Академический Документы

Профессиональный Документы

Культура Документы

Operation & Maintenance Manual What Is Lockout & Tagout?: This Page Intentionally Left Blank

Загружено:

jlfyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Operation & Maintenance Manual What Is Lockout & Tagout?: This Page Intentionally Left Blank

Загружено:

jlfyАвторское право:

Доступные форматы

Operation & Maintenance Manual

What is Lockout & Tagout?

This Page Intentionally Left Blank

CRSH-OM-0003ENG(OCT-2014)

2-6

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Jaw Crusher Description

Section 3 - General Information

Serial Numbers

Jaw Crusher Description

Crushers are assigned a serial number which is

stamped on a plate on the machine.

The Jaw Crusher is a high-capacity compressiontype crusher that fractures material along its

natural fault lines.

Other components on the crusher may have

separate serial numbers or identifying numbers.

Always give the model and serial number or

identifying number of your crusher when ordering

parts or requesting information. If parts are

required for the other certain components, you

should supply that serial number or identifying

number as well as the crusher numbers.

Product size is controlled by adjusting the distance

between the fixed jaw die and the moveable

(swing) jaw die fastened to the pitman assembly.

These jaw dies are replaceable and come in several

different profiles depending upon the type of

material to be crushed and customer preference.

Flywheel Rotation Direction

The pitman is protected from damage by the toggle

plate. The toggle plate is intended to bend or

fracture if an uncrushable object enters the

crushing chamber, and thus opens the chamber

allowing the object to pass through.

Crushers are fitted with two flywheels, one of

which acts as the driven sheave. The direction of

rotation and orientation to the crusher is shown in

(Figure 3 - 2).

The Jaw Crusher may be mounted or installed in

static stationary, modular skid, as well as portable

wheel or mobile track plant applications. No

matter which type application the Jaw Crusher is

used in, it must be level to operate properly.

Figure 3 - 2 Flywheel Rotation Direction

Figure 3 - 1 Typical Jaw Crusher

CRSH-OM-0003ENG(OCT-2014)

3-1

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

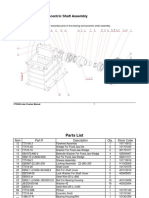

Jaw Crusher Components

Jaw Crusher Components

Each model/size jaw crusher consists of similar

components, however certain models/sizes may

not have all the same components as other models/

sizes.

Be familiar with the crushers components. See

(Figure 3 - 3)

To be certain your machine has the proper

components, check to ensure it was equipped as

ordered.

8

4

3

21

7

9

10

11

20

12

19

13

18

17

16

15

1 2 3 4 5 6 7 8 9 101112131415161718192021-

Crusher Frame

Stationary Jaw Die

Cheek Plate (Key Plate)

Flywheel

Swing Jaw Die

Pitman Liner

Frame Bearing

Pitman

Pitman Bearing

Eccentric Shaft

Spring Guards

Adjustment Hydraulic Ram

Tension Rod Spring

Tension Rod

Shims

Upper Buffer

Toggle Plate

Lower Buffer

Rubber Dust Apron

Wedges for Stationary Jaw

Wedges for Swing Jaw

14

Figure 3 - 3 Typical Jaw Crusher Components

CRSH-OM-0003ENG(OCT-2014)

3-2

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Jaw Crusher Gradation Chart

Jaw Crusher Gradation Chart

.

CT SERIES JAW CRUSHERS PRODUCT GRADATIONS (PERCENT PASSING)

C.S.S. Size Opening

Product

Size

15"

380mm

14"

356mm

13"

330mm

12"

305mm

11"

280mm

10"

250mm

9"

225mm

8"

200mm

7"

175mm

6"

150mm

5"

127mm

4"

100mm

3-1/2"

90mm

3"

76mm

2-1/2"

64mm

2"

50mm

1-3/4"

45mm

1-1/2"

38mm

1-1/4"

32mm

1"

25mm

3/4"

19mm

5/8"

13mm

3/8"

10mm

1/4"

6mm

1"

25 mm

1-1/2"

38mm

2"

50mm

2-1/2"

64mm

3"

76mm

3-1/2"

90mm

4"

100mm

5"

127mm

6"

150mm

7"

175mm

8"

200mm

9"

225mm

10"

250mm

11"

280mm

12"

