Академический Документы

Профессиональный Документы

Культура Документы

Determination of Reducing Sugars

Загружено:

rheamaeАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Determination of Reducing Sugars

Загружено:

rheamaeАвторское право:

Доступные форматы

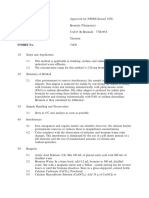

J-58-1

Steepwater Analysis

REDUCING SUGARS

PRINCIPLE

Reducing sugars are most commonly determined by reaction with a stabilized

alkaline solution of a copper salt. When reaction conditions, i.e., time,

temperature, reagent concentration and composition, are controlled, the amount of

copper reduced is proportional to the amount of reducing sugars in the sample

analyzed. In the accompanying adaptation of the Schoorl method (Note 1), the

reducing sugar concentration expressed as dextrose, is estimated by iodometric

determination of the unreduced copper remaining after reaction.

SCOPE

This adaptation of the Schoorl method was designed specifically for analysis of

steepwater (Note 2). Only minor modification is required for application to most

carbohydrate mixtures containing reducing sugars.

REAGENTS

1.

Fehling's Solution (Note 3):

A.

Dissolve 34.65 g of reagent grade crystalline copper sulfate

pentahydrate (CuSO45H2O) in purified water and dilute to 500 mL.

B.

Dissolve 173 g of reagent grade potassium sodium tartrate

tetrahydrate (KnaC4H4O64H2O) and 50 g of reagent grade sodium

hydroxide in purified water and dilute to 500 mL.

2.

Phosphotungstic Acid, Crystals: Reagent Grade

3.

Potassium Iodide Solution, 30%: Dissolve 150 g of reagent grade

potassium iodide (KI) in purified water and dilute to 500 mL. The reagent

should be protected from light during storage, and it should be discarded

when the presence of free iodine becomes evident.

Analytical Methods of the Member Companies of the

Corn Refiners Association, Inc.

Accepted 5-25-64

Revised 10-20-87

J-58-2

Steepwater Analysis

REDUCING SUGARS continued

4.

Sulfuric Acid Solution, 28%: Cautiously pour 85 mL of concentrated

sulfuric acid (96% H2SO4; sp g 1.84) into 400 mL of purified water while

stirring. Cool to room temperature and dilute to 500 mL.

5.

Sodium Thiosulfate Solution, 0.1 N: Standard

6.

Starch Indicator Solution, 1%

PROCEDURE

1.

Mix the heavy steepwater sample and weigh accurately about 10 g (Note 4).

Transfer to a 200 mL Kohlrausch flask with purified water, add 2 g of

phosphotungstic acid crystals, and mix (Note 5). Dilute to 201 mL (Note 6)

with purified water, using a drop of amyl alcohol to disperse foam if

necessary. Mix, gravity filter through Whatman No. 1 filter paper, collect

filtrate in a clean and dry flask.

Pipet 10.0 mL of Fehling's A solution and then 10.0 mL of Fehling's B

solution into a 250 mL Erlenmeyer flask. Add 20.0 mL of sample filtrate

and 10 mL of purified water to bring total volume of reaction mixture to 50

mL. Mix contents of flask by swirling.

Add 2 small glass beads to prevent bumping while boiling, and cover the

mouth of the flask with a small glass funnel or glass bulb. Place the flask

on a hot plate adjusted to bring the solution to a boil in 3 minutes (Note 7),

and continue boiling for exactly 2 minutes (total heating time of 5 minutes).

Cool quickly to room temperature in an ice bath or a cold running water

bath.

Add 10 mL of 30% potassium iodide solution and 10 mL of 28% sulfuric

acid solution; titrate immediately with standard 0.1 N sodium thiosulfate

solution. Near the end point add 1 mL of starch indicator solution, and

continue titrating carefully while agitating the solution continuously until

the blue starch-iodine color is discharged.

Conduct two blank determinations in identical fashion substituting purified

water for the sample.

