Академический Документы

Профессиональный Документы

Культура Документы

This Building Practice Noto Outlines Some of The Details L o Be

Загружено:

kaviarasu0%(1)0% нашли этот документ полезным (1 голос)

109 просмотров15 страницThe following headings are developed briefly: drawings building Codes S By-Laws Financing Estimates; Framing f Drywall Site layout and Flanning building Permits Miscellaneous Charges Temporary Services, the Mechanic's Lien Material Quantities Heavy Equipment Damage Prevent ion of Vandal I m Innovat ions.

Исходное описание:

Оригинальное название

This Building Practice Noto outlines some of the details l o be

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe following headings are developed briefly: drawings building Codes S By-Laws Financing Estimates; Framing f Drywall Site layout and Flanning building Permits Miscellaneous Charges Temporary Services, the Mechanic's Lien Material Quantities Heavy Equipment Damage Prevent ion of Vandal I m Innovat ions.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0%(1)0% нашли этот документ полезным (1 голос)

109 просмотров15 страницThis Building Practice Noto Outlines Some of The Details L o Be

Загружено:

kaviarasuThe following headings are developed briefly: drawings building Codes S By-Laws Financing Estimates; Framing f Drywall Site layout and Flanning building Permits Miscellaneous Charges Temporary Services, the Mechanic's Lien Material Quantities Heavy Equipment Damage Prevent ion of Vandal I m Innovat ions.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 15

This Building Practice Noto outlines some of the details l o be

c~nside~red before a (self-help] house building project is undertaken

by

an individual.

The following headings are developed briefly:

Drawings

Building Codes S By-Laws

Financing

Estimates; Framing F Drywall

Site Layout and Flanning

Building Permits

Miscel 1 aneous Charges

Temporary Services

Sub-contracting

Schedules

Work Undertaken by Owner

Site Clean-Up

Lumber

Framing

Payments, the Mechanic's Lien

Material Quantities

Heavy Equipment Damage

Prevent ion of Vandal i m

Innovat ions

(1) Drawings

Good drawings arc v i t a l to a successful house building operation and

usually form the main contract document because written specifica-

tisns are

seldom prepared when only one house is involved. The drawings

should be

accurately and adequately dimensioned and show at least one

full section

through the house, preferably at a Larger scale than is normal for the

floor plans and elevations, There is often a need for separate

foundation

plan to show clearly any change in the height of the foundation and

openings for doors, windows, piping or other service entry. The anchor

bolt layout should be shown clearly on this foundation drawing

which can

also be valuable for estimating the concrete quantities and designing

the

forms for the concrete.

(21 Building Codes and By-Laws

The administrative section of mast municipal by-laws contains a

statement

similar to the one following, quoted from Part 2 Administration of the

1977 National Building Code of Canada. Subsection 2,4.17. states, in

part:

"The granting of a permit, the kpproval of the drawings and specifications

or inspectians made by the authority having jurisdiction, shall not in any

way relieve the owner af a building from f u l l responsibility for

carrying

out the work or having the work carried out in -accordance with the

requirements

of t h i s By-la~,~' etc. This makes it important that the owner-builder

become familiar with the municipal by-laws wirR respect to t h e

location of

the house on the lot, property drainage, permissible changes in lot

elevation,

the need for sump pumps, etc. The owner should also obtain a copy of the

Building Code in force in the municipality where the house i s to be

built.

The National Building Code of Canada is a set of minimum standards

and in some instances it may be desirable to exceed its requirements.

For example, where the floor joists selected am. at their maximum

allowable

span, undesirable springiness m y be the result when heavyset persons

walk

across the floor. Another exmple would be the decision to use 2-in. x

&in.

studs rather than the permissible 2-in. x 4-in. ones in the exterior

walls

in order to utilize the larger stud space for additional insulation,

Codes

also rcgulatc the grades of lumber used for different purposes, but in

some instances it may be desirable to use higher grades for ease of

workability

or appearance.

