Академический Документы

Профессиональный Документы

Культура Документы

Applications of Chemical Engineering Examinations

Загружено:

PrickАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Applications of Chemical Engineering Examinations

Загружено:

PrickАвторское право:

Доступные форматы

Examination for the Bachelor of Chemical Engineering - B.E.

(Chem)

Semester 1, 2012

105527

105438

105994

CHEMENG 3035 Chemical Engineering Applications A

CHEMENG 3022 Pharmaceutical Engineering Applications A

CHEMENG 7050 Chemical Engineering Applications A PG

Official Reading Time:

Writing Time:

Total Duration:

10 mins

180 mins

190 mins

Part

Questions

Time

Marks

A

B

Answer all 1 question

Answer all 3 questions

60 mins

120 mins

60 marks

120 marks

180 Total

Instructions

Part A is a Closed Book examination Calculators are not permitted.

Part B is an Open Book examination during which reference materials may

be consulted, and calculators may be used.

Part A must be handed in before commencing Part B.

Part B may be attempted early provided that Part A has been handed in.

Answer Parts A and B in separate books.

Begin each question on a new page.

The marks for each question are indicated.

Write your name and Student ID number on all loose diagrams/papers.

Examination materials must not be removed from the examination room.

Materials

Course notes and text books are permitted for Part B.

Calculator is permitted for Part B.

The use of a dictionary is permitted.

Graph paper.

Attachments:

1. Drag coefficient Reynolds number chart.

2. Eckert chart and Packing factor data

3. Batch solids flux data.

DO NOT COMMENCE WRITING UNTIL INSTRUCTED TO DO SO

Examination 2012

CHEMENG 3035 (105527)

CHEMENG 3022 (105438)

CHEMENG 7050 (105994)

PART A. CLOSED BOOK

Question 1

(60 marks)

Give brief answers to the following questions. Marks for individual questions are as indicated.

a)

Consider a square plate-shaped particle having sides a and thickness b. Define

and express the following properties of the particle in terms of its dimensions:

b)

A.

Surface area-equivalent diameter (dS)

B.

Surface-area volume diameter (dSV)

C.

Sphericity ()

[6]

Define the surface-volume number mean diameter (dSVn) for a powder

containing non-spherical particles having the same sphericity (). Explain how

dSVn can be calculated from size distribution data based on (1) particle number

measurement, and (2) particle mass measurement.

c)

[4]

How do you know if the particle sizes of a particulate solid follow log-normal

size distribution? What are the key features of this size distribution function? [3]

d)

Under

what

condition

does

hindered

settling

occur?

Describe

the

characteristics of this type of settling behaviour, and explain how the hindered

settling velocity can be determined experimentally and analytically.

e)

Describe the effects of surface tension and gravity on the shape and terminal

velocity of a rain drop falling in air.

f)

[4]

[3]

For flow through porous media, give the definitions and applications of the

following terms, and show that they are equivalent characteristic dimensions of

a porous medium:

g)

A.

Hydraulic radius

B.

Specific surface area (per unit mass of solids)

[4]

Consider a porous medium initially filled by a liquid. A gas is then introduced

under pressure in order to displace the liquid from the medium. Describe the

flow behaviour of both fluid phases in terms of relative permeability as a

function of saturation, and discuss the effects of wettability and surface tension

on the mobility of the fluids.

Chemical Engineering Applications A/Pharmaceutical Engineering Applications A

[4]

Page 2 of 9

Examination 2012

h)

CHEMENG 3035 (105527)

CHEMENG 3022 (105438)

CHEMENG 7050 (105994)

Consider counter-current flows of a gas and a liquid through a packed column.

Describe how the frictional pressure drop across the packing varies with the gas

and liquid flow rates. Define the critical conditions referred to as loading and

flooding, and explain how design of such a system is carried out.

i)

[5]

Describe incipient fluidisation, and explain how the minimum fluidising

velocity can be determined experimentally and analytically for beds containing

(1) uniform particles and (2) particles of different sizes?

j)

[4]

Under what conditions would a bed of particles be aggregatively fluidised?

