/1m c/c as per required.

c)

Designing ISMB

1. Load Calculation.

2. Assuming the Spacing of ISMB 100 @ 1.5m c/c & 1kg

= 10N.

3.

Dead Load of Concrete on Shuttering (w1) = Breadth

(m)* Height (m)* Density of Concrete (2500 kN/m3). =

1.5m*0.15m*25kN/m3

4. = 5.62kN/m2.

5. Live Load Calculation (w2) = Load of Shuttering

materials above ISMB 100 (Including Self weight) +

Load of labor + Load of Vibrators, etc + Load due to

sudden heap of concrete (rarely). =3.5kN/m2.

6. Total Load on ISMB 100 (w) = 3+4

4. Live Load Calculation (w2) = Load of Shuttering

materials above 2m Vertical (Including Self weight) +

Load of labor + Load of Vibrators, etc + Load due to

sudden heap of concrete (rarely).

7. Assuming the horizontal spacing of ISMB at 1.5m c/c

& using ISMB 100 for shuttering. Assuming that ISMB

100 is simply supported at 1.5m c/c.

5. = 350Kg/ 3.5kN.

8. Calculating Maximum Bending Moment (M.max) =

wl2/8

6. Total Load on Vertical of 2m (w) = 3+4

7. Formula used for determining

8. ac (actual) = 0.5* {(fcc*fy)/[(fcc+fy)n]} where

9. ac = Permissible stress in axial compression MPa.

9. Permissible Compressive stress (bc) or Permissible

tensile stress (bt) = 0.66*fy

10. where fy = yield stress of steel in MPa. And

formula is derived from the book, Design of Steel

Structure (L.S.Negi)

_______________________________________________________________________________________________

ISSN (Online): 2347 - 2812, Volume-4, Issue -3, 2016

86

International Journal of Recent Advances in Engineering & Technology (IJRAET)

_______________________________________________________________________________________________

11. Now the elastic section modulus required (Zreq) =

Max. Bending Moment/ bt or bc

wall thickness for shuttering. Assuming that Square Pipe

is simply supported at 1m c/c on ISMB 100.

12. Check the Shear action on ISMB 100, Maximum

Shear force (actual) = wl/2

6. Calculating Maximum Bending Moment (M.max) =

wl2/8

13. Average Shear Stress (va provided) = actual/

w*d .where w = thickness of web. But permissible

shear stress (va permissible) = 0.4fy

7. Permissible Compressive stress (bc) or Permissible

tensile stress (bt) = 0.66*fy where fy = yield stress of

steel in MPa. And formula is derived from the book,

Design of Steel Structure (L.S.Negi)

14. Checking ISMB 100 for deflection (),

15. Maximum Deflection (actual) = K*(W*l3/E*Ixx)

.where W = concentrated load on support in kN = w*l

8. Now the elastic section modulus required (Zreq) =

Max. Bending Moment/ bt or bc

9. Check the Shear action on Square Pipe

40mm*40mm*2.6mm, Maximum Shear force (actual) =

wl/2

16. l = effective length in meters

17. Ixx = Moment of Inertia about X-X axis

10. Average Shear Stress (va provided) = actual/ area

18. E = Modulus of elasticity in N/cm

19. K = coefficient of maximum deflection

11. Checking Square Pipe 40mm*40mm*2.6mm for

deflection (),

20. But, allowable deflection (allowable) = l/325

12. Maximum Deflection (actual) = K*(W*l3/E*Ixx)

21. Checking web crippling for ISMB 100,

13. So, use Square Pipe 40mm*40mm*2.6mm at a

horizontal spacing of 300mm c/c and simply support it on

ISMB 100 at 1m c/c.

22. Bearing stress at supports = R/ {[ w*(a+h13)]}

23. .where R = Reaction at supports in kN = wl/2 a

length of support i.e. U-Head base length in mm

14. Designing Wooden

e)

Runner Beam

24. h1 = height of ISMB 100 including flange

25. But, Permissible Bearing Stress (b) = 0.75fy

26. So, use ISMB 100 at horizontal spacing of 1m and

simply support ISMB 100 at 1.5m c/c on U-head of base

length 150mm.

d)

Designing Square Pipe

1. Assuming the horizontal spacing of Wooden Beam

100mm*75mm*1600mm at 300mm c/c and the wooden

beam is simply supported on ISMB 100 at 1m c/c. Timber

used for all the Joists is Bijasal of Grade B and Wet

Condition.

