Академический Документы

Профессиональный Документы

Культура Документы

Rheological Properties of Tomato Based

Загружено:

Anonymous vVsidh3nАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Rheological Properties of Tomato Based

Загружено:

Anonymous vVsidh3nАвторское право:

Доступные форматы

JFS

S: Sensory and Nutritive Qualities of Food

Rheological Properties of Tomatobased Products after Thermal

and High-pressure Treatment

I SABEL V ERLENT, MAR

C HENDRICKX, PIERP

AOL

O ROVERE, PAUL

A MOLDENAERS, AND ANN VAN LOE

Y

ARC

IERPA

OLO

ULA

OEY

ABSTRA

CT

heological pr

oper

ties of tomato homogenate w

er

e obser

ved when ther

mally tr

eated

ABSTRACT

CT:: D

Drrastic losses in the rrheological

proper

operties

wer

ere

observ

thermally

treated

ic pr

essur

e and the highest loss was found at 60 C. These losses w

er

e mor

e pr

onounced with incr

easatmospheric

pressur

essure

wer

ere

more

pronounced

increasat atmospher

ing pr

essur

es up to 300 MP

a, after which the negativ

e change in rrheological

heological pr

oper

ties of tomato homogenate depressur

essures

MPa,

negative

proper

operties

cr

eased. A

atur

es up to 60 C combined with 500 MP

a for

mation of a tomato gel str

uctur

e occurr

ed and an

creased.

Att temper

temperatur

atures

MPa

formation

structur

ucture

occurred

heological pr

oper

ties of tomato homogenate was obser

ved. H

owev

er

atur

es

impr

ovement in the rrheological

observ

Ho

ever

er,, at higher temper

temperatur

atures

impro

proper

operties

a, the rrheological

heological pr

oper

ties of the tomato pr

oduct w

er

e unalter

ed and no gel was for

med.

MPa,

proper

operties

product

wer

ere

unaltered

formed.

and 500 MP

ds: tomato homogenate

heological pr

oper

ties

mal and high-pr

essur

e pr

Keywor

ocessing

ties,, ther

thermal

high-pressur

essure

eywords:

homogenate,, rrheological

proper

operties

processing

MS 20050510 Submitted 8/23/05, Revised 10/13/05, Accepted 12/25/05. Authors Verlent, Hendrickx, and Van Loey are with Centre for Food and Microbial Technology, Faculty of Bioscience Engineering, Katholieke Univ. Leuven,

Kasteelpark Arenberg 22, B-3001 Leuven, Belgium. Author Rovere is with La

Stazione Sperimentale per lIndustria delle Conserve Alimentari (SSICA),

Parma, Italy. Author Moldenaers is with Dept. of Chemical Engineering, Faculty of Engineering, Katholieke Univ. Leuven, Leuven, Belgium. Direct inquiries to author Hendrickx (E-mail: Marc.Hendrickx@biw.kuleuven.be).

2006 Institute of Food Technologists

Further reproduction without permission is prohibited

Therefore, there is a growing interest in food processing and preservation technologies that do not make use of heat, or at least that

reduce the heat input of conventional technologies by reducing

treatment time and/or temperature (Mertens and Knorr 1992). One

of the technologies that is a possible alternative for the conventional

thermal processes is high-pressure processing. Besides the possibility to inactivate vegetative microorganisms (Mertens 1992; Knorr

1993), it is also known that high-pressure processing may display either enhancement or reduction in enzyme activity (Hendrickx and

others 1998). In this way, to improve or preserve the viscosity of tomato-based products, high-pressure processing may be used to selectively inactivate PG while maintaining PME activity (Crelier and others 2001; Fachin and others 2002, 2003, 2004). An additional

advantage of using high pressure is the improved preservation of the

nutritional and sensorial quality of processed products (Knorr 1993).

The influence of thermal processing on the rheological properties

of tomato-based products has already been partly described in the

literature, but only for temperatures higher than 65 C (Xu and others

1986; Snchez and others 2002; Valencia and others 2003). However,

literature on the effect of high-pressure processing on the rheological properties of such products is very scarce (Porretta and others

1995; Krebbers and others 2003). So, the aim of the present study is

to investigate the changes in rheological properties of tomato homogenate after processing in a broad temperature-pressure domain.

Materials and Methods

batch of light red tomatoes (Lycopersicon esculentum var. Flandria Prince, Tradiro) was purchased at commercial maturity. Sterilized cold (65 C) and hot (95 C) break tomato puree, both concentrated to about 12.5 Brix by vacuum heating (62 C, 0.2 bar), were produced by La Stazione Sperimentale per lIndustria delle Conserve

Alimentari (SSICA, Parma, Italy). All chemicals were of analytical grade.

Prepar

ation of tomato homogenate

eparation

Tomatoes (~350 g), equilibrated at room temperature, were

washed and chopped into large pieces, and their seeds were removed

by hand. The tomato pieces were then homogenized twice in a blender (Bchi Mixer B-400, Flawil, Switzerland, 9000 tr/min) for 5 s. Half

of the homogenized sample was kept as control. The other part of

Vol. 71, Nr. 3, 2006JOURNAL OF FOOD SCIENCE S243

Published on Web 3/27/2006

S: Sensory & Nutritive Qualities of Food

Introduction

he consumer demand for high-quality processed products with

fresh-like characteristics has increased remarkably in the past few

years. Preferences shift toward fresh, healthy, and rich-flavored readyto-eat foods with enhanced shelf life. Tomato is one of the most important fruit products. It is mainly marketed as processed products, that

is, pastes, concentrates, ketchup, salsa, and so on. Besides microbial

safety, important quality aspects of such tomato products are color,

taste, and viscosity (Gould 1992). Viscosity changes during processing

of tomato fruits are closely related to changes in pectin, a cell wall

polysaccharide, owing to the action of pectinmethylesterase (PME) and

polygalacturonase (PG). Hence, both enzyme systems should be controlled during processing to obtain the desired viscosity.

