Академический Документы

Профессиональный Документы

Культура Документы

Design of Welded Steel Structures 81

Загружено:

druwid6Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design of Welded Steel Structures 81

Загружено:

druwid6Авторское право:

Доступные форматы

Quality Control and Inspection

61

Steel plates and sections are to be checked for their physical and chemical properties by verifying the distinctive cast/heat marks stamped on each

piece with corresponding numbers mentioned in the certificates issued by

the producers. Over and above these, for important structures, independent

sample tests are often carried out to confirm the accuracy of the mill test

results. Test pieces for such additional tests should be cut out from the end of

the material and processed for testing in the presence of the inspectors and

duly documented.

Dimensional tolerances, that is, permissible variations from theoretical

dimensions, of plates and sections from rolling mills, often present problems

during fabrication. Also, materials may become twisted or bent during transit from the mills to the fabrication shops. These should be properly checked

and rectified, as necessary, before being used in the job.

For welded fabrication, lamellar tearing often presents problems.

Therefore, materials to be used for welding should be checked against presence of lamination. In particular, tests for lamination should be carried out

for materials, in which tension stresses are transmitted through the thickness or where lamination could affect the buckling behavior of the member

under compression. Lamination can be detected by nondestructive testing

(NDT) method, such as ultrasonic examination, discussed later in this chapter. Extent of lamination should not exceed those indicated in relevant code

of practice being followed.

As in the case of riveted or bolted fabrication, raw materials for welded

structures should also be stored properly at the storage yard. These should

be carefully unloaded, examined for defects, checked with documents, and

stacked as per specification and size, above the ground on platforms, skids,

or other suitable supports to ensure that these do not come in contact with

water or ground moisture. Electrodes should also be stored specification

wise and kept in dry, warm condition.

6.4 Welding Procedure

In order to ensure that acceptable quality of weld is achievable using the proposed welding procedure, it is necessary to examine the same before actual

fabrication work is taken up. For this purpose, a specimen of welded joint of

adequate length of the same cross section and material is made out with the

same welding parameters (i.e., electrode, wire, flux, current, arc voltage, and

speed of travel) that are proposed to be used in actual contraction. This joint

is then subjected to required tests for acceptance of the welding procedure

by the inspecting agency.

Вам также может понравиться

- Technical Information Regarding Corrosion Testing - : by A. S. KrisherДокумент2 страницыTechnical Information Regarding Corrosion Testing - : by A. S. KrisherWilliam Fernando Barrera ArangurenОценок пока нет

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingОт EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingОценок пока нет

- Quality Control Procedure Strcture-SSДокумент16 страницQuality Control Procedure Strcture-SSKamran AliОценок пока нет

- (Welding) Welding of Coiled Tubing (Ebook, 9 Pages)Документ9 страниц(Welding) Welding of Coiled Tubing (Ebook, 9 Pages)Gustavo de Paula100% (1)

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIОт EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemОценок пока нет

- Heat Exchanger Inspection PDFДокумент8 страницHeat Exchanger Inspection PDFreezmanОценок пока нет

- Experiment and Calculation of Reinforced Concrete at Elevated TemperaturesОт EverandExperiment and Calculation of Reinforced Concrete at Elevated TemperaturesРейтинг: 5 из 5 звезд5/5 (2)

- 273 - Tension Cable and Rod Connectors Alert 10 August 2012Документ3 страницы273 - Tension Cable and Rod Connectors Alert 10 August 2012musiomi2005Оценок пока нет

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresОт EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresРейтинг: 5 из 5 звезд5/5 (1)

- Ce511 Tabinas HW02 PDFДокумент17 страницCe511 Tabinas HW02 PDFKathlyn Kit TabinasОценок пока нет

- Heat Exchanger InspectionДокумент7 страницHeat Exchanger InspectionHamid Albashir100% (1)

- 11-Quality Assurance - HariharanДокумент29 страниц11-Quality Assurance - Hariharanabhinay soniОценок пока нет

- Quality and Inspection: D.DHANASEKAR M.E.,Mem.A.S.M.E., Design Engineer - MechanicalДокумент45 страницQuality and Inspection: D.DHANASEKAR M.E.,Mem.A.S.M.E., Design Engineer - MechanicalRUDHRA DHANASEKARОценок пока нет

- ASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied LiningsДокумент3 страницыASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied LiningsAmanda Ariesta ApriliaОценок пока нет

- Inspection and Welding Repairs of Pressure VesselsДокумент9 страницInspection and Welding Repairs of Pressure VesselsClaudia Mms100% (1)

- Welding Inspection ProcedureДокумент5 страницWelding Inspection ProcedurePugalОценок пока нет

- Distribution Transformer Manufacturing Process ManualДокумент29 страницDistribution Transformer Manufacturing Process ManualAnonymous Jf6X8nОценок пока нет

- Pressure Vessel InspectionДокумент44 страницыPressure Vessel Inspectionأحمد صبحى100% (4)

- Piping InspectionДокумент15 страницPiping Inspectionlester100% (1)

- Welding InspectionДокумент7 страницWelding Inspectionzahid_497100% (1)

- Pipe Fittings InspectionДокумент7 страницPipe Fittings InspectionRamalingam PrabhakaranОценок пока нет

- Inspection of Subsea and Surface Wellhead & Christmas Tree EquipmentДокумент14 страницInspection of Subsea and Surface Wellhead & Christmas Tree Equipmentshifa100% (1)

- Astm G42 - 11 PDFДокумент8 страницAstm G42 - 11 PDFJavier Celada100% (1)

- National Specification: C T o LДокумент6 страницNational Specification: C T o LMduduzi Magiva MahlanguОценок пока нет

- ASME CODE Requirements - Heat ExchangerДокумент9 страницASME CODE Requirements - Heat ExchangerJithin FrancizОценок пока нет

- Guideline On The Approval of New Materials Under The Asme Boiler and Pressure Vessel CodeДокумент2 страницыGuideline On The Approval of New Materials Under The Asme Boiler and Pressure Vessel Codekirandevi1981Оценок пока нет

- GuidelineДокумент2 страницыGuidelineKumar AruОценок пока нет

- AMEC Specification For Titanium 01Документ9 страницAMEC Specification For Titanium 01cenkturkerОценок пока нет

- Third Party Procedure For Heat Exchanger TestingДокумент10 страницThird Party Procedure For Heat Exchanger TestingVarun MalhotraОценок пока нет

- Tack-Welds: of Highest Quality For Strong StructuresДокумент3 страницыTack-Welds: of Highest Quality For Strong Structuressenthil4youОценок пока нет

- Pressure Vessel Inspection PDF FreeДокумент44 страницыPressure Vessel Inspection PDF FreemabroukОценок пока нет

- Temp Pipe WorksДокумент18 страницTemp Pipe WorksnestorОценок пока нет

- Standards & Its Description OverviewДокумент8 страницStandards & Its Description OverviewBalakumarОценок пока нет

- Part II-Chapter 1-API-RP 5 72Документ11 страницPart II-Chapter 1-API-RP 5 72Amr SolimanОценок пока нет

- Welding of High Pressure Vessels and Pipelines Procedure RoadmapДокумент3 страницыWelding of High Pressure Vessels and Pipelines Procedure RoadmapCraigHunterОценок пока нет

- Alternative To Thermal Stress ReliefДокумент9 страницAlternative To Thermal Stress ReliefSharad ShahОценок пока нет

- Dutyies of Welding InspectorДокумент30 страницDutyies of Welding InspectorMorg Actus100% (1)

- British Standard 5289: 1976: Visual InspectionДокумент10 страницBritish Standard 5289: 1976: Visual InspectionMarcelo Rodriguez FujimotoОценок пока нет

- Corrosion Testing PDFДокумент12 страницCorrosion Testing PDFVaish NaviОценок пока нет

- Module 9.qualification 1.welding PerformanceДокумент6 страницModule 9.qualification 1.welding PerformanceMohd NizamОценок пока нет

- DG BusductДокумент16 страницDG BusductanandpurushothamanОценок пока нет

- DT & NDTДокумент46 страницDT & NDTThulasi RamОценок пока нет

- Qualification of Welders, Welding OperatorsДокумент3 страницыQualification of Welders, Welding OperatorssirajvarisОценок пока нет

