Академический Документы

Профессиональный Документы

Культура Документы

ME6008 Welding Test Questions

Загружено:

anon_782224603Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ME6008 Welding Test Questions

Загружено:

anon_782224603Авторское право:

Доступные форматы

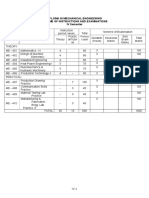

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

7.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

7.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

7.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

7.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

4.

5.

6.

7.

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

7.

1.

2.

3.

4.

5.

6.

7.

1.

2.

3.

4.

5.

6.

7.

1.

2.

3.

4.

5.

6.

7.

1.

2.

3.

4.

5.

6.

7.

1.

2.

3.

4.

5.

6.

7.

1.

2.

3.

4.

5.

6.

7.

ME6008 & Welding Technology - Mech - VII Sem- I Test

Part-A

Answer All Questions

7x2=14

1. Justify the need of flux in welding

2. List any four arc welding devices

3. Why the electrode is covered in SMAW?

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

7.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

7.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

7.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

7.

Differentiate - Flash butt and Upset butt

welding

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable

electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

7.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

ME6008 & Welding Technology - Mech - VII Sem- I Test

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable

electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

7. Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

7.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

7.

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

1.

2.

3.

4.

5.

6.

7.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Differentiate - Flash butt and Upset butt welding

ME6008 & Welding Technology - Mech - VII Sem- I Test

1.

2.

3.

4.

5.

6.

Part-A

Answer All Questions

7x2=14

Justify the need of flux in welding

List any four arc welding devices

Why the electrode is covered in SMAW?

State the principle of electro slag welding

Differentiate - Consumable and Non Consumable electrode

Mention the process parameters of resistance welding

Part-B

Answer any Three Questions

3x12=36

1. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

2. Differentiate

a.

TIG and MIG welding

b.

Transferred and Non Transferred plasma arc welding

3. Describe the sequence of resistance spot welding with neat

sketches.

4. Explain the working principle of high frequency resistance

welding with neat sketch

Part-B

Answer any Three Questions

3x12=36

1. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

2. Differentiate

7. Describe the sequence of resistance spot welding with neat

sketches.

8. Explain the working principle of high frequency resistance

welding with neat sketch

a. TIG and MIG welding

b. Transferred and Non Transferred plasma arc welding

3. Describe the sequence of resistance spot welding with neat

sketches.

4. Explain the working principle of high frequency resistance

welding with neat sketch

Part-B

Answer any Three Questions

3x12=36

5. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

6. Differentiate

a. TIG and MIG welding

b. Transferred and Non Transferred plasma arc welding

Part-B

Answer any Three Questions

3x12=36

1. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

2. Differentiate

7. Describe the sequence of resistance spot welding with neat

sketches.

8. Explain the working principle of high frequency resistance

welding with neat sketch

a. TIG and MIG welding

b. Transferred and Non Transferred plasma arc welding

3. Describe the sequence of resistance spot welding with neat

sketches.

4. Explain the working principle of high frequency resistance

welding with neat sketch

3. Describe the sequence of resistance spot welding with neat

sketches.

4. Explain the working principle of high frequency resistance

welding with neat sketch

7. Describe the sequence of resistance spot welding with neat

sketches.

8. Explain the working principle of high frequency resistance

welding with neat sketch

3. Describe the sequence of resistance spot welding with neat

sketches.

4. Explain the working principle of high frequency resistance

welding with neat sketch

7. Describe the sequence of resistance spot welding with neat

sketches.

8. Explain the working principle of high frequency resistance

welding with neat sketch

Part-B

Answer any Three Questions

3x12=36

5. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

6. Differentiate

3. Describe the sequence of resistance spot welding with neat

sketches.

4. Explain the working principle of high frequency resistance

welding with neat sketch

7. Describe the sequence of resistance spot welding with neat

sketches.

