Академический Документы

Профессиональный Документы

Культура Документы

Drives, Shafts and Shaft Elements: Mechanical Design

Загружено:

dforsythe639Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Drives, Shafts and Shaft Elements: Mechanical Design

Загружено:

dforsythe639Авторское право:

Доступные форматы

Design web

Mechanical Design

ME 2105

Lecture 9

Drives, shafts and shaft elements

Dr Ahmed Kovacevic

School of Engineering and Mathematical Sciences

Room CM124, Phone: 8780, E-Mail: Design@city.ac.uk

www.city-design.tk

www.staff.city.ac.uk/~ra600/intro.htm

Ahmed Kovacevic, City University London

Design web

Introduction

z

z

z

z

z

A shaft a rotating element used to transmit power or

motion. It provides axis of rotation for rotating elements

and controls their motion.

An axle a non-rotating element that carries no torque

and is used to support rotating elements.

A spindle - a short shaft

To design a shaft, other elements: gears, pulleys, bearings

should be specified.

There are two aspects of shaft design:

Deflection and rigidity (bending and torsional deflection)

Stress and strength

Basically it is only necessary to check if a shaft diameter is

sufficient to sustain loads

Ahmed Kovacevic, City University London

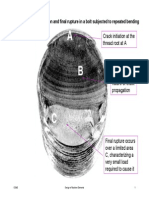

Common shaft loading

mechanisms

Design web

Ahmed Kovacevic, City University London

Design web

Shaft design characteristics

z

z

z

Shaft is usually of circular cross

section

Deflections are function of the

geometry and load.

Steps in the shaft design are:

Define shaft topology

Specify driving elements

Free body diagram

Select bearings

Consider shaft deflection and

stress

Specify connections

Dimensions

Ahmed Kovacevic, City University London

Design web

Shaft design

z

Shaft topology

a)

b)

c)

d)

Choose a shaft configuration to support and locate the two gears + two bearings

Solution uses an integral pinion, shaft with three shoulders, key, keyway and sleeve.

Bearings are located in the housing

Choose fan shaft configuration

Solution uses sleeve bearings, a straight through shaft, locating collars, setscrews,

pulley and fan

Driving elements

1.

Driving elements (gears,

pulleys, sprockets )

have to be selected and

calculated

Minimum diameter of a

rotating element and

forces acting on it are

relevant for a shaft design

2.

Ahmed Kovacevic, City University London

Design web

Shaft design

z

Free body diagram

Free body diagram is calculated such that the

system of interest is separated from the

surrounding and connections are replaced by

forces

a) Reactions in bearings & force diagram

b) Bending moment

c) Torsional moment ( P= T )

Bearing selection

a) Equivalent load (forces)

b) Bearing rating life based on the size

c) Positioning and lubrication

Ahmed Kovacevic, City University London

Design web

Shaft design bearing positioning

Ahmed Kovacevic, City University London

Design web

Shaft design

Shaft deflection and stress minimum diameter

Difficult to calculate exactly. Reasons for complexity:

a)

Variable shaft diameter

b)

Undercuts and grooves stress concentration points

c)

Type of load axial, radial, torsional, bending, static, dynamic

-

In this course we will calculate a minimum shaft diameter without considering stress

concentration points.

Calculations will be based on the maximum static load.

Diameter will be estimated for allowable stress which depends on the shaft material.

Bending stress

Torsional stress

Minimum diameter

(distortion energy)

theory

M

Mc

32 M

=

=

d3

Z

I

T

T c 1 6T

=

=

=

d3

S

J

z =

zy

d =

32 fs

Sy

3

+ T

4

C=d/2

I=d4/64

Z=c/I

J=d4/32

S=c/J

fs

- maximum span

- second moment of area

- section modulus

- second polar moment of area

- polar section modulus

- factor of safety

Ahmed Kovacevic, City University London

Design web

Ahmed Kovacevic, City University London

Design web

Shaft diameter vs Torque

Shaft Dia

Pure Torque

Power (P=T)

(at 100 rpm)

mm

Nm

kW

30

132

1.4

40

313

3.3

50

612

6.4

60

1058

10.6

75

2068

21.6

80

2510

26

100

4900

51.3

Ahmed Kovacevic, City University London

Design web

How to connect elements to the shaft?