(3) Financing

The interest on mortgage money starts from day one on the t o t a l

amount

committed to the project by a lending agency even though the larger

mount

of money will normally m l y be required near the end of the building

operation. FOT instance a $45,000 mortgage at 10% per annum costs

$12.52

in interest per day. Therefore because owner builders usually take longer

to ~6mplete a house than the regular builder, it may be

advisable to arrange

for interim financing, leaving the conventional mortgage applieatimz

until

later in the project. The decision, however, can be difficult because

mortgage money is usually more readily available during the three-

month

period December to February, sometimes becoming more difficult

to obtain

and more expensive as interest rates rise due ta increased building

activity during the s m r months. For either the interim financing or

the conventional mortgage, detailed c o ~ t estimates are usually

required,

along wiah evidence that you have the necessary expertise to undertake

the project. Also in the case of interim financing it will be necessary

ta s k a w that you have sufficient equity ro support the interim loan.

(4) Estimates; Framing and Jkywal l

Framing. - The cost of a framing cantract is usually calculated on

the basis of a unit price per square foot of finished floor area, and is

based on labour only. The estimazing ;end purchase of lumber and all

materials are the resp~nsibility of the owner. An estimate for the

framing contract is usually based on the extensive use of

labour saving

meth-ads such as sheat materials for all sheathing and the use of roof

trusses wherever possible. Extras are added for complicated i n t e r i

or

stair details, porches, exterior stairs, carports, garages, and for a

roof design where trusses are not called far. It is smetimes difficult

to gat a framer to consider the use of shiplap floor or wall sheathing

because of the extra labour involved.

-

Drywall. This estimate is usually based on the number of full

sheets

of marerial required, the amount af comer bead, the number of door

openings

and application problems if high ceilings and cathedral entrances are

involved. Extra thick insulation, which may bulge beyond the face of

the

studs on t h e walls or sag an the ckilings, will cause the estimator to

adjust the charges to allow far these details that make installation of

the hoard and joint finishing difficult. Details like those just mentioned

would result in an increase in the estimates for lath and

plaster finish

also.

(5) Site Layout and Planning

The owner should make cestain that the property has been surveyed

recently and that the corner pests have been located. These are usually

1/Z-in. sqwrc metal rods whose locations arc 1a;irketl by trloodcn stakes, 12

legal survey will be required by tllc Mu~~ieipality before a building l t c ~ ~ u i t

is issucd.

There are text books that describe methods for laying out the

foundations for a simple residential building and these usually describe

the use of batter bards and string lines as well as the use of tsiangulation

ta ensure that the laymx i s quare and accurate. Setbacks and

sideyard clearances should also be checked and if at all possible a

small

margin for emor should be added to these minimum dimensions. A t this

critical stage in planning the owner should verify that these aspects of

the project are correct.

When the foms are in place the municipality usually mquires that

the location of the forms be confirmed by a drawing from a registered

surveyor. In spite of this the owner should again check to scc that

everything is i n order with regard to the required zetback and side yard

clearances. The measurements af the formed foundation should

also be

checked again for accuracy. The forms should be well braced and

all

accidental openings blocked.

(61 Building Permits

Although the, basic permits are Building, Electrical, Plumbing,

Sewer

and Occupancy, larger municipalities may add such items as, kalrh,

Development, Gas, Oil, Fireplace Flue, Sidewalk Grassing, and Damage

Daposit, etc. In some large municipalities building permits account for

a significant cash outlay early in the project.

(7) Miscellaneous Charges

There are many charges to be bore by the project and these include,

building permits, permanent service connections, fire insurance,

provision

for temporary electrical service, charges for water and electrical

consumption,

and heating if construction extends into the cold seasons.

Thcrc are often costs associated w i t h accidental damage Qr

vandalism and

the possibility of theft because af large quantities of materials left

in

t l ~ u ollcn without constant supervision. The owner-builder should

also

allply for Workmcnvs Compcnsatian in case of injury to a worker at

the site.

If workcrs are employed by the owner-builder directly (and not as a

subcontract)

and if t h y are employed cmtinuous~y for a specified number of

days it may be necessary far the employer to pay Canada Pension as

well as

Unmploymcnt Insurance premiums.

(8) Tenprary Services

In many instances the owner or contractor is expected to provide

temp~rary electrical services to t h e subtrades. This is often supplied

through an arrangement with an adjacent property owner, but there

can

be problems sueh as overloading circuits and the need for heavy duty

extension cords where long distances are involved- The situation

can be

aggravated by lack of consideration for the property of the person

supplying the power on the part of some of the tradesmen.

