Академический Документы

Профессиональный Документы

Культура Документы

Manhole Safety Features

Загружено:

Abrar Hussain0 оценок0% нашли этот документ полезным (0 голосов)

139 просмотров2 страницыManhole Safety Feartures

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документManhole Safety Feartures

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

139 просмотров2 страницыManhole Safety Features

Загружено:

Abrar HussainManhole Safety Feartures

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

Product Data Sheet

F0512 F0337 F0338 F0355 F0339 | Manhole Cover Safety Features

Detailed on this page are some of the important

safety features that are exceptional or unique to

all Emco Wheatons manhole covers. We have

manufactured manhole covers for petroleum

tankers for over 50 years and these features have

evolved through our experience and consultation

with international oil companies, nearly all of who

use the Emco Wheaton manhole cover.

Emergency Venting

Emergency Venting at a massive 7000m/hr

via the pressure actuated fill cap safeguards

against tank explosion in the event of a fire.

All bolt holes are blind i.e. they do not break

through to the underside of the manhole

cover. This is to ensure that no liquid cargo

can leak through.

Webs cast on underside of the base

plate and fill cap increases the structural

integrity.

Four visible, corrosion proof, plated spring

emergency venting. The springs are not

shrouded in a rubber sleeve, which was

the cause of a major failure on another

manufacturers manhole cover due to

rainwater ingress that could not dry out and

consequently corroded the single spring.

The corrosion was not evident, as the spring

was not visible. The UK Health & Safety

Commission identified this as a cause of

failure in an official report.

Blind Bolt Holes and Webs Cast

spring emergency venting

F0512 F0337 F0338 F0355 F0339

F0512 F0337 F0338 F0355 F0339 | Manhole cover Safety featureS

As a part of a continuous commitment to product development the company reserves the right to alter the specification of its products without prior notice

Blind Bolt HolEs and WEBs cast

Recessed centre bolt ensures that emergency

venting via the spring loaded fill cap is effective

even if the tanker has rolled upside down.

Many competitive designs do not include this

which means that the tanker could explode if

on fire and overturned.

Raised seal face prevents water dripping into

tank compartment.

The fill opening is 10 (254mm) diameter to

allow easy insertion of the loading arm drop

pipe.

The fill cap includes a water drainage lip to

prevent either rain or wash water dripping

into the compartment and contaminating the

product when the lid is opened for loading etc.

2 High Flow Pressure and Vacuum Vent Valve

allows for a massive 7000 ft/hr (198 m/hr)

of exhaust, and 3500 cubic feet of vacuum,

ensuring that the tanker has adequate

breathing in extreme climatic conditions.

This vent is also designed to seal off to prevent

product loss and consequent environmental

damage in the event of a tanker overturning.

A shield protects the PV vent from damage by

loading arm drop pipe.

cap and opEning

8

6

prEssUrE and VacUUm VEnt ValVE

2 stagE opEning

Sheet Ref. CSMANHOLESAFETY - May 2006 - Revision 0

10 2 stage opening protects the operator against

dangerous kick-back that can be experienced

due to build up of residual pressure.

10

Emco WHEaton UK limited

channel road Westwood Industrial estate

Margate, Kent ct9 4Jr uK

Phone + 44 1843 221521 fax +44 1843 295444

www.emcowheaton.com assist@emcowheaton.com

Вам также может понравиться

- Ssa PDC 6Документ1 страницаSsa PDC 6Mageswary KunalanОценок пока нет

- API - A Specialist in Precast Concrete ProductsДокумент3 страницыAPI - A Specialist in Precast Concrete Productsalgebra1975100% (1)

- Final Thesis Foundation ReportДокумент64 страницыFinal Thesis Foundation ReportDuong TranОценок пока нет

- Expanded Metal Price ListДокумент2 страницыExpanded Metal Price ListaashuranjanОценок пока нет

- 20Ft Flat Pack Container House BOM ListДокумент2 страницы20Ft Flat Pack Container House BOM List陌陌100% (1)

- Brochure - Techfab - Skid Tank - 2013Документ1 страницаBrochure - Techfab - Skid Tank - 2013Mohamed ZaihasrenОценок пока нет

- OKA G45 RC - Square PilesДокумент4 страницыOKA G45 RC - Square PilesTee Bun PinОценок пока нет