Nowadays, 2 conventional thermal processes, namely cold break

and hot break procedures, are applied in the industrial production

of tomato based products. In a cold break process, the chopped tomatoes are pumped into a heat exchanger and preheated to a temperature of approximately 65.5 C, whereby the pectolytic enzymes

PG and PME present in the tomatoes retain a sufficient part of their

activity and consequently are able to degrade the cell wall pectin

during subsequent processing. Hence, quality defects such as a decreased viscosity and syneresis occur, although such products appear

to keep their natural tomato color and fresh flavor. To overcome problems of viscosity loss and syneresis, a hot break process can be

applied. In such a thermal process, the chopped tomatoes are immediately preheated to a temperature between 77 C and 93 C. In this

case, the pectolytic enzymes are inactivated, resulting in a more viscous tomato product that does not separate upon standing. However,

quality losses in terms of flavor, color, and nutritional value are

caused due to this severe thermal treatment (Gould 1992; Snchez

and others 2002; Tiziani and Vodovotz 2005).

Rheological properties of tomato product . . .

the sample was packed and thermal or pressure treated as described subsequently. The total time needed to prepare the packed

homogenized sample and consequently to start the thermal or pressure treatment was standardized at 15 min.

Thermal treatment of tomato homogenate

Half of the prepared tomato homogenate (~150 g) was packed in

double polyethylene plastic bags (250 360 mm, thickness: 50 micron,

Medisch Labo Service, Menen, Belgium) and vacuum-sealed (Multivac

A300/16, Wolfertschwenden, Germany) up to 35 mbar. The sample was

spread over the whole internal area of the plastic bag, resulting in a

maximal average thickness of the filled bags of only 2 mm to avoid or

reduce temperature gradients in the sample. The sample was placed

in a temperature-controlled water bath during 15 min and afterward

immediately cooled in ice water for 2 min. After equilibration at room

temperature for 2 min, the consistency of the sample was measured

by means of a Bostwick consistometer (see Bostwick consistometer

section). During the thermal treatment of the sample, the consistency

of the control was also measured.

Combined pr

pressur

essure-temper

e-temperatur

ature

essur

e-temper

atur

e

tr

eatment of tomato homogenate

treatment

The combined pressure-temperature experiments were performed

in a pilot-scale single vessel high-pressure equipment (SO.5-7422-0,

warm isostatic press, Engineered Pressure Systems Int., Temse, Belgium) with a volume of 590 mL (5-cm dia, 30-cm length). The apparatus allows pressurization up to 600 MPa in combination with temperatures from 30 C to 100 C. The high-pressure pumping system

uses an electrically driven high-pressure intensifier with a displacement of 83 mL/min. The pressure medium is a propylene glycolbased fluid (60% Dowcal N, The Dow Chemical Co., Horgen, Switzerland). A cryostat allows heating or cooling of the system from the

outside of the vessel. An overshoot of pressure as compared with the

preset pressure is always observed due to technical limitations of the

equipment, which makes it difficult to control the exact pressure of

the high-pressure process. Consequently, the conditions of the highpressure process could slightly deviate from the desired conditions.

Half of the prepared tomato homogenate was poured in a flexible

polyethylene plastic flask (LDPE, ~100 mL, Medisch Labo Service),

further packed in double polyethylene plastic bags (120 170 mm,

Medisch Labo Service), and vacuum-sealed (Multivac A300/16, Wolfertschwenden, Germany) up to 35 mbar. The sample was placed in the

vessel, already equilibrated at a preset temperature. Pressurization was

done automatically up to the preset pressure and after 15 min of treatment time; the pressure was manually released and the sample was

immediately cooled in ice water for 2 min. After equilibration at room

temperature for 2 min, the consistency of the sample was measured

by means of a Bostwick consistometer (see the Bostwick consistometer section). During the pressure treatment of the sample, the consistency of the control was also measured.

Rheological measur

ements

measurements

S: Sensory & Nutritive Qualities of Food

Bostwick consistometer

consistometer.. The Bostwick consistometer is used to

determine the consistency of the tomato homogenate by determining

how far the homogenate flows under its own weight along a centimeter

scaled level surface in 30 s. The farthest point of flow on the scale at the

end of this time period was recorded as the index of consistency (cm)

for the tomato homogenate. To determine the alteration (loss or improvement) in consistency (cm) between thermal or pressure treated

(sample) and untreated tomato homogenate (control), the index of

consistency of the control was subtracted from the index of consistency

of the sample. Note that after each measurement the consistometer

was washed with water and dried completely before using again.

S244

JOURNAL OF FOOD SCIENCEVol. 71, Nr. 3, 2006

Drying is necessary as a moist surface will decrease the friction coefficient of the instrument and will result in false readings.

