Академический Документы

Профессиональный Документы

Культура Документы

Assignment - 1 For 1st Test of DOM

Загружено:

Hareesha N GОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Assignment - 1 For 1st Test of DOM

Загружено:

Hareesha N GАвторское право:

Доступные форматы

DAYANANDA SAGAR COLLEGE OF ENGINEERING

Shavige Malleshwara Hills, Kumaraswamy Layout, Bangalore 560 078.

(An Autonomous Institute affiliated to VTU, Approved by AICTE & ISO 9001:2008 Certified)

Accredited by National Assessment and Accreditation Council (NAAC) with A grade

DEPARTMENT OF AERONAUTICAL ENGINEERING

Assignment I

Subject: Dynamics of Machines

Assignment display date: 20-08-2016

before 5pm

Faculty name: Hareesha N G

Sub Code: 10AE53

Assignment Submission date: 06-09-2016,

Return of Assignment: 07-09-2016

All Questions are to be answered compulsorily

Q.N

Question Description

o

1 a Explain the equilibrium of the following systems:

b

c

i) Two force members ii) three force members iii) Member with two forces and

a torque

With usual notations, Explain the principle of virtual work, considering a slider

crank mechanism

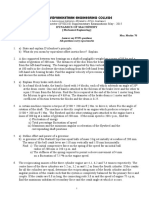

For the mechanism shown in Fig. Q1 (c), Determine the torque on the link AB

for static equilibrium of the mechanism.

Fig. Q.1 (c)

Fig. Q.2 (a)

a In

Fig. Q.2 (b)

a four-link

mechanism shown in Fig. Q.2(a), torque T 3 and T4 have

magnitudes of 30 N.m and20 N.m respectively. The link lengths are AD = 800

mm, AB = 300 mm, BC = 700 mm and CD = 400 mm. For the static equilibrium

of the mechanism, determine the required input torque T 2.

For the static equilibrium of the quick return mechanism shown in fig. Q.2 (b),

Predict the input torque T2 to be applied on link AB for a force of 300N on the

slider D. The dimensions of the various links are OA=400mm, AB=200mm,

OC=800mm, CD=300mm.

a Obtain the expressions for frictional torque in a flat collar bearing for uniform

b

a

b

pressure and wear conditions.

Assess the power lost in overcoming the friction and number of collars

required for a thrust bearing whose contact surfaces are 20cm external radius

and 15cm in internal radius. The coefficient of friction is 0.08. The total axial

load is 30 kN. Intensity of pressure is not to exceed 3.5 x 10 5 N/m2. Speed of the

shaft is 420 rpm.

Establish an expression for ratio of tensions in flat belt drive.

A belt 100 mm wide and 10 mm thick is to transmit power at speed of 1000

m/min. The net driving tension is 1.8 times the tension on slack side. If the safe

permissible stress is 2 MPa. Evaluate the maximum power that can be

transmitted at this speed. Assume the density of leather as 1000 kg/m 3. Also

determine (i) the absolute maximum power. (ii) Percentage increase in power.

2.5 kW of power is transmitted by an open belt drive. The linear velocity of the

a

b

belt is 2.5 m/s, The angle of lap on the smaller pulley is 165. The coefficient of

friction is 0.3. Determine the effect on power transmission in the following

cases: 1) Initial tension in the belt is increased by 8%. 2) Initial tension in the

belt is decreased by 8%. 3) Angle of lap is increased by 8% by the use of an

idler pulley, for the same speed and tension on the tight side. 4) Coefficient of

friction is increased by 8% by suitable dressing to the friction sample of the belt.

An open belt drive connects two pulleys 1.5 m and 0.5m diameter on parallel

shafts 3.5m apart. The belt has a mass of 1 kg/m length and the maximum

tension in the belt is not to exceed 2 kN. The 1.5m pulley, which is the driver,

runs at 250 rpm. Due to belt slip, the velocity of the driven shaft is only 730

rpm. If the coefficient of friction between the belt and the pulley is 0.25

Examine , i) The torque on each shaft ii) Power transmitted iii) The power lost

in friction and iv) The efficiency of the drive.

What do you mean by static balancing and dynamic balancing?. Explain in

detail taking a suitable example.

A rotating shaft carries four masses A, B, C and D, which are radially attached to

it, along the shaft axis. The mass centres are 40mm, 50mm, 60mm and 70mm

respectively from the axis of rotation. The masses B,C and D are 60kg, 50kg and

40kg respectively. The angles of the masses C and D with respect to mass B are

90 and 210 in same sense, respectively. The planes containing B and C are

0.5m apart. For a complete balanced system, Determine ;i) The mass and

angular position of mass A. ii) The position of planes containing masses A and

D.

a A shaft has three eccentrics, each 75 mm diameter and 25 mm thick, machined

in one piece with the shaft. The central planes of the eccentric are 60 mm apart.