Interference fits

z Keys & Keyseats

z Pins

z Hubs

z Integral shaft

z Splines

z

Ahmed Kovacevic, City University London

Design web

Limits and Fits

Tolerance difference between the

maximum and minimum size limits

of a part.

International Tolerance Grade

Numbers are used to specify the size

of a tolerance zone.

Ahmed Kovacevic, City University London

Design web

International tolerance grade numbers

Ahmed Kovacevic, City University London

Design web

Preferred fits in the Basic-Hole System

To differentiate

between holes and

shafts, upper and

lower case letters are

used

H Holes; h - Shafts

Ahmed Kovacevic, City University London

Design web

Fundamental deviations for shafts

Ahmed Kovacevic, City University London

Design web

Force Fit - example

Ahmed Kovacevic, City University London

Keys and pins

Design web

Used on shafts to secure rotating elements; gears, pulleys, wheels.

Keys transmit torque between the shaft and the rotating element

Pins axial positioning, transfer of torque or/and thrust.

Ahmed Kovacevic, City University London

Design web

Strength of a key

W D

4

Allowed torque on the key:

D

T =F ;

A = WL

2

DWL S y

F

2T

= =

T=

A DWL

4 fs

Ahmed Kovacevic, City University London

Design web

Example

Determine the diameter for the solid round shaft 450

mm long, as shown in Figure. The shaft is supported by

self-aligning bearings at the ends. Mounted upon the

shaft are a V-belt pulley, which contributes a radial load

of F1=8kN to the shaft, and a gear which contributes a

radial load of F2=3kN. The two loads are in the same

plane and have the same directions. The allowable

bending stress (strength) is S=70 MPa.

F1=8 kN

F2=3 kN

a=450 mm

b=150 mm

c=200 mm

S=70 MPa

d=?

SOLUTION:

Assumptions

- the weight of the shaft is neglected

- the shaft is designed for the normal bending

stress in the location of max. bending moment

Ahmed Kovacevic, City University London

Design web

Solution

M

= a R1 + (a b) F1 + (a b c) F2

R1 = 6 kN

R2 = 5 kN

M max = M A = a R1 = 900 Nm

Second moment of area (moment of inertia)

Section modulus =--------------------------------------------------------------d4

d max span

I=

c=

64

2

I d3

Z= =

0.1d 3

c 32

Stress = Strain = Bending moment / section modulus

S = =

d=

900

Mc M

6

=

=

=

70

10

I

Z 0.1 d 3

900

= 0.050 m = 50mm

5

70 10

Ahmed Kovacevic, City University London

Вам также может понравиться

- MD VI Shaft DesignДокумент11 страницMD VI Shaft DesignShatendra SahuОценок пока нет

- MECH2410 - Lecture 7 Shaft DesignДокумент21 страницаMECH2410 - Lecture 7 Shaft Designaaarid1Оценок пока нет

- Me-331 Design of Machine Elements Unit Iv Design of Basic ElementsДокумент25 страницMe-331 Design of Machine Elements Unit Iv Design of Basic ElementsMuthuvel MОценок пока нет

- Shafts and Shaft Components: Machine Design IIДокумент48 страницShafts and Shaft Components: Machine Design IIEngr Aleem AmjadОценок пока нет

- Lec 02 Shaft DesignДокумент0 страницLec 02 Shaft DesignamdevaОценок пока нет

- MECH68Документ8 страницMECH68GogyОценок пока нет

- Design Concept RCC SuperstructureДокумент5 страницDesign Concept RCC SuperstructureSaroj BhattaraiОценок пока нет

- 2 ShaftsДокумент24 страницы2 Shaftsrdksj100% (1)

- Fatigue DesignДокумент56 страницFatigue Designarrow_inspectОценок пока нет

- Design and Fabrication of Power Scissor Jack: A Project ReportДокумент39 страницDesign and Fabrication of Power Scissor Jack: A Project ReportBaliwe moyakheОценок пока нет