Portable

gasoline powered generators ape available but these are expensive

to

purchase and daily rental charges are.high. Temporary hydro service is

usually available from 9;he provincial hydro company. A drawing for

this

purpose should be available from the hydro office and the total cost of

the pole and temporary service will be approximately $150,

(9) Sub-C~ntract ing

Most residential construction projects use the sub-contracling

method of building, normally under the direction of an

experienced

general contractor or developer-

The awnex-builder usually lacks on-site experience and should be

aware of the following:

[I) The work of the various sub-contractors must be scheduled

and co-ordinated.

(2) Most sub-contracts are undertaken with a minimum of written

specifications or detailed drawings.

( 3 Different trades work independently af one another, therefore

the owner-builder must try ta anticipate those areas where

the work of one trade may interfere with that of the trades

to fallow. Problems arise because each trade will have a

tendency to proceed in a manner that will expedite their

particular part of the work, The situation is aggravated

because there are seldom detailed drawings showing the layout

of plumbing or ductwork to help define where problems might

occur.

(4) Competitive bidding among sub-contractors can result in some

tr:ldcs sul~rnitting bids slightLy lower than they would like.

'rherofore if for any reason the job takes more time than

csrimatcd it can cause a poor attitude to prevail at the end

of that phase of the sub-contract work.

(53 Insulation and vapour barrier installation procedures may

leave a build up of materials an the stud faces if the

tabs on the insulation are not installed smoothly and each

staple driven properly. This cushion effect can makc it

very difficult for the boardmen to install gypsum board.

Thick ceiling insulation may sag between the ceiling or

roof j o i s t s , and the drywall applicator may push the

insulation up into the space between the joists to relieve

the pressure an the gypsum board. The spaces formed

between the insulation and the gypsum board could have an

adverse effect on the performance of t h e insulation. The

owner should be awafe of these problems and be prepared to

discuss them with the sub-cl-rntractors.

(10) Schedules

It is often difficult to maintain the proper' sequence of

construction.

Trades may be brought in before their proper place in the schedule

just to use them when they are available; i . e . , the finish coat of stucco

should not go on until after the drywall because the amount of

hammering

involved in drywall application could cause cracking in the stucco f i n

ish

coat. The roughed in plluuhing has to be in place and inspected prior to

the house being insulated.

There is always a strong tendency to try and find work for the owncr

or site supervisor, such as the early installation of perimeter drain

tile. This wuld result i n the tile being damaged or the levels

disturbed by oEher workmen because the t i l e must be left without

the

protection of stone and earth cover until the installation has been

inspected.

(1 11 Work Undertaken by Owner

Quite frequently owner-builders will undertake the actual placing

sf thc concrete in the forms, and the new delivery equipment

encourages

this trcnd. It is risky t o do t h i s , however, unless at least one crew

member has had same experience with placing concrete. If the site is

reasonably accessiblc the trucks can provide a fairly long reach with

their chutes to keep thc use of wheelbarrows to a minimum. The

concrete

suppliers allow the placers a few minutes of the trucks idle time per

ton before an extra charge is made against the purchase price. Where

site accessibility is d i f f i c u l t , a concrete pumper may be required; this

equipment has a long boom and flexible trunk which can greatly

simplify

the placing operation. Where there is any doubt about zha site, the

supplier should be asked to send a representative to assess the

bearing

capacity of the site and confirm its ability to support heavily loaded

vehicles, It should also be remembered that if the trucks get

stuck

their downtime may be charged to the project. Trucks have been known

to get bagged down on a relatively go~d site where the ground became

muddy due to an unexpected rain,

The placing of anchor bolts seems like a simple operation but they

must be placed quickly when the concrete is at the right stage of set.

The location of the anchor bolts should be marked on the special

foundation drawing mentioned under "Drawings" (page 1). The National

Building Code of Canada calls for anchor bolts at a maximum of eight

ft

on centre, but accomplishing this is not as simple as it sounds, For

instance it i s usually desirable to have bolts near the corners in

each

direction and at least t w o bolts even in a fairly short section ~f wall.

Furthermare a narrow plate is sometimes located to one s i d e on a

section

sf a wide foundation wall, a detail cbmon lo brick veneer

construction.

When this detail is used, the bolts must be accurately located off

centre

to match with the wall plate location. It can be seen readily that there

may have to be morq bolts provided than would be estimated by simply

dividing the total length of the foundation walls by eight. It should

also be remembered that the placing of an additional anchor balt after

the concrete has set up is an extremely difficult ta5.k.