Immediately after the consistency measurement of sample or

control, the homogenate was packed in double polyethylene plastic

bags (250 360 mm, thickness: 50 micron), vacuum-sealed up to 35

mbar, and treated at 90 C for 15 min to inactivate the enzymes,

which are possibly still present in the tomato homogenate. After

cooling in ice water, the homogenate was stored at 4 C until determination of its rheological properties by means of a rotational rheometer (see the Rotational rheometer section).

The reproducibility of the consistency measurements was tested

for 2 selected (T, P) conditions, namely at 40 C and atmospheric

pressure (0.1 MPa) and at 40 C and elevated pressure (300 MPa). At

least 3 replications were performed for each condition (T, P). The

average loss in consistency was found to be 6.55 0.45 cm at 0.1 MPa

and 12.10 1.10 cm at 300 MPa, yielding a standard deviation of less

than 10% for both (T, P) conditions.

Rotational rrheometer

heometer

heometer.. To obtain rheological parameters, such

as viscosity () and viscoelastic properties (storage [G] and loss

[G] moduli), steady-shear and oscillatory-shear experiments were

carried out by means of the rotational Physica Modular Compact

Rheometer (MCR) 300 (Anton Paar GmbH, Graz, Austria) using a 6bladed vane geometry. The primary reason for using the vane geometry instead of the cylinder for shearing the tomato homogenate

was to eliminate serious wall-slip effects. An additional advantage

of using the vane is the minimum amount of disturbance of the

thixotropic homogenate, when adding the vane into the tomato

sample (Barnes and Nguyen 2001). Temperature was controlled by

means of Peltier elements and kept at 20.0 C.

The tomato homogenate was poured into the cup and the vane

was lowered into the sample. First, steady-shear experiments, describing the viscosity of the tomato homogenate, were carried out

using shear rates from 10/s to 0.1/s. The time duration for each

measuring point was 20 s and a total of 14 points were obtained for

each sample. Second, a 5-min rest period (shear rate was 0/s) was

introduced because tomato-based products are thixotropic. Hence,

the network, disturbed in the steady-shear experiments, could restore again. Third, oscillatory-shear experiments, measuring the

viscoelastic properties of the tomato homogenate, were done at

angular frequencies between 100 and 0.1 rad/s, using a constant

strain of 0.1%. Finally, amplitude tests (oscillation) were carried out

in which the angular frequency is kept constant at 10 rad/s, while

varying the strain between 0.01% and 10%. This final test is required

because the strain amplitude used in the oscillatory-shear experiments should be situated in the linear viscoelastic region, that is,

where the storage modulus G is nearly invariant with strain.

The reproducibility of the data obtained with the rheometer was also

tested for 2 selected (T, P) conditions, namely at 40 C and atmospheric

pressure (0.1 MPa) and at 40 C and elevated pressure (300 MPa). At least

3 replications were performed for each condition (T, P). A deviation of

less than 5% with regard to both the average viscosity and the average

moduli was found for both (T, P) conditions. Hence, measurements

performed with the rotational rheometer were reproducible.

Consistency of ther

mal-tr

eated

thermal-tr

mal-treated

eak tomato pur

break

puree

cold/hot br

ee

Originally, the aim was to use hot and/or cold break tomato purees as real tomato-based products, from which PME and PG were

inactivated. First, Tomato PG and PME were extracted using a method modified from that of Pressey (1986), which is described by Verlent

and others (2004). Further, different amounts of these purified tomato

PME (1 PME unit is defined as the amount of enzyme that produces 1 mol of acid per min at pH 7 and 22 C [Verlent and others

URLs and E-mail addresses are active links at www.ift.org

Rheological properties of tomato product . . .

Results and Discussion

Rheological pr

oper

ties of tomato

proper

operties

mal tr

eatment

thermal

treatment

homogenate after ther

The effect of temperature on the alteration in the consistency, the

viscosity, and the viscoelasticity of tomato homogenate was studied

for temperatures ranging from 30 C to 90 C.

At all temperatures tested, loss in consistency of the tomato homogenate after thermal treatment was observed, that is, the index of

consistency of the sample was always higher than the index of consistency of the respective control, yielding positive values (Figure 1 and

Figure 2). The highest loss in consistency was found at 60 C (Figure 1).

Generally, loss in consistency is due to pectin depolymerization by

the action of PG on pectin. However, PME also contributes indirectly to loss in consistency, as PME creates a good substrate for PG. Verlent and others (2005; Effect of temperature and pressure on the combined action of purified tomato pectinmethylesterase and

polygalacturonase in presence of pectin, submitted to Enzyme and

Microbial Technology) investigated the effect of temperature and pressure on the combined action of purified tomato PME and PG in the

presence of pectin at pH 4.4 and found an optimal temperature for

PME activity and PG activity around 60 C and 50 C, respectively,

explaining the drastic and even highest loss (60 C) in consistency of

tomato homogenate treated at these temperatures. The fact that only

PG contributes to loss in consistency was investigated in literature

URLs and E-mail addresses are active links at www.ift.org

(Porretta and Poli 1997; Errington and others 1998), by using transgenic tomato fruits, which had reduced amounts of PG activity. They

found no loss in consistency of both cold (65.5 C) and hot (77 C to

93 C) break tomato puree, as PG activity was inhibited. Errington and

others (1998) also investigated the alteration in consistency when

using transgenic tomatoes with reduced amounts of PME activity. They

found no significant differences between the consistency of the control

and the transgenic tomato sample, indicating that PME alone cannot

cause loss in consistency and consequently that no good substrate can

be created for PG because of the reduced PME activity.

