Академический Документы

Профессиональный Документы

Культура Документы

Building Si Report

Загружено:

Henj MirasolАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Building Si Report

Загружено:

Henj MirasolАвторское право:

Доступные форматы

Structural Investigation (SI)

Structural Steel with Bamboo

Bambusa Resto Project

_

Proposed Condition

No Seismic Design

SI Rev. No. 00

Report Version No. MSDC-SI-EB-2-2016

TABLE OF CONTENT

1. Introduction

2. Parameters

3. Load Design/ Combination

3.1 Floor Dead Load (DL)

3.2 Roof Dead Load (DL)

3.3 Rain Load (RL)

3.4 Live Load (LL)

3.5 Seismic Load (E)

3.6 Load Combination

4. Design Method/Model of Analysis

5. Design Consideration

6. Structure Layout/Geometry

7. Design Allowable

7.1 Cross-section conversion from Bamboo to Steel properties

7.2 Steel Requirement for Flexural Stresses/Shrinkage & Temperature

8. Design Software Analysis

9. Result and Findings

10. Conclusion and Recommendation

11. Reference

Prepared By: Engr. H. Mirasol Page 1

Structural Investigation (SI)

Structural Steel with Bamboo

Bambusa Resto Project

_

Proposed Condition

No Seismic Design

SI Rev. No. 00

Report Version No. MSDC-SI-EB-2-2016

STRUCTURAL INVESTIGATION OF BAMBOO STRUCTURE

1. Introduction

Structurally, over a long period of time as if maintained and preserved---on its vigorous

characteristic, bamboo can withstands against the live loads and dead loads of the building it purposely

served. Due to this natural material---silica, that suite correspondingly with concrete materials its

component as for structural foundation support (bamboos as a column cased by concrete materials).

Supposed bamboo materials in its organic sense has so much to give attention on its design by not

exposing it to the rain for it will deteriorate much of the material at the end cut of culm (into the internode) but not so much on the outside surface layer. While exposed to rainwater, fungus and insects

might be attacking these sections of culm of the bamboo since the hollow portion contained starch

(large number of glucose were present on this area) that if not treated by chemical for preservation after

the harvest .

Bamboo accepted as a building material, aside from low cost, its light weight that can also resist

earthquake loads and for main reason that take into account the aesthetic beauty as being native

material: as far the good design of its connections and the placing of members that serving the main

stresses. The mechanical properties, bamboo on its extreme outside layer of the culm contained dense

cellulose fibers and vessel (like reinforced concrete members, cellulose is like a reinforcing steel) and

the material surrounded these fiber are called parenchyma1 (like the concrete between the steel bars)

and that composed the culm of the bamboo. As it is found far from the center of hollow the higher

Moment of Inertia it gets compared to wood material with equal cross-sectional area, this give more

stiffness to the material.

Service life of untreated bamboo on rough estimates is in the average of 5 years under cover

and free from contact with the soil (pg. 52 of ref.). Some fundamental rule concerning the harvest of the

bamboos to be sensitively used is on the season when the starch content is low; local people could

greatly identified such bamboo species.

However, this bamboo structure is Moment-framed by steel members to keep responsible for

large stresses and ultimate capacity of the structure itself. These composed by structural pipes for main

columns & framed beams and other secondary elements. Slab is made of bamboo cuts for light weight

response for not generating earthquake forces to its main structural members.

2. Parameters

Bamboo & Steel Structure/Building:

Material Specifications:

Concrete Compressive Strength, fc' = 21.0 N/mm^2 (@ 28days)

Reinforcing Steel Yield Strength, fy = 415.0 N/mm^2 (Gr. 40; All Reinforcements)

Bamboo Ultimate Stress, fub = 84.0 N/mm^2

Prepared By: Engr. H. Mirasol Page 2

Structural Investigation (SI)

Structural Steel with Bamboo

Bambusa Resto Project

_

Proposed Condition

No Seismic Design

SI Rev. No. 00

Report Version No. MSDC-SI-EB-2-2016

Structural pipes, Fu = 400N/mm^2

Structural pipes, Fy = 241N/mm^2

Material Unit Weight:

Bamboo Weight, Bw = 5.87 Kn/M^3

Masonry Wall, w = 19 Kn/M^3

Backfill Material, s = 15.7 Kn/M^3

[NSCP Table 204-2]

[NSCP Table 204-1]

3. Load Design/ Combination

3.1 Floor Dead Loads (DL)

Shall be the basic dead load, is 1.5Kn/M^2 and Ceiling load of 0.5Kpa, a total of 1.5Kn/M^2

3.2 Roof Dead Loads (DL)

The combined ceiling and roof material load is 1.0Kn/M^2.