2. Dead Load on Wooden Beam (w1) = R.C.C beam load

in terms of U.D.L

1. Assuming the horizontal Spacing of Square Pipe @

300mm c/c on ISMB 100, using square pipe

40mm*40mm*2.6mm wall thickness & 1kg = 10N.

3. Live Load on Wooden Beam (w2) = Load due to

movement of labour + Load due to heap of concrete

(rarely) + load due to equipments + Self weight of

Wooden Beam

2. Dead Load of Concrete on Shuttering (w1) = Breadth

(m)* Height(m)* Density of Concrete (2500 kN/m2).

4. Total load on Wooden Beam (w) = 2+3

3. Live Load Calculation (w2) = Load of Shuttering

materials above Square Pipe (Including Self weight) +

Load of labor + Load of Vibrators, etc + Load due to

sudden heap of concrete (rarely). = 1kN

4. Total Load on Square Pipe (w) = 2+3

5. Assuming the horizontal spacing of Square Pipe at

300mm c/c & using Square Pipe 40mm*40mm*2.6mm

5. Calculating Maximum Bending Moment on Wooden

Beam (M.max) = wl/8

6. But, permissible bending stress for Bijasal timber in

wet condition as per table of book, Design of Steel

Structures (L.S.Negi) (b) = 9.8 N/mm

7. Elastic Section Modulus required (Zreq) = M.max/ b

8. Checking Bijasal timber Beam for Shear agency,

_______________________________________________________________________________________________

ISSN (Online): 2347 - 2812, Volume-4, Issue -3, 2016

87

International Journal of Recent Advances in Engineering & Technology (IJRAET)

_______________________________________________________________________________________________

9. Permissible Shear Stress from the table given for

Bijasal

timber = 0.9 N/mm But, Actual Vertical

Shear Force on timber beam (V) = w [(l/2)-d]

14. Bearing Area (a) = 75mm*100mm

.... (where

75mm = width of ISMB 100, 100mm = width of timber

beam)

10. Maximum Horizontal Shear Stress (max) = 1.5V/bd

15. Bearing area required (a.req) = End reaction/ c

11. Checking Bijasal timber joists for deflection,

So, use Bijasal timber of c/s 100mm*75mm, length

1600mm, simply supported at 1m c/c on ISMB 100 and

horizontal spacing of 300mm c/c.

12. Maximum Deflection (max) = K*(W*l3/E*Ixx)

13. Checking the bearing strength at supports,

VI. COST ANALYSIS & COST COMPARISON

Comparitive: Mivan Shuttering v/s Conventional + Peri Shuttering

Sr.

Description

Aspect in

Mivan

Conventional

No.

Consideration

Shuttering

Shuttering

(Only Slab)

1

Material Cost

Cost/Sq.ft

41.29

105.00

Cost/Sq.Mtr

444.41

1,131.00

2

Labour Cost

Cost/Sq.ft

24.53

22.46

Cost/Sq.Mtr

264.01

241.68

3

Repititions

Nos/set of

29.50

6.00

Considered

shuttering material

4

Minimum

Days

7.00

15.00

Duration of Slab

Cycle

5

Quality

Surface Finsh

Form Finish

Comparative

Poor

6

Surface

Gypsum / Plaster / Internal

Internal

Application

Naked

Gypsum

Gypum

Direct Paint

External

Plaster

7

Workability

Material

Ease

Harder than

Handling, etc

Mivan

VII. CONCLUSION

At the end it can be concluded that though there is not

much of literature available on Shuttering Design and

Cost Analysis, it is available in an indirect way. It requires

a search on top of various engineering basics to design

shuttering. Cost analysis of shuttering also cannot be done

without vigorous observation from place to place and

from site to site to arrive at a conclusion.

At the end I would sincerely like to thank Professor

Atulya Kumar Singh & Mr. Rinkle Anajwala for being

with us through thick and thin for our project and also for

being the support system needed for succesful

accomplishment of this serious aspect formwork design

and cost comparison.

REFERENCES

[1]

Is 6461: part 5: 1972:- glossary of terms relating to

cement concrete, part 5: form work for concrete.