- Multi - Storey Buildings - III AnalysisДокумент35 страницMulti - Storey Buildings - III AnalysisMohamed El MotazОценок пока нет

- Non Linear Analysis-Pushover (Sap 2000)Документ69 страницNon Linear Analysis-Pushover (Sap 2000)suman33100% (2)

- Ch8notes PDFДокумент60 страницCh8notes PDFAshish LoyaОценок пока нет

- Adobe Scan Jul 01, 2021Документ24 страницыAdobe Scan Jul 01, 2021Syko GamingОценок пока нет

- Lec01-Springs (Ch10)Документ32 страницыLec01-Springs (Ch10)Kiril AckovskiОценок пока нет

- C ClampДокумент26 страницC Clamparulmurugu100% (4)

- Design Spur Gear Study Material LectДокумент6 страницDesign Spur Gear Study Material Lectprashant mishraОценок пока нет

- ME2233 Mechanics of Materials - I: Credit Hours - 3 Spring 2016 Lecture 2 (Week 2)Документ26 страницME2233 Mechanics of Materials - I: Credit Hours - 3 Spring 2016 Lecture 2 (Week 2)Chaudhry Muhammad AliОценок пока нет

- Mdid Lab ManualДокумент48 страницMdid Lab Manualjaimin777Оценок пока нет

- Addis Ababa Science & Technology University Department of Electromechanical EngineeringДокумент28 страницAddis Ababa Science & Technology University Department of Electromechanical EngineeringMitiku AbebeОценок пока нет

- Design and Analysis of Connecting Rod Using Forged Steel Report 31-08-2014 6.20 PM PDFДокумент20 страницDesign and Analysis of Connecting Rod Using Forged Steel Report 31-08-2014 6.20 PM PDFbalamech1230% (1)

- 6 Shafts PDFДокумент23 страницы6 Shafts PDFViven SharmaОценок пока нет

- Shafts: Standard Sizes of ShaftsДокумент9 страницShafts: Standard Sizes of ShaftssyampnaiduОценок пока нет

- Power Screws Fasteners and Rivted Joints Mech 2011Документ12 страницPower Screws Fasteners and Rivted Joints Mech 2011Eslam Mohamed SayedОценок пока нет

- Sr. No Topic Page Number: MAE 577 CAD Applications Adwait Joshi (2954-1696)Документ38 страницSr. No Topic Page Number: MAE 577 CAD Applications Adwait Joshi (2954-1696)Narendra Kumar DhayalОценок пока нет

- SpringsДокумент36 страницSpringsMuhammad Rehan100% (1)

- Rohit Rai Research PaperДокумент11 страницRohit Rai Research PaperRohit RaiОценок пока нет

- Design Rod of Diesel EngineДокумент15 страницDesign Rod of Diesel EngineRakesh Rockzss0% (1)

- MCQ in Machine DesigngДокумент15 страницMCQ in Machine DesigngRobert V. AbrasaldoОценок пока нет

- Lecture 17 - Design of Reinforced Concrete Beams For Shear: November 1, 2001 CVEN 444Документ35 страницLecture 17 - Design of Reinforced Concrete Beams For Shear: November 1, 2001 CVEN 444Ram RamisettiОценок пока нет

- Fatigue FailureДокумент47 страницFatigue FailureOmar KhanОценок пока нет

- ThesisДокумент235 страницThesisviralisurs67% (6)

- Thesis 108ME022 Hoisting Mechanism of An EOT CraneДокумент34 страницыThesis 108ME022 Hoisting Mechanism of An EOT CraneAshish NandyОценок пока нет

- Verity & Ss Ansys West PNGДокумент32 страницыVerity & Ss Ansys West PNGcklconОценок пока нет

- Design and Structural Dynamic Analysis of Overhead Elliptical ConveyorДокумент18 страницDesign and Structural Dynamic Analysis of Overhead Elliptical ConveyorIJSTEОценок пока нет

- Lecture 5 Shaft Design With SolutionsДокумент38 страницLecture 5 Shaft Design With Solutionsgatoradeqazwsx100% (2)