8. Explain the working principle of high frequency resistance

welding with neat sketch

Part-B

Answer any Three Questions

3x12=36

9. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

10. Differentiate

a. TIG and MIG welding

11. Describe the sequence of resistance spot welding with neat

sketches.

12. Explain the working principle of high frequency resistance

welding with neat sketch

Part-B

Answer any Three Questions

3x12=36

9. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

10. Differentiate

a. TIG and MIG welding

b. Transferred and Non Transferred plasma arc welding

Part-B

Answer any Three Questions

3x12=36

5. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

6. Differentiate

11. Describe the sequence of resistance spot welding with neat

sketches.

12. Explain the working principle of high frequency resistance

welding with neat sketch

a. TIG and MIG welding

b. Transferred and Non Transferred plasma arc welding

7. Describe the sequence of resistance spot welding with neat

sketches.

8. Explain the working principle of high frequency resistance

welding with neat sketch

Part-B

Answer any Three Questions

3x12=36

5. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

6. Differentiate

c.

TIG and MIG welding

d.

Transferred and Non Transferred plasma arc welding

11. Describe the sequence of resistance spot welding with neat

sketches.

12. Explain the working principle of high frequency resistance

welding with neat sketch

a. TIG and MIG welding

a. TIG and MIG welding

b. Transferred and Non Transferred plasma arc welding

a. TIG and MIG welding

b. Transferred and Non Transferred plasma arc welding

b. Transferred and Non Transferred plasma arc welding

Part-B

Answer any Three Questions

3x12=36

1. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

2. Differentiate

Part-B

Answer any Three Questions

3x12=36

9. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

10. Differentiate

a. TIG and MIG welding

a. TIG and MIG welding

b. Transferred and Non Transferred plasma arc welding

11. Describe the sequence of resistance spot welding with neat

sketches.

12. Explain the working principle of high frequency resistance

welding with neat sketch

b. Transferred and Non Transferred plasma arc welding

Part-B

Answer any Three Questions

3x12=36

5. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

6. Differentiate

b. Transferred and Non Transferred plasma arc welding

Part-B

Answer any Three Questions

3x12=36

1. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

2. Differentiate

a. TIG and MIG welding

a. TIG and MIG welding

a. TIG and MIG welding

b. Transferred and Non Transferred plasma arc welding

Part-B

Answer any Three Questions

3x12=36

9. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

10. Differentiate

b. Transferred and Non Transferred plasma arc welding

Part-B

Answer any Three Questions

3x12=36

5. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

6. Differentiate

b. Transferred and Non Transferred plasma arc welding

Part-B

Answer any Three Questions

3x12=36

1. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

2. Differentiate

Part-B

Answer any Three Questions

3x12=36

9. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

10. Differentiate

e.

TIG and MIG welding

f.

Transferred and Non Transferred plasma arc welding

11. Describe the sequence of resistance spot welding with neat

sketches.

12. Explain the working principle of high frequency resistance

welding with neat sketch

Part-B

Answer any Three Questions

3x12=36

9. Sketch the three types of flames in oxy acetylene welding

and state their characteristics

10. Differentiate

a. TIG and MIG welding

b. Transferred and Non Transferred plasma arc welding

11. Describe the sequence of resistance spot welding with neat

sketches.

12. Explain the working principle of high frequency resistance

welding with neat sketch

Вам также может понравиться

- Automation in Manufacturing 10ME757: Department of Mechanical Engineering, SIRMVIT (Ramesh C G & Hanamantraygouda M B)Документ193 страницыAutomation in Manufacturing 10ME757: Department of Mechanical Engineering, SIRMVIT (Ramesh C G & Hanamantraygouda M B)Wtf rajuОценок пока нет

- 06 Question Bank MV 2018 Unit V Vibration Measurement PDFДокумент1 страница06 Question Bank MV 2018 Unit V Vibration Measurement PDFNABIL HUSSAINОценок пока нет

- Hydraulic and pneumatic systems examДокумент2 страницыHydraulic and pneumatic systems examAravinthОценок пока нет