The distance of the centres from the axis of rotation are 12 mm, 18 mm and 12

mm and their angular positions are 120 apart. The density of metal is 7000

kg/m3. Inspect the amount of out-of-balance force and couple at 600 r.p.m. If

the shaft is balanced by adding two masses at a radius 75 mm and at distances

of 100 mm from the central plane of the middle eccentric, find the amount of

the masses and their angular positions.

Four masses M1 = 100 kg, M2 = 175 kg, M3 = 200 kg and M4 = 125 kg are fixed

to the crank of 200 mm radius and revolve in planes 1, 2, 3 and 4 respectively.

The angular position of the planes 2, 3 and 4 with respect to first mass are 75,

135 and 240 taken in the same sense. Distance of the planes 2, 3 and 4 from

first are 600 mm, 1800 mm and 2400 mm. Evaluate the magnitude and

position of the balancing masses at radius 600 mm in planes 'L' and M' located

in the middle of 1 and 2 and in the middle of 3 and 4 respectively.

Вам также может понравиться

- Design and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainОт EverandDesign and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainОценок пока нет

- School of Mechanical and Building Sciences Mee 301 Dynamics of MachineryДокумент4 страницыSchool of Mechanical and Building Sciences Mee 301 Dynamics of MachineryNirman ParasharОценок пока нет

- Design of Machinery Jntua Previous PapersДокумент20 страницDesign of Machinery Jntua Previous PapersHimadhar SaduОценок пока нет

- DOM Assignment 2022-23Документ11 страницDOM Assignment 2022-23Pratham DakoriaОценок пока нет

- Dynamics of Machinery QuestionsДокумент11 страницDynamics of Machinery Questionslogeshboy0070% (1)

- Jntu Question PaperДокумент3 страницыJntu Question Paperrohitchanakya76Оценок пока нет

- DOM Model PaperДокумент2 страницыDOM Model PaperRambabuDaraОценок пока нет

- 9A03502 Dynamics of MachineryДокумент4 страницы9A03502 Dynamics of MachinerysivabharathamurthyОценок пока нет

- 2 - Dynamics of Machinery PDFДокумент8 страниц2 - Dynamics of Machinery PDFAkhil C KОценок пока нет

- DOM2Документ7 страницDOM2ds_shivaОценок пока нет

- S6 QB MeДокумент18 страницS6 QB MevenkiteshksОценок пока нет

- CAD/CAMДокумент2 страницыCAD/CAMNarayanarao PalagaraОценок пока нет

- Vibration Paper3Документ32 страницыVibration Paper3Debabrata PaulОценок пока нет

- 07a60304 - Dynamics of MachineryДокумент8 страниц07a60304 - Dynamics of MachineryRajaganapathy GanaОценок пока нет

- Tutorial 6: Me 313: Dynamics of Machinery Tutorial ProblemsДокумент4 страницыTutorial 6: Me 313: Dynamics of Machinery Tutorial Problemsdab111Оценок пока нет

- Dynamics of Machinery Question PapersДокумент22 страницыDynamics of Machinery Question PapersMohan Babu S0% (1)

- Dynamics of MachineryДокумент8 страницDynamics of Machineryrajamutyala4uОценок пока нет

- Diploma-4 Sem Course Code: 403 Subject Name: Theory of Machines Important QuestionsДокумент6 страницDiploma-4 Sem Course Code: 403 Subject Name: Theory of Machines Important Questionssuneel kumar rathoreОценок пока нет

- Rr320304 Dynamics of MachinesДокумент8 страницRr320304 Dynamics of MachinesSrinivasa Rao GОценок пока нет

- Unit IДокумент3 страницыUnit Imahendra babu mekalaОценок пока нет

- WWW - Manaresults.co - In: (Mechanical Engineering)Документ3 страницыWWW - Manaresults.co - In: (Mechanical Engineering)rajuОценок пока нет

- 07a4ec04 Kinematics of MachineryДокумент8 страниц07a4ec04 Kinematics of Machineryaditya56Оценок пока нет

- Question Paper Code:: (10×2 20 Marks)Документ4 страницыQuestion Paper Code:: (10×2 20 Marks)Iyyappan SubramanianОценок пока нет

- University QuestionsДокумент4 страницыUniversity QuestionsMartin De Boras PragashОценок пока нет