- NSC LECTURE Sept 2010 - Inspection of Pressure VesselsДокумент21 страницаNSC LECTURE Sept 2010 - Inspection of Pressure VesselsMohammad Abubakar SiddiqОценок пока нет

- 32 Saip 11Документ9 страниц32 Saip 11malika_00Оценок пока нет

- Guide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodsДокумент24 страницыGuide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodszaheermechОценок пока нет

- Tex-601-J, Sampling and Testing Elastomeric Materials: ContentsДокумент7 страницTex-601-J, Sampling and Testing Elastomeric Materials: Contentsraviteja036Оценок пока нет

- Mechanical Interview Rev 1Документ86 страницMechanical Interview Rev 1Syed Mohamed Gani GaniОценок пока нет

- RLA in High Temp Zones of Power Plant ComponentsДокумент7 страницRLA in High Temp Zones of Power Plant ComponentsEzhil Vendhan PalanisamyОценок пока нет

- Inspection and Welding Repairs of Pressure VesselsДокумент8 страницInspection and Welding Repairs of Pressure VesselsAlper Çakıroğlu100% (1)

- Corrosion Testing and MeasurementsДокумент9 страницCorrosion Testing and MeasurementsVaish NaviОценок пока нет

- Part II Chapter 1 API RP 572Документ9 страницPart II Chapter 1 API RP 572Amr Mohamed SolimanОценок пока нет

- Heat Exchanger InspectionДокумент11 страницHeat Exchanger InspectionVivek Bhangale100% (1)

- 23 TMSS 02 R0Документ0 страниц23 TMSS 02 R0renjithas2005Оценок пока нет

- Chapter 8Документ31 страницаChapter 8louie jay aguadoОценок пока нет

- DT & NDTДокумент46 страницDT & NDTKumar SahebОценок пока нет

- 4 - Mike ShandДокумент6 страниц4 - Mike ShandPieter Vd MerweОценок пока нет

- Aggressivity of The Environment: Main Exposure ClassesДокумент2 страницыAggressivity of The Environment: Main Exposure Classesdruwid6Оценок пока нет

- The Abc'S of Autolisp by George Omura: Managing Large Acad - LSP FilesДокумент1 страницаThe Abc'S of Autolisp by George Omura: Managing Large Acad - LSP Filesdruwid6Оценок пока нет

- Design of Welded Steel Structures 51Документ1 страницаDesign of Welded Steel Structures 51druwid6Оценок пока нет

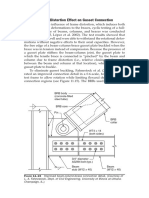

- 11.5.3 Frame Distortion Effect On Gusset ConnectionДокумент1 страница11.5.3 Frame Distortion Effect On Gusset Connectiondruwid6Оценок пока нет

- Simplified Calculation Method For Integral of Mean Square Value of Various Nonstationary Random ResponsesДокумент1 страницаSimplified Calculation Method For Integral of Mean Square Value of Various Nonstationary Random Responsesdruwid6Оценок пока нет

- Chapter Six Applications of Plastic Analysis: 6.6 Displacement Compatibility of Nonductile SystemsДокумент1 страницаChapter Six Applications of Plastic Analysis: 6.6 Displacement Compatibility of Nonductile Systemsdruwid6Оценок пока нет

- Chapter Eleven: A B C D E FДокумент1 страницаChapter Eleven: A B C D E Fdruwid6Оценок пока нет

- Sketching A Complete View Containing Circles and ArcsДокумент1 страницаSketching A Complete View Containing Circles and Arcsdruwid6Оценок пока нет

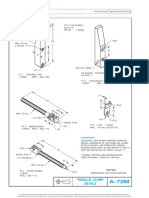

- Interpreting Engineering Drawings: Parallel Clamp DetailsДокумент1 страницаInterpreting Engineering Drawings: Parallel Clamp Detailsdruwid6Оценок пока нет

- Problem 6.2: 06 - Bruneau - Ch06 - P273-308.indd 305 6/13/11 3:13:56 PMДокумент1 страницаProblem 6.2: 06 - Bruneau - Ch06 - P273-308.indd 305 6/13/11 3:13:56 PMdruwid6Оценок пока нет

- Interpreting Engineering Drawings Common Types of CamsДокумент1 страницаInterpreting Engineering Drawings Common Types of Camsdruwid6Оценок пока нет