Concrete foundation placement is one task that should not be started

on Friday afternoon because it is always desirable to complete this phase

of tbc operation without interruption to avoid pour lines,

Wen deep foundat ions cantairring large quatititics of co~lcrcte :Ire

used the placement should be left to an experienced crcn who c;m evnlurttc

the adequacy of the formwork and thus avoid form failure.

(12). Site Clean-Up

Unlike a regular contractor the owner-builder cannot use the

power

of persuasion generated by the possibility of additional

contracts. He

will therefore seldom have much success in ab'taining the necessary

subcontractors

if any serious attempt is made to have each of the trades

agree to clean up the site on completion of their phase of the work. It

can be asswncd therefore that considerable labour will be required

after

cach sub-contract operation to keep the building site clear of scrap

material.

The drywall contractor, far instance, will often leave a great deal

of scrap gypsum board to be disposed of. The drywall finishers often

splatter the joint-filler mate~ials on the sub-floors and t h i s has to

be

scraped off. Window sills are usually in place prior to t h e joint

filling and they must be protected or cleaned after this operation is

completed. Sanding of the joints generates a great deal of dust

which

must also be removed.

Extensive clean-up may also be required after any rosfing operation

and this can extend to adjacent properties when narraw side yards are

involved.

Some types of stuccs application will splatter window glass and

frames. These, along with drips and splatters from exterior painting,

can be difficult to remove.

There is a wide variety in lumber grades and quality and it may be

difficult for an inexperienced person to make the right selection. For

example, lumber that has been sawn green and stacked can look very

sound

and straight but may warp or twist when air dried.

Unless a higher grade is required for a special purpose mast lumber

used for the structural frame of houses is classified in the following

two main categories; Stud Grades for wall framing and Structural

Grades

for floor, ceiling or roof joists and rafters. Except for stud grades

or special orders, the framing lumber for shipments to building sites

is

normally referred to as number two or better structural, in the

species

of lumber most common to the area,

Wood -shrinks on drying and may warp or twist. To minimize these

problems the 1977 National. Building Code of Canada requires

that the

moisture content of lumber shall not be greater than 19 per cent

at the

time of installation in a building.

Roof trusses are very popular and one reason has been that many

suppliers arc highly selective in their choice af lumber for the trusses,

Where long spans are involved, it would be difficult to achieve the

same result using conventional on-site roof-framing methods unless the

lumber was carefully selected,

Because every house building project requires a varying number af

short lengths of 2 x 4'5, savings are possible through the use of 2 x 4

lumber known as "shorts1'. The term "shortsi' is used to refer to ends

that are left aftex a mill has cut a series of standard lengths. These

are very often of good quality and considerably less expensive than the

regular lengths. These, short pieces can he used for stakes, blacking,

formwork, roof-rafter lookouts and soffit supports.

High quality workmanship on the part of the framer is essential

to

the success of wood-frame house constructidn. He should be able

to offer

inspection of some of the other completed framing projects for

evaluation.

The framing sub-contract usually starts with the const~uction of the

footing and foundation forms. The ngad for accuracy with respect to

squareness and level cannot be over emphasized. It also takes an

experienced tradesman to know when forms are adequately tied and braced

to resist the weight, of the concrete.

The framer will be anxious to remaire the foundation forma the day

following< the placing af the concrete so ellat tIic main laouse framing can

proceed. In thc case of the foorings and f~untiat ior~ walls, saiw

gutllorities

suggest that thc forms sl~ould bu left in place for t i t l k a s t twentyfour

Iiours, but that this period should be extended if the weatl~er is hat

and sunny. During cold weather, the forms should not be removed w h i l e

the concrete is still warm, as rapzd cooling of the surface will cause

checkgng and surface crack-s.

Stripping of the forms should be done carefully because comer5

and thin sections of t h e green eancrete are easily damaged by rough

fanaval p$ the farm boards .

The fallowing are sane examples af framsng procedures that may require

special attention :

To avoid problems when f i t t i n g door and window frames, obtain

accurate actual dimensions for the frames so t h z the rdugh

openings may h~ adjusted accordingly. Otherwisd the framer

w i l l probably leave rough openings slightly larger than necessary

knowing that the openings can be blocked out to suit the door or

window frames, A lnrgc scale drawing sl~owing the window and dsqr

installation details should be available frnm the suppliers to

assis in establishing the proper cloarnrrces.