Figure 3 represents steady-shear experiments, describing the

viscosity (Pa.s) of tomato homogenate in the function of the shear

rate (/s), after treatment for 15 min at various temperatures. The

figure shows how the viscosity values decrease with increasing

shear rate at all given temperatures, indicating that tomato homogenate displays shear-thinning flow behavior (this behavior is also

called pseudoplastic). This specific non-Newtonian behavior is

also described in the available literature (Fito and others 1983; Vercet and others 2002; Tiziani and Vodovotz 2005). The viscosity curve

Figure 1Loss in consistency of tomato homogenate after

thermal treatment at 0.1 MPa for 15 min

a)

b)

Figure 2Comparison of the index of consistency of untreated

tomato homogenate or control (a) with tomato homogenate

or sample treated at 40 C and 0.1 MPa for 15 min (b)

Vol. 71, Nr. 3, 2006JOURNAL OF FOOD SCIENCE

S245

S: Sensory & Nutritive Qualities of Food

2004]) (30 to 200 units/100 L) and PG (1 PG unit is defined as the

amount of enzyme that produces 1 mol of reducing groups per

min at pH 4.4 and 35 C [Verlent and others 2004]) (10 to 150 units/

100 L) enzymes were added to several samples of 150 g of either

the hot or the cold break tomato purees. The enzyme-puree mixtures were then subjected to thermal treatment at temperatures of

30 C, 40 C, 50 C, or 60 C for 1 h, performed as described for tomato homogenate (see Thermal treatment of tomato homogenate section), followed by a consistency measurement with the

Bostwick consistometer (see Bostwick consistometer section).

However, at all enzyme concentrations tested, these treatments

had no effect on the consistency of the tomato puree, that is, no difference was observed between the index of consistency of the sample and the index of consistency of the respective control or untreated hot/cold break tomato puree. Besides the fact that

interfering compounds can be present in real food systems, another

possible explanation may be that free enzymes cannot easily access pectin in contrast to endogenous enzymes. Hence, to counter

this problem, another real tomato-based product was used, namely

the previously described tomato homogenate, in which the enzymes are endogenous and active.

Consistency of high-pr

essur

e-tr

eated tomato pieces

high-pressur

essure-tr

e-treated

pieces.. Tomatoes

(~350 g), equilibrated at room temperature, were washed and

chopped, and their seeds were removed by hand. Half of the pieces was

kept as control and homogenized (Bchi Mixer B-400, Flawil, Switzerland, 9000 tr/min) twice for 5 s, after which the consistency was measured with the Bostwick consistometer (see the Bostwick consistometer section). The other portion of tomato pieces was packed in double

polyethylene plastic bags (60 220 mm, thickness: 50 microns, Medisch Labo Service) and vacuum-sealed (Multivac A300/16, Wolfertschwenden, Germany) up to 35 mbar. After a pressure treatment with the

pilot-scale single-vessel high-pressure equipment (SO.5-7422-0, warm

isostatic press, Engineered Pressure Systems Int), the sample was

immediately cooled in ice water. After equilibration at room temperature for 2 min, the sample was homogenized, after which the consistency of the sample was also measured with the Bostwick consistometer (see the Bostwick consistometer section).

Rheological properties of tomato product . . .

of 60 C is positioned lowest with regard to the viscosity curves of the

other given temperatures, pointing out that the viscosity of tomato

homogenate decreases most when treated at 60 C. These viscosity

observations are comparable with the consistency experiments.

The viscoelastic behavior of tomato homogenate, determined with

an oscillatory-shear experiment using angular frequencies between 100

and 0.1 rad/s and a constant strain of 0.1%, after treatment for 15 min

at 50 C is represented in Figure 4. Similar graphs were obtained for all

other temperatures tested. The storage modulus G represents the elastic

behavior of the sample and the loss modulus G represents the viscous

behavior. The curve functions of both parameters together describe the

viscoelastic behavior. The figure shows that tomato homogenate is viscoelastic, in which the elastic portion (G) dominates over the viscous

portion (G), concluding that tomato homogenate behaves as a weak gel.

This observation is consistent with available literature (Snchez and

others 2002; Valencia and others 2003; Tiziani and Vodovotz 2005). For

both sample and control, the storage modulus (G) reaches a plateau

with decreasing angular frequency (rad/s), indicating that a network in

the tomato homogenate is formed. Under the experimental conditions

explored here, no relationship was observed between the temperature

treatments and the viscoelastic properties.

Figure 5 illustrates the results of a typical strain sweep experiment

using a constant angular frequency of 10 rad/s and strains between

0.01% and 10% after treatment of the tomato homogenate for 15 min

at 50 C. For all other temperatures tested (30 C, 40 C, 60 C, 70 C,

80 C, and 90 C), similar graphs were obtained. Two regions can be

observed from the figure, namely a linear viscoelastic region, that is,

where the storage modulus (G) is nearly constant with strain, and a

nonlinear region with decreasing values of G. It can be seen that a

0.1% strain amplitude is in the linear viscoelastic region. Therefore,

the 0.1% strain amplitude used in the oscillatory-shear experiments

(Figure 4) is allowed to be used in these measurements.

Rheological properties of tomato homogenate

after high-pr

essur

e tr

eatment

high-pressur

essure

treatment

The effect of combined pressure-temperature treatments on the

alteration in the consistency, the viscosity, and the viscoelasticity of

tomato homogenate was studied for temperatures ranging from 30 C

to 70 C and pressures ranging from 100 to 500 MPa.