3.3. Rain Load (RL) [ Whenever included ]

Shall be base on current Rainfall Rate of Typhoon Report of NASA's Tropical Rainfall Measuring

Mission (TRMM).

RL=5.2(ds+dh)

where:

dh =

ds =

R=

Additional depth of water on the undeflected roof above the inlet of secondary

drainage system at its design flow (the hydraulic head), inches (mm).

Depth of water on the undeflected roof up to the inlet of secondary drainage

system when the primary drainage system is blocked (the static head), inches (mm).

Rain load on the undeflected roof, in kN/m^2. When the phrase "undeflected

roof" is used, deflections from loads (including dead loads) shall not be considered

when determining the amount of rain on the roof.

Given:

Primary roof drain and overflow scupper:

Static head, ds

= 3 inches

Tributary area A

= 150 square feet

Rainfall rate, i

= 2.5 inches/hour (Tropical Rainfall Measuring Mission)

= 0.208333 feet/hour

Determine:

Hydraulic head, dh

Rain load, RL

Calculate required flow rate, Q, at scupper in gallons per minute (gpm).

Prepared By: Engr. H. Mirasol Page 3

Structural Investigation (SI)

Structural Steel with Bamboo

Bambusa Resto Project

_

Proposed Condition

No Seismic Design

SI Rev. No. 00

Report Version No. MSDC-SI-EB-2-2016

Q = Ai = 250 ft^2 0.208333 feet/hour

= 52 cubic ft /hour

= 0.868 cubic ft /minute

= 6.49 gpm

dh = 0 (below minimum hydraulic head requirement)

Determine rain load, RL

Total head = (ds + dh) = 3 inches

RL = 5.2 (3+ 0)

RL = 15.6 psf

RL = 15.6*0.047880259

RL = 0.7469 kpa

let say, 1.0 kpa

3.4 Live Load (LL)

Consider the live load of 1.90Kn/m^2 [NSCP Table 205-1] for all floors (basic) and balconies of

4.80Kn/m^2 [NSCP Table 205-1] and the like. Rain load here shall be considered as Live Load in

some instances that needs thorough evaluation in the effect of load combinations and type of structure.

3.5 Seismic Load (E)

See Design Consideration

3.6 Load Combination

Building Load Factors Combination/s:

1.2*DL + 1.6*LL

Prepared By: Engr. H. Mirasol Page 4

EQ. C 9-1

[ ACI 9.1.3 / R9.1 ]

Structural Investigation (SI)

Structural Steel with Bamboo

Bambusa Resto Project

_

Proposed Condition

No Seismic Design

SI Rev. No. 00

Report Version No. MSDC-SI-EB-2-2016

4. Design Method/Model of Analysis

Structure Model:

Structure had been model to evaluate structural geometric compatibility of all adjacent and

connecting elements and members against full loading with respect to the combination of dead load and

Rain/Live load or dead load.

5. Design Consideration

ACI 318-08, Sect. 9.1.3 and the R9.1, for Gravity Load (dead & live) will be comparable to obtain

using the strength reduction & load factors of the 1999 and the earlier code; where the these factors of

1999 code were revised and moved to Appendix C, But 1.4DL+1.7LL did not assumed the equivalent,

since a light material being used in the design and the dead load consideration is nullified.

Earthquake resistance of bamboo or bamboo is a perfect material for earthquake because of its light

weight and the hollow form gives much stiffness.

The Sub-structure (building) is assumed to rest at soil with Design Allowable Bearing Pressure of

50kpa (Modulus of Elasticity of 6500kn/m^2/m). However, it should be verify in actual soil.

.

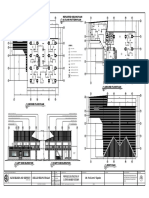

6. Structure Layout/Geometry

Prepared By: Engr. H. Mirasol Page 5

Structural Investigation (SI)

Structural Steel with Bamboo

Bambusa Resto Project

_

Proposed Condition

No Seismic Design

SI Rev. No. 00

Report Version No. MSDC-SI-EB-2-2016

7. Design Allowable

7.1 Cross-section conversion from Bamboo to Steel properties (whenever used)

The Ultimate Stress-to-Area ratio:

FUS*AS = FUB*AB

Where:

FUS

AS

FUB

AB

=

=

=

=

Ultimate Stress of Steel (241N/mm^2)

Area of Steel (mm^2)

Ultimate Stress of Bamboo (84N/mm^2, see ref.)