Peri Shuttering

(Only

Columns)

13.24

142.50

9.68

104.17

150.00

Conventional +

Peri Shuttering

(Column & Slab)

118.24

1,273.50

32.14

345.84

-

7.00

15.00

Form Finish

Not Better than

Mivan

Internal Gypum

Internal

Gypum

External

Plaster

Better than

Conventional

External Plaster

Not as easy as

Mivan

[2]

Is 4990: 1993:- specification for plywood for

concrete shuttering work.

[3]

Is 1200: part 5: 1982:- method of measurement of

building and civil engg works, part 5: form work.

[4]

Is 875: part 1: 1987:- code of practise for design

loads, part 1 for dead loads.

[5]

Is 875: part 2: 1987:- code of practise for design

loads, part 2 for imposed loads.

[6]

Is 875: part 3: 1987:- code of practise for design

loads, part 3 for wind loads.

[7]

Is 875: part 5: 1987:- code of practise for design

loads, part 5 for special loads and combinations.

[8]

Is 2636: 1972:- specification for wing nuts.

[9]

Is 4923: 1997:- hollow steel sections for structural

use- specifications.

_______________________________________________________________________________________________

ISSN (Online): 2347 - 2812, Volume-4, Issue -3, 2016

88

International Journal of Recent Advances in Engineering & Technology (IJRAET)

_______________________________________________________________________________________________

[10]

Is 710: 2010:- marine plywood specifications.

[14]

Applied mechanics by sunil deo 2011 edition by

nirali prakshan.

[11]

Is sp- 6(1): 1964:- hand book for structural

engineers.

[15]

Design of steel structure by l.s.negi second edition.

[16]

R.c.c theory and design by m.g.shah and c.m.kale

revised edition.

[17]

Formwork for concrete structure by robert l.

Peurifcy & garold d. Oberlender.

[18]

Concrete technology by m.s.shetty revised edition

& nirali prakashan.

[12]

Strength of materials by r.s.khurmi revised edition

in 2006, s. Ramamrutham 14th edition published in

2011.

[13]

Theory of structure by r.s.khurmi revised edition

in 2000, s. Ramarutham 2010 edition.

_______________________________________________________________________________________________

ISSN (Online): 2347 - 2812, Volume-4, Issue -3, 2016

89

Вам также может понравиться

- BOQ and Item Rates FY 2064/65Документ280 страницBOQ and Item Rates FY 2064/65kantish0% (2)

- Rate Analysis 076-077Документ66 страницRate Analysis 076-077Sujan MalbulОценок пока нет

- Rate Analyses Door and Window FixingДокумент1 страницаRate Analyses Door and Window Fixingsachin_mateОценок пока нет

- Interior Design Project ScheduleДокумент12 страницInterior Design Project ScheduleMuhammad Ramadhan YustiansyahОценок пока нет

- EstimateДокумент24 страницыEstimateKamal Kumar MallikarjunaОценок пока нет

- Flyover QuantityДокумент29 страницFlyover QuantityHemant GaikwadОценок пока нет

- Measurements BookДокумент36 страницMeasurements BookDileepОценок пока нет

- Rate Analysis For Pergola at 8th Floor SL - No Description Unit Qty Rate AmountДокумент3 страницыRate Analysis For Pergola at 8th Floor SL - No Description Unit Qty Rate AmountvinothОценок пока нет

- 4thrA&Final BillДокумент49 страниц4thrA&Final BillsinghОценок пока нет

- Construction of Boundary Wall For Mr. Kugan at Kokuvil: Removing of Fence and Site ClearingДокумент48 страницConstruction of Boundary Wall For Mr. Kugan at Kokuvil: Removing of Fence and Site ClearingNavam NanthanОценок пока нет

- 1BHK Quantity SheetДокумент36 страниц1BHK Quantity SheetsamОценок пока нет

- Summary of Balance Quantity R17 27-10-18Документ75 страницSummary of Balance Quantity R17 27-10-18Priyank DUbeyОценок пока нет

- Rate Analy. 2019Документ574 страницыRate Analy. 2019Roopesh ChaudharyОценок пока нет

- Date-070209 SR - No. Description Unit Rate A Rcc. WorkДокумент6 страницDate-070209 SR - No. Description Unit Rate A Rcc. WorkNiroshan Naguleswaran0% (1)

- New Brindavan Chs LTD Final Rev. Estimate (8!1!2018)Документ3 страницыNew Brindavan Chs LTD Final Rev. Estimate (8!1!2018)Royston FernandesОценок пока нет