Describe the various stages of bubbling fluidisation as the fluid velocity is

increased.

k)

[4]

What is a solids flux plot? Describe the procedure used to construct the solids

flux plot from batch settling data.

l)

[4]

Describe the four possible concentration zones in a type II settling slurry.

Show how the movements of the interfaces associated with these zones can be

predicted from batch solids flux data.

m)

[5]

The general filtration equation is usually given in the following form:

R dV

CS

=

P

V+ m

2

A dt

A

A.

Outline the basic steps involved in the development of the above equation,

and define all terms.

B.

[4]

Describe how the parameters and Rm for incompressible materials can

be determined from laboratory filtration experiments.

n)

[3]

Describe the various stages of a filtration cycle in a continuous rotary drum

filter.

[3]

END OF PART A

Chemical Engineering Applications A/Pharmaceutical Engineering Applications A

Page 3 of 9

Examination 2012

CHEMENG 3035 (105527)

CHEMENG 3022 (105438)

CHEMENG 7050 (105994)

PART B. OPEN BOOK

Question 2

(40 marks)

A vessel with a diameter of 2 m contains 3400 kg of granular solids with a surfacevolume mean diameter of 600 m, sphericity of 0.81 and density of 1500 kg/m3. The

initial depth of the packed bed is 1.2 m. The particles are to be fluidised using a liquid

of specific gravity of 1.0 and viscosity of 1 cp.

a.

Calculate the minimum flow rate required to fluidise the bed. No information

about the voidage at minimum fluidisation is available.

b.

What should be the maximum operating liquid flow rate for this fluidised bed?

c.

In operation, the bed will be expanded to 2.5 times its initial depth. Calculate the

fluidising flow rate required and the pressure drop across the bed under this

condition. State any assumption made.

d.

Would particulate fluidisation occur in the bed?

Question 3

(40 marks)

A column, packed with 3 m of 50-mm plastic Pall rings, uses hot air to remove impurity

from an absorber oil. The oil (SG = 0.9, viscosity = 10 cp) is fed at the top of the column

at a rate of 300 kg/min, and the air (1.3 atm and 200oC) enters the bottom of the column

at 20 kg/min.

a.

Calculate the minimum column diameter that can be used without flooding.

b.

If the column diameter is 15 percent greater than the minimum size, what is the

pressure drop across the packing?

c.

After a long period of operation, scales built up on the surfaces of the packing,

reducing its performance. Consequently, the tower will flood if operated under the

condition stated in (b). Determine the new flow rate of the oil such that the tower

can operate, without flooding, at the same pressure drop as in (b).

Data: MW of air = 29; Gas constant: R = 8.314 m3.kPa/(kgmol.K); 1 atm = 101.325 kPa

Eckert correlation and Packing Factor data can be found in Attachment 2.

Chemical Engineering Applications A/Pharmaceutical Engineering Applications A

Page 4 of 9

Examination 2012

CHEMENG 3035 (105527)

CHEMENG 3022 (105438)

CHEMENG 7050 (105994)

Question 4

(40 marks)

A residue mineral slurry containing 30 wt% solids in water is concentrated by gravity

sedimentation to remove as much water as possible prior to disposal. The slurry is

fed to a continuous thickener at a rate of 300 m3/h, and the thickened underflow is

discharged by a slurry pump at 120 m3/h. The thickener has a diameter of 15 m in the

vertical cylindrical section. The specific gravity is 2.5 for the dry solids and 1.0 for

water. Laboratory batch solids flux data for the slurry is attached (Attachment 3).

a.

By means of the continuous solids flux method, assess the performance of the

thickener by determining the solids concentrations in the underflow, in the

overflow and in the thickening zone below the feed line of the thickener.

b.

