Академический Документы

Профессиональный Документы

Культура Документы

DR201-Instruction de TRADUS

Загружено:

Gelu DrăjneanuИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DR201-Instruction de TRADUS

Загружено:

Gelu DrăjneanuАвторское право:

Доступные форматы

- factory settings restoration: 0-No, 1-Yes. To restore factory settings set H1=1.

Process is signalled

by command indicated on the display:

- memory reset: 0-No, 1-Yes. To reset the memory

set H2=1.

Memory deletion process is signalled on the display:

- password, range 0..99. Access to the configuration menu can be password protected

0 - password off; 21 - emergency password.

9.4. PARAMETERS EDITION

DR-201

Recorder operates on 8-segmental LED display. The edition of alphabetic and digital marks in these

parameters is possible due to the following character table:

Caption:

Character number

Character

TEMPERATURE RECORDER

Service:

Next character

from the schedule

USER MANUAL / WARRANTY

Exit and changes

confirmation

Default character _ signifies a blank field

A

None

Next character to edit

Previous character

from the schedule

A sign on 8-segmental LED display

Character map:

Character

A B C D E F G H I J K L M N O P Q R S

T U V W X Y Z 1 2 3 4 5 6 7 8 9 0

None

10. REPORT PRINTOUT.

10.1. BRIEF REPORT.

To print the report press

button

The type of brief report can be set in P7 parameter in Others group:

- actual measurements (current recorder measurements)

- from the delivery (from the last delivery, from loading to unloading)

- from the last hour

- from current day

10.2. FULL REPORT.

To start the printout press

button. To stop the printout at any moment press

button again. In this

mode, the recorder prints all data from the memory from the newest measurements to the oldest. By means

of this function you can print data from any period of time, from the beginning of the printout stopping data

printing at any moment.

10.3. REPORT FROM GIVEN PERIOD OF TIME.

In this mode, recorder prints data from the specified period of time.

Press

OK

button to enter the menu and select print from

and enter with

Enter the beginning of the printing period (year/month/day/hour/minute).

Then print to command display

and enter with

OK

button.

Enter the end of the printing period (year/month/day/hour/minute).

Recorder prints the report and exits from the configuration menu

OK.. button.

Version 1.0

1. TECHNICAL CHARACTERISTICS.

9.3 DESCRIPTION OF THE PARAMETERS:

DR-201 is the temperature recorder with built-in printer designed to be installed in the cab, both in heavy lorries

and small delivery vans. Due to small size and compact design is ideal for daily use. The device is mounted on

the dashboard due to included fixing clamps. Power supply and temperature sensor are connected with

connectors to the rear panel.

Recorder has included:

- two temperature sensors

- cable for connecting the door opening sensor

- distributor

- feeding cable with a fuse

The recorder has a memory buffer for 62000 measurements (lasts for 2 years at a frequency of memorizing

every 15 minutes). The frequency of data memorizing to the memory can be set from 1 to 999 minutes. The

device operates in two modes:

- continuous recording,

- recording during the drive.

In the second case, recording process turns on/off with START/STOP button, which marks the beginning and

the ending of the drive at the same time. When operating, the recorder indicates the temperature from the first

and the second sensors alternately and the current time. The mode of recording and duration of the drive is

indicated by LED diodes. Additionally, the driver can set MIN and MAX temperature alarms which, when

exceeded will be stored in memory and signalled acoustically. The stored data can be deleted and the access to

the menu can be password-protected. Due to built-in thermal printer, it is possible to print data from the memory

from any period of time.

Print from/print to - recorder allows you to print a report from the specified period of

time. You should enter the beginning and the ending of the printing period.

date - current date

time - current time

Description - in the report header you can place a brief description of the user, e.g. business data,

company address (maximum 32 figures, figures edition, see: point 9.4)

Registration number - in the report header you can place the registration number of the vehicle

(maximum 32 figures, figures edition, see point. 9.4)

alarm - The user can activates the temperature alarm function and set the lower temperature

alarm

and upper temperature alarm

for each sensor. When exceeding the limit, the

user will be informed by a message on the display and beeper. When an alarm occurs, you can

mute the beeper by pressing any configuration button. Ocurred emergency states will be recorded

in the device memory and marked on the printout. Parameter

determines an alarm

switching delay in minutes.