J-58-3

Steepwater Analysis

REDUCING SUGARS continued

CALCULATION

Subtract sample titer from the average blank titer. Find reducing sugar content (expressed as dextrose)

equivalent to the titer difference by reference to the accompanying table (Note 8).

% Reducing Sugars (as is) (as Dextrose) =

mg Dextrose (From Table) 200 mL 100

Sample Wt. (g) 20 mL 1000 mg/g

NOTES AND PRECAUTIONS

1.

Copper oxidation of carbohydrates is not a simple reaction; end products

are mixtures of acids, so equations are not usually written. Iodometric

determination of excess copper (II) is summarized:

2 Cu + + + 4I -

H 3O +

Cu 2 I 2 + I 2

I 2 + 2 S2O3 = a S4O 6 = + 2 I -

2.

The steeping (soaking) of corn in a dilute sulfurous acid solution extracts

solubles including carbohydrates, and the latter are largely fermented to

lactic acid during the process. The concentrated extract is known as heavy

steepwater in the corn wet milling industry, and it is designated Condensed

Fermented Corn Extractives by the Association of American Feed Control

Officials. The latter organization provides the following definition:

"Condensed Fermented Corn Extractives is the product obtained by the

partial removal of water from the liquid resulting from steeping corn in a

water and sulfur dioxide solution which is allowed to ferment by the action

of naturally occurring lactic acid producing microorganisms as practiced in

the wet milling of corn.

3.

The Fehling's solution recommended here is equivalent to that used in

Dextrose Equivalent Methods E-26 and F-22, where careful standardization

of the reagent is essential. However, copper concentration in the Schoorl

method is not highly critical and adjustment may be unnecessary.

Satisfactory results can be obtained with reagents giving blank titers

ranging from 27.5 to 29.5 mL of 0.1 N sodium thiosulfate solution, and

adjustment of the copper sulfate solution (Fehling's A solution)

concentration to provide blank titers in this range is recommended.

J-58-4

Steepwater Analysis

REDUCING SUGARS continued

4.

Use a 100 g sample when analyzing light steepwaters from the process

containing about 5% dry substance.

5.

Treatment with phosphotungstic acid precipitates proteinaceous materials

which interfere in the reducing sugar analysis.

6.

Dilution to 201 mL corrects for the precipitate volume, giving a filtrate

volume of 200 mL.

7.

Alternatively, the flask may be placed on a wire gauze and heated over a

Bunsen burner, but control of the heating cycle is more difficult by this

technique. Heating on a hot plate with a stepless control is recommended

for best precision.

8.

Use of the accompanying table for conversion of titer difference to mg of

reducing sugar (expressed as dextrose) presumes ability of the analyst to

duplicate exactly the conditions under which the table was developed. This

approach is quite accurate in most cases but it does entail a risk of error.

9.

The risk of error can be avoided by careful duplicate standardization using

known quantities of pure dextrose. The standardization plot is slightly

curvilinear, passing through the origin.

REFERENCES

1.

Schoorl, N., Zurjodometrischen Zuckerbestimmung mittels Fehlingscher

Lsung., Zeitschr. f. agnew. Chem., 12, 633 (1899)

2.

Schoorl, N. and Regenbogen, A., Massanalytische Zuckerbestimmung,

Zeitschr. f. anal. Chem., 56, 191 (1917)

3.

Flohil, J. T., report of the subcommittee on the development of a volumetric

copper reduction method for sugar determinations, Cereal Chem, 10, 471 (1933)

4.

Cereal laboratory methods, 3rd Edition, pp 18-19, 1935, American Society

of Cereal Chemists

5.

Physical and Chemical Methods of Sugar Analysis, Edited by C. A.