What is the highest underflow concentration (in %wt solids) that can be

achieved with the thickener?

c.

Although the current operation is satisfactory, the management is considering

replacing the existing thickener with a smaller unit having a diameter of 11 m. If

all operating conditions remain unchanged, would this option work? Present

your case with detailed analysis of the new thickeners performance supported

by calculations of the solids concentrations of all streams leaving the thickener.

END OF PART B

END OF THE PAPER

Chemical Engineering Applications A/Pharmaceutical Engineering Applications A

Page 5 of 9

Examination 2012

CHEMENG 3035 (105527)

CHEMENG 3022 (105438)

CHEMENG 7050 (105994)

ATTACHMENT 1: Drag Coefficient Reynolds Number chart for non-spheres

Chemical Engineering Applications A/Pharmaceutical Engineering Applications A

Page 6 of 9

Examination 2012

CHEMENG 3035 (105527)

CHEMENG 3022 (105438)

CHEMENG 7050 (105994)

ATTACHMENT 2: Eckert Correlation

G 2FP L0.2 w

g G L L

Table: Packing Factor (Fp) for Some Plastic Packing Materials

Packing Type

Intalox saddles, plastic

(polypropylene)

Pall rings, plastic

(polypropylene)

Nominal size, mm

25

50

75

25

38

50

90

Packing factor Fp, m-1

105

69

50

170

105

82

52

Chemical Engineering Applications A/Pharmaceutical Engineering Applications A

Page 7 of 9

Examination 2012

CHEMENG 3035 (105527)

CHEMENG 3022 (105438)

CHEMENG 7050 (105994)

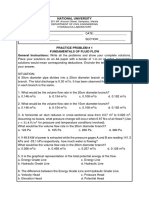

ATTACHMENT 3: Batch Solids Flux Data for Question 4

0.16

Solids flux, (mm/s)

0.14

0.12

0.1

0.08

0.06

0.04

0.02

0

0

0.1

0.2

0.3

0.4

0.5

0.4

0.5

Solids volume fraction, c

0.16

Solids flux, (mm/s)

0.14

0.12

0.1

0.08

0.06

0.04

0.02

0

0

0.1

0.2

0.3

Solids volume fraction, c

Chemical Engineering Applications A/Pharmaceutical Engineering Applications A

Page 8 of 9

Examination 2012

CHEMENG 3035 (105527)

CHEMENG 3022 (105438)

CHEMENG 7050 (105994)

Chemical Engineering Applications A/Pharmaceutical Engineering Applications A

Page 9 of 9

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Low Speed Aerodynamics (Aerodynamics-I) : Multiple Choice Questions Set 5Документ4 страницыLow Speed Aerodynamics (Aerodynamics-I) : Multiple Choice Questions Set 5Harish MathiazhahanОценок пока нет

- Flow of Water Over WeirsДокумент9 страницFlow of Water Over Weirsmujette godmalin100% (13)

- Hydraulic Schematic PDFДокумент1 страницаHydraulic Schematic PDFGabo Gabo100% (2)

- Experimental and Numerical Assessment of Cold Restart Process of Heavy 7 WHOC12 - 277Документ5 страницExperimental and Numerical Assessment of Cold Restart Process of Heavy 7 WHOC12 - 277han.velthuis431Оценок пока нет

- AntonPaar White PaperДокумент4 страницыAntonPaar White PaperPablo AntezanaОценок пока нет

- Chapter 2 - Hydrodynamics of Pumps - Christopher E. BrennenДокумент14 страницChapter 2 - Hydrodynamics of Pumps - Christopher E. Brennenmete2009Оценок пока нет

- WPG 200L33: 65 MM 65 MMДокумент1 страницаWPG 200L33: 65 MM 65 MMMamiherintsoa Issaia RanaivoarimananaОценок пока нет