- Pile Boring Analysis PDFДокумент1 страницаPile Boring Analysis PDFRanjan Kumar SahooОценок пока нет

- RA BILL 9 For BD ROAD After Adding All BillДокумент20 страницRA BILL 9 For BD ROAD After Adding All BillnandiniОценок пока нет

- Analysis of Rate For Providing MS FrameДокумент2 страницыAnalysis of Rate For Providing MS FrameBilal Ahmed BarbhuiyaОценок пока нет

- 9 - BOQ Item Details Vol. - IIIДокумент34 страницы9 - BOQ Item Details Vol. - IIIBadsha BiswasОценок пока нет

- Revised Estimate Format Note File.Документ4 страницыRevised Estimate Format Note File.Thirukandiyur Sudarsana Sri Raman0% (1)

- Bar Bending Schedule for Box CulvertДокумент1 страницаBar Bending Schedule for Box CulvertMaladi MustamilОценок пока нет

- Rate Analysis For 1CUM ConcreteДокумент7 страницRate Analysis For 1CUM ConcreteHitesh JaniОценок пока нет

- Civil Work - CONCRETE GRADE - M5 1 - 4 - 8 M10 1 - 3 - 6 M15 1 - 2 - 4 M20 PDFДокумент6 страницCivil Work - CONCRETE GRADE - M5 1 - 4 - 8 M10 1 - 3 - 6 M15 1 - 2 - 4 M20 PDFArjun S SanakanОценок пока нет

- Question Calculate Rate Analysis For Size Stone Masonry (SSM) in CM 1:6 in Foundation SolДокумент1 страницаQuestion Calculate Rate Analysis For Size Stone Masonry (SSM) in CM 1:6 in Foundation SolAnusha ChikmathОценок пока нет

- Heading / Description: 1 - EARTHWORK, FILLING AND CONCRETINGДокумент9 страницHeading / Description: 1 - EARTHWORK, FILLING AND CONCRETINGUmakant AryaОценок пока нет

- Kattupalli Buildings BOQ Preliminary Rev.Документ24 страницыKattupalli Buildings BOQ Preliminary Rev.VasanthakumarОценок пока нет

- Name of Work: Rate Analysis For Valve Chamber (1.5 M X 1.5 M X 1 M)Документ5 страницName of Work: Rate Analysis For Valve Chamber (1.5 M X 1.5 M X 1 M)Vijay SinghОценок пока нет

- 20KL SUMP TITLEДокумент3 страницы20KL SUMP TITLEvisali garikapatiОценок пока нет

- BOQ - TaramaniДокумент46 страницBOQ - Taramanismith0% (1)

- Construction of 400 2BHK Houses Specification ReportДокумент110 страницConstruction of 400 2BHK Houses Specification ReportK KARTHIKОценок пока нет

- Boundary Wall DrawingДокумент1 страницаBoundary Wall DrawingBig Boy ToyzОценок пока нет

- Steel QuantityДокумент21 страницаSteel QuantityAshish Jain100% (1)

- EstimateДокумент14 страницEstimateAnonymous fQLEF2tQpqОценок пока нет

- NIFT DE Vertical ExtnДокумент45 страницNIFT DE Vertical Extnexecutive engineer1Оценок пока нет

- RA Bill-03-CheckedДокумент26 страницRA Bill-03-CheckedpandikumarОценок пока нет

- Measurement Sheet OIDCДокумент26 страницMeasurement Sheet OIDCAV ChavdaОценок пока нет

- Boq - Civil Work of Kilpauk ResidenceДокумент16 страницBoq - Civil Work of Kilpauk ResidenceVasanthakumarОценок пока нет

- Built Up Area Basis MaterialДокумент2 страницыBuilt Up Area Basis MaterialHossen Ali MollahОценок пока нет

- RCC SLAB 11-12 Rate AnalysisДокумент2 страницыRCC SLAB 11-12 Rate AnalysisRiazahemad B Jagadal0% (1)

- Competitive Quotation for PEB Civil Foundation WorkДокумент2 страницыCompetitive Quotation for PEB Civil Foundation WorkSreenivas BandiОценок пока нет

- Detailed Estimate of Stree Shakti BhavanДокумент9 страницDetailed Estimate of Stree Shakti BhavanObuladas MОценок пока нет