- NGSB Method Statement - RoadworkДокумент8 страницNGSB Method Statement - RoadworkFitrikamarudin mpppsaОценок пока нет

- VCP Pipe Installation: Method Statement ForДокумент11 страницVCP Pipe Installation: Method Statement ForBELLAОценок пока нет

- Method Statement: Underfloor Trunking, Conduit and Junction BoxesДокумент2 страницыMethod Statement: Underfloor Trunking, Conduit and Junction Boxesfatinjamal22Оценок пока нет

- Application of Braced and Unbraced Frame in Reinforced Concrete StructureДокумент2 страницыApplication of Braced and Unbraced Frame in Reinforced Concrete StructureNazmi DhiyauddinОценок пока нет

- Lembaga Arkitek Malaysia (Lam) Inspector of Work (Iow) Practical Experience Log Book GuideДокумент7 страницLembaga Arkitek Malaysia (Lam) Inspector of Work (Iow) Practical Experience Log Book GuideMuhammad Zulfadhli0% (1)

- PilesДокумент17 страницPilesntah84Оценок пока нет

- Boral Plasterboards CatalogueДокумент15 страницBoral Plasterboards Catalogueteng fsОценок пока нет

- Method Statement Water Ponding Test at Wet AreaДокумент1 страницаMethod Statement Water Ponding Test at Wet AreaHao SingОценок пока нет

- Pyeacryl-Bond 128Документ1 страницаPyeacryl-Bond 128oybiewОценок пока нет

- GREENSEAL Flexi 201 - Method StatementДокумент3 страницыGREENSEAL Flexi 201 - Method StatementKmrul HisyamОценок пока нет

- Moreover,: A 116-Page Report Was Released by The Penang State Commission of Inquiry (SCI) On The Worksite IncidentДокумент4 страницыMoreover,: A 116-Page Report Was Released by The Penang State Commission of Inquiry (SCI) On The Worksite IncidentAsogan JagaОценок пока нет

- SAGA Catalogue MegapowerДокумент16 страницSAGA Catalogue Megapowerarchery100% (2)

- A910 Line Dulux Weathershield Acrylic Exterior Wall FinishДокумент2 страницыA910 Line Dulux Weathershield Acrylic Exterior Wall FinishAbd Aziz MohamedОценок пока нет

- MS-Slurry Jcking PDFДокумент8 страницMS-Slurry Jcking PDFRoif SamsulОценок пока нет

- Welder CardДокумент1 страницаWelder CardRaju KumarОценок пока нет

- Air TestДокумент13 страницAir TestNur Fatin AzarinaОценок пока нет

- IWK Submission FormДокумент4 страницыIWK Submission FormMuhammad Hanafi100% (2)

- 5.0 Kos Sewa Loji & PeralatanДокумент3 страницы5.0 Kos Sewa Loji & PeralatanRizalFaiz100% (1)

- MS Outside Scaffolding - Orkide RV00Документ10 страницMS Outside Scaffolding - Orkide RV00Thành CôngОценок пока нет

- Types of Cement: Advanced Concrete Technology CE484/CE684Документ24 страницыTypes of Cement: Advanced Concrete Technology CE484/CE684Gyanesh PatnaikОценок пока нет

- PDS - Sika MonoTop-412 MYДокумент4 страницыPDS - Sika MonoTop-412 MYNorlizawati YusofОценок пока нет

- Catalogue PIPECOДокумент20 страницCatalogue PIPECOhditОценок пока нет

- Kertas Penerangan 1 - Independent 2Документ27 страницKertas Penerangan 1 - Independent 2Dasb ScaffoldingОценок пока нет

- BQ To SubCont - Infra - DrainageДокумент8 страницBQ To SubCont - Infra - Drainagemuhammad iqbalОценок пока нет

- Ecothene DPM: DescriptionДокумент3 страницыEcothene DPM: DescriptionAbdul Wafiy NaqiuddinОценок пока нет

- POLYSTOR Catalog - Specification (WR)Документ2 страницыPOLYSTOR Catalog - Specification (WR)Pipi K0% (1)

- CIDB - Main Building Material Price 2015 (SABAH)Документ11 страницCIDB - Main Building Material Price 2015 (SABAH)Anonymous vmeAM32w100% (2)

