Академический Документы

Профессиональный Документы

Культура Документы

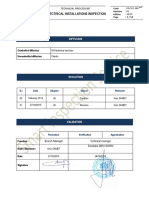

Electrical Wiring Methods and Check List

Загружено:

ssbАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Electrical Wiring Methods and Check List

Загружено:

ssbАвторское право:

Доступные форматы

Electrical Inspection Manual Checklists

This documents contains electrical inspection checklists taken from the

2014 Electrical Inspection Manual with

.

The checklists are intended to help inspectors keep track of the

numerous aspects of an electrical installation

are also intended to serve as an organizational tool for contractors,

project managers, or anyone who conducts,

receives, or is responsible for electrical inspections, or who may wish to

perform self-inspections, of electrical

Installations.

The checklists are organized as follows.

General Safety Checklist for Electrical Inspections 1.1

1. Does the inspection task involve exposed energized conductors or

circuit parts?

2. Can the risk of exposure to electrical hazards be justified?

3. What is the voltage of the equipment that requires inspection?

4. Where are the approach boundaries for shock protection?

5. Will the inspection involve crossing any of the approach boundaries?

6. Has an incident energy analysis been performed for the equipment?

7. Are the available short-circuit current and clearing times known?

8. Where is the Arc Flash Boundary?

9. Will any part of the body be within the Arc Flash Boundary?

10. How will PPE for arc flash protection be selected?

11. Is the appropriate arc-rated PPE available?

12. Is the inspector qualified for this specific task and risk?

General Safety Checklist for Electrical Inspections-1.2

1. Identify installations or parts of installations that are covered by

2. Verify that installations have been made in accordance with the

Instructions included in listing and labelling of materials and

equipment.

3. Identify installations and equipment requiring special approval or

Investigation.

4. Verify that interrupting ratings and short-circuit current ratings

are adequate for the conditions of the installation.

5. Verify that unused openings have been effectively closed.

6. Check for broken or damaged parts and contamination by foreign

materials.

7. Check for secure mounting and adequate ventilation space for

equipment.

8. Check for proper use and ratings of splices and terminations.

9. Check temperature ratings of terminations.

10. Check for arc flash protection warning signs.

11. Check for markings on enclosures and verify appropriate ratings for

the environment.

12. Verify adequate working clearances, dedicated spaces, and

headroom around equipment.

13. Verify that working space and dedicated space are not used for

storage.

14. Check adequacy of entrance to and egress from working space in

general and verify that spaces containing large equipment have at least

two entrances/exits or the equivalent.

15. Verify that working spaces have adequate illumination.

16. Check for identification of disconnecting means and circuit

directories for panel boards, switchboards, switchgear and similar

G e n e r al

W i ri n g

M e t h o d s

1. Identify the wiring methods in use and verify their suitability for the

occupancy and conditions. Various Chapter 3articles

2. Verify that all conductors of a circuit are grouped together.

3. Check insulation values where conductors of different systems share

common enclosures.

4. Check wiring methods for spacing from edges of framing and for

protection from nails and screws.

5. Check for insulating bushings or grommets where NM cable is

installed through metal studs or where insulated conductors 4 AWG or

larger enter enclosures.

6. Check cover, fill, protection, and allowances for ground movement on

underground conductors and raceways.

7. Verify that electrical raceways and cable trays are used exclusively for

electrical conductors.

8. Check for continuity and completeness in metal raceways and

enclosures.

9. Verify that wiring methods are securely fastened in place, supported

independently of suspended ceilings, and not used as supports.

10. Check for continuity of grounded conductors in multiwire branch

circuits.

11. Check for adequate length of free conductors in boxes

12. Verify that boxes are installed at junction, splice, outlet, switch, and

pull points.

13. Check conductor fill in raceways.

14. Verify that raceway systems are complete prior to installation of

conductors.

15. Check vertical raceways for adequate conductor supports.

16. Verify that fire ratings have been restored at electrical penetrations.

17. Check installations of wiring in ducts, plenums, and other airhandling

spaces for proper methods and materials.

18. Verify that access to equipment behind removable panels is not

compromised by cables, raceways, or equipment.