Area of Bamboo (mm^2)

Hence, As = 0.20*AB

AB12

AB2

= Area of 12nos. Of Bamboo Column

= Area of 2nos. Of Bamboo Beam

From the basic formula of Hollow Pipe Section, I = pi()* (D^4 - d^4) /64 ; A = pi()* (D^2 - d^2)/4

Prepared By: Engr. H. Mirasol Page 6

Structural Investigation (SI)

Structural Steel with Bamboo

Bambusa Resto Project

_

Proposed Condition

No Seismic Design

SI Rev. No. 00

Report Version No. MSDC-SI-EB-2-2016

Hence, I = 0.03*D^4 ; A = 0.26*D^2

A12

A2

= 0.20*AB12 = 0.2*0.26*D12^2

= 0.20*AB2 = 0.2*0.26*D2^2

Let D is the average thickness of Bamboo outside diameter and is equal to 100mm.

AB12 = 0.2*0.26*100^2 * 12 = 6240mm^2

6240 = 0.26*DS12

DS12

= 155mm

dS12

= 127mm

tS12

= 14mm

AB2 = 0.2*0.26*100^2 * 2 = 1040mm^2

1040 = 0.26*DS2

DS2

= 63mm

dS2

= 51mm

tS2

= 6mm

7.2 Steel Requirement for Flexural Stresses/shrinkage & Temperature

If the reinforcement required to resist the maximum moment (Mx & Mx, negative and positive) is less

than the capacity of the element with minimum reinforcement, only minimum reinforcement is

provided. NSCP 6th ed., sect. 407.13.2.1, provision of minimum reinforcement for shrinkage and

temperature shall be used:

ASMIN = 0.0018*Ag (for Grade 414 deformed bar)

ASMIN = 0.0020*Ag (for Grade 276 deformed bar)

8. Design Program Analysis

(SEE STRUCTURAL ANALYSIS IN THE NEXT PAGES)

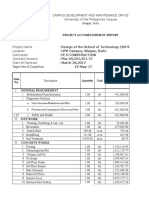

9. Result and Findings

The Steel structural elements PASS the LRFD code design requirements . The members maximum

actaul load to section capacity ratio of 0.978.

10. Conclusion and Recommendation

Conclusion

Prepared By: Engr. H. Mirasol Page 7

Structural Investigation (SI)

Structural Steel with Bamboo

Bambusa Resto Project

_

Proposed Condition

No Seismic Design

SI Rev. No. 00

Report Version No. MSDC-SI-EB-2-2016

The proposed steel with bamboo accessories to the structural building is structurally safe to carry

the basic floor loads of the same.

In reference to the design data (pg.22) relating the comparison of two elements has resemblance

and it was found out that bamboo materials provide more stiffness and almost equal range with its

strength than the steel materials. That the two elements are quite the same in terms of response to

load-and-stresses.

Recommendation

1. On areas where rainwater will get off the eaves (because bamboo roof doesnt have a gutter or

it is free falling from the roof materials), might be splashing into the bamboo walls by wind.

Specially on the structural components should aesthetically designed with plastic cover on that

areas for protection from water or other elements to kept dry.

2. Foundation or the concrete pedestal must be higher than the natural ground surfaces and cast

the bamboo column to get off the soil.

3. Regardless of No.1 & 2, bamboo structural material shall address the matter of taking

precaution by replacing old members or that are rotten over the estimated life of the bamboos.

And the factor like: the change of climate on the region; overloaded bamboo slabs & beams;

adjacent bamboo walls that exposed too much in the rain that affect the main bamboo beams &

columns.

4. Steel shall have the protected coating and be elevated from the ground with the use of concrete

support.