- Fibres: Named After The Swiss Jacob Bernoulli (1654-1705), From A Famous Family of Mathematicians and PhysicistsДокумент1 страницаFibres: Named After The Swiss Jacob Bernoulli (1654-1705), From A Famous Family of Mathematicians and Physicistsdruwid6Оценок пока нет

- Ground Improvement Techniques and Lining Systems 119: WaterproofingДокумент1 страницаGround Improvement Techniques and Lining Systems 119: Waterproofingdruwid6Оценок пока нет

- Wide-Flange Beam: Plate:: Beams, Girders, and ColumnsДокумент1 страницаWide-Flange Beam: Plate:: Beams, Girders, and Columnsdruwid6Оценок пока нет

- -ε diagram for glass.: Engineering Mechanics. Volume 2: Stresses, Deformations, DisplacementsДокумент1 страница-ε diagram for glass.: Engineering Mechanics. Volume 2: Stresses, Deformations, Displacementsdruwid6Оценок пока нет

- -ε diagram with a distinct yield region.: Engineering Mechanics. Volume 2: Stresses, Deformations, DisplacementsДокумент1 страница-ε diagram with a distinct yield region.: Engineering Mechanics. Volume 2: Stresses, Deformations, Displacementsdruwid6Оценок пока нет

- Figure 1.1 Partial Factors and Their Significance in Eurocode 1 (European Standard, 2000)Документ1 страницаFigure 1.1 Partial Factors and Their Significance in Eurocode 1 (European Standard, 2000)druwid6Оценок пока нет

- Land Clearing and ControlsДокумент1 страницаLand Clearing and Controlsdruwid6Оценок пока нет

- 80 PDFДокумент1 страница80 PDFdruwid6Оценок пока нет

- Tunnel 130 PDFДокумент1 страницаTunnel 130 PDFdruwid6Оценок пока нет

- 15.6.4 Damping, Defining Reduced Frequencies and Modal MatricesДокумент1 страница15.6.4 Damping, Defining Reduced Frequencies and Modal Matricesdruwid6Оценок пока нет

- 12.4.5 Functions Called: Tdofssmodalfun.m, Tdofssmodal1fun.m, Tdofssmodal2fun.m, Tdofssmodal3fun.mДокумент1 страница12.4.5 Functions Called: Tdofssmodalfun.m, Tdofssmodal1fun.m, Tdofssmodal2fun.m, Tdofssmodal3fun.mdruwid6Оценок пока нет

- The Art of Woodworking - Finish Carpentry 1994Документ148 страницThe Art of Woodworking - Finish Carpentry 1994Zorila Dan100% (14)

- Drywall HandbookДокумент44 страницыDrywall Handbookdeepali bangeraОценок пока нет

- The Current General Uses of QT Steels and Nippon Steel Corp.'s HT SteelsДокумент14 страницThe Current General Uses of QT Steels and Nippon Steel Corp.'s HT SteelsardeshirОценок пока нет

- Mazak QT 200 250 Nexus Operating Manual PDFДокумент466 страницMazak QT 200 250 Nexus Operating Manual PDFosteanu100% (2)

- Metal DetectorДокумент8 страницMetal DetectorsamodraОценок пока нет

- KS Series Master Format CSI SpecificationДокумент14 страницKS Series Master Format CSI SpecificationMohammad Maher AlSafariniОценок пока нет

- PRV Catlogue-Samson (09!06!09)Документ6 страницPRV Catlogue-Samson (09!06!09)pkrishna984Оценок пока нет

- BASF Process For Producing 1Документ4 страницыBASF Process For Producing 1Tasneem MОценок пока нет

- Strength and Microscale Properties of Bamboo FiberДокумент14 страницStrength and Microscale Properties of Bamboo FiberDm EerzaОценок пока нет

- Msds For BenzilДокумент5 страницMsds For BenzilArfin FardiansyahОценок пока нет

- Basement Parking PDFДокумент6 страницBasement Parking PDFShameel PtОценок пока нет

- Furniture Production Materials - 2Документ9 страницFurniture Production Materials - 2Pitz Shady ShinОценок пока нет