- SBTET AP C-14 SYLLABUS DME IV SemesterДокумент36 страницSBTET AP C-14 SYLLABUS DME IV Semesterthirukumar50% (2)

- Pre-Planning FunctionДокумент10 страницPre-Planning FunctionSandeep ChoudharyОценок пока нет

- MT 1 Lab Manual PDFДокумент40 страницMT 1 Lab Manual PDFrajamanickam sОценок пока нет

- Me2204 Fluid Mechanics and Machinery SyllabusДокумент1 страницаMe2204 Fluid Mechanics and Machinery SyllabusrajapratyОценок пока нет

- LTCC and HTCC PDFДокумент3 страницыLTCC and HTCC PDFPhan Xuân TuấnОценок пока нет

- Manufacturing Technology: Unit - IДокумент18 страницManufacturing Technology: Unit - Iapi-271354682100% (1)

- Unit-III, Advanced Mechanisms PDFДокумент41 страницаUnit-III, Advanced Mechanisms PDFvamsi krishnaОценок пока нет

- Mechatronics - Unit 5 - NotesДокумент13 страницMechatronics - Unit 5 - NotesDulce DeОценок пока нет

- SEC Mechatronics Lab Manual R2013 Shan PDFДокумент93 страницыSEC Mechatronics Lab Manual R2013 Shan PDFMonish KumarОценок пока нет

- Building Automation Sample PapersДокумент4 страницыBuilding Automation Sample Papersrashmi patilОценок пока нет

- Particles - Kinematics and KineticsДокумент249 страницParticles - Kinematics and KineticsMinh Vu100% (1)

- Sample 40404Документ16 страницSample 40404Rahul RoyОценок пока нет

- Experimental Stress Analysis PaperДокумент2 страницыExperimental Stress Analysis PaperAbdul FattahОценок пока нет

- Mechanics of Material - SyllabusДокумент2 страницыMechanics of Material - SyllabusRahul PatilОценок пока нет

- KOM Important QuestionsДокумент12 страницKOM Important QuestionsJithin KОценок пока нет

- SyllabusДокумент1 страницаSyllabusKarthi SundarОценок пока нет

- CAD CAM Unit - 3 PPT-ilovepdf-compressedДокумент66 страницCAD CAM Unit - 3 PPT-ilovepdf-compressedTaha SakriwalaОценок пока нет

- Virtual LaboratoryДокумент14 страницVirtual LaboratoryArie Febry Fardheny, MTОценок пока нет

- Advanced IC EngineДокумент6 страницAdvanced IC EngineThulasi RamОценок пока нет

- Agni College of Technology: Office of Examcell Model ExamДокумент3 страницыAgni College of Technology: Office of Examcell Model ExamohmshankarОценок пока нет

- EE8552 POWER ELECTRONICS SyllabusДокумент1 страницаEE8552 POWER ELECTRONICS SyllabuscoolrajeeeОценок пока нет

- 53207-mt - Industrial TribologyДокумент2 страницы53207-mt - Industrial TribologySRINIVASA RAO GANTAОценок пока нет

- Computer Application in DesignДокумент1 страницаComputer Application in DesignAntony PrabuОценок пока нет

- ME2309 CAD CAM Lab ManualДокумент36 страницME2309 CAD CAM Lab Manualkumar km100% (1)

- Robotics 2markДокумент14 страницRobotics 2markisirajudeen17Оценок пока нет

- Festo Students enДокумент6 страницFesto Students enEKANSH SHARMAОценок пока нет

- Important Questions and Answers - Robot Drive Systems and End Effectors PDFДокумент5 страницImportant Questions and Answers - Robot Drive Systems and End Effectors PDFvicky tОценок пока нет

- ch06刪減版Документ88 страницch06刪減版zanibtahiraОценок пока нет

- CIM Lecture Notes 12Документ13 страницCIM Lecture Notes 12Babatunde Victor JuniorОценок пока нет

