Академический Документы

Профессиональный Документы

Культура Документы

W

Загружено:

Ridwan NugrahaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

W

Загружено:

Ridwan NugrahaАвторское право:

Доступные форматы

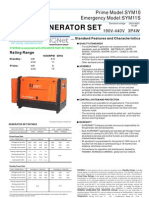

ProductSpecification82451

(RevisionW,9/2015)

TM25LPandTM200LP

LinearProportionalActuators

Application

Proportional

electric-hydraulic

25 mm (1 inch)

linear output

Maximum work

ratings from

72 to 231 J

(53 to 170 ft-lb)

Corrosion resistant

construction

The actuators have aluminum cases and through-hardened stainless-steel internal parts.

A 40 m low-capacity screen is provided in the supply inlet fitting to protect the torque motor

servovalve in case of failure of the external filter.

The units will operate with either centrifugal or fixed-displacement type pumps providing

hydraulic pressure.

The actuators are calibrated at the factory for bias in the minimum-fuel direction in event of the

loss of input current.

A dual-coil torque motor is optional for redundancy. The dual-coil actuator has an optional

position-feedback transducer.

For more information, refer to Woodward Manual 82450.

Models are

available with

certification for

Canada

Hazardous

Locations

Models are

available with

listings for United

States Hazardous

Locations

Specifications

Models are

available

compliant with the

applicable CE

Directives

ATEX, Pressure

Equipment,

Machinery

Models are

available with TIIS

and Korea-KC

certification for use

in hazardous

locations

The TM-25/200LP actuators provide

25 mm (1 inch) of linear movement of

valves for steam or gas turbines.

Description

The TM-25LP and TM-200LP

actuators are electric-hydraulic,

proportional actuators for positioning

steam and fuel-control valves

requiring low/high force linear inputs.

Factory setting determines if the

actuator output shaft extends or

retracts on increasing current.

Features

Output Shaft

Hardened 17-4 stainless steel 0.625-inch (15.88 mm) round, with one-inch square (645 mm) 17-4

stainless steel rod end attached by 0.375-inch (9.52 mm)/24-threads/inch threads. Optional rod end

features 0.625-inch (15.88 mm) slot with 0.500-inch (12.70 mm) hole to pin linkage to valve. Other

designs are available.

Work Capacity

TM-25LP

TM-200LP

72 J (53 ft-lb) at 2586 kPa (375 psig)

231 J (170 ft-lb) at 8274 kPa (1200 psig)

Output Force

TM-25LP

TM-200LP

2833 N (637 lb) maximum at 2586 kPa (375 psig) in either direction

9074 N (2040 lb) maximum at 8274 kPa (1200 psig) in either direction

Response Time Constant (25% to 75% step)

TM-25LP

0.065 second at 1724 kPa (250 psi)

0.150 second at 690 kPa (100 psi)

TM-200LP

0.045 second at 6895 kPa (1000 psi)

Hysteresis

TM-25LP

TM-200LP

1% of travel

1% of travel

Side Load

TM-25LP

TM-200LP

222 N (50 lb) maximum

222 N (50 lb) maximum

Woodward 82451 p.2

HYDRAULIC SUPPLY REQUIREMENTS

Fluid Types

Mineral or synthetic based oils, diesel fuels, kerosenes,

gasolines, or light distillate fuels.

Specific Gravity

0.6 to 1.0

Recommended Viscosity

0.6 to 400 centistokes; 150200 SSU; ISO 32 grade

External Filtration Required

10 m nominal, 25 m absolute

Hydraulic Cleanliness Level

ISO 4406 20/18/15 minimum

Woodward recommends adequate dither be used on all

hydraulic actuators to minimize mA threshold and hysteresis

which can result from second stage static friction or hydraulic

contamination.

Dither is a low amplitude, relatively high frequency periodic

signal that is superimposed on the servovalve input current

signal. A typical dither signal generated by a Woodward control

is:

25 Hz, 010 mA (tunable) amplitude

25% duty cycle, bipolar, square wave

Adequate dither is defined as that amount which produces no

more than 0.0005 inch (0.013 mm) total oscillation in output

shaft position.