305mm

100

100

90

100

90

85

100

90

85

75

100

90

85

75

70

100

90

83

75

70

65

100

90

83

75

70

65

60

100

90

83

75

70

65

60

55

100

90

83

75

70

63

60

55

45

100

95

83

75

68

63

58

55

45

40

100

90

85

75

68

60

58

48

45

40

35

100

90

83

75

65

60

55

48

45

40

35

25

95

83

75

70

60

55

50

45

40

35

25

22

100

83

75

70

65

55

50

45

35

30

25

22

20

100

90

75

68

60

55

50

42

35

30

25

22

20

17

90

75

65

58

55

50

40

35

30

25

22

20

17

12

85

70

60

55

50

45

35

30

25

22

20

17

12

10

100

75

65

55

50

45

40

30

25

22

20

17

12

10

95

70

55

50

40

35

30

25

22

20

17

15

10

75

65

45

43

35

30

25

20

17

15

12

10

70

55

40

30

25

22

20

17

15

12

10

60

45

35

25

20

17

15

13

10

45

30

25

20

15

13

10

30

20

15

10

TH E ABOV E TABL ES

AR E BAS ED ON R ES UL TS OBTA INE D D U RIN G AC TUA L OP ER ATION AN D CO UL D V AR Y D EPE ND IN G ON TH E TYPE

OF MA TER IA L, GR AD ATION OF FEED , M ETH OD OF FEE DIN G , MOISTU R E AN D CL AY C ON TEN T , AN D OTH ER MA TER IAL

C HA RA CTE RISTIC S. TH E IN DIC ATED TOP S IZE , AL SO INFL U EN CE D B Y THE ABOV E CO ND ITIO NS , IS PR OVID ED TO A SSIST IN TH E

SE LE CTION OF TH E C R US HIN G EQU IPME NT TO FOL LOW . C ONTA CT YOU R DE AL ER FOR MOR E D ETA IL S.

Jaw crushers reduce large rock to smaller stone using exceptional force. The foundation

therefore must be substantial enough to support the crusher without distortion.

CRSH-OM-0003ENG(OCT-2014)

3-4

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Jaw Crusher Specifications

Jaw Crusher Specifications

Jaw Crusher Weight & Dimensions

Specifications for the jaw crusher are found in the

serial specific parts manual.

Weights and dimensions for the jaw crusher are

found in the serial specific parts manual.

CRSH-OM-0003ENG(OCT-2014)

3-5

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Jaw Crusher Capacities Chart

Jaw Crusher Capacities Chart

.

CT SERIES JAW CRUSHERS OPEN CIRCUIT MAXIMUM CAPABILITIES (STPH)

Jaw

Model

C.S.S. Size

Opening

1"

25 mm

1-1/2"

38mm

2"

50mm

2-1/2"

64mm

3"

76mm

3-1/2"

90mm

4"

100mm

5"

127mm

6"

150mm

7"

175mm

8"

200mm

9"

225mm

10"

250mm

11"

280mm

12"

305mm

CT1030

CT1040

CT1048

CT1252

CT2036

23

30

35

50

28

37

44

63

34

45

55

77

90

42

56

68

90

110

50

66

80

105

60

79

95

130

CT2436

CT2645

CT3042

NCT3042

CT3254

CT3648

CT4254

CT4763

CT6080

96

250

150

126

300

140

170

155

200

220

340

170

190

189

230

240

370

190

210

218

260

280

400

330

230

250

300

300

320

440

310-400

380-500

250-300

391

300-400

320-420

400-500

370-470

450-580

500-650

320-400

522

350-460

380-500

470-570

430-540

520-650

590-750

490-610

575-730

650-840 780-1100

550-700

630-810

740-930 860-1215

675-980

700-900 800-1010 950-1340

880-1100 1030-1455

950-1180 1120-1575

1.

The above information is bas ed on average feed material that weighs approximately 100 lbs/ft crushed of a size which is

readily fed into the crushing chamber without clogging.

2.

Capacities shown may vary depending on the type, size, moisture content, and clay content of material, the bulk density,

method of material feeding. Undersize material should be removed from the crusher feed to eliminate packing and excess

wear.

SETTINGS G REATER THAN INDICATED MAY BE WITHIN DESIGN CAPABILITIES OF THE MACHINES BUT ARE NOT

SHOWN DUE TO ANTICIPATED HIG HER OPERATING CO STS.

The above tables are based on results obtained during actual operation and could vary depending on the type of material, gradation

of feed, method of feeding, moisture and clay content, and other material characteristics. The indicated top size, also influenced by

the above c onditions, is provided to assist in the selection of the c rushing equipment to follow. Contact your dealer for more details.