- Assignment 2Документ5 страницAssignment 2aiao90Оценок пока нет

- Machine design philosophy and procedure considerationsДокумент20 страницMachine design philosophy and procedure considerationsS VОценок пока нет

- Engineering Workshop Notes, Viva Questions PDFДокумент12 страницEngineering Workshop Notes, Viva Questions PDFMbogi TokaОценок пока нет

- Intelligent Manufacturing SystemsДокумент5 страницIntelligent Manufacturing SystemsVenkata RamuduОценок пока нет

- Me2401 Mechatronics - 2 Marks With AnswerДокумент29 страницMe2401 Mechatronics - 2 Marks With AnswerAravind Selva50% (2)

- Unit 3 Me8501 MM Part B 2017Документ1 страницаUnit 3 Me8501 MM Part B 2017srknotesОценок пока нет

- EIM PPT 1Документ17 страницEIM PPT 1rahul0% (1)

- Design and Fabrication of 4 Straight Line MechanismsДокумент34 страницыDesign and Fabrication of 4 Straight Line MechanismsArunkuma81Оценок пока нет

- Robotics Unit-3 2-MarksДокумент17 страницRobotics Unit-3 2-Marksveerapandian100% (1)

- 2-Marks Question Bank - Industrial Engineering - MID1 UNIT - 1Документ1 страница2-Marks Question Bank - Industrial Engineering - MID1 UNIT - 1Anonymous YkDJkSqОценок пока нет

- What is a Transfer FunctionДокумент27 страницWhat is a Transfer FunctionNandakumarОценок пока нет

- ME 6008 Welding Technology Question BankДокумент9 страницME 6008 Welding Technology Question BankkumareshОценок пока нет

- Additive Manufacturing QsДокумент5 страницAdditive Manufacturing QsrkОценок пока нет

- CS8251 Programming in CДокумент32 страницыCS8251 Programming in CShrutiОценок пока нет

- SS QB FinishДокумент19 страницSS QB FinishSwamy ChintalaОценок пока нет

- Vocational Training Report Format-HSCL, VineetДокумент12 страницVocational Training Report Format-HSCL, VineetVineet Anand SinghОценок пока нет

- Robot Drive Systems and End Effectors GuideДокумент10 страницRobot Drive Systems and End Effectors GuideMICHEL RAJ0% (1)

- DMS QB 2015 RДокумент8 страницDMS QB 2015 RKeerthe VaasanОценок пока нет

- SMART MATERIALS AND STRUCTURES TECHNOLOGYДокумент40 страницSMART MATERIALS AND STRUCTURES TECHNOLOGYAnkit ShandilyaОценок пока нет

- Cim Automation Lab Manual 10me78Документ57 страницCim Automation Lab Manual 10me78chandrashekar mОценок пока нет

- Mechatronics - AbstractДокумент1 страницаMechatronics - AbstractPragathi Sundar100% (2)

- GE 6261 Final PDFДокумент58 страницGE 6261 Final PDFPrasath Murugesan0% (1)

- Fabrication of Microelectronic Devices Final - 2 PDFДокумент30 страницFabrication of Microelectronic Devices Final - 2 PDFAdarsh BarnwalОценок пока нет

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987От EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonОценок пока нет

- Sheilded Metal Arc Welding (Smaw)Документ28 страницSheilded Metal Arc Welding (Smaw)itsmeeeakkiОценок пока нет

- Important Questions For Nov Dec 2016 ME6008 Welding TechnologyДокумент1 страницаImportant Questions For Nov Dec 2016 ME6008 Welding TechnologyRajueswarОценок пока нет

- 1.2.4.a CircuitcalculationsДокумент2 страницы1.2.4.a CircuitcalculationsomОценок пока нет

- Sae Flange GLДокумент42 страницыSae Flange GLsaeflangeОценок пока нет

- Use of Structural Stainless SteelДокумент4 страницыUse of Structural Stainless SteelMark Vista AgusОценок пока нет