It is also imyortarlt that tlle finish floor thickness be

estimated at each door opening so that it can be taken into

account when establishing the height af the rough openings for

the interior doors. The rough op.ening sizes are of particular

COTIC~TII where top hung closct doors al*e used and the-return of

the gypsum bomd fenlaces the use of a wood frame.

It is also important thiit the lumber used for framing the rough

openings be selected carefu1J.y so as to minimize, the possibility

of warping because it is d-iffTcult to install the da6r frames and

t r i m if warping occurs.

Lintels: framers may use heavier linxels than necessary unless

a l l sizes are noted on the drawings. This is sometimes done tp

expedite the framing operatian by eliminating th& variatien in

length of the short studs between the lintel and the top plates

when lintels of different sizes c a l d be used. The lintel

suppo- studs should be, tightly f i t t e d because the lintel will

usually shrink slightly and latex when the load comes on the

structure the slightest downward movement of the l i n t e l may add

to the possibility of a crack forming in the wall finish above

the corners of the door and window openings,

Dimensions for ceiling drops above kitchen cupboards are seldom

detailed clearly and it is advisable to determine how much

projection is desirable and see that the dimension is uniform

above a l l cupboards.

Fire stowing of the stud spaces around the framing for the

ceiling drops shauld be installed before the ceiling drops are

put in place ( F i ~ u r e 1). This is another detail seldom shown

on plans and the proposed meThod QE accomplishing the fire

stopping should be broughr to the attention of the huilding

inspection department.

Drains from toilets, bathtubs and showers often occur directly

over floor joists making extensive modifications necessary.

This can ba avoided by preparing drawings to show a joist layout

in relation to the bathroom fixtures

(153 Payments, the Mechanicsf Lien

Because sub-cantracts for small projects in residential

construction

are undertaken with a minimum of written specifications,

misunderstandings

can easily develop. If a difference of opinion betmen the owner and

subcontractor

cannot be resolved, the owner may have no alternative but to

hold back part of the final payment. The sub-contractor may then use

the

ultimate weapon and threaten the project with a Mechanics1 Lien- The

implication being that this will shut down the project. However, this

is not necessarily the case.

Rather than comment further on t h i s legal procedure, the nutllar

would strongly recommend that builders and tradesmen become familiar

wit11 the law relating to Mechanics' Lien through reference books from a

Public Library, and if necessary by discussing the solution with a

solicitor.

Material Quantities

It is difficult to check on the quantities of bulk Materials such as

cnncrcto, sand, gravel or s o i l when it is delivered to the site. The

quantities sl~ould be based on estimates taken from the plans but in

many

instances tllc estimates are low, The reasons given are often that the

gratlc was uneven, grade levels are seldom measured accurately and

compaction of the hase material. With concrete quantities the

forms

might be slightly oversize or have bulged, and there may be sorne

leakage

of concrete from the forms.

To avoid additional delivery charges lumber is often ordered in

large loads, and because the lumber is slid from the truck in a

compact

bundle the pile would have to be taken apmt and restacked for an

accurate check to be niade.

(173 Heavy Equipment Darnage

In subdivZsions where roads, sidewalks and services are in place

before building commences, there is the possibility that these new

Ea~iXities will be damaged by heavy equipment, and that the

repair costs

will be charged to the owner. The heaviest equipment is usually the

truck that delivers the concrete. When these trucks ga over new

curbs

or sidewalks there is great potential for damage. The size of the

vehicles and the fact that the concrete materials must be used once

chey

are mixed makes it possible far inexperienced persons to be intimidated

by the operators of the trucks. For these and other Ireavily loaded

vehicles, care should be taken to clearly mark entry routes, whenever

it is possible, to avoid crossing curbs nr sidewalks. Otherwi~e ramps

should be prepared. Underground services should be clearly marked

SQ

that accidental damage by trucks, excavating or back-filling equipment

can be avoided.

Whenever heavy equipment is working on the site an owner's

representative should be present to ensure that the operator stays

clear of the building, even if this means some extra close-in work by

hand.

[18) Prevention of Vandalism

Minor theft and damage to building sites has always been a

problem

because a partially completed house has a particular fascinatiw~ for

inquisitive children. A t various stages each site can have large

quantities of unguarded and valuable materials, much of it

vulnerable

to damage. The builder therefore has had to depend heavily on the

inhcrent honesty of the public to have a successful operation.