Supply Pressure

TM-25LP

5522586 kPa (80375 psig)

TM-200LP

27588274 kPa (4001200 psig)

Minimum Supply Flow (Steady State)

TM-25LP

3.8 L/min (1.0 US gal/min)

TM-200LP

3.8 L/min (1.0 US gal/min)

Maximum Supply Flow (Transient)

TM-25LP

18.9 L/min (5.0 US gal/min)

TM-200LP

18.9 L/min (5.0 US gal/min)

HYDRAULIC TEMPERATURE REQUIREMENTS

Ambient Temperature Range

40 to +93 C (40 to +199 F)

Hydraulic Fluid Temperature Range

16 to 79 C (60 to 175 F)

ELECTRICAL CHARACTERISTICS

(For both TM-25LP and TM-200LP)

Input Current Range

20 to 200 mA

Null current shifts of up to 4% of maximum rated current

(200 mA) can occur due to variations in the following

parameters: hydraulic supply and return pressures, hydraulic

fluid temperature servovalve, and actuator wear.

Due to the inherent null shifts and position drift of all hydraulic

servovalves and proportional actuators, engine control

applications must be designed with these errors in mind.

Coil Resistance (at 21 C / 70 F)

26 (single-coil)

40 (dual-coil)

Maximum Coil Current

460 mA

TM-25LP dual coil

250 mA

TM-25LP single coil

250 mA

TM-200LP

Position Feedback Transducer

Optional on dual-coil models only

CONNECTIONS

2-wire connection in 0.500-inch/14-TPI rigid conduit connector; 2x

18 AWG (0.8 mm) wires extend approximately 91 cm (36 inches)

0.750-inch/16 TPI Hydraulic Supply connection

UNJF-3A (-08) (MS 33656)

0.875-inch/14 TPI Hydraulic Drain connection

UNJF-3A (-10) (MS 33656)

MOUNTING

The attitude of installation does not affect the performance of

the actuator.

Six-inch (152 mm) mounting flange with 2.938-inch (74.62 mm)

hub contains six 0.438-inch (11.13 mm) bolt holes on

4.875-inch (123.82 mm) bolt circle; flange is approximately

0.625-inch (15.88 mm) thick.

TERMINAL SHAFT OPTIONS

TM actuators are available with either internal (female) 0.375-24

UNF threads or external (male) 0.375-24 threads. A clevis-type rod

end can also be purchased and installed on the external threads.

MASS / WEIGHT

9 kg (20 lb), approximate dry weight

REGULATORY COMPLIANCE

European Compliance for CE Marking:

These listings are limited only to those TM-25LP units bearing

the CE Marking.

ATEX Potentially Explosive Atmospheres Directive:

Declared to 94/9/EC COUNCIL DIRECTIVE of 23 March

1994 on the approximation of the laws of the Member States

concerning equipment and protective systems intended for

use in potentially explosive atmospheres.

TM-25LP Single Coil: LCIE 12 ATEX 3022 X; Zone 1,

Category 2, Group II, Ex e IIC T4 Gb IP54

TM-25LP Dual Coil: Zone 2, Category 3, Group II, Ex nA

IIC T4 Gc IP54; LCIE 12 ATEX 3064 X; Zone 1,

Category 2, Group II, Ex d IIB T4 Gb c IIB T4 IP54

Note: Special conditions for safe use are provided in manual 82450.

Other European Compliance: Compliance with the following

European Directives or standards does not qualify this product

for application of the CE Marking:

EMC Directive: Not applicable to this product. Electromagnetically

passive devices are excluded from the scope of the

2004/108/EC Directive.

Machinery Directive: Compliant as Partly Completed

Machinery with 2006/42/EC of the European Parliament and

the Council of 17 May 2006 on machinery.

Pressure Equipment Directive: Compliant as SEP per

Article 3.3 to Pressure Equipment Directive 97/23/EC of 29

May 1997 on the approximation of the laws of the Member

States concerning pressure equipment.

Other International Compliance:

TIIS: The TM-25LP Single Coil Actuator is certified for use in

Japanese hazardous locations per TIIS Certificate TC17927

as Ex e II T3 (155 C).

KC Korea: Certified for use in explosive atmospheres per KTL

Certificate 14-KB4BO-0390X as Ex e IIC T4

IECEx: TM-25LP Single Coil: LCI 12.0010X Ex e IIC T4 Gb IP54

TM-25LP Dual Coil: LCI 12.0011X Ex nA IIC T4 Gc IP54;

Ex d IIB T4 Gb IP54

North American Compliance: These listings are limited only

to those units bearing the CSA agency identification.