Sampling - This parameter allows you to set the data sampling time in 1min...24hours range. (The

frequency of memorizing data to the recorder memory).

2. SPECIFICATIONS

Other parameters:

Inputs:

2 temperature sensors: NTC 5k by 25C

1 logical inputs (normally closed or opened)

Measuring range:

NTC: -40...+120C

Accuracy:

NTC in: -40...+80C range: 0,5C, in other 1C

- sensor calibration T1, range: -9..9C When the temperature value deviates from the

actual value, you can calibrate the temperature sensor. The parameter value is added

to the measured value.

Memory cache:

62 000 measurements, non-volatile memory

- sensor T2: 1-ON, 0-OFF

Data memorizing frequency:

1min...24hours.

Display resolution:

0,1C in whole range

Display:

LED with graphic icons

Printer:

thermal, printing speed 50mm/s, heat-sensitive paper

57mm width, roll diamter 40mm

Protection class:

IP-30

- sensor calibration T2, range: -9...9C

Power supply:

12...24VAC/DC 20%

Power consumption:

when recording 40mA, when printing - to 3A

Operation and storage

conditions:

operation: -20...50C; storage: -40...60C

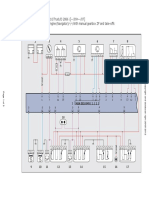

3. REAR PANEL.

DR-201

1

0

Sensors socket

Unused

- sensor T1: 1-ON, 0-OFF

Power socket

Cut-out

O

- logical input: 0-off, 1-on (NO), 2- on (NC), 3-delivery function

Thermograph is equipped with two logical inputs for events recording (door opening,

unit operation, defrosting cycles) or to carry out the delivery function. Commands

loading and unloading in a delivery function are triggered by shorting signal.

Connect a shorting signal to a wire, e.g. Ordinary doorbell button. Shorting the circuit

commands will be activated and stored in the recorder memory. Delivery command

is signalled on the display by LED diode

- beeper: 1-ON; 0-OFF

- display blanking after a period of inactivity, range 0...99sec.

P6=99 - display blanked constantly, P6=0 - display does not blanking

- brief report printout type by pressing

button 0-actual measurements, 1-delivery

report, 2-last hour report, 3-current day report

- recording mode:

1-CONTINUOUS

0-ONLY DURING DRIVE

- saving data continuously

- saving data only during the drive

- diode signalling

- to start the drive and immidiately

- the moment of the beginning and of the activates recording press

(diode

signalling the delivery, and

drive: loading and unloading

diode

signalling recording).

are triggered by button

(diode

signalling the delivery).

- language: 0-polish; 1-english, 2-german

4. MOUNTING.

9. RECORDER CONFIGURATION.

Recorder.

When choosing an assembly location you have to remember

that the casing of the recorder is non resistant to difficult

environment conditions. Therefore, it should be mounted

inside the vehicle cabin. Included fixing clamp allows you to

adjust the angle of attachment to the vehicle dashboard,

clipboard or bulkhead. An assembly location must provides

comfort in daily use.

Loosen the lower clamp screws (Pic. 2 point 2) and unscrew

side cap nuts (Pic. 2 point1) and remove the fixing clamp (Pic.

2 point 3). Fit the clamp to the dashboard and mark the holes.

Then drill the holes with diameter of 3mm and fasten with

screw with diameter of 3,5mm. Mount the recorder back on the

clamp and adjust the angle of slope so that it resists in the front

of the dashboard. .Then tighten the cap nuts (1) and lower

chuck screws (2).

After recorder and measuring sensors mounting correctly, plug in the power and configure the

device.

9.1. MENU HANDLER.

- starts menu and parameters edition and accepts changes

- changes the parameters values and passes between them

- backs up one level higher in the menu nad exits from the configuration menu,

it is also used to go back to the previous character edition

Recorder DR-201

Door opening sensor

9.2. MENU DIAGRAM.

Print from

Month

Year

Day

Hour

Temperature sensor

Minute

Pic.1 The example of recording system

in the truck.