- DOM QP ScribdДокумент5 страницDOM QP ScribdvsanthanamОценок пока нет

- Kinematics of Machinery (MEE - 205) RCSДокумент2 страницыKinematics of Machinery (MEE - 205) RCSmanmonbhaОценок пока нет

- Part B & Part C Questions - Unit WiseДокумент3 страницыPart B & Part C Questions - Unit WiseShobiОценок пока нет

- Dynamics of Machines 4 Units New Question BankДокумент4 страницыDynamics of Machines 4 Units New Question BankgbharathreddysОценок пока нет

- DOM Assignment 1 2017 18Документ2 страницыDOM Assignment 1 2017 18_hrithik_rkОценок пока нет

- 9A03502 Dynamics of MachineryДокумент2 страницы9A03502 Dynamics of MachinerysivabharathamurthyОценок пока нет

- Question Bank All Units With VTU Old Questions With Front PageДокумент11 страницQuestion Bank All Units With VTU Old Questions With Front PageHareesha N GОценок пока нет

- Dynamics of MachineДокумент3 страницыDynamics of MachinegokulavaannanОценок пока нет

- Dynamics of MachineryДокумент8 страницDynamics of MachineryNORIMAR24Оценок пока нет

- DOM TutorialsДокумент11 страницDOM TutorialsNishankzattОценок пока нет

- MODEL EXAM QUESTION PAPER Kom Final PDFДокумент2 страницыMODEL EXAM QUESTION PAPER Kom Final PDFCarlos ContrerasОценок пока нет

- Dynamics of Machines QP DOM UPTO 2010Документ32 страницыDynamics of Machines QP DOM UPTO 2010Chennai TuitionsОценок пока нет

- Alva'S Institute of Engineering and Technology: Department of Mechanical EnginrringДокумент1 страницаAlva'S Institute of Engineering and Technology: Department of Mechanical EnginrringenggsantuОценок пока нет

- Dynamics of MachineryДокумент2 страницыDynamics of MachinerySoumya BsoumyaОценок пока нет

- Question Paper Code:: Reg. No.Документ3 страницыQuestion Paper Code:: Reg. No.Keesanth Geetha ChandrasekaranОценок пока нет

- Assignment MomДокумент4 страницыAssignment Momdudescape0% (3)

- Dynamics of Machinery Question BankДокумент8 страницDynamics of Machinery Question BankArun ShawnОценок пока нет

- Dynamics of MachineryДокумент8 страницDynamics of MachinerysrinivasОценок пока нет

- Btme-402 - Theory of Machines: Two Marks QuestionsДокумент6 страницBtme-402 - Theory of Machines: Two Marks QuestionsNavneet Singh DhamiОценок пока нет

- Dokument - Pub Dom Assignment Flipbook PDFДокумент22 страницыDokument - Pub Dom Assignment Flipbook PDFMuhammad SaboorОценок пока нет

- DOM Question BankДокумент4 страницыDOM Question BankAMIT SOLANKIОценок пока нет

- Me2302: Dynamics of Machinery Question BankДокумент14 страницMe2302: Dynamics of Machinery Question BankNagendar SelvakumarОценок пока нет

- PBR Visvodaya Institute of Technology and Science: Kavali: Mechanical EngineeringДокумент7 страницPBR Visvodaya Institute of Technology and Science: Kavali: Mechanical Engineeringhod mechОценок пока нет

- Analysis OF Mechanisms GTU IMPДокумент5 страницAnalysis OF Mechanisms GTU IMPSwastik PanchalОценок пока нет

- Assignment 2 Mekanik Mesin S1 - 20132014Документ2 страницыAssignment 2 Mekanik Mesin S1 - 20132014Nadia BalqisОценок пока нет

- MEC304 ModelДокумент2 страницыMEC304 ModelKKОценок пока нет

- Dec 2019 ME304 - Dynamics of Machinery (S) - Ktu QbankДокумент3 страницыDec 2019 ME304 - Dynamics of Machinery (S) - Ktu QbankMidhun SukumaranОценок пока нет

- WWW - Manaresults.Co - In: (Common To Ame, MSNT, Me, MCT)Документ3 страницыWWW - Manaresults.Co - In: (Common To Ame, MSNT, Me, MCT)Sameer MDОценок пока нет

- Important Questions DomДокумент6 страницImportant Questions DomSanthosh RasaОценок пока нет

- 161411-161901-Dynamics of MachineryДокумент2 страницы161411-161901-Dynamics of Machinerywind projectОценок пока нет

- Mom T2 QPДокумент1 страницаMom T2 QPsutha_me20098282Оценок пока нет

- 2mid Imp Questions ModelsДокумент4 страницы2mid Imp Questions ModelsSrimanthula SrikanthОценок пока нет