For all conditions tested, the highest loss in consistency of the tomato homogenate after combined pressure-temperature treatment was

found at 300 MPa at all temperatures tested (Figure 6). The combined

action of purified tomato PME and PG on pectin during thermal and

high-pressure processing was studied at pH 4.4 by Verlent and others

S: Sensory & Nutritive Qualities of Food

Figure 3Steady-shear viscosity data of tomato homogenate,

obtained with the rheometer, after treatment for 15 min at

30 C (), 40 C (), 60 C (), 90 C ()

Figure 5Amplitude test (oscillation), performed with the

rheometer, after treatment for 15 min at 50 C to determine

the limit of the linear viscoelastic range: storage modulus

(G) of sample () and control () and loss modulus (G) of

sample () and control ()

Figure 4Viscoelastic behavior of tomato homogenate,

measured with the rheometer, after treatment for 15 min at

50 C: storage modulus (G) of sample () and control () and

loss modulus (G) of sample () and control ()

Figure 6Loss in consistency of tomato homogenate after

combined pressure-temperature treatments for 15 min: 30 C

(), 40 C (), 50 C (), 60 C (), 70 C ()

S246

JOURNAL OF FOOD SCIENCEVol. 71, Nr. 3, 2006

URLs and E-mail addresses are active links at www.ift.org

Rheological properties of tomato product . . .

(2005; Effect of temperature and pressure on the combined action of

purified tomato pectinmethylesterase and polygalacturonase in presence of pectin, submitted to Enzyme and Microbial Technology), and

they observed that tomato PME was very active in presence of tomato

PG at pressures up to 300 MPa. PME creates a good substrate for PG,

which also has a sufficient high activity at 300 MPa. These findings

may explain the drastic loss in consistency of tomato homogenate treated at 300 MPa. Striking was that negative values were observed at temperatures up to 60 C combined with 500 MPa, indicating that the

consistency of the treated tomato homogenate was improved with

regard to the control, which is favorable (Figure 7).

However, the disadvantage is that a jelly-like translucent structure

was formed and serious syneresis occurred, which is unacceptable

for the consumer. These 2 phenomena were not or only to a small extent observed at lower pressure levels or at atmospheric pressure

(Figure 8). Porretta and others (1995) and Krebbers and others

(2003) also found that high-pressure-treated (>500 MPa) tomatobased products resulted in an improved viscosity and that a jelly-like

homogenous structure was formed. Porretta and others (1995) ascribed this gel formation to protein-tissue coagulation and compacting. At 70 C combined with 500 MPa, neither loss nor improvement

in consistency of the tomato homogenate was observed. So, this

seems to be the best processing condition toward food quality but

also toward food safety, as vegetative microorganisms are already

inactivated at 500 MPa and 25 C and outgrowth of remaining bacterial spores is prevented by the low pH (Mertens 1992; Porretta and

others 1995; Hendrickx and others 1998; Heinz and Knorr 2002). Several Salmonella and hepatitis outbreaks from tomato-based products have already been reported. However, it was found in the literature that, toward food safety, both Salmonella and hepatitis can be

easily inactivated by high-pressure processing, even at pressures

lower than 500 MPa combined with ambient temperature (Calci and

others 2005; Bayindirli and others 2006).

The improved consistency and the gel formation at 500 MPa were

further investigated. First, the treatment time of 15 min was shortened. However, even after a treatment time of only 5 min at 40 C

and 500 MPa, the same improvement in consistency was obtained,

and the appearance of the pressure-treated tomato homogenate was

a)

the same compared with a treatment time of 15 min. Porretta and

others (1995) described that viscosity is strongly dependent on the

pressure applied, but independent of treatment time. Second, by

addition of the chelator EDTA (Sigma), it was investigated to what extent the formation of the gel and the improved consistency at 40 C

and 500 MPa can be ascribed to the presence of calcium ions. 5 g

EDTA, allowing calcium ion binding, was added to 350 g chopped tomatoes from which the seeds were removed. The whole was then

homogenized, and the obtained homogenate was pressure treated

at 40 C and 500 MPa. The index of consistency of the control was

much higher than usual, indicating that in all probability the chelator

EDTA bounded present calcium ions, resulting in a break down of

current bonds between pectin and calcium ions. After treatment at

40 C and 500 MPa, the index of consistency was the same as compared with the control, but no gel formation or syneresis occurred.

Hence, it is presumable that calcium ions play a crucial role in the gel

formation and improvement of the consistency at 500 MPa due to

crosslinking of low-methoxyl pectin chains, generated by PME, with

calcium ions. Very recently in the context of thermal processing, Anthon and others (2005) observed an improved firmness of diced tomatoes during calcium treatment. They found that an increased

PME activity leads to extensive pectin deesterification and increased

calcium cross-linking of the pectins.

In a final experiment, tomato pieces were pressure-treated at 40 C

and 500 MPa for 15 min (see Materials and Methods section) after

which the consistency of the homogenized sample was measured.

The index of consistency of the sample was lower than that of the

control, yielding again a negative Bostwick-value which is of course

favorable. Even though the tomato pieces appeared to be jelly-like

before blending, after homogenization, no gel structure occurred

anymore. At 1st instance, hardly no syneresis was observed, but after

awhile, separation of water was perceptible.