Print to

Date

Year

Year

Month

Month

Day

Day

Hour

Minute

Printing report

from the period

Hour

Time

Minute

Description

First sign

Second sign

Third sign

Record no.

First sign

Second sign

Last sign

DASHBOARD

Pic.2 Fixing clamp (3).

Alarm

Wiring.

Lower limit T1 Upper limit T1 Lower limit T2 Upper limit T2

Sampling

Recorder is equipped with:

- two temperature sensors

- cable for connecting the door opening sensor

- feeding cable with fuse socket

All sensor wires are terminated with standard RJ-11 connectors.

Alarm delay

Sampling time

Other parameters Sensor T1

Calibration T1

Sensor T2

Calibration T2

Screen blanking time Brief report

Recording

Language

Logical input

Beeper

Temperature sensors:

Temperature sensors should be installed in cold chamber in a safety place, not exposed to mechanical damage,

where is a proper air circulation. The source of indoor lighting should not be closer than 50cm from the sensors.

The recommended location of the sensors is on the wall, 30cm of the ceiling, properly 1/3 and 2/3 of the

chamber length from the outlet of the evaporator. The sensor is mounted in a vertical position with an ending

upwards, directly on the wall inside the chamber by means of clamps and fixing chucks.

50

Factory settings

recall

Memory

reset

Password

Pic.3 Choice of angle to the deashboard.

Protection class

IP67

5 or 10m

Connector RJ-11

Temperature sensor are marked by 1 and

2 numbers.The sensors does not require

wiring polarity. To extend the sensors use

standard OMY wires with a section not less

than 0,5mm2. Maximum wire length should

not exceed 100 meters depending on

quality and section of used wire.

Rys.4 Wymiary czujnika naciennego.

Rys.4. Wiring sensor dimensions.

5

Door opening sensor:

Thermograph has a logical input for events recording( doors opening, defrosting cycles, unit operation, loading

and unloading time recording). The wire to connect the event sensor is included (e.g. Reed door sensor). The

type of event sensor is specified by P4 parameter in the Others (NC - normally closed/ NO - normally opened).

When connecting contacts signalling the unit operation or defrosting cycle to the digital input, you should make

surethat no signalling circuit is not a live both in active and inactive state! Otherwise, the recorder will break

down. Signalling relies on short-circuiting or digital input circuit opening, rather than the charge transfer!

Each closing and opening the circuit will be recordered in the recorder memory.

The sensor does not require wiring polarity.

7. FRONT PANEL.

Power supply.

The recorder is powered by the vehicle wiring system 12V and 24V. It is possible to connect the recorder directly

from the accumulator, fuse strip or the lighter socket. The feeding cable is equipped with a 5A fuse socket with

(+) and (-) marks. Maximum power consumption (when printing) is 40W. When recording, the power

consumption is negligible, about 40mA.

Printer flap

opening

5. DIAGRAM OF CONNECTING RECODER with one temperature sensor.

Display

If the recoderd is installed in a small delivery van and the user uses only one temperature sensor, it is possible to

opt out of the distributor and connect the sensor no. 1 to the recorder directly as follows:

Full report printing button

Sensors

socket

Unused

Supply

socket

DR-201

1

0

Cut-out

Brief report printing button

Confirming key, it is also used for configuration

menu start-up

Delivery and changes cancellation button,

pressing for 5 sec turns on/off recording

Temperature sensor number

Temperature indicator

Fuse socket 5A

Time indicator

Temperature recording runs

Temperature sensor T1

Temperature alarm or temperature sensor failure

Power supply 12V or 24V

Logical input activation (for example, door opened)

6. DIAGRAM OF CONNECTING RECORDER with two temperature sensors.

Delivery of goods (drive lasts)

If the user uses two temperature sensors, it is necessary to use the distributor:

Power supply indicator

Sensors

socket

Unused

Power

socket

DR-201

1

0

Cut-out

Distributor

Fuse socket 5A

1

4

Temperature

sensor T1

2

Temperature

sensor T2

Power supply 12V or 24V

Out of paper alarm

Paper eject button

8. PAPER INSTALLATION.

Put an included roll of thermal paper in the printer. The thermal paper used for printing is standard and

available in every stationery point of sale.It is recommended to use rolls of a width of 57mm and diameter of

40mm.