Вам также может понравиться

- Method Statement For Laying of Low Voltage Cables and WiresДокумент5 страницMethod Statement For Laying of Low Voltage Cables and WiresMark Anthony AlanoОценок пока нет

- Power and Control Cable Method of StatementДокумент7 страницPower and Control Cable Method of StatementAhmad Dagamseh100% (1)

- STP-ELECT-DB Distribution Board TestДокумент18 страницSTP-ELECT-DB Distribution Board TestYouwan LeeОценок пока нет

- Method of Statement For Conduit InstallationДокумент15 страницMethod of Statement For Conduit InstallationMohd MuksinОценок пока нет

- MS Conduit InstallationДокумент6 страницMS Conduit InstallationSopi Labu0% (1)

- METHOD of STATEMENT Modifying Extending Relocating Existing Lighting Circuits and PointsДокумент7 страницMETHOD of STATEMENT Modifying Extending Relocating Existing Lighting Circuits and PointsKhyle Laurenz DuroОценок пока нет

- Method Statement - Concealed ConduitДокумент4 страницыMethod Statement - Concealed Conduitjoo2585Оценок пока нет

- Method Statement - Cable ConduitДокумент3 страницыMethod Statement - Cable Conduitjoo2585100% (1)

- Quality Assurance PlanДокумент2 страницыQuality Assurance PlanSAGARОценок пока нет

- Cable Tray Installation Quality Control and Inspection Report FormДокумент2 страницыCable Tray Installation Quality Control and Inspection Report FormSyam Chitturi0% (1)

- Method Statement Lamps, Switches and Socket Outlets InstallationДокумент2 страницыMethod Statement Lamps, Switches and Socket Outlets InstallationVõ Khắc GhiОценок пока нет

- Method Statement For Cable Laying, Termination, TestingДокумент10 страницMethod Statement For Cable Laying, Termination, Testingahmedshah512Оценок пока нет

- MOS For Water Supply Pipe InstallationДокумент3 страницыMOS For Water Supply Pipe InstallationDon Roseller Dumaya100% (1)

- Earthing Method StatementДокумент5 страницEarthing Method StatementMuhammad Saqib AsifОценок пока нет

- How To Use A Megger Insulation TesterДокумент2 страницыHow To Use A Megger Insulation TesterRakesh Babu0% (1)

- Field Work Procedure: 8. 8.1 Pre Hand ChecksДокумент7 страницField Work Procedure: 8. 8.1 Pre Hand Checkselsayed abdemagied100% (1)

- Transformer Maintenance Checklist - 5 Must Do Routine ChecksДокумент3 страницыTransformer Maintenance Checklist - 5 Must Do Routine Checksmurthy237Оценок пока нет

- Distribution Transformers & RMUДокумент7 страницDistribution Transformers & RMUWalidОценок пока нет

- Cable Tray Inst in The Concrete-EnДокумент15 страницCable Tray Inst in The Concrete-EngkutОценок пока нет

- Method Statement For Installation of Electric PVC Conduits and AccessoriesДокумент6 страницMethod Statement For Installation of Electric PVC Conduits and AccessoriessamsungloverОценок пока нет

- Testing and Commissioning of Motor Control Center Method StatementДокумент3 страницыTesting and Commissioning of Motor Control Center Method StatementHumaid Shaikh75% (4)

- BEW - Method Statement For G.I. Box & DB InstallationДокумент9 страницBEW - Method Statement For G.I. Box & DB InstallationArun UdayabhanuОценок пока нет

- Cable Ladder Method of Statement.Документ4 страницыCable Ladder Method of Statement.Ahmad DagamsehОценок пока нет

- Busway Method of StatementДокумент18 страницBusway Method of StatementmahmoudОценок пока нет

- Pole Planting QUALITY CHECKLISTДокумент3 страницыPole Planting QUALITY CHECKLISTTHEOPHILUS ATO FLETCHERОценок пока нет

- Method Statement - Embedded ConduitsДокумент3 страницыMethod Statement - Embedded ConduitsSimeon James Defeo Villacrusis100% (2)

- Method Statement For Installation of SwitchboardsДокумент5 страницMethod Statement For Installation of SwitchboardsDimitris NikouОценок пока нет

- Testing & Commissioning of Telephone Data SystemДокумент1 страницаTesting & Commissioning of Telephone Data Systemhaytham65Оценок пока нет

- Method Statement - Cable Joint LVДокумент4 страницыMethod Statement - Cable Joint LVanuraj arackal60% (5)