CSA: CSA Certified for use in the United States and Canada

Single and dual coil actuators certified for Class I, Division 2,

Groups A, B, C, & D

Dual coil actuators certified for Class I, Division 1, Groups C & D

Woodward 82451 p.3

Outline Drawing of Single Coil TM-25/200LP Actuator (Do not use for construction)

Outline Drawing of Dual Coil TM-25/200LP Actuator (Do not use for construction)

Woodward 82451 p.4

Single/Dual Coil Schematic TM-25/200LP Actuator

A change in control signal to the torque motor results in a proportional change in terminal shaft position as follows: In

the actuator, the torque motor servovalve is energized by the electronic control to generate a hydraulic pressure

differential which is applied to the ends of the second stage spool valve. Hydraulic supply pressure to the servo

piston is controlled by the second stage spool valve to move the double-acting piston and provide terminal shaft

movement. Internal mechanical feedback re-centers the torque motor flapper which equalizes pressure across the

second stage spool valve and stops terminal shaft movement.

PO Box 1519, Fort Collins CO, USA 80522-1519

1000 East Drake Road, Fort Collins CO 80525

Tel.: +1 (970) 482-5811 Fax: +1 (970) 498-3058

www.woodward.com

Distributors & Service

Woodward has an international network of distributors and service facilities.

For your nearest representative, call the Fort Collins plant or see the

Worldwide Directory on our website.

This document is distributed for informational purposes only. It is not to be construed as

creating or becoming part of any Woodward contractual or warranty obligation unless

expressly stated in a written sales contract.

Copyright Woodward, Inc. 19992015, All Rights Reserved

For more information contact:

Вам также может понравиться

- Champion 700 Series Motor Grader Series I Operators Manual Revision 1 8-24-1977 PDFДокумент54 страницыChampion 700 Series Motor Grader Series I Operators Manual Revision 1 8-24-1977 PDFjulianmata77% (13)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsОт EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsРейтинг: 3.5 из 5 звезд3.5/5 (6)

- Marine Electrical Practice: Marine Engineering SeriesОт EverandMarine Electrical Practice: Marine Engineering SeriesРейтинг: 4 из 5 звезд4/5 (8)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- 110 Waveform Generator Projects for the Home ConstructorОт Everand110 Waveform Generator Projects for the Home ConstructorРейтинг: 4 из 5 звезд4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Рейтинг: 2.5 из 5 звезд2.5/5 (3)

- ASV Posi-Track PT-80 Track Loader Parts Catalogue Manual PDFДокумент14 страницASV Posi-Track PT-80 Track Loader Parts Catalogue Manual PDFfisekkkdОценок пока нет

- Sevice Manual BOBCAT S630 PDFДокумент890 страницSevice Manual BOBCAT S630 PDFArtemio Garcia Barrientos100% (11)

- DC - DC ConverterДокумент14 страницDC - DC ConverterVara Prasad ReddyОценок пока нет

- Perkins Diesel Generator P400pub 360kwДокумент4 страницыPerkins Diesel Generator P400pub 360kwTariq KoyrattyОценок пока нет

- Motor Pump Protection RelaysДокумент6 страницMotor Pump Protection RelaysAnand ShuklaОценок пока нет

- Moog D633Документ16 страницMoog D633Balu M100% (1)

- SR.11.10961 - Sour Well Design GuideДокумент52 страницыSR.11.10961 - Sour Well Design GuideMahmoud Ahmed Ali Abdelrazik100% (1)

- D 633 Series Valves eДокумент16 страницD 633 Series Valves ehaggОценок пока нет

- Ansaldo Thomassen - Flexible Service Agreements (2014)Документ4 страницыAnsaldo Thomassen - Flexible Service Agreements (2014)guerrezОценок пока нет

- Date Company Code Bank RefДокумент16 страницDate Company Code Bank RefSrinivas YОценок пока нет

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlОт EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlРейтинг: 5 из 5 звезд5/5 (1)

- TM25Документ4 страницыTM25Richarson Ochoa100% (1)

- Switch On To The Best: Cam Operated Rotary SwitchesДокумент32 страницыSwitch On To The Best: Cam Operated Rotary Switchesbagastc100% (1)

- Diesel Generator Set: Prime Model:LP90P Standby Model:LP100SДокумент4 страницыDiesel Generator Set: Prime Model:LP90P Standby Model:LP100SLeonardusHSijabatОценок пока нет

- Perkins P200Документ4 страницыPerkins P200PaulusIwanОценок пока нет

- Woodward CPC Convertidor de Corriente A Presion EspecificacionesДокумент4 страницыWoodward CPC Convertidor de Corriente A Presion EspecificacionesJossi Perez AОценок пока нет