How to install the paper:

1. Open the printer cover (pull the cover up on both sides of the printer: look at the fibula on the picture)

2. Put the roll of paper in the printer

3. Pull out about 3cm of paper outside the cover

4. Close the cover of the printer so that the paper came out correctl tough th output hole.

5. If it is necessary pull out thr paper using FEED button

ATTENTION:

Thermal paper is unilateral and has to be mounted from the correct side in the printer. If the print-out is

empty, reverse the papre to the other side.

5

Вам также может понравиться

- Carrier DATACOLD 500 T-R User Manual PDFДокумент30 страницCarrier DATACOLD 500 T-R User Manual PDFAmir MohammedОценок пока нет

- Truck/MAN/TG-A/310/Truck/D 2866 / ( - /99 - /07) VDO/FFR Vehicle-Engine (Navigator) /-/-/with Manual Gearbox ZF and Take-OffsДокумент5 страницTruck/MAN/TG-A/310/Truck/D 2866 / ( - /99 - /07) VDO/FFR Vehicle-Engine (Navigator) /-/-/with Manual Gearbox ZF and Take-OffsRomica CiorneiОценок пока нет

- Autocom FAQ - Доработка IVECO 30pinДокумент3 страницыAutocom FAQ - Доработка IVECO 30pinAvs Electron100% (1)

- Pilot VW LTДокумент10 страницPilot VW LTSilviuCocoloș100% (2)

- Ford Transit 2.4 Tdci 140 Duratorq H9Fb: Timing Chain: Removal/InstallationДокумент33 страницыFord Transit 2.4 Tdci 140 Duratorq H9Fb: Timing Chain: Removal/InstallationAMAT COMERCIAL MAQUINARIA S.L.0% (1)

- D400 Manuale enДокумент72 страницыD400 Manuale eninstengg100% (1)

- Man Truck Fault Code Control Unit Air Suspension (Ecas)Документ2 страницыMan Truck Fault Code Control Unit Air Suspension (Ecas)BassieОценок пока нет

- TLB30Документ11 страницTLB30Victor GuzmanОценок пока нет

- 043 Man TruckДокумент4 страницы043 Man TruckFilipposОценок пока нет

- Plugin 832: New Trasdata: NT - BOSCH - EDC17CV42 - TC1797 - IROM - MAN - GPTДокумент5 страницPlugin 832: New Trasdata: NT - BOSCH - EDC17CV42 - TC1797 - IROM - MAN - GPTHumberto Cadori FilhoОценок пока нет

- Aib - Qas 125-150 VolvoДокумент62 страницыAib - Qas 125-150 VolvoJorge CarrascoОценок пока нет

- Temic Istruction ConnectorДокумент10 страницTemic Istruction ConnectorRuberli de LimaОценок пока нет

- Datakom 309 ManualДокумент63 страницыDatakom 309 ManualSalvador Millán Estrada100% (1)

- Dst4400 EngДокумент20 страницDst4400 EngFrancisco Stonly Amador Rodriguez33% (3)

- Component Description For Single Signal Acquisition and Actuation Module (SSAM) Control UnitДокумент1 страницаComponent Description For Single Signal Acquisition and Actuation Module (SSAM) Control UnitrudiОценок пока нет

- Truck Adblue Emulator For MAN INSTRUCTIONS PDFДокумент4 страницыTruck Adblue Emulator For MAN INSTRUCTIONS PDFobd2worksОценок пока нет

- ST10F273Документ4 страницыST10F273Poongodi RangasamyОценок пока нет

- GYSMI 160 Inverter WelderДокумент9 страницGYSMI 160 Inverter Welderthorsharp100% (1)