- Method Statement For GIДокумент9 страницMethod Statement For GIAleen Gamal Al-DinjiОценок пока нет

- Power and Control Cable Installation ITPДокумент1 страницаPower and Control Cable Installation ITPkamilОценок пока нет

- Method Statement - Bus BarДокумент2 страницыMethod Statement - Bus Barsoubhagya100% (1)

- MOS For Electrical UG Ducts (PVC Pipes) InstallationДокумент3 страницыMOS For Electrical UG Ducts (PVC Pipes) Installationmagdi badran100% (1)

- Table of Contents: Method Statement FOR Lightning Protection System InstallationДокумент10 страницTable of Contents: Method Statement FOR Lightning Protection System Installationw fathyОценок пока нет

- Cable Tray InstallationДокумент6 страницCable Tray InstallationsbpathiОценок пока нет

- Method Statement For Installation & Termination of Elecrtical Panels PDFДокумент14 страницMethod Statement For Installation & Termination of Elecrtical Panels PDFSazali Khamsan0% (1)

- Insulation Resistance Test Report For Control Cables: Document NumberingДокумент1 страницаInsulation Resistance Test Report For Control Cables: Document NumberingAhmad DagamsehОценок пока нет

- Method Statement For The Installation of TransformerДокумент2 страницыMethod Statement For The Installation of Transformeramg007100% (3)

- 007 LV & Control Cable Pre-CommissioningДокумент6 страниц007 LV & Control Cable Pre-CommissioningMohamed KasemОценок пока нет

- Testing and Commissioning ProceduresДокумент8 страницTesting and Commissioning Proceduresbhukya lachiramОценок пока нет

- Check ListДокумент6 страницCheck Listiman2222Оценок пока нет

- PQ-TEC-300 - Inspection Procedure of Electrical InspectionДокумент13 страницPQ-TEC-300 - Inspection Procedure of Electrical InspectionTouil Houssem100% (1)

- Job Procedure 02 For TRANSFORMERДокумент7 страницJob Procedure 02 For TRANSFORMERSoumik KarОценок пока нет

- Megger Testing Method StatementДокумент7 страницMegger Testing Method StatementRay Agacia0% (1)

- PRECOMMISSIONING and COMMISSIONING METHOD STATEMENT PROCEDURE FOR CCTV SYSTEMДокумент2 страницыPRECOMMISSIONING and COMMISSIONING METHOD STATEMENT PROCEDURE FOR CCTV SYSTEMHumaid ShaikhОценок пока нет

- Installation of Flow Meter Check ListДокумент1 страницаInstallation of Flow Meter Check ListZulfequar R. Ali Khan100% (2)

- Method Statement For The Installation of TransformerДокумент11 страницMethod Statement For The Installation of TransformerShaikh Ahamed100% (1)

- Checklist For Cable Try Fabrication and EractionДокумент2 страницыChecklist For Cable Try Fabrication and Eractionnayum100% (1)

- Method Statement Earthing, Bonding and Lightning Protection LatestДокумент11 страницMethod Statement Earthing, Bonding and Lightning Protection Latestasombrado_jeraldОценок пока нет

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFДокумент3 страницыTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid Shaikh100% (1)

- Method Statement For Firefighting Piping Equipment and Accessories InstallationДокумент12 страницMethod Statement For Firefighting Piping Equipment and Accessories InstallationMohamedОценок пока нет

- Testing and Commissioning of Submain Distribution Boards SMDBsДокумент2 страницыTesting and Commissioning of Submain Distribution Boards SMDBsHumaid Shaikh0% (1)

- WMS INFINEON PROJECT TOWER (MSB, SSB AND DBs INSTALLATION) - REV-1Документ5 страницWMS INFINEON PROJECT TOWER (MSB, SSB AND DBs INSTALLATION) - REV-1tanaОценок пока нет

- Method Statement For Cable Pulling & Final Electrical Connections.Документ6 страницMethod Statement For Cable Pulling & Final Electrical Connections.Ubah ChigozieОценок пока нет

- 1.method of Statement For Splicing of Fibre Optic CableДокумент2 страницы1.method of Statement For Splicing of Fibre Optic CableAung Thein OoОценок пока нет

- Electrical Inspection ChecklistsДокумент13 страницElectrical Inspection ChecklistsNuraisyah BatrisyiaОценок пока нет