Browne and F. W. Zerban, 3rd Edition, John Wiley & Sons, Inc., New

York, N. Y., 1948

J-58-5

Steepwater Analysis

REDUCING SUGARS continued

Schoorl Method: Conversion of Titer Difference to Reducing Sugars

Titer

Difference*

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Reducing Sugars (As Dextrose), mg

__________________________________________________________

0.0 mL

1.0

2.0

3.0

4.0

0.0

3.2

6.4

9.4

12.6

0.3

3.5

6.6

9.8

13.0

0.7

3.8

6.9

10.1

13.3

1.0

4.1

7.2

10.4

13.6

1.3

4.4

7.5

10.7

14.0

1.6

4.7

7.8

11.0

14.3

1.9

5.0

8.1

11.4

14.6

2.2

5.3

8.5

11.7

15.0

2.5

5.6

8.8

12.0

15.3

2.8

5.9

9.1

12.3

15.6

5.0

6.0

7.0

8.0

9.0

15.9

19.2

22.4

25.6

28.9

16.3

19.5

22.7

25.9

29.3

16.6

19.8

23.0

26.2

29.6

16.9

20.1

23.3

26.6

30.0

17.2

20.5

23.7

26.9

30.3

17.6

20.8

24.0

27.3

30.6

17.9

21.1

24.3

27.6

31.0

18.2

21.4

24.6

28.0

31.3

18.5

21.8

24.9

28.3

31.6

18.9

22.1

25.2

28.6

31.9

10.0

11.0

12.0

13.0

14.0

32.3

35.7

39.0

42.4

45.8

32.7

36.0

39.3

42.8

46.2

33.0

36.3

39.6

43.1

46.5

33.3

36.7

40.0

43.4

46.9

33.7

37.0

40.3

43.7

47.2

34.0

37.3

40.6

44.1

47.6

34.3

37.6

41.0

44.4

47.9

34.6

38.0

41.3

44.8

48.3

35.0

38.3

41.7

45.2

48.6

35.3

38.7

42.0

45.5

48.9

15.0

16.0

17.0

18.0

19.0

49.3

52.8

56.3

59.8

63.3

49.6

53.2

56.7

60.1

63.6

49.9

53.5

57.0

60.5

64.0

50.3

53.9

57.3

60.9

64.3

50.7

54.2

57.7

61.2

64.7

51.1

54.5

58.1

61.5

65.0

51.4

54.9

58.4

61.9

65.4

51.7

55.3

58.8

62.3

65.8

52.1

55.6

59.1

62.6

66.1

52.4

56.0

59.5

63.0

66.5

20.0

21.0

22.0

23.0

24.0

66.9

70.7

74.5

78.5

82.6

67.2

71.1

74.9

78.9

83.0

67.6

71.5

75.3

79.3

83.4

68.0

71.9

75.7

79.7

83.8

68.4

72.2

76.1

80.1

84.2

68.8

72.6

76.5

80.5

84.6

69.1

73.0

76.9

80.9

85.0

69.5

73.4

77.3

81.3

85.4

69.9

73.7

77.7

81.7

85.8

70.3

74.1

78.1

82.1

86.2

25.0

26.0

27.0

86.6

90.7

94.8

87.0

91.1

87.4

91.5

87.8

91.9

88.2

92.3

88.6

92.7

89.0

93.1

89.4

93.5

89.8

93.9

90.2

94.3

*mL of 0.1000 N sodium thiosulfate solution.

Вам также может понравиться

- AOCS CD 8 53 Peroxido Con CL PDFДокумент2 страницыAOCS CD 8 53 Peroxido Con CL PDFIvone Sulistya92% (13)

- WP - High Efficiency Axial Flux Machines - Whitepaper v1.5Документ21 страницаWP - High Efficiency Axial Flux Machines - Whitepaper v1.5unknown234uОценок пока нет

- Report Reducing SugarДокумент8 страницReport Reducing SugarRedzuan Hussin83% (6)

- Iodine ValueДокумент4 страницыIodine ValueRobert Gilmore100% (4)

- Carbohydrate Qualitative AnalysisДокумент9 страницCarbohydrate Qualitative AnalysisRamesh KandagatlaОценок пока нет

- Advanced Pharmaceutical analysisОт EverandAdvanced Pharmaceutical analysisРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Dextrose EquivalentДокумент3 страницыDextrose EquivalentdarisОценок пока нет

- Method: Determination of Dextrose EquivalentДокумент3 страницыMethod: Determination of Dextrose EquivalentEnamul hasanОценок пока нет