- Autocom CDP Pro For Trucks Workable Trucks Models EngДокумент624 страницыAutocom CDP Pro For Trucks Workable Trucks Models Engsausalp1998Оценок пока нет

- Edic Installation GuideДокумент54 страницыEdic Installation GuideJuan FernandezОценок пока нет

- Bosch Edc7c32 ManДокумент3 страницыBosch Edc7c32 ManEmi DОценок пока нет

- Manitou ElektrikДокумент152 страницыManitou ElektrikMuhammad Ma'mumОценок пока нет

- Iveco Especificaciones y Diagramas Stralis Trakker 2 PDFДокумент4 страницыIveco Especificaciones y Diagramas Stralis Trakker 2 PDFSaidi JalelОценок пока нет

- Manual EHLA Part 2 V01-00Документ52 страницыManual EHLA Part 2 V01-00danielvepОценок пока нет

- 1316370B Workshop Manual Thermo Top Evo en WEBДокумент48 страниц1316370B Workshop Manual Thermo Top Evo en WEBSanja Frankola100% (2)

- Wabco Atc CanДокумент36 страницWabco Atc CanCostel Caraman100% (1)

- Coduri TelecomenziДокумент3 страницыCoduri TelecomenziBogdan Terteș100% (1)

- Accelerator Pedal Position Sensor/IVS Switch (APS/IVS)Документ2 страницыAccelerator Pedal Position Sensor/IVS Switch (APS/IVS)Franz JW MontezaОценок пока нет

- Dispositivi Associati Alla DST4400Документ1 страницаDispositivi Associati Alla DST4400Bruno MarianoОценок пока нет

- In NT AMF 1.2 Fast User GuideДокумент2 страницыIn NT AMF 1.2 Fast User GuidesdiamanОценок пока нет

- Defecte ABS2Документ64 страницыDefecte ABS2Goranka Bulatovic IlicОценок пока нет

- Acronime BMWДокумент7 страницAcronime BMWmaciu1Оценок пока нет

- Electrics DAF XF CF Euro 4 5Документ199 страницElectrics DAF XF CF Euro 4 5Anonymous YAb02JОценок пока нет

- 21Документ4 страницы21Cao LanОценок пока нет

- Renault Kerax 440.35T Dxi 6X4 HD: WWW - Renault-Trucks - Co.ZaДокумент4 страницыRenault Kerax 440.35T Dxi 6X4 HD: WWW - Renault-Trucks - Co.Zaentreprise.tgctp201550% (4)

- Temsa BusДокумент71 страницаTemsa Busmannguyenbkdn100% (1)

- Touran 2006 1.4 1.6 B EДокумент35 страницTouran 2006 1.4 1.6 B EJanos HallaОценок пока нет

- Twin-3.1 General ManualДокумент64 страницыTwin-3.1 General ManualBV JdvОценок пока нет

- SYS TXT Pentru Primo Rezolutie AutomataДокумент2 страницыSYS TXT Pentru Primo Rezolutie AutomataVlad DascaluОценок пока нет

- Swiftec ManualДокумент47 страницSwiftec ManualJANDREY MENEGHINIОценок пока нет

- Workshop Manual Thermo DW 300Документ98 страницWorkshop Manual Thermo DW 300kumbrovОценок пока нет

- DSE8610 MKII Installation InstructionsДокумент2 страницыDSE8610 MKII Installation Instructionssorangel_123Оценок пока нет

- VW Radio RCD 300 Silver ManualДокумент5 страницVW Radio RCD 300 Silver ManualSalmiMohamedОценок пока нет

- LVA3344 LVA444 Operation Manual PDFДокумент86 страницLVA3344 LVA444 Operation Manual PDFjaduzy0% (1)

- Arocs Genearal InformationДокумент55 страницArocs Genearal InformationAhmad NawawiОценок пока нет

- Manualesipldk 300 Im 36Документ214 страницManualesipldk 300 Im 36rfarias79Оценок пока нет

- MAN ECAS 2 Fault Codes PDF - CompressedДокумент3 страницыMAN ECAS 2 Fault Codes PDF - Compressedjohnny flahaОценок пока нет