- API Trim Material and Hardfacing GuideДокумент1 страницаAPI Trim Material and Hardfacing Guideccie33639756Оценок пока нет

- Lecture 1-Eng Materials and Iron and Steel MakingДокумент44 страницыLecture 1-Eng Materials and Iron and Steel Makingم.ذكى فضل ذكى100% (1)

- Lesson 1 - Basics of Arc WeldingДокумент35 страницLesson 1 - Basics of Arc WeldingBBGОценок пока нет

- Stainless Steel Pipe and Fittings SupplierДокумент2 страницыStainless Steel Pipe and Fittings SupplierPoonam EnterprisesОценок пока нет

- Steel Manufacturing ProcessДокумент7 страницSteel Manufacturing ProcessWinny Shiru MachiraОценок пока нет

- DPR 3Документ68 страницDPR 3MITHUNОценок пока нет

- Pipeline Welding SpecificationДокумент35 страницPipeline Welding Specificationyehia100% (1)

- Chapter 5a Material SelectionДокумент54 страницыChapter 5a Material SelectionAhmad FaidhiОценок пока нет

- Carbon&Low-Alloy Steel Sheet and StripДокумент5 страницCarbon&Low-Alloy Steel Sheet and Stripducthien_80Оценок пока нет

- Estandares AstmДокумент22 страницыEstandares AstmAgus HermantoОценок пока нет

- Ador CWC Booklet WebДокумент97 страницAdor CWC Booklet Webreeet87Оценок пока нет

- An Introduction to Steel Metallurgy: Processing, Structure, and PropertiesДокумент27 страницAn Introduction to Steel Metallurgy: Processing, Structure, and PropertiesSilverio AcuñaОценок пока нет

- Group of ASTM Standards For Steel PipesДокумент6 страницGroup of ASTM Standards For Steel PipesGunawanОценок пока нет

- 6th Sem Group Diploma Front Pkiet BargarhДокумент10 страниц6th Sem Group Diploma Front Pkiet BargarhPrabir Kumar PatiОценок пока нет

- Typical Material Specifications For Major Component PartsДокумент9 страницTypical Material Specifications For Major Component PartsSampath KumarОценок пока нет

- MARKENÜBERSICHT - STEEL GRADES SURVEYДокумент12 страницMARKENÜBERSICHT - STEEL GRADES SURVEYMAKTUBEОценок пока нет

- ASTM MATERIAL COMPARISON TABLEДокумент10 страницASTM MATERIAL COMPARISON TABLEMardeOpamenОценок пока нет

- Hertel Indexable InsertsДокумент2 страницыHertel Indexable InsertsDamir MarijanovicОценок пока нет

- Weld CalculationДокумент34 страницыWeld CalculationAshwani DograОценок пока нет

- Welding Consumables Product Catalogue 09 10Документ698 страницWelding Consumables Product Catalogue 09 10stkm100% (2)

- STEEELДокумент8 страницSTEEELPravin SinghОценок пока нет

- asme aws 규격 리스트Документ1 страницаasme aws 규격 리스트kyeong cheol leeОценок пока нет

- CV Welder with Extensive ExperienceДокумент37 страницCV Welder with Extensive ExperienceHaniv RechaArifinОценок пока нет

- AWWA D100 Tension TableДокумент1 страницаAWWA D100 Tension Tablejojo_323Оценок пока нет

- Introduction To Advanced High Strength SteelsДокумент4 страницыIntroduction To Advanced High Strength Steelslennad1Оценок пока нет

- Complete ComparisonДокумент22 страницыComplete ComparisonMalcolm DadinaОценок пока нет

- Classification of Carbon and Alloy SteelsДокумент29 страницClassification of Carbon and Alloy SteelsjanakОценок пока нет

- Sta. Maria Mixed Use Building Beam Reinforcement DetailsДокумент5 страницSta. Maria Mixed Use Building Beam Reinforcement DetailsGia GuallarОценок пока нет