- Fehling A and BДокумент5 страницFehling A and BXiao MieОценок пока нет

- Dextr 02Документ4 страницыDextr 02Rahmad Nauli LubisОценок пока нет

- Full Report Carbs On 161.1Документ23 страницыFull Report Carbs On 161.1Kim Leonard BolandosОценок пока нет

- BIC 101 Manual 2022Документ49 страницBIC 101 Manual 2022charusrirajkumar27Оценок пока нет

- PPĐG ReportДокумент15 страницPPĐG ReportHà ChiОценок пока нет

- K-Bglu 1107 DataДокумент16 страницK-Bglu 1107 Datapi_yoanaОценок пока нет

- Lane-Eynon Table (Dextrose)Документ4 страницыLane-Eynon Table (Dextrose)yani100% (1)

- PreparationДокумент2 страницыPreparationmghaffarzadehОценок пока нет

- Calcium by Titrametric MethodДокумент4 страницыCalcium by Titrametric MethodRajeev ChandОценок пока нет

- CHM 2962 Report 4Документ9 страницCHM 2962 Report 4Yun KiatОценок пока нет

- AstmДокумент3 страницыAstmphamkieuОценок пока нет

- Amylose/ Amylopectin: Assay ProcedureДокумент12 страницAmylose/ Amylopectin: Assay ProcedureAdriannah AdrianОценок пока нет

- Preparation of Banana FlavorsДокумент8 страницPreparation of Banana Flavorsnathan3602Оценок пока нет

- (Doi 10.1016/b978!1!4832-2832-7.50007-1), - ICUMSA Methods of Sugar Analysis - Determination of Sucrose - (By Polarimetry)Документ6 страниц(Doi 10.1016/b978!1!4832-2832-7.50007-1), - ICUMSA Methods of Sugar Analysis - Determination of Sucrose - (By Polarimetry)marifa16Оценок пока нет

- Method CodДокумент3 страницыMethod CodAndreea LilianaОценок пока нет

- Cukry Schoorl Eng PDFДокумент4 страницыCukry Schoorl Eng PDFMega NingrumОценок пока нет

- Acido Pectico MucilagoДокумент8 страницAcido Pectico MucilagoPilar Salazar GallegoОценок пока нет

- Annex 1 - Titration Method For Determining Salt Iodate and Iodide ContentДокумент5 страницAnnex 1 - Titration Method For Determining Salt Iodate and Iodide ContentFTIR FSTUNAIRОценок пока нет

- Glucose Oxidase: Assay ProcedureДокумент12 страницGlucose Oxidase: Assay ProcedureCharles PreciousОценок пока нет

- 121ferrous GluconateДокумент3 страницы121ferrous GluconateAira Jherese MarcosОценок пока нет

- Preparation of Buffer: Experiment No: 1 DateДокумент44 страницыPreparation of Buffer: Experiment No: 1 Dateecogandhi5203Оценок пока нет

- Jam and PreservesДокумент6 страницJam and Preserveskolita kamalОценок пока нет

- Determination of The Alcohol LabДокумент3 страницыDetermination of The Alcohol LabVIctoriakay100% (1)

- Biochemical Test For CarbohydrateДокумент24 страницыBiochemical Test For Carbohydrateanandbggu88% (8)

- Is 14684 - 1999 Determination of Nitrogen and Nitrogenous Compounds in SoilsДокумент5 страницIs 14684 - 1999 Determination of Nitrogen and Nitrogenous Compounds in SoilsPrapa KaranОценок пока нет

- 2007 07 10 Methods Method 410 3Документ3 страницы2007 07 10 Methods Method 410 3Syahrul AminОценок пока нет

- Ascorbic Acid Iodometric TitrationДокумент2 страницыAscorbic Acid Iodometric TitrationÂngelo Jesus100% (8)

- Uv Vis SpectrophotometerДокумент8 страницUv Vis SpectrophotometerFath Bond100% (1)

- Experiment One Preparation of Benzophenone Oxime: 1. ProcedureДокумент5 страницExperiment One Preparation of Benzophenone Oxime: 1. Procedurek ucheОценок пока нет