- Material Safety Data Sheet For Blended CementДокумент8 страницMaterial Safety Data Sheet For Blended Cementshahrilzainul77Оценок пока нет

- AMSGB Power Transformer Brochure (Final 27.05.2010)Документ4 страницыAMSGB Power Transformer Brochure (Final 27.05.2010)winston11Оценок пока нет

- Greencon Catalogue 2018 PDFДокумент16 страницGreencon Catalogue 2018 PDFAfizshueОценок пока нет

- Cadangan Pembaikan Cerun Dan Kerja-Kerja Berkaitan Di SK Kauluan Ranau, SabahДокумент6 страницCadangan Pembaikan Cerun Dan Kerja-Kerja Berkaitan Di SK Kauluan Ranau, SabahAsdia Aseffah Fathiya100% (1)

- Mackintosh ProbeДокумент2 страницыMackintosh ProbeE~cha67% (3)

- Nisbah Konkrit g40Документ3 страницыNisbah Konkrit g40Faeez ZainОценок пока нет

- Brochure EurotilesДокумент12 страницBrochure EurotilesVincent 2020Оценок пока нет

- 3a MSMA - Guidelines - PresentationДокумент26 страниц3a MSMA - Guidelines - PresentationSyakiroh Mohd TaufikОценок пока нет

- Precase Concrete Pipes (Mac, 16)Документ4 страницыPrecase Concrete Pipes (Mac, 16)KpChuaОценок пока нет

- WTP 3013 Roofing System InstallationДокумент11 страницWTP 3013 Roofing System InstallationWan AnisОценок пока нет

- Ms 966 Part 1 2001 Playground Equipment Part 1 Specifications For Materials First Revision PDFДокумент17 страницMs 966 Part 1 2001 Playground Equipment Part 1 Specifications For Materials First Revision PDFAhmad HafizОценок пока нет

- Conbextra EP300Документ3 страницыConbextra EP300Tori SmallОценок пока нет

- Jack Micro PDFДокумент48 страницJack Micro PDFHizbar ArsjadОценок пока нет

- RC PilesДокумент4 страницыRC Pileshasif21Оценок пока нет

- TL MR100 (EU) 1.20 DatasheetДокумент7 страницTL MR100 (EU) 1.20 DatasheetJohnyОценок пока нет

- TeksiДокумент1 839 страницTeksiJoy StewartОценок пока нет

- P01B01-Laporan Harian TapakДокумент1 страницаP01B01-Laporan Harian TapakZulKhaliliОценок пока нет

- 3) Catalogue & Techincal Data - Unispan 9.5mmДокумент2 страницы3) Catalogue & Techincal Data - Unispan 9.5mmfarie ahmadОценок пока нет

- InternshipДокумент26 страницInternshipfawwaz sazalliОценок пока нет

- Checklist Material For Approval (13705)Документ3 страницыChecklist Material For Approval (13705)Matt CerosОценок пока нет

- BQ - AllДокумент76 страницBQ - Allapi-417090110Оценок пока нет

- Floating Roof Tanks Catalog - 090603Документ0 страницFloating Roof Tanks Catalog - 090603piolinwallsОценок пока нет

- Internal Floating Roof CatalogДокумент22 страницыInternal Floating Roof Catalogluisvidal24100% (3)

- Ackeral Oil Tools Pvt. LTD.: Product CatalogueДокумент10 страницAckeral Oil Tools Pvt. LTD.: Product CatalogueDuy NguyenОценок пока нет

- Vents & Fire Protection System For Storage TanksДокумент24 страницыVents & Fire Protection System For Storage TanksMohammad Rawoof100% (2)

- Floating and Trunnion Ball Valves PDFДокумент15 страницFloating and Trunnion Ball Valves PDFAlienshowОценок пока нет

- MS100-00 - (M-MA Series)Документ6 страницMS100-00 - (M-MA Series)atorresh090675Оценок пока нет

- SP2000v5 Summary of Change - To Vehicle OEMsДокумент11 страницSP2000v5 Summary of Change - To Vehicle OEMsAbrar HussainОценок пока нет

- PV Vent Data SheetДокумент2 страницыPV Vent Data SheetAbrar Hussain100% (1)