UnfbTtunatcly

public moral attitudes are changing to the point where theft

and serious malicious damage to building sites is common. The

builder

to-day, tl~creforc, musr either plan for the cost of a security patrol

or risk llcavy monetary loss.

Undcr these circumsrances it is always advisable to bring the house

to the lockup stage as quickly as possible. This w i l l require careful

co-ordination to get the doors and windows delivered at the proper

time.

A door with a temporary lock becomes advisable so that keys can be

given to the various trades when necessary. Picture windows and

sliding

glass doors should be protected with sheet materials whenever

possible.

(19) Innovations

The trades and manufacturers have developed ingenious methods of

keeping on-site labkur costs down. Perhaps the foremost af these was the

development of gypsun drywall as well as t h e new pre-finished shcct

materials

and pre-finished exterior sidings. Plywood and other com~rosirio~~ boards

uscd

for sheathing have also been responsible far reducing on-site labour,

Baseboards have been eliminated in many areas in houses by

bringing

the drywall ta within 12 m of the floor so that the remaining j o i n t can

be covered by thick carpet and underlay.

Most of the extruded metal window frames have a wide flange around

the perimeter to permit rapid maunting of ehe window from the

exterior.

Drywall is often returned at the windows and a plastic cap has been

developed to minimize damage to the drywall frm condensation that might

form an the metal window frame. There are, bowcvcr, some p o t e n t i a l

problems with these window details. A narrow space is left

between -the

metal frame and the rough opening frame. This is seldom packed with

insulation and there is a danger of air fr~m the house entering this

space and condensing an the mter metal frame. I t is extremely

difficult

to extend the airjvapour barrier to the metal window frame at: this

point.

Considerablc time can also be requircd to blo~-k out around the rough

opening so that the drywall and plastic bead will lap the metal window

evenly all arou~~d (Figure 23.

Gypsum board returns around closet doors, like those at windows,

substitute for the usual wood frame and trim. The gypsum board extends

12 mm beyond the opening and is capped with a metal cap. This projection

hides the sides, top and hottom of bifold closet doors (Figure 3).

Designers are also eliminating the returns ar0un.d closet doors (Figure 4 )

.

Ceiling height interior doors have been tried f r o m rime to t i m e . Tlre

metric house built by HUDAC at Habitat in Vancouver in 1976

featured a

ceiling height set of sliding doors to enclose a closet wall. These

were prefinished sliding doors of hardboard with the edges capped with

simple plastic moulding.

Metal capped gypsum valance boards are very popular, but. they are

often backed with heavies than necessary 2 in. material because it is

usually available on the site and provides a solid backing. Some

builders

use special metal brackots to reduce the amount of wood used and t h e

brackets also make the insulation, drywall and air barrier easier to

install, because they are placed over the gypsum board. Wood or gypsum

valances can bc used on the heavy woad frame backing or the metal

brackets (Figure 51- Folding closet doors and hardware as well as the

interior shcfving rods and hardware have also been designed to minimize

installation t i m c .

Spray produced textured ceiling finishes afe widely used as they

minimize the d i f f i c u l t y of hiding the drywall seams. It is

necessary to

clearly specify those areas where the spray is not desirable. such as

in

kitchens and bathrams.

Prefinished vinyl doors are available and if acceptable Is the

owner are a significant saving aver other finishes. For instance a

standard 30-in. vinyl prefinished door costs only slightly more than a

select grade mahogany door ready for staining! It should be noted,

however, that the prefinished vinyl door is difficult to repair if the

vinyl is damaged.

Prehung prefinished doors are popular. The split jamb is expensive

but it includes the prefitted door trim and it is adjustable to minor

variations in wall thickness.

There is strong competition among manufacturers of kitchen and

bathroom cabinets and counter tops. This gives the owner the advantage

of high quality factory finishes and a wide selection at competitive

prices.

Plastic plumbing for drain, waste, and vent pipe is widely used in

single-family housing and aids in keeping dawn the price of

plumbing

installations through reduced on-site labour.

Factory produced roof trusses certainly speed the on-site operation,

however, the job scheduling must be precise in order t o have the

fiame

complete to the point where the truck delivering the trusses can use irs

hydraulic boom to place the Trusses on the home. Qtherwise they will

simply be left at the site and it can be a difficult task getting them on

the house by hand.