- Epa360 2DOWinklerДокумент5 страницEpa360 2DOWinklerSujith KumarОценок пока нет

- Sales Amónicas Del Ácido Fosfatídico SIN 442Документ4 страницыSales Amónicas Del Ácido Fosfatídico SIN 442Andrea Sanchez AbarcaОценок пока нет

- Estimation of Total Reducing Sugar in The Given SampleДокумент12 страницEstimation of Total Reducing Sugar in The Given SampleKHYATI BHINDEОценок пока нет

- Analysis of An Unknown Vinegar SampleДокумент8 страницAnalysis of An Unknown Vinegar Samplearfanadib13Оценок пока нет

- PDFДокумент4 страницыPDFلوغيتفيكافوزيةОценок пока нет

- Methods of Test For Food Microorganisms - Test of Escherichia ColiДокумент16 страницMethods of Test For Food Microorganisms - Test of Escherichia ColiatОценок пока нет

- Synthesis of Acetophenone DerivativesДокумент6 страницSynthesis of Acetophenone DerivativesAwad SaidОценок пока нет

- Biochem Lab ManualДокумент5 страницBiochem Lab ManualshaneskiranrajaОценок пока нет

- Final-Cole's Method and Vital StainingДокумент5 страницFinal-Cole's Method and Vital StainingpaktiОценок пока нет

- Experiment 5Документ9 страницExperiment 5Ames Morales TorresОценок пока нет

- Working With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsДокумент5 страницWorking With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundskasliwalrajeshОценок пока нет

- Titration VДокумент24 страницыTitration VwaefsОценок пока нет

- Corn Starch A-20.1986Документ6 страницCorn Starch A-20.1986cleanalatlabОценок пока нет

- Bromide (Titrimetric) 320 - 1Документ5 страницBromide (Titrimetric) 320 - 1maría joséОценок пока нет

- KonjacДокумент2 страницыKonjacJovin NgОценок пока нет

- Carbohydrates LabДокумент20 страницCarbohydrates LabChristian Dave MativoОценок пока нет

- J. Biol. Chem.-1948-Barker-715-24Документ11 страницJ. Biol. Chem.-1948-Barker-715-24Rudy QuismorioОценок пока нет

- Hydrolysis of Methyl Salicylate ExpДокумент7 страницHydrolysis of Methyl Salicylate ExpPradeep100% (1)

- Srndwandwe, Practical Report 2Документ17 страницSrndwandwe, Practical Report 2siphiweОценок пока нет

- 33.2.21 AOAC Official Method 896.01 Lactose in Milk: Polarimetric Method Final Action A. ReagentsДокумент1 страница33.2.21 AOAC Official Method 896.01 Lactose in Milk: Polarimetric Method Final Action A. ReagentsMabel Elena Avila CorreaОценок пока нет

- Cod Method and FailureДокумент3 страницыCod Method and FailureIoanna DivОценок пока нет

- The Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterОт EverandThe Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterОценок пока нет

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterОт EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterОценок пока нет

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresОт EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresРейтинг: 5 из 5 звезд5/5 (1)

- LicenseДокумент3 страницыLicenseSourav SharmaОценок пока нет

- RarДокумент42 страницыRarntc7035Оценок пока нет

- Read MeДокумент1 страницаRead MeSourav SharmaОценок пока нет

- Whats NewДокумент27 страницWhats NewrheamaeОценок пока нет

- LogДокумент1 страницаLogrheamaeОценок пока нет

- Wine BookДокумент179 страницWine Bookdalyj2009100% (2)

- How To Use Bentonite To Clarify Wine - Winemaker's Academy - Winemaker's AcademyДокумент7 страницHow To Use Bentonite To Clarify Wine - Winemaker's Academy - Winemaker's Academyrheamae100% (1)

- GC OkeДокумент8 страницGC OkeNola IeLhaОценок пока нет

- Luff Schoorl MethodДокумент4 страницыLuff Schoorl MethodrheamaeОценок пока нет

- Er enДокумент1 страницаEr enrheamaeОценок пока нет

- 5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop SchematicsДокумент46 страниц5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop Schematicsamier jrs100% (1)