- Sewergems Conduit Table OutputДокумент7 страницSewergems Conduit Table OutputKramyerОценок пока нет

- Soliman Et Al. - 1968 - A General Heat Transfer Correlation For Annular FLДокумент8 страницSoliman Et Al. - 1968 - A General Heat Transfer Correlation For Annular FLMartinОценок пока нет

- DAYRIT, JOSHUA MICHAEL ANGELO - ACTIVITY No.3Документ9 страницDAYRIT, JOSHUA MICHAEL ANGELO - ACTIVITY No.3Joshua DayritОценок пока нет

- Induced Drag Reduction Using Multiple Winglets, Looking Beyond The Prandtl-Munk Linear ModelДокумент21 страницаInduced Drag Reduction Using Multiple Winglets, Looking Beyond The Prandtl-Munk Linear ModelBlas CaramutoОценок пока нет

- Flow Element: Base Maximum Flow Normal Flow Property MethodДокумент1 страницаFlow Element: Base Maximum Flow Normal Flow Property MethodSureshОценок пока нет

- Practice Problem No. 1 Hydraulics Fundamentals of Fluid FlowДокумент2 страницыPractice Problem No. 1 Hydraulics Fundamentals of Fluid FlowCharlamagne MirandaОценок пока нет

- Boundary Layer FlowsДокумент28 страницBoundary Layer FlowsAmy RamirezОценок пока нет

- Vacuum Booster Application of Bernoulli's PrincipleДокумент9 страницVacuum Booster Application of Bernoulli's PrincipleDouglas OngomОценок пока нет

- Annexure XXX - Stilling BasinДокумент1 страницаAnnexure XXX - Stilling BasinMd Ghani HaiderОценок пока нет

- Inspection of PenstockДокумент9 страницInspection of PenstockDangol RupeshОценок пока нет

- Fluid Mechanics ProjectsДокумент7 страницFluid Mechanics Projectsyu yanОценок пока нет

- Ultrasonic Flow Measurement TechniqueДокумент2 страницыUltrasonic Flow Measurement TechniqueAnish MajumderОценок пока нет

- WTT 2 MarksДокумент10 страницWTT 2 MarksSwetha SharmaОценок пока нет

- Department of Mechanical and Industrial Engineering: MIN-304: Fluid Machines Mid-Term ExaminationДокумент1 страницаDepartment of Mechanical and Industrial Engineering: MIN-304: Fluid Machines Mid-Term ExaminationSaifullah AhmadОценок пока нет

- ME10 - Heat and Flow 1 - Module DescДокумент2 страницыME10 - Heat and Flow 1 - Module DescSridhar TholasingamОценок пока нет

- Convective Mass TransferДокумент34 страницыConvective Mass TransferRishabh JainОценок пока нет

- 9 - Cone NozzleДокумент2 страницы9 - Cone NozzleSinalau ButodОценок пока нет

- Pumps - HandoutsДокумент30 страницPumps - HandoutsPuviyarasan MОценок пока нет

- CE - 1253 Applie Hydraulic EngineeringДокумент2 страницыCE - 1253 Applie Hydraulic EngineeringManimaran SellamuthuОценок пока нет

- Tech Docs Ksew Wss Jmu STD Item1 RKB 50 15l 9stg 75kc2 250m 45.45m3 07 09 2023Документ4 страницыTech Docs Ksew Wss Jmu STD Item1 RKB 50 15l 9stg 75kc2 250m 45.45m3 07 09 2023vivek dhadwalОценок пока нет

- MECH 2262 OutlineДокумент4 страницыMECH 2262 OutlineSantiago GarcíaОценок пока нет

- Predicting Pressure Distributions Using CFDДокумент177 страницPredicting Pressure Distributions Using CFDdedysusila100% (5)

- Fire Hydraulic CalculationДокумент2 страницыFire Hydraulic CalculationShubhajit ChakrabortyОценок пока нет