- Autosmart Factsheet 9 eДокумент2 страницыAutosmart Factsheet 9 eAbrar HussainОценок пока нет

- D400-40 (Regulatory Compliance Manual) PDFДокумент16 страницD400-40 (Regulatory Compliance Manual) PDFLazzarus Az GunawanОценок пока нет

- Modification Work For Abloy LocksДокумент1 страницаModification Work For Abloy LocksAbrar HussainОценок пока нет

- How To Implement A Fleet Preventive Maintenance Program PDFДокумент4 страницыHow To Implement A Fleet Preventive Maintenance Program PDFAbrar HussainОценок пока нет

- Wear Limit Gauges JOST en 09 14Документ4 страницыWear Limit Gauges JOST en 09 14Abrar HussainОценок пока нет

- 01 Intro Fifth Wheel Couplings and Mounting Plates eДокумент7 страниц01 Intro Fifth Wheel Couplings and Mounting Plates eAbrar HussainОценок пока нет

- Risks With 5th Wheel Designs and Coupling ProceduresДокумент2 страницыRisks With 5th Wheel Designs and Coupling ProceduresAbrar HussainОценок пока нет

- Operating Manual JSK 38 50Документ15 страницOperating Manual JSK 38 50Abrar HussainОценок пока нет

- Tds - Tankguard Plus - English Uk - Issued.04.07.2013Документ4 страницыTds - Tankguard Plus - English Uk - Issued.04.07.2013Abrar HussainОценок пока нет

- Wearlimitgauge PDFДокумент1 страницаWearlimitgauge PDFAbrar HussainОценок пока нет

- 26 Mounting Plates For Heavy Duty Fifth Wheel Couplings eДокумент2 страницы26 Mounting Plates For Heavy Duty Fifth Wheel Couplings eAbrar HussainОценок пока нет

- Tankguard Plus PDFДокумент11 страницTankguard Plus PDFAbrar HussainОценок пока нет

- Brochure 500 PDFДокумент6 страницBrochure 500 PDFAbrar HussainОценок пока нет

- Brochure 500 PDFДокумент6 страницBrochure 500 PDFAbrar HussainОценок пока нет

- Tankgarud SFДокумент5 страницTankgarud SFAbrar HussainОценок пока нет

- TankGuard DownloadДокумент10 страницTankGuard DownloadAbrar HussainОценок пока нет

- Silicate - or Epoxy Zinc PrimersДокумент16 страницSilicate - or Epoxy Zinc PrimersChioibasNicolae100% (1)

- Tds - Tankguard Plus - English Uk - Issued.04.07.2013Документ4 страницыTds - Tankguard Plus - English Uk - Issued.04.07.2013Abrar HussainОценок пока нет

- EI 1541 Performance Requirements For Protective Coatings Used in Aviatio...Документ17 страницEI 1541 Performance Requirements For Protective Coatings Used in Aviatio...Abrar Hussain100% (1)

- SAQS Section 04.02.02Документ2 страницыSAQS Section 04.02.02Abrar HussainОценок пока нет

- Knorr EBS PDFДокумент8 страницKnorr EBS PDFAbrar HussainОценок пока нет

- TankGuard Plus Product DescДокумент5 страницTankGuard Plus Product DescAbrar HussainОценок пока нет

- Penguard HB: Technical Data Sheet Application GuideДокумент10 страницPenguard HB: Technical Data Sheet Application GuideAbrar HussainОценок пока нет

- Penguard HB: Technical Data Sheet Application GuideДокумент10 страницPenguard HB: Technical Data Sheet Application GuideAbrar HussainОценок пока нет

- TankGuard Plus Com BДокумент15 страницTankGuard Plus Com BAbrar HussainОценок пока нет

- Silicate - or Epoxy Zinc PrimersДокумент16 страницSilicate - or Epoxy Zinc PrimersChioibasNicolae100% (1)

- Commonrail XeMANДокумент47 страницCommonrail XeMANYên Ngỗng97% (70)

- Gearbox Failure of Large Gas Turbine Generator Case StudyДокумент2 страницыGearbox Failure of Large Gas Turbine Generator Case StudyJesusОценок пока нет

- Some Info On IEEE 841 MotorsДокумент9 страницSome Info On IEEE 841 Motorsb89502164Оценок пока нет