CRSH-OM-0003ENG(OCT-2014)

3-3

Model CT-Series Jaw Crushers

Вам также может понравиться

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingОт EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingРейтинг: 4.5 из 5 звезд4.5/5 (9)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreОт EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreРейтинг: 4.5 из 5 звезд4.5/5 (11)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsОт EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsРейтинг: 5 из 5 звезд5/5 (1)

- Serie 60 Informacion AdicionalДокумент51 страницаSerie 60 Informacion AdicionalMauricio Campos QuirosОценок пока нет

- Gets InglesДокумент1 088 страницGets InglesKjatunMayu Gutierrez100% (6)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheОт EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.От EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Оценок пока нет

- Emco Unimat SL All AccessoriesДокумент16 страницEmco Unimat SL All AccessoriesKuso199592% (12)

- Luz de Valvulas e Inyectores Serie 60Документ6 страницLuz de Valvulas e Inyectores Serie 60Kelvin Ramirez100% (1)

- Impact Socket PDFДокумент40 страницImpact Socket PDFMr. S.L. AdvaniОценок пока нет

- Bridgeport Milling Machine OperationДокумент40 страницBridgeport Milling Machine OperationALLEN FRANCIS100% (3)

- PSK GET 9th v2Документ827 страницPSK GET 9th v2Luis PozoОценок пока нет

- Townsend CatalogДокумент88 страницTownsend CatalogVictor89% (9)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsОт EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsРейтинг: 4 из 5 звезд4/5 (1)

- How To Run A Horizontal Metalworking ShaperДокумент43 страницыHow To Run A Horizontal Metalworking ShaperALLEN FRANCIS100% (2)

- Export DocumentsДокумент22 страницыExport DocumentsHarano PothikОценок пока нет

- GEE ElectrodeДокумент17 страницGEE ElectrodeSatyamEngОценок пока нет

- Mission S and W Dims and Curve Chart PDFДокумент28 страницMission S and W Dims and Curve Chart PDFcaballero_tigreОценок пока нет

- Specifications For Crankshafts in Caterpillar Engines (1202) : Cerrar SISДокумент82 страницыSpecifications For Crankshafts in Caterpillar Engines (1202) : Cerrar SISLuis TepezanoОценок пока нет

- The GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...Документ18 страницThe GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...jlfyОценок пока нет

- Ball Bearing Case Studies enДокумент8 страницBall Bearing Case Studies ensubodh ranjanОценок пока нет

- Fletcher 2100 ManualДокумент27 страницFletcher 2100 ManualLaura Stolfi67% (3)

- Eicher MotorsДокумент7 страницEicher MotorsSuyash NigotiaОценок пока нет

- Optimize CT2436 Jaw Crusher ManualДокумент13 страницOptimize CT2436 Jaw Crusher ManualVladimir Illich Pinzon100% (1)

- Service Guide 2012Документ180 страницService Guide 2012Chang YuОценок пока нет

- Jaw Part3Документ6 страницJaw Part3jlfy100% (1)

- Torrens TitleДокумент5 страницTorrens TitleBLP Cooperative100% (1)

- Catálogo de Camisas MELLINGДокумент24 страницыCatálogo de Camisas MELLINGricassterОценок пока нет

- Bearing and Eccentric Shaft PartsДокумент6 страницBearing and Eccentric Shaft PartsjlfyОценок пока нет

- Single Toggle Jaw Crusher Manufacturers, Single Toggle Jaw Crusher For SaleДокумент3 страницыSingle Toggle Jaw Crusher Manufacturers, Single Toggle Jaw Crusher For SaleHashani Anuttara AbeygunasekaraОценок пока нет

- SH Series Cone CrusherДокумент48 страницSH Series Cone CrusherShanhu Group100% (1)

- TRIO Feeders BrochureДокумент8 страницTRIO Feeders BrochureZiggy GregoryОценок пока нет

- DJF - Model Question PaperДокумент6 страницDJF - Model Question PaperMohammedRafficОценок пока нет

- Materi 4Документ24 страницыMateri 4AuliamОценок пока нет

- NT Features03r1Документ15 страницNT Features03r1mistermango100% (2)

- GekkoДокумент6 страницGekkojlfyОценок пока нет

- GekkoДокумент6 страницGekkojlfyОценок пока нет

- Alignment Coupling Operation Manual Tyre-FlexДокумент37 страницAlignment Coupling Operation Manual Tyre-Flexer_sanjaypatelОценок пока нет

- Sandvik Jaw Crushers - ENДокумент8 страницSandvik Jaw Crushers - ENAlexis Iván Pérez GuerreroОценок пока нет