- Guidelines To Visual Inspection of Electrical InstallationsДокумент4 страницыGuidelines To Visual Inspection of Electrical InstallationsadgasОценок пока нет

- Inspection and Testing of Electrical InstallationsДокумент7 страницInspection and Testing of Electrical InstallationsOdoch HerbertОценок пока нет

- Earth Loop Impedance TestsДокумент18 страницEarth Loop Impedance TestsKedarnath Sastry susarlaОценок пока нет

- Maintenance InstructionsДокумент24 страницыMaintenance InstructionsivishnurkОценок пока нет

- Lighitng DesignДокумент10 страницLighitng DesignssbОценок пока нет

- Industrial LTG Cal-2Документ1 страницаIndustrial LTG Cal-2ssbОценок пока нет

- Lighting Simulation For RoomДокумент4 страницыLighting Simulation For RoomssbОценок пока нет

- Lighting DesignДокумент321 страницаLighting DesignssbОценок пока нет

- 11 KV Switch Board - Specification DetailsДокумент18 страниц11 KV Switch Board - Specification DetailsssbОценок пока нет

- Electrical Power Distribution Specification-IIДокумент6 страницElectrical Power Distribution Specification-IIssb100% (1)

- Electrical Design DocumentДокумент6 страницElectrical Design DocumentssbОценок пока нет

- Lighting Simulation For RoomДокумент4 страницыLighting Simulation For RoomssbОценок пока нет

- Electrical Check List For Electrical Wiring: Project Name: Unit: Checked By: Reviewed byДокумент1 страницаElectrical Check List For Electrical Wiring: Project Name: Unit: Checked By: Reviewed byssb100% (1)

- Specification For Earthing, UPS System and Lan NetworkДокумент8 страницSpecification For Earthing, UPS System and Lan NetworkssbОценок пока нет

- Lighting Design For Training Room With Example of Dialux File in DetailingДокумент13 страницLighting Design For Training Room With Example of Dialux File in DetailingssbОценок пока нет

- Electrical Check List For Electrical Wiring: Project Name: Unit: Checked By: Reviewed byДокумент1 страницаElectrical Check List For Electrical Wiring: Project Name: Unit: Checked By: Reviewed byssb100% (1)

- Testing Directional Overcurrent ProtectionДокумент2 страницыTesting Directional Overcurrent ProtectionZokiОценок пока нет

- Safety Module - PSR-SPP-24DC/TS/S - 2986232: Your AdvantagesДокумент9 страницSafety Module - PSR-SPP-24DC/TS/S - 2986232: Your AdvantagesaaqibfarhanОценок пока нет

- Kilowatt Labs Sirius-Technical Data Sheet - 60-12-2C-TM-SD-GДокумент2 страницыKilowatt Labs Sirius-Technical Data Sheet - 60-12-2C-TM-SD-GIvanОценок пока нет

- Transformer ProtectionДокумент29 страницTransformer ProtectionSathish Kumar100% (1)

- Toyo Intelligent Inverter: Operating ManualДокумент344 страницыToyo Intelligent Inverter: Operating ManualLAZZOLAAОценок пока нет

- 70E A2011 ROPDraftДокумент101 страница70E A2011 ROPDraftMUTHU krishnanОценок пока нет

- Daikin Siesta Error Code PDFДокумент169 страницDaikin Siesta Error Code PDFfuturamsОценок пока нет

- SECTION - 16465 Bus-Way & Power FeedersДокумент7 страницSECTION - 16465 Bus-Way & Power FeedersWaleed Abd El-HamiedОценок пока нет

- Digital Motor Protection RelayДокумент16 страницDigital Motor Protection RelaySukant Kumar MohantyОценок пока нет

- FK, FM Pages 1526 - 1628 GeneralДокумент103 страницыFK, FM Pages 1526 - 1628 Generalpyae100% (7)

- 65/78/81XE 100/120/140XEL : Operator'S Manual Parts CatalogueДокумент57 страниц65/78/81XE 100/120/140XEL : Operator'S Manual Parts CatalogueCarlОценок пока нет

- Elementary Circuits - Circuits - Instructor PDFДокумент13 страницElementary Circuits - Circuits - Instructor PDFssshhhkiОценок пока нет