- Bar Bending Schedule: DDU-HOS-STR-107aДокумент21 страницаBar Bending Schedule: DDU-HOS-STR-107avat007Оценок пока нет

- Acfrogdqwmeslskvqklrdq8wbbv7 Pt3p5q4 N Mbvijr8q8evymkkpjn2 Mhloeijuvdzws0mkhfj2fy4mg4xd56fpalrrqyfwyfkiwzdfwbvgu8cto8vqtrjg1psgДокумент2 страницыAcfrogdqwmeslskvqklrdq8wbbv7 Pt3p5q4 N Mbvijr8q8evymkkpjn2 Mhloeijuvdzws0mkhfj2fy4mg4xd56fpalrrqyfwyfkiwzdfwbvgu8cto8vqtrjg1psgSrinivas SukhavasiОценок пока нет

- Abstract Estimate: Description Rate AmountДокумент8 страницAbstract Estimate: Description Rate AmountPUMAОценок пока нет

- Maintenance & EstimateДокумент40 страницMaintenance & EstimatePerkresht PawarОценок пока нет

- Main Gate & Emergency Gate DrawingДокумент2 страницыMain Gate & Emergency Gate DrawingAkil Vahora100% (1)

- Rate Analysis 15-09 Final Road LATESTДокумент18 страницRate Analysis 15-09 Final Road LATESTKotoju Rajitha SaisindhujaОценок пока нет

- Print Rate AnalysisДокумент124 страницыPrint Rate Analysisfelix sowah-laryeaОценок пока нет

- Project drainage programme reviewДокумент2 страницыProject drainage programme reviewMukhlish AkhatarОценок пока нет

- RCC Building Cost EstimateДокумент15 страницRCC Building Cost EstimateVirajee Civil Tech and consultantОценок пока нет

- CPWD Dar Vol II 14092023 CivilДокумент1 149 страницCPWD Dar Vol II 14092023 CivilNizar AhamedОценок пока нет

- Is 10067 1982Документ19 страницIs 10067 1982Sanjeev ChoudharyОценок пока нет

- Paving Flooring and DadoДокумент17 страницPaving Flooring and DadozfrlОценок пока нет

- Structure Work Order FormatДокумент4 страницыStructure Work Order FormatSRK QSОценок пока нет

- L B H No. Dia KG/M Weight No. Dia KG/M Weight C To CДокумент4 страницыL B H No. Dia KG/M Weight No. Dia KG/M Weight C To CPrasanta BoraОценок пока нет

- Cost estimate for construction of RCC footing and wall shutteringДокумент2 страницыCost estimate for construction of RCC footing and wall shutteringAtulJainОценок пока нет

- Shuttering Design & Cost Comparisons: Rawal Meet Hemant, Bharakhada Mayank Prakash, Dhawde Akash AnkushДокумент5 страницShuttering Design & Cost Comparisons: Rawal Meet Hemant, Bharakhada Mayank Prakash, Dhawde Akash AnkushmjrulezОценок пока нет

- MDPE Final TutorialДокумент4 страницыMDPE Final Tutoriallata sinsinwarОценок пока нет

- Complex Textile Structures As Reinforcement For Advanced Composite MaterialsДокумент16 страницComplex Textile Structures As Reinforcement For Advanced Composite MaterialsBayrak AlmuhsinОценок пока нет

- Reinforced building design and cost estimation case studyДокумент8 страницReinforced building design and cost estimation case studyPacha Khan KhogyaniОценок пока нет

- Sci P342Документ111 страницSci P342VijayОценок пока нет

- Advance Reinforced Concrete Design by Verghis - by WWW - Easyengineering.net-Pc VargeeshДокумент277 страницAdvance Reinforced Concrete Design by Verghis - by WWW - Easyengineering.net-Pc VargeeshBala SubramanianОценок пока нет

- Effeect of Shear Wall Vertical Discontin PDFДокумент14 страницEffeect of Shear Wall Vertical Discontin PDFBadr AmmarОценок пока нет

- Modelling Crack Propagation Using XFEM PDFДокумент16 страницModelling Crack Propagation Using XFEM PDFBala SubramanianОценок пока нет

- Matrix Structural Analysis 2nd Edition PDFДокумент482 страницыMatrix Structural Analysis 2nd Edition PDFetan100% (3)