- Project ProblemsДокумент9 страницProject Problemsvivek geddamОценок пока нет

- A Research To Cable Force Optimizing Calculation of Cablestayed BridgeДокумент6 страницA Research To Cable Force Optimizing Calculation of Cablestayed BridgeParth TrivediОценок пока нет

- 10-Lateral Systems PDFДокумент38 страниц10-Lateral Systems PDFClaireNgokОценок пока нет

- Steel PowerPoint I (2018-2019)Документ89 страницSteel PowerPoint I (2018-2019)ohnmarzawОценок пока нет

- 181-186 For Web PDFДокумент6 страниц181-186 For Web PDFdiego.peinado8856100% (1)

- SAMДокумент38 страницSAMCHELVASERОценок пока нет

- NC11-1100X500 - (30th-Roof StyДокумент4 страницыNC11-1100X500 - (30th-Roof StyJONHCENA13Оценок пока нет

- Session 11.Документ12 страницSession 11.vijayakumarОценок пока нет

- Gear Design NhpancholiДокумент66 страницGear Design NhpancholiDINESH KUMARОценок пока нет

- RC ColumnsДокумент42 страницыRC Columnsyenrai100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsОт EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsОценок пока нет

- Design of Steel Structures: Materials, Connections, and ComponentsОт EverandDesign of Steel Structures: Materials, Connections, and ComponentsОценок пока нет

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОт EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОценок пока нет

- Hyperbolic Structures: Shukhov's Lattice Towers - Forerunners of Modern Lightweight ConstructionОт EverandHyperbolic Structures: Shukhov's Lattice Towers - Forerunners of Modern Lightweight ConstructionОценок пока нет

- Datasheet: This Manual Applies To The Following ProductsДокумент4 страницыDatasheet: This Manual Applies To The Following Productsdforsythe639Оценок пока нет

- Electronic 7 Day Programmable Room Thermostat: TP7000 RangeДокумент11 страницElectronic 7 Day Programmable Room Thermostat: TP7000 Rangedforsythe639Оценок пока нет

- Installation of Valve Troubleshooting: Bi-Directional Straight Valve With Flow-Selectable FeatureДокумент2 страницыInstallation of Valve Troubleshooting: Bi-Directional Straight Valve With Flow-Selectable Featuredforsythe639Оценок пока нет

- Tp5000siplusrf Easy User GuideДокумент2 страницыTp5000siplusrf Easy User Guidedforsythe639Оценок пока нет

- Programmable Room Thermostat: User GuideДокумент4 страницыProgrammable Room Thermostat: User Guidedforsythe639Оценок пока нет

- Iinstruction Manual: VLT FC Series Option PanelДокумент68 страницIinstruction Manual: VLT FC Series Option Paneldforsythe639Оценок пока нет

- Steels For Low Temperature Applications PDFДокумент16 страницSteels For Low Temperature Applications PDFdforsythe639Оценок пока нет

- USA Motorsport: Market Research ReportДокумент60 страницUSA Motorsport: Market Research Reportdforsythe639Оценок пока нет

- Perfecto T Range: DescriptionДокумент2 страницыPerfecto T Range: Descriptiondforsythe639Оценок пока нет

- Flow Diagram For Meng Fluids Assignment: Feed Pipe Supply TankДокумент1 страницаFlow Diagram For Meng Fluids Assignment: Feed Pipe Supply Tankdforsythe639Оценок пока нет

- Crimp or SolderДокумент6 страницCrimp or Solderdforsythe639Оценок пока нет

- Realizing Higher Productivity by Implementing Air Drilling Tech For Drilling Hard Top Hole Sections in Vindhyan FieldsДокумент7 страницRealizing Higher Productivity by Implementing Air Drilling Tech For Drilling Hard Top Hole Sections in Vindhyan FieldsLok Bahadur RanaОценок пока нет

- PrePeg XC110 210g 450gДокумент3 страницыPrePeg XC110 210g 450gPrakashChouhanОценок пока нет

- Top 100 Networking Interview Questions & Answers - PDFДокумент26 страницTop 100 Networking Interview Questions & Answers - PDFVeera PandiОценок пока нет