- Altivar® 28 Adjustable Speed Drive Controllers User GuideДокумент88 страницAltivar® 28 Adjustable Speed Drive Controllers User GuideplsalmrajОценок пока нет

- E+I Product (Sales) 2Документ35 страницE+I Product (Sales) 2Gohar Saleem KinaiОценок пока нет

- FireNET Trouble Messages List PDFДокумент2 страницыFireNET Trouble Messages List PDFStevenОценок пока нет

- S803N-D80 High Performance MCBДокумент4 страницыS803N-D80 High Performance MCBErik Marcelo BarrenecheaОценок пока нет

- Fault Code List For Drive Control (FR)Документ5 страницFault Code List For Drive Control (FR)UGIОценок пока нет

- Material Safety Data Sheet: 1. Product & Company IdentificationДокумент7 страницMaterial Safety Data Sheet: 1. Product & Company Identificationlurab3991Оценок пока нет

- All About TPI InspectionДокумент31 страницаAll About TPI InspectionAneesh JoseОценок пока нет

- ps441 0604762enДокумент12 страницps441 0604762enHimdad Tahir100% (1)

- LS VCB Mec PDFДокумент100 страницLS VCB Mec PDFDarrell Wilson100% (2)

- CA Abb V-ContactДокумент92 страницыCA Abb V-ContactWiliam CopacatiОценок пока нет

- Electrical Safety A Guide To The Causes and Prevention of Electrical Hazards by Adams, J. MaxwellДокумент204 страницыElectrical Safety A Guide To The Causes and Prevention of Electrical Hazards by Adams, J. Maxwellasdqwe999Оценок пока нет

- Simulation and Analysis of A Gas Insulated Switchg PDFДокумент7 страницSimulation and Analysis of A Gas Insulated Switchg PDFlukiОценок пока нет

- I558 E2 02 X+JX+UsersManualДокумент220 страницI558 E2 02 X+JX+UsersManualhartmans63Оценок пока нет

- ABB Motor Starter MS116Документ8 страницABB Motor Starter MS116AhmedKhaledSalahОценок пока нет

- DIN Fuses 7.2kV - 36kVДокумент124 страницыDIN Fuses 7.2kV - 36kVlarryОценок пока нет

- Midea Air Conditioner Error Code R SeriesДокумент9 страницMidea Air Conditioner Error Code R SeriesGeorge H. Gutierrez, PECSAОценок пока нет

- TATA Fault Codes PDFДокумент11 страницTATA Fault Codes PDFshinaskhan08867% (6)

- 05 Item 235 (Salwico NS-SCI)Документ1 страница05 Item 235 (Salwico NS-SCI)AlexDorОценок пока нет

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionОт EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionРейтинг: 4.5 из 5 звезд4.5/5 (2)

- A Place of My Own: The Architecture of DaydreamsОт EverandA Place of My Own: The Architecture of DaydreamsРейтинг: 4 из 5 звезд4/5 (242)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesОт EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesОценок пока нет

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseОт EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseРейтинг: 5 из 5 звезд5/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyОт EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyРейтинг: 4 из 5 звезд4/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideОт Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideРейтинг: 3.5 из 5 звезд3.5/5 (7)

- Civil Engineer's Handbook of Professional PracticeОт EverandCivil Engineer's Handbook of Professional PracticeРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 1От EverandBuilding Construction Technology: A Useful Guide - Part 1Рейтинг: 4 из 5 звезд4/5 (3)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishОт EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishРейтинг: 4 из 5 звезд4/5 (3)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsОт EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsРейтинг: 1 из 5 звезд1/5 (4)

- Estimating Construction Profitably: Developing a System for Residential EstimatingОт EverandEstimating Construction Profitably: Developing a System for Residential EstimatingОценок пока нет

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОт EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОценок пока нет

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyОт EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyРейтинг: 4 из 5 звезд4/5 (1)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftОт EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftРейтинг: 5 из 5 звезд5/5 (5)

- Real Life: Construction Management Guide from A-ZОт EverandReal Life: Construction Management Guide from A-ZРейтинг: 4.5 из 5 звезд4.5/5 (4)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEОт EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEРейтинг: 4 из 5 звезд4/5 (1)

- Field Guide for Construction Management: Management by Walking AroundОт EverandField Guide for Construction Management: Management by Walking AroundРейтинг: 4.5 из 5 звезд4.5/5 (3)