- Mid 185 - Sid 254 - Fmi 9Документ3 страницыMid 185 - Sid 254 - Fmi 9AkbarОценок пока нет

- Zepro Card Install. InstrucДокумент29 страницZepro Card Install. InstrucriisseliОценок пока нет

- Bader-451 04511530english - v114 PDFДокумент37 страницBader-451 04511530english - v114 PDFkumbrovОценок пока нет

- Mid 185 - Psid 2 - Fmi 7Документ3 страницыMid 185 - Psid 2 - Fmi 7AkbarОценок пока нет

- DimSport JTAG Cable Pinout PDFДокумент1 страницаDimSport JTAG Cable Pinout PDFnicamarcosОценок пока нет

- Mid 185 - Pid 245 - Fmi 2Документ3 страницыMid 185 - Pid 245 - Fmi 2AkbarОценок пока нет

- Panou Sigurante Si Relee DokkerДокумент28 страницPanou Sigurante Si Relee DokkercristianОценок пока нет

- ECДокумент339 страницECulisse_Оценок пока нет

- Manual: Monitoring, Control and Alarm SystemДокумент38 страницManual: Monitoring, Control and Alarm SystemSteve OliveiraОценок пока нет

- L99-YQ Intelligent Pressure RecorderДокумент3 страницыL99-YQ Intelligent Pressure RecorderJesus Eduardo Rosero CordobaОценок пока нет

- Comet 0221 - IcДокумент22 страницыComet 0221 - Icmarian07kОценок пока нет

- WWW - Johnsoncontrols.in Content Dam WWW Jci Be Eu Library Product Information Bms Products Electronic Control Tech Info Facility Explorer Product Bulletin TUC0311 Europe 12 2011Документ11 страницWWW - Johnsoncontrols.in Content Dam WWW Jci Be Eu Library Product Information Bms Products Electronic Control Tech Info Facility Explorer Product Bulletin TUC0311 Europe 12 2011Leo Prasanth Xavier MartinОценок пока нет

- Sf-5100 Tech ModeДокумент6 страницSf-5100 Tech ModeapcloicОценок пока нет

- Subiect Barem EngДокумент4 страницыSubiect Barem EngGelu DrăjneanuОценок пока нет

- 20 Test 3Документ2 страницы20 Test 3Gelu DrăjneanuОценок пока нет

- T Eal 153 21 Party Games For Esl - Ver - 2Документ27 страницT Eal 153 21 Party Games For Esl - Ver - 2Gelu DrăjneanuОценок пока нет

- Test Limba Engleza Clasa 3Документ3 страницыTest Limba Engleza Clasa 3Stan Ana Maria100% (1)

- 2006 Peugeot 206 64834 PDFДокумент192 страницы2006 Peugeot 206 64834 PDFdrkiranrkОценок пока нет

- Test Intensiv Engleza 5Документ30 страницTest Intensiv Engleza 5Simona Singiorzan90% (30)

- DDEN507SWD+ - Manual de UtilizareДокумент60 страницDDEN507SWD+ - Manual de UtilizareTarulescuClaudiuОценок пока нет

- Hansel and GretelДокумент21 страницаHansel and GretelGelu DrăjneanuОценок пока нет

- Dongle Support On The Rv130 and Rv130w 0Документ5 страницDongle Support On The Rv130 and Rv130w 0Gelu DrăjneanuОценок пока нет

- Sab LoaneДокумент52 страницыSab LoaneGelu DrăjneanuОценок пока нет

- Pre TaskДокумент6 страницPre Taskedgar armando marinОценок пока нет

- Introduction To Terahertz Electronics (2021)Документ371 страницаIntroduction To Terahertz Electronics (2021)Numa Luma100% (1)

- Sinusoidal Oscillator: An Electronic Device That Generates Sinusoidal Oscillations of DesiredДокумент22 страницыSinusoidal Oscillator: An Electronic Device That Generates Sinusoidal Oscillations of DesiredbasimОценок пока нет