- Fundamentals of ElectronicsДокумент2 страницыFundamentals of ElectronicsatulzendeОценок пока нет

- Payment Advice Outward Telegraphic Transfer: DateДокумент2 страницыPayment Advice Outward Telegraphic Transfer: DateRomanov DalsheОценок пока нет

- Scan 1111111111Документ1 страницаScan 1111111111angela1178Оценок пока нет

- ATI Practice CodesДокумент1 страницаATI Practice Codesvanassa johnson100% (4)

- Revised Syllabus Filipino 2 PAGSASALINДокумент8 страницRevised Syllabus Filipino 2 PAGSASALINErza Scarler100% (4)

- Na Edifact Desadv SpecificationsДокумент17 страницNa Edifact Desadv Specificationsrajendra2505Оценок пока нет

- Mail Scanner - Community Ubuntu DocumentationДокумент4 страницыMail Scanner - Community Ubuntu DocumentationAjith PathiranaОценок пока нет

- BRIDGES - PPT 404 SEMДокумент204 страницыBRIDGES - PPT 404 SEMlokendraОценок пока нет

- Vacuum WordДокумент31 страницаVacuum Wordion cristian OnofreiОценок пока нет

- Sony NX Series PDFДокумент62 страницыSony NX Series PDFMaya Tes0% (1)

- Creating Flight Plan and User Waypoint Files For The Flight1 GTNДокумент6 страницCreating Flight Plan and User Waypoint Files For The Flight1 GTNJosé A. Montiel QuirósОценок пока нет

- Spherical Pillow Block Manual (MN3085, 2018)Документ13 страницSpherical Pillow Block Manual (MN3085, 2018)Dillon BuyeОценок пока нет

- Model Variant Description Variant Code Extended Warranty Price Royal PlatinumДокумент2 страницыModel Variant Description Variant Code Extended Warranty Price Royal PlatinumRiyasОценок пока нет

- Macmillan English Grammar in Context Advanced PDFДокумент3 страницыMacmillan English Grammar in Context Advanced PDFAnonymous l1MDLhBFXОценок пока нет

- BE Spec Flash EconomizerДокумент4 страницыBE Spec Flash Economizeronkarrathee100% (1)

- Faqs: Instant Credit Card Approval and IssuanceДокумент1 страницаFaqs: Instant Credit Card Approval and Issuancedaong_84Оценок пока нет

- Analysis and Design of Bridge Substructures PDFДокумент195 страницAnalysis and Design of Bridge Substructures PDFsuheilbugs100% (1)

- Sanghvi: Protein Self TestДокумент11 страницSanghvi: Protein Self TestNewborn2013Оценок пока нет

- Ferro Manganese Slag PDFДокумент2 страницыFerro Manganese Slag PDFDebraОценок пока нет

- Aspect Oriented ArchitectureДокумент43 страницыAspect Oriented ArchitectureerzhanbaiОценок пока нет

- New DatabaseДокумент18 страницNew DatabaseShafiq RosmanОценок пока нет

- LECTURE 6-Forming and Shaping of Plastics and CompositesДокумент52 страницыLECTURE 6-Forming and Shaping of Plastics and CompositesM.k. VarmaОценок пока нет

- Clearcase Branching and Labeling Best Practices For Parallel DevelopmentДокумент50 страницClearcase Branching and Labeling Best Practices For Parallel DevelopmentakkachotuОценок пока нет

- Orion Manual - Chess Pairing Software For Team Tournament - VegaChessДокумент46 страницOrion Manual - Chess Pairing Software For Team Tournament - VegaChessVictor FeitosaОценок пока нет

- Corrective MaintenanceДокумент12 страницCorrective MaintenanceMohammed Nerissa100% (1)

- ACR Methodology For The Conversion of High-Bleed Pneumatic Controllers in Oil and Natural Gas Systems v1.1Документ33 страницыACR Methodology For The Conversion of High-Bleed Pneumatic Controllers in Oil and Natural Gas Systems v1.1mlkrembsОценок пока нет

- Chopra Scm5 Ch13Документ58 страницChopra Scm5 Ch13Faried Putra SandiantoОценок пока нет