Steady-shear experiments after treatment of the tomato homogenate for 15 min at 30 C combined with various pressures are represented in Figure 9. Similar graphs were obtained for all other pressure-temperature combinations tested. As at atmospheric pressure,

the viscosity values decrease with increasing shear rate at all given

pressures at 30 C, pointing out that tomato homogenate displays

pseudoplastic flow behavior. The sample treated at 500 MPa has

the highest viscosity, and the sample treated at 300 MPa has the

lowest viscosity. These findings are comparable with the results acquired in the consistency experiments.

An example of an oscillatory-shear experiment after treatment of

Figure 7Comparison of the index of consistency of untreated

tomato homogenate or control (a) with tomato homogenate or

sample treated at 40 C and 500 MPa for 15 min (b)

URLs and E-mail addresses are active links at www.ift.org

Figure 8Comparison of the appearance of processed tomato

homogenates at 40 C for 15 min at 0.1 MPa (a) and at 500

MPa (b)

Vol. 71, Nr. 3, 2006JOURNAL OF FOOD SCIENCE

S247

S: Sensory & Nutritive Qualities of Food

b)

Rheological properties of tomato product . . .

the tomato homogenate for 15 min at 30 C and 500 MPa, showing

the viscoelastic behavior of tomato homogenate, is represented in

Figure 10, which is similar to Figure 4. For all other pressure-temperature combinations tested, similar graphs were obtained. However,

only at pressures of 500 MPa the curves of the sample are positioned

above the curves of the control, which is the opposite for all other

pressures tested lower than 500 MPa. This observation is analogous

to the negative Bostwick-values at 500 MPa in the consistency experiments. Under the experimental conditions explored here, no other

relationships were observed between the temperature-pressure

treatments and the viscoelastic properties. Apart from that, the same

findings were observed as at atmospheric pressure.

efficient to improve the rheological properties of tomato homogenate. However, other quality defects, such as syneresis and formation of a jelly-like translucent structure, occurred. Nevertheless, no

gel structure was observed anymore after homogenization, the problem of syneresis still exists but to a lesser extent. No change in rheological properties or in appearance of the tomato homogenate treated at 500 MPa and 70 C was observed. Hence, the tomato product

quality is preserved at this process condition but based on the literature, the microbial safety of the tomato product is also retained.

The conditions described previously need validation for other tomato varieties that might have differences, for example, in pectin content, enzyme activity, and pH.

Conclusions

Acknowledgments

ectin in tomato puree, in which the pectin degrading enzymes

were inactivated, cannot be degraded by freely added tomato PME

and PG. Consequently, to improve the rheological properties of tomato-based products, proper process conditions must be chosen to

enhance and reduce the activity of the endogenous tomato PME and

PG, respectively. Thermal treatments and high-pressure treatments

up to 400 MPa of tomato homogenate lead to serious damages of

rheological properties. On the contrary, high-pressure treatments at

500 MPa, combined with temperatures up to 60 C, seemed to be very

This research has been supported by the Flemish GovernmentIWT, the Fund for Scientific Research Flanders, and the Research

Council of the Katholieke Universiteit Leuven.

Figure 9Steady-shear viscosity data of tomato homogenate,

obtained with the rheometer, after treatment for 15 min at

30 C combined with 0.1 MPa (), 100 MPa (), 300 MPa (),

500 MPa ()

S: Sensory & Nutritive Qualities of Food

Figure 10Viscoelastic behavior of tomato homogenate,

measured with the rheometer, after treatment for 15 min at

30 C and 500 MPa: storage modulus (G) of sample () and

control () and loss modulus (G) of sample () and control ()

S248

JOURNAL OF FOOD SCIENCEVol. 71, Nr. 3, 2006

References

Anthon GE, Blot L, Barrett DM. 2005. Improved firmness in calcified diced tomatoes by temperature activation of pectin methylesterase. J Food Sci 70:3427.

Barnes HA, Nguyen QD. 2001. Rotating vane rheometrya review. J Non-Newtonian

Fluid Mech 98:114.

- F, Hizal M. 2006. Efficiency of high pressure treatBayindirli A, Alpas H, Bozoglu

ment on inactivation of pathogenic microorganisms and enzymes in apple,

orange, apricot and sour cherry juices. Food Control 17:528.

Calci KR, Meade GK, Tezloff RC, Kingsley DH. 2005. High-pressure inactivation

of hepatitis A virus within oysters. Appl Environ Microbiol 71:33943.

Crelier S, Robert MC, Claude J, Juillerat MA. 2001. Tomato (Lycopersicon esculentum)

pectin methylesterase and polygalacturonase behaviors regarding heat- and pressure-induced inactivation. J Agric Food Chem 49:556675.

Errington N, Tucker GA, Mitchell JR. 1998. Effect of genetic down-regulation of polygalacturonase and pectin esterase activity on rheology and composition of tomato

juice. J Sci Food Agric 76:5159.

Fachin D, Smout C, Verlent I, Ly Nguyen B, Van Loey AM, Hendrickx ME. 2004. Inactivation kinetics of purified polygalacturonase by thermal and high pressure processing. J Agric Food Chem 52:2697703.

Fachin D, Van Loey AM, Ly Nguyen B, Verlent I, Indrawati, Hendrickx ME. 2002. Comparative study of the inactivation kinetics of pectinmethylesterase in tomato juice

and purified form. Biotechnol Progr 18:73944.