- Oscilloscope Lab Manual11Документ16 страницOscilloscope Lab Manual11DM RafiunОценок пока нет

- SOP For TOSHIBA VFDДокумент8 страницSOP For TOSHIBA VFDJoseph Jojo100% (1)

- 02 Introduction To Shock and VibrationДокумент34 страницы02 Introduction To Shock and Vibrationkostarica123100% (1)

- FarField Method - With AuthorsДокумент4 страницыFarField Method - With AuthorsFety AyuОценок пока нет

- Grade 11 Waves and Sound Unit PlanДокумент9 страницGrade 11 Waves and Sound Unit Planapi-272399401Оценок пока нет

- AQA-Physics Experiments PDFДокумент63 страницыAQA-Physics Experiments PDFAnonymous zfqrXhuОценок пока нет

- PhysicsДокумент39 страницPhysicsRosdy DyingdemonОценок пока нет

- Procedure 1B: Packaged-Products 150 LB (68Документ8 страницProcedure 1B: Packaged-Products 150 LB (68Truong Huy Hoang100% (1)

- Signal Generator Library: Module User's Guide C28x Foundation SoftwareДокумент80 страницSignal Generator Library: Module User's Guide C28x Foundation SoftwareAshwani RanaОценок пока нет

- Light and Architectural Lighting SystemsДокумент17 страницLight and Architectural Lighting SystemsCrystal Kaye CortezОценок пока нет

- Nortek Primers - Getting Started With Waves MeasurementsДокумент9 страницNortek Primers - Getting Started With Waves MeasurementsKarun DasОценок пока нет

- Natural Frequency of Simply Supported STAAD Vs MathCADДокумент6 страницNatural Frequency of Simply Supported STAAD Vs MathCADnanobots37Оценок пока нет

- ALTPSB010-Procedure For Testing Bearing Status On GTA41 AlternatorsДокумент45 страницALTPSB010-Procedure For Testing Bearing Status On GTA41 AlternatorsEGOTRONIC100% (2)

- R-6.Docxrajesh KR YadavДокумент4 страницыR-6.Docxrajesh KR YadavsanjayОценок пока нет

- Physics Yr 10 Waves TestДокумент11 страницPhysics Yr 10 Waves TestDorcas NyabokeОценок пока нет

- A2 - Magnectic - Fields ANSДокумент11 страницA2 - Magnectic - Fields ANSNight Mist7Оценок пока нет

- Experimentation and Data Acquisition: Figure 3.1 Schematic Diagram of Set-UpДокумент24 страницыExperimentation and Data Acquisition: Figure 3.1 Schematic Diagram of Set-UpasprillaОценок пока нет

- Correlation Between Belt Natural Frequencies and Vibration SpectraДокумент7 страницCorrelation Between Belt Natural Frequencies and Vibration SpectraSrinivasan RaviОценок пока нет

- Signals and Systems (K-Wiki - Sampling)Документ10 страницSignals and Systems (K-Wiki - Sampling)madivala nagarajaОценок пока нет

- A Handbook of Sound and VibrationДокумент207 страницA Handbook of Sound and VibrationDan Roy100% (2)

- Doppler EffectДокумент11 страницDoppler EffectJoyceTangОценок пока нет

- Astm C-597-02Документ4 страницыAstm C-597-02Bayron Medina Ospina67% (3)

- Lab # 2Документ6 страницLab # 2Muhammad FarzanОценок пока нет

- The Most Important Words English Language PDFДокумент29 страницThe Most Important Words English Language PDFAhmed AlbasrihhkkОценок пока нет

- AP Chem Unit 3.11 Spectroscopy & The Electromagnetic Spectrum - AP Chemistry - FiveableДокумент3 страницыAP Chem Unit 3.11 Spectroscopy & The Electromagnetic Spectrum - AP Chemistry - FiveableDan HimelsteinОценок пока нет

- Antenna Lab#9Документ11 страницAntenna Lab#9Ahmad Abu BakrОценок пока нет

- EMC Guidelines PCBДокумент13 страницEMC Guidelines PCBCristian BarrosОценок пока нет