- Eurotrace Installation Instructions: Installation On A PipeДокумент6 страницEurotrace Installation Instructions: Installation On A PipeNicolas150956Оценок пока нет

- Administration-Guide Open Bee OCSДокумент7 страницAdministration-Guide Open Bee OCSpeka76Оценок пока нет

- Flying Qualities CriteriaДокумент24 страницыFlying Qualities CriteriajoereisОценок пока нет

- Vineeth - Curriculum VitaДокумент8 страницVineeth - Curriculum VitaVineeth NBОценок пока нет

- Croner PKE280 H35 Spec SheetДокумент2 страницыCroner PKE280 H35 Spec Sheetvictor hugoОценок пока нет

- PPTДокумент22 страницыPPTMuhamMad TaufikОценок пока нет

- WCM Combined Rough DraftДокумент258 страницWCM Combined Rough Draftpalanivendhan_186170Оценок пока нет

- Steel Erection Code of PracticeДокумент94 страницыSteel Erection Code of Practicedadz mingiОценок пока нет

- s1fnmdl3sm PDFДокумент26 страницs1fnmdl3sm PDFmn_aminОценок пока нет

- MBA Database Marketing and FinanceДокумент9 страницMBA Database Marketing and FinanceSelvam RajОценок пока нет

- Under Slung Steel Truss Bridge With Composite RCC Deck BridgeДокумент5 страницUnder Slung Steel Truss Bridge With Composite RCC Deck BridgeShaileshRastogiОценок пока нет

- Torre Sauter 0 - 5 - 320 - 025 - 4 PDFДокумент27 страницTorre Sauter 0 - 5 - 320 - 025 - 4 PDFGuiОценок пока нет

- Toyota 80 SeriesДокумент5 страницToyota 80 Seriesaagi_dОценок пока нет

- Gopez Wood Craft Spot Rep Feb 06, 2022Документ2 страницыGopez Wood Craft Spot Rep Feb 06, 2022Eller-Jed Manalac MendozaОценок пока нет

- Overview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Документ3 страницыOverview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Sravan Kumar PendyalaОценок пока нет

- Course Catalog 2019Документ34 страницыCourse Catalog 2019Mehaboob BashaОценок пока нет

- Cored Wires - ESAB - OK TubrodДокумент87 страницCored Wires - ESAB - OK TubrodElias KapaОценок пока нет

- Ammendement No.1 - List of Approved VendorsДокумент3 страницыAmmendement No.1 - List of Approved VendorsLakhwant Singh KhalsaОценок пока нет

- CI 1580A ENG User ManualДокумент50 страницCI 1580A ENG User ManualArdy KristianОценок пока нет

- Netapp Cabling and Hardware BasicsДокумент14 страницNetapp Cabling and Hardware BasicsAnup AbhishekОценок пока нет

- Iso 7040Документ1 страницаIso 7040serzo75Оценок пока нет

- Reference Frame Theory PDFДокумент42 страницыReference Frame Theory PDFSubaragavanОценок пока нет

- Notificatio N (Rese Rvation) Gove Rnment: A Cu) UTДокумент1 страницаNotificatio N (Rese Rvation) Gove Rnment: A Cu) UT122-Ayush Kumar ParganihaОценок пока нет

- GEN CHEM 2 LESSON 3 Intermolecular Forces of Solids and Their Properties1.1Документ27 страницGEN CHEM 2 LESSON 3 Intermolecular Forces of Solids and Their Properties1.1Loraine Castro0% (1)

- Propeller (PRELIMS LESSON)Документ34 страницыPropeller (PRELIMS LESSON)Aidrian AidОценок пока нет

- Chemical BondingДокумент27 страницChemical BondingSachin Kumar50% (2)

- Panduit Electrical CatalogДокумент1 040 страницPanduit Electrical CatalognumnummoОценок пока нет

- Diagrama Electrico VespaДокумент1 страницаDiagrama Electrico Vespavetgesto3Оценок пока нет