- 2014-Impact Behaviour of Concrete BeamsДокумент9 страниц2014-Impact Behaviour of Concrete BeamsBala SubramanianОценок пока нет

- Earthquake Analysis Using Seismic Coefficient MethodДокумент4 страницыEarthquake Analysis Using Seismic Coefficient MethodV.m. RajanОценок пока нет

- Good For Construction: Key PlanДокумент6 страницGood For Construction: Key PlanBala SubramanianОценок пока нет

- Check List For Concreting: Project: Doc. No.: Qa/Cl-Con/ Client: ContractorДокумент1 страницаCheck List For Concreting: Project: Doc. No.: Qa/Cl-Con/ Client: ContractorBala SubramanianОценок пока нет

- Modelling of Concrete Specimen in Abaqus For Crack StudyДокумент7 страницModelling of Concrete Specimen in Abaqus For Crack StudyBala SubramanianОценок пока нет

- INCO 70.4 Composite Slab: Making Progress On Solid GroundДокумент4 страницыINCO 70.4 Composite Slab: Making Progress On Solid GroundBala SubramanianОценок пока нет

- Check List For Concreting: Project: Doc. No.: Qa/Cl-Con/ Client: ContractorДокумент1 страницаCheck List For Concreting: Project: Doc. No.: Qa/Cl-Con/ Client: ContractorBala SubramanianОценок пока нет

- Concrete Pouring Check List For Building ExecutionДокумент27 страницConcrete Pouring Check List For Building ExecutionBala SubramanianОценок пока нет

- Compressive Membrane Action in Slab at Edge and Corner Column in A Continuous Reinforced Flat SlabДокумент6 страницCompressive Membrane Action in Slab at Edge and Corner Column in A Continuous Reinforced Flat SlabBala SubramanianОценок пока нет

- 2017-Nonlinear FE Modeling of Reinforced Concrete PDFДокумент4 страницы2017-Nonlinear FE Modeling of Reinforced Concrete PDFBala SubramanianОценок пока нет

- Design of RCC DrainsДокумент7 страницDesign of RCC DrainsSatyanarayana Balaraman100% (1)

- Quasi-Static Failure Criteria For Concrete CubeДокумент33 страницыQuasi-Static Failure Criteria For Concrete CubeBala SubramanianОценок пока нет

- EXTENDED ABSTRACT Carolina ChurroДокумент11 страницEXTENDED ABSTRACT Carolina ChurroBala SubramanianОценок пока нет

- Autocad Tutorial 4 PDFДокумент7 страницAutocad Tutorial 4 PDFMaarij AnjumОценок пока нет

- Modelling Crack Propagation Using XFEM PDFДокумент16 страницModelling Crack Propagation Using XFEM PDFBala SubramanianОценок пока нет

- Earth Quake Load CalculationДокумент15 страницEarth Quake Load CalculationBala SubramanianОценок пока нет

- Man Hole PDFДокумент7 страницMan Hole PDFBala SubramanianОценок пока нет

- Silo DesignДокумент42 страницыSilo Designchaithra_14Оценок пока нет

- Earth Quake Load CalculationДокумент15 страницEarth Quake Load CalculationBala SubramanianОценок пока нет

- Internship Report - FinalДокумент113 страницInternship Report - Finalharnishtanna212Оценок пока нет

- Silo DesignДокумент42 страницыSilo Designchaithra_14Оценок пока нет

- Behaviour of Composite Floor Slabs Under Fire Conditions: M. M. Florides & K. A. CashellДокумент8 страницBehaviour of Composite Floor Slabs Under Fire Conditions: M. M. Florides & K. A. Cashellاحمد حسينОценок пока нет

- Level PDFДокумент1 страницаLevel PDFBala SubramanianОценок пока нет

- 573Документ11 страниц573Soveja LucianОценок пока нет

- Thin and Thick CylinderДокумент8 страницThin and Thick CylinderBala SubramanianОценок пока нет

- DO - 160 - s2016 Item 416 - Carbon Fiber SheetДокумент6 страницDO - 160 - s2016 Item 416 - Carbon Fiber Sheetfredelino jumbasОценок пока нет

- Flexible Fire Resistant Acoustic Mastic: ApprovalsДокумент2 страницыFlexible Fire Resistant Acoustic Mastic: ApprovalsibrahimОценок пока нет