- Diesel Generator Set Specifications and FeaturesДокумент4 страницыDiesel Generator Set Specifications and Featuressahat100% (1)

- lmb24 SR TДокумент5 страницlmb24 SR Talakazum28Оценок пока нет

- TM 55P Actuator: ApplicationДокумент4 страницыTM 55P Actuator: Applicationdew lp63Оценок пока нет

- Vacon NX Filters User Manual DPD01571A UKДокумент70 страницVacon NX Filters User Manual DPD01571A UKTanuTiganuОценок пока нет

- P40PB (1004G) GensetДокумент4 страницыP40PB (1004G) GensetBudi WaskitoОценок пока нет

- S7-1200 DataSheetДокумент14 страницS7-1200 DataSheetperuhayaОценок пока нет

- fp50 fp100 fp200Документ10 страницfp50 fp100 fp200ducmanh83Оценок пока нет

- P1500PB (4012 46tag2a)Документ4 страницыP1500PB (4012 46tag2a)astwan81Оценок пока нет

- Perkins Diesel Generator Set - ISO Certified, 50Hz 3-Phase GeneratorДокумент4 страницыPerkins Diesel Generator Set - ISO Certified, 50Hz 3-Phase GeneratorConstantyn_FrederikОценок пока нет

- Siemens - Tyco V23084 C2001 A303Документ5 страницSiemens - Tyco V23084 C2001 A303meda меда100% (1)

- Schneider Altivar 21Документ65 страницSchneider Altivar 21fcruz12Оценок пока нет

- Ael6 PDFДокумент9 страницAel6 PDFCarlos Rafael Pereyra SegoviaОценок пока нет

- TM25 PDFДокумент4 страницыTM25 PDFHendi AfriyanОценок пока нет

- Output Filters Design GuideДокумент41 страницаOutput Filters Design GuideKristopher BuckleОценок пока нет

- 10 KvaДокумент4 страницы10 KvaLeonardusHSijabatОценок пока нет

- Data Sheet Unit ENERGENCE Info LCH 3 4 5 y 6 Tons ENGДокумент56 страницData Sheet Unit ENERGENCE Info LCH 3 4 5 y 6 Tons ENGAnonymous qg0hpB2xNUОценок пока нет

- Prime Model: P70 Emergency Model: P76E Diesel Generator Technical SpecificationsДокумент4 страницыPrime Model: P70 Emergency Model: P76E Diesel Generator Technical SpecificationsLeonardusHSijabatОценок пока нет

- Catalog: General Purpose Plug-In RelaysДокумент12 страницCatalog: General Purpose Plug-In Relaysmicaziv4786Оценок пока нет

- BELIMO LM24 ActuadorДокумент2 страницыBELIMO LM24 ActuadordcarunchioОценок пока нет

- 2Документ16 страниц2nivas12155Оценок пока нет

- ICF - Control Panel - Manual (1999)Документ27 страницICF - Control Panel - Manual (1999)sangramjitОценок пока нет

- Sycrowave 200Документ4 страницыSycrowave 200Robert HarveyОценок пока нет

- Fuji MC SelectionДокумент14 страницFuji MC SelectionmasakpОценок пока нет

- Micro 280 Relays Marca TYCOДокумент4 страницыMicro 280 Relays Marca TYCOPegasusZeroОценок пока нет

- MFA160 :: ROAL Living EnergyДокумент4 страницыMFA160 :: ROAL Living EnergyroalscribdОценок пока нет

- MCДокумент300 страницMCdiegobenitezОценок пока нет

- Diesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PДокумент4 страницыDiesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PYashveer TakooryОценок пока нет

- Capacitor Voltage TransformerДокумент12 страницCapacitor Voltage TransformerThangco HutОценок пока нет

- Monitoring RelaysДокумент7 страницMonitoring Relaysgdesh90Оценок пока нет

- Advanced Motion Controls Srst185Документ4 страницыAdvanced Motion Controls Srst185ElectromateОценок пока нет

- Walvoil Cartridge Ventielen HICДокумент20 страницWalvoil Cartridge Ventielen HICddОценок пока нет

- HyundaiДокумент42 страницыHyundaiwindaidenОценок пока нет

- LET-4000-RDM High Current Test EquipmentДокумент4 страницыLET-4000-RDM High Current Test EquipmentrsgrsgrsgОценок пока нет

- ARI Armaturen ARI SteviДокумент12 страницARI Armaturen ARI SteviCaptain98Оценок пока нет