- Mechanism MechanicsДокумент5 страницMechanism MechanicsEzmel KazimОценок пока нет

- Our Official Android App - REJINPAUL NETWORK FromДокумент3 страницыOur Official Android App - REJINPAUL NETWORK FromAjay KumarОценок пока нет

- O level Physics Questions And Answer Practice Papers 3От EverandO level Physics Questions And Answer Practice Papers 3Рейтинг: 3 из 5 звезд3/5 (1)

- BAI and ASI Syllabus For QP Setting Aug 2020Документ6 страницBAI and ASI Syllabus For QP Setting Aug 2020Hareesha N GОценок пока нет

- 06CS36-Unix and Shell Programming-Jan 2010Документ1 страница06CS36-Unix and Shell Programming-Jan 2010Hareesha N GОценок пока нет

- 15CS35 - Unix and Shell Programming-July 2018Документ2 страницы15CS35 - Unix and Shell Programming-July 2018Hareesha N GОценок пока нет

- 15CS35 - Unix and Shell Programming-Jan 2018Документ2 страницы15CS35 - Unix and Shell Programming-Jan 2018Hareesha N GОценок пока нет

- 06CS36-Unix and Shell Programming-Jan 2014Документ1 страница06CS36-Unix and Shell Programming-Jan 2014Hareesha N GОценок пока нет

- 06CS36-Unix and Shell Programming-Jan 2009Документ2 страницы06CS36-Unix and Shell Programming-Jan 2009Hareesha N GОценок пока нет

- 10CS44 - Unix and Shell Programming-Dec 2012Документ2 страницы10CS44 - Unix and Shell Programming-Dec 2012Hareesha N GОценок пока нет

- 06CS36-Unix and Shell Programming-July 2011Документ1 страница06CS36-Unix and Shell Programming-July 2011Hareesha N GОценок пока нет

- Practice Final SolutionsДокумент41 страницаPractice Final SolutionsHareesha N GОценок пока нет

- 06CS36-Unix and Shell Programming-Dec 2010Документ1 страница06CS36-Unix and Shell Programming-Dec 2010Hareesha N GОценок пока нет

- 06CS36-Unix and Shell Programming-Dec 2011Документ1 страница06CS36-Unix and Shell Programming-Dec 2011Hareesha N GОценок пока нет

- 06CS36-Unix and Shell Programming-Jan 2008Документ1 страница06CS36-Unix and Shell Programming-Jan 2008Hareesha N GОценок пока нет

- Exam Question BankДокумент1 страницаExam Question BankHareesha N GОценок пока нет

- JET ENGINE FundamentalsДокумент18 страницJET ENGINE FundamentalsHareesha N GОценок пока нет

- Phase1 Closure July 2004Документ27 страницPhase1 Closure July 2004Hareesha N GОценок пока нет

- Pert Chart MineДокумент1 страницаPert Chart MineHareesha N GОценок пока нет

- MOM COsДокумент1 страницаMOM COsHareesha N GОценок пока нет

- Modelling and Analysis Laboratory Manual VTU PDFДокумент42 страницыModelling and Analysis Laboratory Manual VTU PDFHareesha N GОценок пока нет

- File Identifier - StickersДокумент50 страницFile Identifier - StickersHareesha N GОценок пока нет

- PhaseII Final IITДокумент26 страницPhaseII Final IITHareesha N GОценок пока нет

- Chapter NumbersДокумент11 страницChapter NumbersHareesha N GОценок пока нет

- ARDB Rules - Grants PDFДокумент38 страницARDB Rules - Grants PDFHareesha N GОценок пока нет

- Application For Grant of Research/Development Project/Facilities Under Grants-In-Aid Scheme of Aeronautics R&D BoardДокумент3 страницыApplication For Grant of Research/Development Project/Facilities Under Grants-In-Aid Scheme of Aeronautics R&D BoardHareesha N GОценок пока нет

- Alg LabДокумент22 страницыAlg LabShobha KumarОценок пока нет

- Database AwsДокумент15 страницDatabase AwsHareesha N GОценок пока нет

- Appendix: Where To Approach For R&D Funds?Документ15 страницAppendix: Where To Approach For R&D Funds?malini72Оценок пока нет

- Sample Q and AДокумент47 страницSample Q and AHareesha N G100% (1)

- 2015 Project TitlesДокумент9 страниц2015 Project TitlesHareesha N GОценок пока нет

- Lab26 - Configure Endpoint and Access S3Документ18 страницLab26 - Configure Endpoint and Access S3Hareesha N GОценок пока нет