- Regulador de PrecionДокумент7 страницRegulador de PrecionjlfyОценок пока нет

- Comminution Handbook 101 125Документ25 страницComminution Handbook 101 125lucar.bazan.jose.antonioОценок пока нет

- ATT 039 Earth Drill Range SalesflashДокумент7 страницATT 039 Earth Drill Range SalesflashArturo Muñoz RamosОценок пока нет

- Jaw Coupling PDFДокумент4 страницыJaw Coupling PDFhibhavuОценок пока нет

- Virabrequim C6.6Документ5 страницVirabrequim C6.6Cesar AugustoОценок пока нет

- Jaw CrushersДокумент2 страницыJaw CrushersOrlando Melipillan0% (1)

- RaiseBoringUsersManual PDFДокумент40 страницRaiseBoringUsersManual PDFJhonatanLiCuadradoОценок пока нет

- A Liated Company of Sumitomo Heavy Industries, LTDДокумент28 страницA Liated Company of Sumitomo Heavy Industries, LTDBuciu Ioan BogdanОценок пока нет

- Doosan Puma 2600yДокумент24 страницыDoosan Puma 2600ybaumgconradoОценок пока нет

- 5188 - Jaw Selection - 2bДокумент2 страницы5188 - Jaw Selection - 2bAngel D. Córdova PortocarreroОценок пока нет

- Roller Screw BrochureДокумент8 страницRoller Screw BrochureRjgandhi65Оценок пока нет

- BB3000 Line Boring MachineДокумент8 страницBB3000 Line Boring MachineadnyaОценок пока нет

- C 107 Pulley Catalog 11 05 LowДокумент42 страницыC 107 Pulley Catalog 11 05 LowMauricio MpintoОценок пока нет

- Metal Sawing MachinesДокумент6 страницMetal Sawing MachinesRitik agarwalОценок пока нет

- Cylinder Liner Projection - Inspect: Testing and AdjustingДокумент5 страницCylinder Liner Projection - Inspect: Testing and AdjustingВиталийОценок пока нет

- Manual: STPEF0710 and STPEF0912 Jaw CrusherДокумент14 страницManual: STPEF0710 and STPEF0912 Jaw CrusherMANUEL ALBERTO CORTES ZARATEОценок пока нет

- Catalog Kafo Ka40 PDFДокумент8 страницCatalog Kafo Ka40 PDFFrederik HenderwanzaОценок пока нет

- Procedimiento de Pulido CrankshaftsДокумент19 страницProcedimiento de Pulido CrankshaftsJavier Hector CayaОценок пока нет

- Accessories WrenchesДокумент1 страницаAccessories WrenchesabbycanОценок пока нет

- MotoniveladorasДокумент22 страницыMotoniveladorasperulocaОценок пока нет

- Brake ChamberДокумент6 страницBrake ChamberEder AcasieteОценок пока нет

- User manual SANDVIK updated July 2012Документ51 страницаUser manual SANDVIK updated July 2012Pato CarmonaОценок пока нет

- HKKGHGJHT Sisweb Sisweb Techdoc Techdoc Print Page - JSPДокумент11 страницHKKGHGJHT Sisweb Sisweb Techdoc Techdoc Print Page - JSPchakrouneОценок пока нет

- Autoclave - Tools, Installation. Operation and MaintenanceДокумент16 страницAutoclave - Tools, Installation. Operation and Maintenancemaz234Оценок пока нет

- Proyeccion de Las Camisas C-9Документ4 страницыProyeccion de Las Camisas C-9Alejandro ValenzuelaОценок пока нет

- Puma 2100 2600 3100 EnglishДокумент32 страницыPuma 2100 2600 3100 EnglishUrke VukОценок пока нет

- Pedal Opperated Grain MillДокумент38 страницPedal Opperated Grain Millpitufito100% (1)

- Disc Plow SpecificationsДокумент9 страницDisc Plow SpecificationsJosé Inés Bazán Mota100% (1)

- Operation Manual LC-10EДокумент12 страницOperation Manual LC-10EKevin CaballeroОценок пока нет

- Crankshafts and Camshafts: Efficient Machining ofДокумент20 страницCrankshafts and Camshafts: Efficient Machining ofAnees SheikhОценок пока нет

- 2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenanceДокумент3 страницы2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenancejlfyОценок пока нет

- Posibles Soluciones en La OperaciónДокумент3 страницыPosibles Soluciones en La OperaciónjlfyОценок пока нет