- Production & Operations Management: POM - ProductivityДокумент22 страницыProduction & Operations Management: POM - ProductivityabhaybittuОценок пока нет

- Use of Geospatial Tech in Civil EngineeringДокумент2 страницыUse of Geospatial Tech in Civil EngineeringWinklerОценок пока нет

- Slab Punching Design According ACI318-08Документ6 страницSlab Punching Design According ACI318-08Mohammed HanafiОценок пока нет

- Proposed Three-Storey Commercial Building (Autosaved)Документ113 страницProposed Three-Storey Commercial Building (Autosaved)Shōya IshidaОценок пока нет

- Architects DictumДокумент3 страницыArchitects DictumChristian James TuazonОценок пока нет

- Gantt Chart - Project Management - Christal WongДокумент3 страницыGantt Chart - Project Management - Christal WongChristal WongОценок пока нет

- Ce - 07Документ1 страницаCe - 07Arnulfo Jose Pi DiОценок пока нет

- Proceedings of The 16th International Symposium For Tubular Structures (ISTS 2017) DecemДокумент721 страницаProceedings of The 16th International Symposium For Tubular Structures (ISTS 2017) DecemPhan Đào Hoàng HiệpОценок пока нет

- PLANT LAYOUT OF PHARMACEUTICALSДокумент20 страницPLANT LAYOUT OF PHARMACEUTICALSAli Akand AsifОценок пока нет

- Critical Regionalism in ArchitectureДокумент75 страницCritical Regionalism in ArchitecturebranishОценок пока нет

- Fit-Out Guidelines - VCB TowerДокумент36 страницFit-Out Guidelines - VCB TowerTrần Xuân HòaОценок пока нет

- Box Culvert BrochureДокумент4 страницыBox Culvert Brochurepramoedya04Оценок пока нет

- Ahmed Suleiman 1Документ3 страницыAhmed Suleiman 1HOSAM HUSSEINОценок пока нет

- Quiz 12Документ6 страницQuiz 12John Taylor BernasОценок пока нет

- MC ProcedureДокумент14 страницMC ProcedureHELIO SANTOS JUNIORОценок пока нет

- GPT Nadu NeduДокумент222 страницыGPT Nadu NeduSwarna LathaОценок пока нет

- 2007 Minnesota State Buidling Code PDFДокумент416 страниц2007 Minnesota State Buidling Code PDFRyan KuntzОценок пока нет

- Raines Court 2010 - LR-compressedДокумент37 страницRaines Court 2010 - LR-compressedPATEL MIHIKAОценок пока нет

- DOCUMENT Summary of Bending Moment & Shear ForceДокумент2 страницыDOCUMENT Summary of Bending Moment & Shear ForceHitendra MojidraОценок пока нет

- Roof and Floor Finish ScheduleДокумент1 страницаRoof and Floor Finish SchedulePrycian TaerОценок пока нет

- Fashion Crew Kids Jacket Styles Fabric DetailsДокумент26 страницFashion Crew Kids Jacket Styles Fabric DetailsTanmoy DebnathОценок пока нет

- Tamil Quarters PondicherryДокумент6 страницTamil Quarters PondicherryAkash MvОценок пока нет

- Experimental investigation on bamboo reinforced concrete beamsДокумент5 страницExperimental investigation on bamboo reinforced concrete beamsJoji Ann UayanОценок пока нет

- Pre-Engineered Building System (PEB) of Bangladesh: Volume-IДокумент10 страницPre-Engineered Building System (PEB) of Bangladesh: Volume-IMohsin Ul Amin KhanОценок пока нет

- Mbizm Value Stream Mapping For Manufacturing (VSM) Public TrainingДокумент1 страницаMbizm Value Stream Mapping For Manufacturing (VSM) Public TrainingRicky MarkОценок пока нет

- 11 - 20180221 - Materi Auditor PDFДокумент128 страниц11 - 20180221 - Materi Auditor PDFYan SuryoОценок пока нет

- Interview Questions122Документ75 страницInterview Questions122Sai GnanadeepОценок пока нет

- Estimating The Strength of Concrete Cube Using Copper Slag in The Replacement of Fine AggregateДокумент5 страницEstimating The Strength of Concrete Cube Using Copper Slag in The Replacement of Fine Aggregateshivanand hippargaОценок пока нет