Fachin D, Van Loey AM, Ly Nguyen B, Verlent I, Indrawati, Hendrickx ME. 2003. Inactivation kinetics of polygalacturonase in tomato juice. Innovative Food Science and Emerging Technologies (IFSET) 4:13542.

Fito PJ, Clemente G, Sanz FJ. 1983. Rheological behavior of tomato concentrate

(hot break and cold break). J Food Eng 2:5162.

Gould WA. 1992. Tomato production, processing and technology. 3 ed. Timonium, Md.: CTI Publications. 536 p.

Heinz V, Knorr D. 2002. Effects of high pressure on spores. In: Hendrickx MEG, Knorr

D, editors. Food engineering series. Ultra high pressure treatments of foods. New

York: Kluwer Academic/Plenum Publishers. p 77113.

Hendrickx M, Ludikhuyze L, Van den Broeck I, Weemaes C. 1998. Effects of high pressure on enzymes related to food quality. Trends Food Sci Technol 9:197203.

Knorr D. 1993. Effects of high-hydrostatic-pressure processes on food safety and quality. Food Technol 47:15661.

Krebbers B, Matser AM, Hoogerwerf SW, Moezelaar R, Tomassen MMM, van den Berg

RW. 2003. Combined high-pressure and thermal treatments for processing of tomato puree: evaluation of microbial inactivation and quality parameters. Innov Food

Sci Emerg Technol 4:37785.

Mertens B, Knorr D. 1992. Developments of nonthermal processes for food preservation. Food Technol 46:12433.

Mertens B. 1992. Under pressure. Food Manuf 67:234.

Porretta S, Birzi A, Ghizzoni C, Vicini E. 1995. Effects of ultra-high hydrostatic pressure treatments on the quality of tomato juice. Food Chem 52:3541.

Porretta S, Poli G. 1997. Tomato pure quality from transgenic processing tomatoes.

Int J Food Sci Technol 32:52734.

Pressey R. 1986. Extraction and assay of tomato polygalacturonases. HortScience

21:4902.

Snchez MC, Valencia C, Gallegos C, Ciruelos A, Latorre A. 2002. Influence of processing on the rheological properties of tomato paste. J Sci Food Agric 82:9907.

Tiziani S, Vodovotz Y. 2005. Rheological effects of soy protein addition to tomato

juice. Food Hydrocoll 19:4552.

Valencia C, Snchez MC, Ciruelos A, Latorre A, Madiedo JM, Gallegos C. 2003. Nonlinear viscoelasticity modeling of tomato paste products. Food Res Int 36:9119.

Vercet A, Snchez C, Burgos J, Montas L, Buesa PL. 2002. The effects of manothermosonication on tomato pectic enzymes and tomato paste rheological

properties. J Food Eng 53:2738.

Verlent I, Van Loey A, Smout C, Duvetter T, Hendrickx ME. 2004. Purified tomato polygalacturonase activity during thermal and high-pressure treatment. Biotechnol Bioeng 86:6371.

Xu SY, Shoemaker CF, Luh BS. 1986. Effect of break temperature on rheological

properties and microstructure of tomato juices and pastes. J Food Sci 51:399

402, 407.

URLs and E-mail addresses are active links at www.ift.org

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Emission Control (2uz-Fe)Документ15 страницEmission Control (2uz-Fe)Abbode HoraniОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- 17-QA-QC ManualДокумент34 страницы17-QA-QC ManualAbdul Gaffar100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Conduction Convection Radiation ReadingДокумент5 страницConduction Convection Radiation ReadingAnonymous vVsidh3nОценок пока нет

- Decommissioning HSE PDFДокумент105 страницDecommissioning HSE PDFRafael Rocha100% (1)

- Membrane AutopsyДокумент2 страницыMembrane AutopsyBiljana TausanovicОценок пока нет

- Hydrocolloids As Thickening and Gelling Agents in FoodДокумент11 страницHydrocolloids As Thickening and Gelling Agents in FoodAnonymous vVsidh3nОценок пока нет

- Switchyard Equipments, Switching Schmes & LayoutsДокумент66 страницSwitchyard Equipments, Switching Schmes & LayoutsPraveen Kumar88% (17)

- Sensory Evaluation in FoodДокумент32 страницыSensory Evaluation in FoodAnonymous vVsidh3nОценок пока нет

- User Manual: Samsung Medison Diagnostic Ultrasound SystemДокумент686 страницUser Manual: Samsung Medison Diagnostic Ultrasound SystemHuế Trần100% (1)

- Food Laws and Regulations PDFДокумент102 страницыFood Laws and Regulations PDFAnonymous vVsidh3n83% (12)

- D 7752Документ6 страницD 7752Asep TheaОценок пока нет

- 3 Growing in FaithДокумент5 страниц3 Growing in FaithJohnny PadernalОценок пока нет

- Molecules: Antifungal Activity of Eugenol Derivatives Against Botrytis CinereaДокумент14 страницMolecules: Antifungal Activity of Eugenol Derivatives Against Botrytis CinereaAnonymous vVsidh3nОценок пока нет

- 1303-Article Full Text-2150-1-10-20171117Документ13 страниц1303-Article Full Text-2150-1-10-20171117Anonymous vVsidh3nОценок пока нет

- Diet Optimization Using Linear ProgrammingДокумент8 страницDiet Optimization Using Linear ProgrammingAnonymous vVsidh3nОценок пока нет