- Implant Abutment NeckДокумент7 страницImplant Abutment NecknobelcyrilОценок пока нет

- Mfaf BK: ScopeДокумент23 страницыMfaf BK: ScopesbalajimОценок пока нет

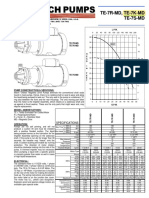

- Manual March Te-7k-MdДокумент2 страницыManual March Te-7k-MdjoseОценок пока нет

- Brayton and Rankine CycleДокумент12 страницBrayton and Rankine CycleDaryl Calderon100% (1)

- Repair of A Hull 15 M Below The WaterlineДокумент8 страницRepair of A Hull 15 M Below The WaterlineRonny De La CruzОценок пока нет

- Ervice Arts IST: 16D2149 P T D S LCB 13150 P S F CДокумент16 страницErvice Arts IST: 16D2149 P T D S LCB 13150 P S F Cjasmin selimić100% (3)

- HTD 250 En-ItДокумент60 страницHTD 250 En-ItbrasgОценок пока нет

- DFG/TFG 316-550: Operating InstructionsДокумент144 страницыDFG/TFG 316-550: Operating InstructionsbenjaminОценок пока нет

- Structural Mechanics NotesДокумент6 страницStructural Mechanics NotesAiden A. CunninghamОценок пока нет

- BRS Manual Rev 4-10Документ38 страницBRS Manual Rev 4-10RondrashОценок пока нет

- 15780Документ16 страниц15780uddinnadeemОценок пока нет

- Dahilog Chemistry Activity On Gas LawsДокумент7 страницDahilog Chemistry Activity On Gas LawsYbur Clieve Olsen DahilogОценок пока нет

- v1903 2203tvengineДокумент46 страницv1903 2203tvenginehuo sun100% (1)

- Hydro Power PlantsДокумент7 страницHydro Power PlantsKyambadde FranciscoОценок пока нет

- HS-2172 Vs HH 5500 Centrifuge ComparisonДокумент10 страницHS-2172 Vs HH 5500 Centrifuge ComparisonRicardo VillarОценок пока нет

- Physics Project: Topic: To Study Simple Harmonic MotionДокумент7 страницPhysics Project: Topic: To Study Simple Harmonic Motiongorilla soupОценок пока нет

- GR00000900 00 PDFДокумент64 страницыGR00000900 00 PDFSaHdo AbdelHamidОценок пока нет

- MODEL XQ140/20 Hydraulic Power Tong: Parts and Operation ManualДокумент57 страницMODEL XQ140/20 Hydraulic Power Tong: Parts and Operation ManualCarlos Antonio Fontalvo Carrascal100% (1)

- Auto Chassis NotesДокумент70 страницAuto Chassis NotesSrinivas NadellaОценок пока нет

- Final/5.Thermal Stress and Heat Transfer Analysis of PlatesДокумент3 страницыFinal/5.Thermal Stress and Heat Transfer Analysis of PlatesKkaaОценок пока нет

- Fea 2 Marks and AnswersДокумент20 страницFea 2 Marks and AnswerssnvijayanОценок пока нет

- 01 Excelon FiltersДокумент16 страниц01 Excelon Filtersalex_alfonso9407Оценок пока нет

- Dynamics FULL Equation SheetДокумент2 страницыDynamics FULL Equation SheetZachОценок пока нет

- Lecture 1 - Joining Processes-1Документ9 страницLecture 1 - Joining Processes-1Shaheer FarrukhОценок пока нет

- Manual de Servicio ES12-25WAДокумент38 страницManual de Servicio ES12-25WARonald PiedrahitaОценок пока нет

- Speed Torque Gear Ratios Motor Vehicles Internal Combustion Engine Rotational Speed TorqueДокумент45 страницSpeed Torque Gear Ratios Motor Vehicles Internal Combustion Engine Rotational Speed TorqueAkshay SinghОценок пока нет

- Entropy of Mixing PDFДокумент16 страницEntropy of Mixing PDFrupaliroyОценок пока нет

- Summer Internship: Ray-Hans Precision Tools Private LimitedДокумент18 страницSummer Internship: Ray-Hans Precision Tools Private LimitedyasirОценок пока нет