- Traymaster Boiler BookДокумент7 страницTraymaster Boiler Bookfauzi endraОценок пока нет

- LC3 For Cem Tech Oct 2020Документ62 страницыLC3 For Cem Tech Oct 2020Subhan MuhammadОценок пока нет

- VTT R 05984 12Документ72 страницыVTT R 05984 12Soma Shekar AОценок пока нет

- Rim-Loc Rotoblast: Reversible 8-Vane WheelДокумент2 страницыRim-Loc Rotoblast: Reversible 8-Vane WheelBoanerges Brito100% (1)

- Gas Metal Arc WeldingДокумент26 страницGas Metal Arc WeldingnansusanОценок пока нет

- 1977 Puch Maxi Moped Wiring DiagramДокумент9 страниц1977 Puch Maxi Moped Wiring DiagramMopedgal100% (1)

- Rawlplug en R Kex II Pure Epoxy Resin Threaded RodsДокумент9 страницRawlplug en R Kex II Pure Epoxy Resin Threaded RodsgumuskapiОценок пока нет

- Gearbox ProblemsДокумент5 страницGearbox ProblemsAdugna KasimОценок пока нет

- Bar TrussДокумент18 страницBar TrussJithinGeorgeОценок пока нет

- ASV ST50 Service ManualДокумент114 страницASV ST50 Service ManualbrunosamaeianОценок пока нет

- High Voltage FusesДокумент10 страницHigh Voltage FusesDuvan Nieto CañonОценок пока нет

- Title Description - Soda Ash+Документ1 страницаTitle Description - Soda Ash+glitterxinchauОценок пока нет

- Cable Trays NEMA ClassificationsДокумент2 страницыCable Trays NEMA ClassificationsJoel Alcantara100% (1)

- Compare The Different Options For NGL Recovery From Natural GASДокумент21 страницаCompare The Different Options For NGL Recovery From Natural GASRashveenaОценок пока нет

- MiCOM P72x Manual Global File P72x en T B21Документ256 страницMiCOM P72x Manual Global File P72x en T B21Yahya DarОценок пока нет

- Competitive Industrial Performance Index 2023Документ2 страницыCompetitive Industrial Performance Index 2023Nigel DsilvaОценок пока нет

- Brochure Cleaning Cationic Surfactant ThickenersДокумент4 страницыBrochure Cleaning Cationic Surfactant Thickenersrachmi.kartiniОценок пока нет

- FBE Installation Manual PDFДокумент60 страницFBE Installation Manual PDFMario R. KallabОценок пока нет

- Waste: One Woman’s Fight Against America’s Dirty SecretОт EverandWaste: One Woman’s Fight Against America’s Dirty SecretРейтинг: 5 из 5 звезд5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionОт EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionРейтинг: 3 из 5 звезд3/5 (1)

- Principles of direct and superior responsibility in international humanitarian lawОт EverandPrinciples of direct and superior responsibility in international humanitarian lawОценок пока нет

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaОт EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaРейтинг: 4 из 5 звезд4/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontОт EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontРейтинг: 4.5 из 5 звезд4.5/5 (18)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksОт EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksОценок пока нет

- Busted!: Drug War Survival Skills and True Dope DОт EverandBusted!: Drug War Survival Skills and True Dope DРейтинг: 3.5 из 5 звезд3.5/5 (7)

- The Rights of Nature: A Legal Revolution That Could Save the WorldОт EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldРейтинг: 5 из 5 звезд5/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionОт Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionОценок пока нет

- Environmental Education in Practice: Concepts and ApplicationsОт EverandEnvironmental Education in Practice: Concepts and ApplicationsОценок пока нет

- Farming for Our Future: The Science, Law, and Policy of Climate-Neutral AgricultureОт EverandFarming for Our Future: The Science, Law, and Policy of Climate-Neutral AgricultureОценок пока нет

- Down to the Wire: Confronting Climate CollapseОт EverandDown to the Wire: Confronting Climate CollapseРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Natural Hazard Mitigation: Recasting Disaster Policy And PlanningОт EverandNatural Hazard Mitigation: Recasting Disaster Policy And PlanningОценок пока нет

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontОт EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontРейтинг: 4.5 из 5 звезд4.5/5 (9)

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933От EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Оценок пока нет