- Biodegradable Films Obtained From Mixtures of Fibrous and Nanoparticulated ChitosansДокумент2 страницыBiodegradable Films Obtained From Mixtures of Fibrous and Nanoparticulated ChitosansAnonymous vVsidh3nОценок пока нет

- 2006 Journal of Agricultural and Food Chimes TryДокумент7 страниц2006 Journal of Agricultural and Food Chimes TryAnonymous vVsidh3nОценок пока нет

- Flower Colour Analyses in Tulip (TulipaДокумент2 страницыFlower Colour Analyses in Tulip (TulipaAnonymous vVsidh3nОценок пока нет

- PhysicoChemicalThermal and Mechanical Approaches For The Characterization of Solubilized and Solid State ChitosansДокумент9 страницPhysicoChemicalThermal and Mechanical Approaches For The Characterization of Solubilized and Solid State ChitosansAnonymous vVsidh3nОценок пока нет

- Experimental Study of Natural Convection Heat Transfer From An EnclosedДокумент8 страницExperimental Study of Natural Convection Heat Transfer From An EnclosedAnonymous vVsidh3nОценок пока нет

- CHavan (2012), Pointing (1973), Pokharkar (1998) PDFДокумент8 страницCHavan (2012), Pointing (1973), Pokharkar (1998) PDFGagah AnaldiОценок пока нет

- Kinetic Analysis of Non-Enzymatic Browning in Carrot JuiceДокумент8 страницKinetic Analysis of Non-Enzymatic Browning in Carrot JuiceAnonymous vVsidh3nОценок пока нет

- Possibilities and Limitations of Pervaporation For Improved Ac 2012 ProcediaДокумент3 страницыPossibilities and Limitations of Pervaporation For Improved Ac 2012 ProcediaAnonymous vVsidh3nОценок пока нет

- Basics of Heat TransferДокумент14 страницBasics of Heat TransferPahile Bajirao PeshaveОценок пока нет

- 2015 Amsa Sensory Guidelines 1 0 PDFДокумент105 страниц2015 Amsa Sensory Guidelines 1 0 PDFAnonymous vVsidh3nОценок пока нет

- Unit: 3 - Vouching: by Mahitha VasanthiДокумент15 страницUnit: 3 - Vouching: by Mahitha VasanthianuragОценок пока нет

- ACED Murugadoss PPT TAFEДокумент91 страницаACED Murugadoss PPT TAFEMarikya GuptaОценок пока нет

- TMP DEDAДокумент8 страницTMP DEDAFrontiersОценок пока нет

- Peritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionДокумент10 страницPeritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionAjeng SuparwiОценок пока нет

- Ans Sheet Chemical 23111Документ96 страницAns Sheet Chemical 23111Aejaz MujawarОценок пока нет

- Disease PreventionДокумент14 страницDisease PreventionJoan InsonОценок пока нет

- Bakery Business PlanДокумент15 страницBakery Business PlanGayu AishuОценок пока нет

- Pressure MeasurementДокумент293 страницыPressure MeasurementGlen Lauren PerezОценок пока нет

- 3.0.2 3.0.2 Thermax Inc.: Pressure Building Ambient Vaporizers For Bulk Storage TanksДокумент2 страницы3.0.2 3.0.2 Thermax Inc.: Pressure Building Ambient Vaporizers For Bulk Storage TanksSiDdu KalashettiОценок пока нет

- Manuscript 1Документ26 страницManuscript 1Juan Paolo CapatiОценок пока нет

- Measurement LabДокумент4 страницыMeasurement LabHenessa GumiranОценок пока нет

- Medical Devices Industry in IndiaДокумент6 страницMedical Devices Industry in IndiaMurali Krishna Reddy100% (1)

- Reading Comprehension MaterialsДокумент6 страницReading Comprehension MaterialsDiana PundavelaОценок пока нет

- Research Methods - Print - QuizizzДокумент5 страницResearch Methods - Print - QuizizzpecmbaОценок пока нет

- Azure Essentials: Module 5: Azure Cost Management and Service Level AgreementsДокумент9 страницAzure Essentials: Module 5: Azure Cost Management and Service Level Agreementsrajagopalan19Оценок пока нет

- 2016 Liberal Policy ResolutionsДокумент86 страниц2016 Liberal Policy ResolutionsCPAC TVОценок пока нет

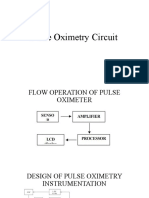

- Pulse Oximetry CircuitДокумент19 страницPulse Oximetry Circuitنواف الجهنيОценок пока нет

- Permatex, Inc - Ultra Gasket Sealant 1ozДокумент3 страницыPermatex, Inc - Ultra Gasket Sealant 1ozjaredf@jfelectric.comОценок пока нет

- BS Pharmacy - ProspectusДокумент9 страницBS Pharmacy - ProspectusDomz BucadОценок пока нет

- Field Study 1-Act 5.1Документ5 страницField Study 1-Act 5.1Mariya QuedzОценок пока нет

- Maintenance Service Procedure Document For AMC: Scada &telecom System For Agcl Gas Pipeline NetworkДокумент17 страницMaintenance Service Procedure Document For AMC: Scada &telecom System For Agcl Gas Pipeline NetworkanupamОценок пока нет

- BRSM Form 009 - QMS MDD TPDДокумент15 страницBRSM Form 009 - QMS MDD TPDAnonymous q8lh3fldWMОценок пока нет