- Lab25 - Command Line InterfaceДокумент22 страницыLab25 - Command Line InterfaceHareesha N GОценок пока нет

- Errata PT1A2022Документ2 страницыErrata PT1A2022Beyond ur imaginationОценок пока нет

- Diffusion DefinitionДокумент7 страницDiffusion DefinitionTechnical UmairjiОценок пока нет

- CFD Analysis of Liquid-Liquid Extraction Pulsed ColumnДокумент6 страницCFD Analysis of Liquid-Liquid Extraction Pulsed ColumnArunОценок пока нет

- 2022 Springer Nature Fully Open Access JournalsДокумент36 страниц2022 Springer Nature Fully Open Access JournalsEntertainment HubОценок пока нет

- Phuong Phap Tinh Tai Theo Phan Mem MistralДокумент8 страницPhuong Phap Tinh Tai Theo Phan Mem Mistralntt_121987Оценок пока нет

- A CarДокумент6 страницA CarharshanauocОценок пока нет

- Plane Wave Propagation in Lossless MediaДокумент70 страницPlane Wave Propagation in Lossless MediaM. Ahmad IjazОценок пока нет

- LTE Nokia & ZTE Parameter MappingДокумент12 страницLTE Nokia & ZTE Parameter MappingAndi Hamid100% (1)

- Fastener Modeling For Joining Parts Modeled by Shell and SolidДокумент26 страницFastener Modeling For Joining Parts Modeled by Shell and SolideguldirimОценок пока нет

- Electronics Engg.: Detailed Solutions ofДокумент57 страницElectronics Engg.: Detailed Solutions ofAshish ChoudharyОценок пока нет

- Friction &belt DrivesДокумент55 страницFriction &belt Drivesshubhaastro2827Оценок пока нет

- Wind Power Technology and ControlДокумент91 страницаWind Power Technology and ControlbahrowiadiОценок пока нет

- GTM - Torque Primary Standard MachineДокумент12 страницGTM - Torque Primary Standard MachinergénezОценок пока нет

- CO & PO of Physics-2Документ4 страницыCO & PO of Physics-2ansari_poly5264Оценок пока нет

- E6-165-13 - ASME STRESS CLASSIFICATION in Pressure Vessels and PipingДокумент20 страницE6-165-13 - ASME STRESS CLASSIFICATION in Pressure Vessels and PipingLuis Ortiz100% (3)

- CH 14Документ53 страницыCH 14Giuseppe TestarossaОценок пока нет

- Ch-1 Measurement (Eocq)Документ4 страницыCh-1 Measurement (Eocq)Mahendra ModiОценок пока нет

- Understanding Motor Temperature Rise LimitsДокумент3 страницыUnderstanding Motor Temperature Rise Limitspp_electrical100% (2)

- Airpax Stepper MotorДокумент8 страницAirpax Stepper MotorTiago GalloОценок пока нет

- Architectural Acoustic: Prepared By:-Rushit PatelДокумент32 страницыArchitectural Acoustic: Prepared By:-Rushit PatelSaurabh SinghОценок пока нет

- Problem Set 6-Chapter 1sdfsdfds - Helical Compression Spring-Selected ProblemsДокумент28 страницProblem Set 6-Chapter 1sdfsdfds - Helical Compression Spring-Selected ProblemsvivekzzОценок пока нет

- Level 1:basic Problems: NeetДокумент16 страницLevel 1:basic Problems: Neettanmoy bhattacharjeeОценок пока нет

- R 1621034112018Документ8 страницR 1621034112018maheshОценок пока нет

- MathematicaSteppedHull PDFДокумент14 страницMathematicaSteppedHull PDFДмитрий КирзуновОценок пока нет

- Fundamentals of Heat and Mass Transfer 7th Edition Incropera Solutions Manual20190709 74173 2j05lf PDFДокумент20 страницFundamentals of Heat and Mass Transfer 7th Edition Incropera Solutions Manual20190709 74173 2j05lf PDFAndiОценок пока нет

- 107D Iv Feg 05a 00012Документ68 страниц107D Iv Feg 05a 00012vinayak jadhavОценок пока нет

- Ebook Ebook PDF Physical Universe 15th Edition PDFДокумент41 страницаEbook Ebook PDF Physical Universe 15th Edition PDFderek.lewis562100% (39)

- Qada Qadar Dan Parallel UniverseДокумент14 страницQada Qadar Dan Parallel Universeambiya086114Оценок пока нет

- Stability of Nonlinear SystemsДокумент18 страницStability of Nonlinear SystemssalimОценок пока нет