Further useful information is available from Central Mortgage and

Housing Corporation, Montreal Road, Ottawa, Ontario KIA OP7 in their

publication entitled Canadian Wood-Frame House Cclilstruction (Order no.

NHA 5031, Price $1.00).

ENDS FIRE

STOPPED WITH

GYPSUM BOARD

BEFORE FRAME

I S NAILED IN

PLACE

F IRE

STOP

FIGURE I

CEILING DROP

EXTERIOR

BLOCKING:

A I R BARRIER'

TO HERE

CAP

FIGMRE 2

WINDOW JAMB

DRYWALL

METAL CAP] - DOORS

FIGURE 3

TOP AND SIDES OF CLOSETS

CONVENTIONALiml CLOTHES CLOSETS

PROPOSED

FIGURE 4

irll

DESIGNERS EL IAI INATE

RETURNS

FIGURE 5

VALANCES

Вам также может понравиться

- Function keys in ExcelДокумент27 страницFunction keys in Excel1012804201Оценок пока нет

- Tonic To Mind 1Документ1 страницаTonic To Mind 1kaviarasuОценок пока нет

- Tips For Travelers2001Документ2 страницыTips For Travelers2001kaviarasuОценок пока нет

- Know Ur English 2Документ2 страницыKnow Ur English 2kaviarasu100% (4)

- Check This Cool PuzzleДокумент2 страницыCheck This Cool PuzzlekaviarasuОценок пока нет

- Stretching ExercisesДокумент6 страницStretching Exerciseskaviarasu100% (4)

- Amazing Facts of WorldДокумент4 страницыAmazing Facts of Worldkaviarasu100% (5)

- 5 - Minute Management LessonsДокумент3 страницы5 - Minute Management Lessonskaviarasu100% (2)

- Filename: 3266657-ART-OF-HAPPINESS PDFДокумент2 страницыFilename: 3266657-ART-OF-HAPPINESS PDFPino De PinisОценок пока нет

- Filename: 3266657-ART-OF-HAPPINESS PDFДокумент2 страницыFilename: 3266657-ART-OF-HAPPINESS PDFPino De PinisОценок пока нет

- Age of Empire 2Документ2 страницыAge of Empire 2kaviarasu100% (8)

- Lucky NumberДокумент29 страницLucky NumberSreejith SasikumarОценок пока нет

- Stroke 2Документ8 страницStroke 2kaviarasu100% (5)

- DEADLOCKДокумент1 страницаDEADLOCKkaviarasu100% (4)

- Try This Intelligence TestДокумент2 страницыTry This Intelligence Testkaviarasu100% (5)

- JSTL ReferenceДокумент108 страницJSTL ReferencekaviarasuОценок пока нет

- Advanced Java Programming: Unit Two: Servers and ServletsДокумент52 страницыAdvanced Java Programming: Unit Two: Servers and ServletskaviarasuОценок пока нет

- Kokology-Ish Personality TestДокумент9 страницKokology-Ish Personality TestAnton Dy38% (13)

- ItextДокумент55 страницItextkaviarasu100% (1)

- Java SQL QuestionsДокумент3 страницыJava SQL Questionskaviarasu100% (1)

- Java STRUTS QuestionsДокумент13 страницJava STRUTS Questionskaviarasu100% (3)

- PersistenceEJB3 0Документ64 страницыPersistenceEJB3 0kaviarasu100% (3)

- Java JSP QuestionsДокумент3 страницыJava JSP Questionskaviarasu100% (1)

- Java Servlet QuestionsДокумент17 страницJava Servlet Questionskaviarasu100% (1)

- Java 1Документ99 страницJava 1kaviarasu100% (1)

- JSPДокумент15 страницJSPkaviarasuОценок пока нет

- ServletДокумент40 страницServletkaviarasuОценок пока нет

- JSP1Документ11 страницJSP1kaviarasuОценок пока нет

- SQLДокумент37 страницSQLkaviarasuОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Resort Detailed Estimates (1) NewKapДокумент12 страницResort Detailed Estimates (1) NewKapブラヤン スヘデОценок пока нет

- Grundfos PDFДокумент8 страницGrundfos PDFDan PetricОценок пока нет

- Mac ModularДокумент19 страницMac ModulartakamuralyОценок пока нет

- Experimental Studies of Thin-Ply Laminated Composites: Composites Science and TechnologyДокумент13 страницExperimental Studies of Thin-Ply Laminated Composites: Composites Science and TechnologyCarlo PignagnoliОценок пока нет