11. Reference

1. Design & Building with Bamboo (by: Jules J.A. Janssen)

Prepared By: Engr. H. Mirasol Page 8

Structural Investigation (SI)

Structural Steel with Bamboo

Bambusa Resto Project

_

Proposed Condition

No Seismic Design

SI Rev. No. 00

Report Version No. MSDC-SI-EB-2-2016

2. Staad.pro training manual (Infrasys/Bentley Channel Partner)

Prepared By: Engr. H. Mirasol Page 9

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Sample: Standard Form of Agreement Between Owner and Design-Builder - Lump SumДокумент23 страницыSample: Standard Form of Agreement Between Owner and Design-Builder - Lump SumHenj MirasolОценок пока нет

- Ground Floor Plan Second Floor Plan: Nle Builders and Services Niel Lester P. Eupalao Mr. Niel Lester P. EupalaoДокумент1 страницаGround Floor Plan Second Floor Plan: Nle Builders and Services Niel Lester P. Eupalao Mr. Niel Lester P. EupalaoHenj MirasolОценок пока нет

- Maningas Quotation April 04, 2016Документ2 страницыManingas Quotation April 04, 2016Henj MirasolОценок пока нет

- Maningas Quotation April 04, 2016Документ2 страницыManingas Quotation April 04, 2016Henj MirasolОценок пока нет

- MSDC Request LetterДокумент16 страницMSDC Request LetterHenj MirasolОценок пока нет

- Foundation Plan Second Floor Framing Plan: Nle Builders and Services Niel Lester P. Eupalao Mr. Niel Lester P. EupalaoДокумент1 страницаFoundation Plan Second Floor Framing Plan: Nle Builders and Services Niel Lester P. Eupalao Mr. Niel Lester P. EupalaoHenj MirasolОценок пока нет

- Reflected Ceiling Plan & Floor Pattern Plan: Nle Builders and Services Niel Lester P. Eupalao Mr. Niel Lester P. EupalaoДокумент1 страницаReflected Ceiling Plan & Floor Pattern Plan: Nle Builders and Services Niel Lester P. Eupalao Mr. Niel Lester P. EupalaoHenj MirasolОценок пока нет

- MSDC Billing StatementДокумент24 страницыMSDC Billing StatementHenj MirasolОценок пока нет

- Structural Design Isolated Footing Proposed Condition Zone Ii, Exposure C REV.00 G4647 Stability Check-FoundationДокумент6 страницStructural Design Isolated Footing Proposed Condition Zone Ii, Exposure C REV.00 G4647 Stability Check-FoundationHenj MirasolОценок пока нет

- Ser Vic I AbilityДокумент6 страницSer Vic I AbilityHenj MirasolОценок пока нет

- Tower Information 3. Design Parameters and SpecificationsДокумент14 страницTower Information 3. Design Parameters and SpecificationsHenj MirasolОценок пока нет

- Ser Vic I AbilityДокумент6 страницSer Vic I AbilityHenj MirasolОценок пока нет

- Wind Load For: 2. Wind Direction: 3. Structure Type: 4. Design ParametersДокумент16 страницWind Load For: 2. Wind Direction: 3. Structure Type: 4. Design ParametersHenj MirasolОценок пока нет

- Structural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Документ39 страницStructural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Henj MirasolОценок пока нет

- Ser Vic I AbilityДокумент6 страницSer Vic I AbilityHenj MirasolОценок пока нет

- 2G National Roll-Out "FTK Project - Phase Ii": Owner/S NameДокумент5 страниц2G National Roll-Out "FTK Project - Phase Ii": Owner/S NameHenj MirasolОценок пока нет

- Print3 NarrativeДокумент14 страницPrint3 NarrativeHenj MirasolОценок пока нет

- Wind Antenna 0'90'180'270'Документ113 страницWind Antenna 0'90'180'270'Henj MirasolОценок пока нет

- Weld & Bolt DesignДокумент8 страницWeld & Bolt DesignHenj MirasolОценок пока нет

- 2G National Roll-Out "FTK Project - Phase Ii": Owner/S NameДокумент5 страниц2G National Roll-Out "FTK Project - Phase Ii": Owner/S NameHenj MirasolОценок пока нет

- Guide To Design Criteria For Bolts and Riveted JointsДокумент352 страницыGuide To Design Criteria For Bolts and Riveted JointsHomero Silva96% (24)

- 2G National Roll-Out "FTK Project - Phase Ii": Owner/S NameДокумент7 страниц2G National Roll-Out "FTK Project - Phase Ii": Owner/S NameHenj MirasolОценок пока нет

- Designing and Building With Bamboo Janssen PDFДокумент211 страницDesigning and Building With Bamboo Janssen PDFGretel Adrianne UmaliОценок пока нет

- Bamboo StructureДокумент37 страницBamboo Structureniravhirpara67% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Transverse Plate-To-squarerectangular Hss ConnectionsДокумент7 страницTransverse Plate-To-squarerectangular Hss Connectionsdeepak_dce_meОценок пока нет