- 160 80-PW3Документ5 страниц160 80-PW3juan991Оценок пока нет

- MFVU Alstom PDFДокумент8 страницMFVU Alstom PDFkggganiОценок пока нет

- g3520c Im Natural Gas For 1966Документ6 страницg3520c Im Natural Gas For 1966Pankaj KambleОценок пока нет

- Allen Bradley - PowerFlex 400Документ28 страницAllen Bradley - PowerFlex 400Marcos José Nuñez YsseleОценок пока нет

- Reliability and Innovation in Directional Control Valve Slide ValvesДокумент9 страницReliability and Innovation in Directional Control Valve Slide ValvesEnis LoureiroОценок пока нет

- Instruction For Installation and Maintenance - CT - AДокумент12 страницInstruction For Installation and Maintenance - CT - AcataconstantinОценок пока нет

- POWER TRANSFORMERS 2,5 – 80 MVAДокумент3 страницыPOWER TRANSFORMERS 2,5 – 80 MVAabuhurairamunirОценок пока нет

- ABB S203-C20 - Miniature Circuit Breakers MCBs - Modular DIN Rail ProductsДокумент4 страницыABB S203-C20 - Miniature Circuit Breakers MCBs - Modular DIN Rail Productsvs.prasannaОценок пока нет

- Samsung DRAM Module Handling Guide - 1128 - 10090119049407 PDFДокумент9 страницSamsung DRAM Module Handling Guide - 1128 - 10090119049407 PDFreza_azadОценок пока нет

- JVC TH-M606 - 603 - SMДокумент101 страницаJVC TH-M606 - 603 - SMCaillouxОценок пока нет

- Process Management: Operating SystemsДокумент48 страницProcess Management: Operating SystemsvidishsaОценок пока нет

- Em 2 SupplyДокумент4 страницыEm 2 Supplykrishn murariОценок пока нет

- Converting Urban Waste To EnergyДокумент11 страницConverting Urban Waste To EnergyDéépákОценок пока нет

- FinePrint pdfFactory Pro Trial Version PDF CreationДокумент40 страницFinePrint pdfFactory Pro Trial Version PDF CreationTUAN NGUYEN VANОценок пока нет

- Huffman & ShannonДокумент30 страницHuffman & ShannonDhamodharan SrinivasanОценок пока нет

- Tablet ToolingДокумент51 страницаTablet ToolingDr. Muhammad Imran Khan100% (2)

- 300G IM SettingsSheets 20160122Документ27 страниц300G IM SettingsSheets 20160122zeljkoradaОценок пока нет

- Assignment OracleДокумент4 страницыAssignment OracleKyle Austin PabustanОценок пока нет

- Or & LPPДокумент14 страницOr & LPPAjay Kumar Sharma100% (1)

- Culata JD 6466Документ4 страницыCulata JD 6466TECNOTRAC AldanaОценок пока нет

- Strategic Human Resource Management and The HR ScorecardДокумент20 страницStrategic Human Resource Management and The HR ScorecardRajat JainОценок пока нет

- Acha Teff ThresherДокумент62 страницыAcha Teff ThresherTANKO BAKO100% (2)

- Medical Robot ReportДокумент21 страницаMedical Robot Reporta_m_shihaОценок пока нет

- Parts List CMX1402Документ36 страницParts List CMX1402Jayden BarnesОценок пока нет

- Eaton 9130 Rack 700-3000vaДокумент4 страницыEaton 9130 Rack 700-3000vaJose Luis PintoОценок пока нет

- By Himanshu Panwar Asst. Prof. Civil Engineering Department AkgecДокумент34 страницыBy Himanshu Panwar Asst. Prof. Civil Engineering Department AkgecAlok0% (1)

- IQ3-95SP-BC dimensional data sheetДокумент2 страницыIQ3-95SP-BC dimensional data sheetren kaiОценок пока нет

- FREE UX Books @UXlinksДокумент4 страницыFREE UX Books @UXlinksSyaifudin MashuriОценок пока нет

- Sat - RPMSДокумент4 страницыSat - RPMSAeroz RednaxelaОценок пока нет

- Behaviour of Cold Formed Steel Single and Compound Plain Angles in CompressionДокумент13 страницBehaviour of Cold Formed Steel Single and Compound Plain Angles in Compressionthiya123Оценок пока нет

- DT Progression Pathways ks3 Textiles Y9Документ1 страницаDT Progression Pathways ks3 Textiles Y9api-240012980Оценок пока нет

- VTT R 01177 17Документ27 страницVTT R 01177 17Joseph BookerОценок пока нет