- Steel Construction and Bridges Allowable Stress DesignДокумент263 страницыSteel Construction and Bridges Allowable Stress DesignSaharAkthamОценок пока нет

- Electrical Installation Lecture No.12 DR - Mohammed Tawfeeq Al-ZuhairiДокумент10 страницElectrical Installation Lecture No.12 DR - Mohammed Tawfeeq Al-ZuhairiTĩnh LặngОценок пока нет

- IGBC GREEN BUILDING RATING SYSTEM UPDATEДокумент8 страницIGBC GREEN BUILDING RATING SYSTEM UPDATEEHS HalolОценок пока нет

- ATP 3-37.10 Base CampsДокумент173 страницыATP 3-37.10 Base Campscondorblack2001100% (1)

- Trane Clearance SpecsДокумент20 страницTrane Clearance SpecsdaveeeescribdОценок пока нет

- Professional Indemnity in ConstructionДокумент35 страницProfessional Indemnity in ConstructionMurat YilmazОценок пока нет

- Ramanathan, (2011) - Risk Factors Influencing Time and Cost Overrun in Multiple D&B Projects in Malaysia A Case StudyДокумент6 страницRamanathan, (2011) - Risk Factors Influencing Time and Cost Overrun in Multiple D&B Projects in Malaysia A Case StudyPriyaah KarunakaranОценок пока нет

- Explanation of NSK life calculation factors and reliability in bearing selectionДокумент5 страницExplanation of NSK life calculation factors and reliability in bearing selectionAndiniPermanaОценок пока нет

- Significance of Test and Properties of Concrete and Concrete Making MaterialДокумент220 страницSignificance of Test and Properties of Concrete and Concrete Making MaterialHarun Alrasyid78% (9)

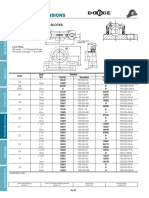

- Bearing Reference Guide - Setscrew Ball Bearings DimensionsДокумент2 страницыBearing Reference Guide - Setscrew Ball Bearings DimensionsjaviervbОценок пока нет

- TWI Paper On Fatigue and GridingДокумент42 страницыTWI Paper On Fatigue and GridingKatsaras SotirisОценок пока нет

- Seismic Strengthening and Repair of RC Shear Walls PDFДокумент8 страницSeismic Strengthening and Repair of RC Shear Walls PDFSri LathaОценок пока нет

- R.Agore Objective For SSC Je and Gate Etc PDFДокумент539 страницR.Agore Objective For SSC Je and Gate Etc PDFamarjeet50% (2)

- Sustainable Design PrinciplesДокумент15 страницSustainable Design PrinciplesyaraОценок пока нет

- 002 Fairmate - PiiДокумент4 страницы002 Fairmate - PiifairmatechemicalОценок пока нет

- Donald DeskeyДокумент12 страницDonald DeskeyDiksha GuptaОценок пока нет

- Progress ReportДокумент9 страницProgress ReportMunashe NyayaОценок пока нет

- Laos EarthquakeДокумент2 страницыLaos EarthquakeShreyansh Manojkumar AjmeraОценок пока нет

- Staad Pro Work Book PDFДокумент4 страницыStaad Pro Work Book PDFGunawan IwanОценок пока нет

- Schedule Q - Quality RequirementsДокумент73 страницыSchedule Q - Quality RequirementsFirdaus Nasir93% (14)

- Mmse Journal Vol11Документ319 страницMmse Journal Vol11Mmse JournalОценок пока нет

- Ten Storey Construction MethodologyДокумент18 страницTen Storey Construction MethodologyeteureОценок пока нет

- ECG303 - BASIC SOIL MECHANICS: CONSOLIDATION AND COMPACTIONДокумент90 страницECG303 - BASIC SOIL MECHANICS: CONSOLIDATION AND COMPACTIONMukhriz Mansor0% (1)

- Sample MOAДокумент8 страницSample MOAStewart Paul TorreОценок пока нет

- Char-Lynn Hydraulic MotorДокумент13 страницChar-Lynn Hydraulic MotorRui ArezesОценок пока нет

- Design - Calcs - Coupling Beams 4-7Документ4 страницыDesign - Calcs - Coupling Beams 4-7Krishna AnishОценок пока нет