- Elementary Theory of Structures PDFДокумент408 страницElementary Theory of Structures PDFPropllus67% (3)

- KTP PPVCДокумент55 страницKTP PPVCShumei ZhouОценок пока нет

- BOQ Proposed Completion of Three Storey Building For Isolation RoomsДокумент12 страницBOQ Proposed Completion of Three Storey Building For Isolation RoomsJake CanlasОценок пока нет

- Local Buckling and Section ClassificationДокумент7 страницLocal Buckling and Section ClassificationMohammed Junaid ShaikhОценок пока нет

- Unified Equivalent Frame Method For at Plate Slab Structures Under Combined Gravity and Lateral Loads - Part 1: DerivationДокумент16 страницUnified Equivalent Frame Method For at Plate Slab Structures Under Combined Gravity and Lateral Loads - Part 1: DerivationSrilakshmi MekapothulaОценок пока нет

- Spread Footing Design: ASDIP Foundation 4.4.2Документ4 страницыSpread Footing Design: ASDIP Foundation 4.4.2heherson juanОценок пока нет

- Case Study: Sheraton Hotel, Bilbao, SpainДокумент13 страницCase Study: Sheraton Hotel, Bilbao, Spainfloi dОценок пока нет

- PublicationДокумент34 страницыPublicationYuliarti KusumawardaningsihОценок пока нет

- Hybrid Pile Foundations IPWE SeminarДокумент22 страницыHybrid Pile Foundations IPWE Seminarrohit100% (1)

- Efficient Assumption of Design Variables For Stress Ribbon FootbridgesДокумент11 страницEfficient Assumption of Design Variables For Stress Ribbon FootbridgesJORGE BARRERAОценок пока нет

- Cutting List RoofingДокумент2 страницыCutting List RoofingCzarinaCanarAguilarОценок пока нет

- Basics of Structural DesignДокумент233 страницыBasics of Structural DesignmargitorsiОценок пока нет

- S CurveДокумент121 страницаS CurveJohn ChristopherОценок пока нет

- Reinforced Concrete DesignДокумент61 страницаReinforced Concrete DesignJonel Catalan100% (1)

- Types of WallsДокумент3 страницыTypes of Wallsrowell naragОценок пока нет

- Elementary Design of Structures Notes PDFДокумент53 страницыElementary Design of Structures Notes PDFAsiimwe Moses Kasirika100% (7)

- Generate Column Interaction DiagramДокумент88 страницGenerate Column Interaction DiagramSaad SekkateОценок пока нет

- On Drift Limits Associated With Different Damage Levels: June 2004Документ13 страницOn Drift Limits Associated With Different Damage Levels: June 2004RaviKanthSrivastavОценок пока нет

- P.C. Varghese - Advanced Reinforced Concrete Design, 2Nd Edition-Prentice-Hall of India PVT - LTD (2005)Документ556 страницP.C. Varghese - Advanced Reinforced Concrete Design, 2Nd Edition-Prentice-Hall of India PVT - LTD (2005)M Hasnain AnsariОценок пока нет

- Complete Working Drawings - Tyrone CarinoДокумент13 страницComplete Working Drawings - Tyrone CarinoTyroneskie Carino100% (1)

- Part 27 Concept and Scheme Lecture IДокумент18 страницPart 27 Concept and Scheme Lecture IHisham alazzaniОценок пока нет

- Factory Building Cost 210625Документ365 страницFactory Building Cost 210625Matthew SiagianОценок пока нет

- PT EUrocodeДокумент90 страницPT EUrocodeKilaru HareeshОценок пока нет

- Mi VanДокумент37 страницMi Vankaran9027Оценок пока нет

- Retaining Wall: Analysis and Design by SAP 2000Документ15 страницRetaining Wall: Analysis and Design by SAP 2000qwerty qwertyОценок пока нет

- WCS 8034Документ8 страницWCS 8034Sani Oghang PekanОценок пока нет

- Stainless Steel Structure Design HandbookДокумент20 страницStainless Steel Structure Design Handbookgnino2Оценок пока нет

- RCD-Lecture 6-Shear DesignДокумент94 страницыRCD-Lecture 6-Shear DesignHassan AhmedОценок пока нет

- Loadings - NSCP 2015 - 2 Storey Residential Concrete Structure1Документ52 страницыLoadings - NSCP 2015 - 2 Storey Residential Concrete Structure1Renvil PedernalОценок пока нет