- Motor FalconДокумент4 страницыMotor FalconjlfyОценок пока нет

- Filtro de AireДокумент7 страницFiltro de AirejlfyОценок пока нет

- Selenoid eДокумент9 страницSelenoid ejlfyОценок пока нет

- Posibles Soluciones en La OperaciónДокумент3 страницыPosibles Soluciones en La OperaciónjlfyОценок пока нет

- 2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenanceДокумент3 страницы2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenancejlfyОценок пока нет

- Digital PresureДокумент11 страницDigital PresurejlfyОценок пока нет

- Falcon C ConcentradoДокумент6 страницFalcon C ConcentradojlfyОценок пока нет

- Parametros OperativosДокумент5 страницParametros OperativosjlfyОценок пока нет

- Condiciones de OperacionДокумент2 страницыCondiciones de OperacionjlfyОценок пока нет

- ComisionamientoДокумент2 страницыComisionamientojlfyОценок пока нет

- Falcon c1000Документ9 страницFalcon c1000jlfyОценок пока нет

- Seguridad y TransporteДокумент6 страницSeguridad y TransportejlfyОценок пока нет

- C1000-R3.1 Installation, Operations, and Maintenance ManualДокумент8 страницC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyОценок пока нет

- C1000-R3.1 Installation, Operations, and Maintenance ManualДокумент8 страницC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyОценок пока нет

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceДокумент4 страницы5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyОценок пока нет

- C1000-R3.1 Installation, Operations, and Maintenance ManualДокумент6 страницC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyОценок пока нет

- C1000-R3.1 Installation, Operations, and Maintenance ManualДокумент6 страницC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyОценок пока нет

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceДокумент4 страницы5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyОценок пока нет

- Rinse AUTO Is The Standard Operating Mode For Most ApplicationsДокумент6 страницRinse AUTO Is The Standard Operating Mode For Most ApplicationsjlfyОценок пока нет

- Especificaciones 2Документ8 страницEspecificaciones 2jlfyОценок пока нет

- Rinse AUTO Is The Standard Operating Mode For Most ApplicationsДокумент6 страницRinse AUTO Is The Standard Operating Mode For Most ApplicationsjlfyОценок пока нет

- Descripcion FalconДокумент4 страницыDescripcion FalconjlfyОценок пока нет

- Dewa Noc LetterДокумент5 страницDewa Noc LetterSenthilnathan NagarajanОценок пока нет

- Elasto-Deck 5001 HT TDSДокумент3 страницыElasto-Deck 5001 HT TDSspinalfarmОценок пока нет

- Stainless Steel CatalogДокумент114 страницStainless Steel CatalogSiva KumarОценок пока нет

- CATALOGO U-Bolt Cote BrochureДокумент4 страницыCATALOGO U-Bolt Cote BrochureEdwin Junior Castillo Luzon100% (1)

- Importance of Roadways, Railways, Pipelines and Tourism in India's EconomyДокумент2 страницыImportance of Roadways, Railways, Pipelines and Tourism in India's EconomySiddharth JainОценок пока нет

- Types of LabelsДокумент22 страницыTypes of LabelsTarunMishra100% (2)

- APH Lube Oil Flushing - RajeevДокумент4 страницыAPH Lube Oil Flushing - Rajeevvishal_vajatОценок пока нет

- NPTEL Advanced Manufacturing ProcessesДокумент2 страницыNPTEL Advanced Manufacturing ProcessesNiaz ManikОценок пока нет

- Lincoln Weldman Rental CatalogueДокумент14 страницLincoln Weldman Rental Cataloguek_vasanОценок пока нет

- 27k Crane Lifting PermitДокумент1 страница27k Crane Lifting Permitsafety86Оценок пока нет

- I Grades enДокумент230 страницI Grades enDougPabitonОценок пока нет

- Reverse EngineeringДокумент3 страницыReverse EngineeringRahul SureshОценок пока нет

- Section 6. Corrosion Removal ProceduresДокумент3 страницыSection 6. Corrosion Removal ProceduresblackhawkОценок пока нет

- VSR - Popustanje Napetosti VibriranjermДокумент8 страницVSR - Popustanje Napetosti Vibriranjermdag9Оценок пока нет

- MR M G Somashekar - PG Setty Construction Technology PVT LTDДокумент78 страницMR M G Somashekar - PG Setty Construction Technology PVT LTDAnkur BaghelОценок пока нет

- Report on Bridge Structures Development in PakistanДокумент8 страницReport on Bridge Structures Development in Pakistankhawaja Ali100% (1)

- Bachelor of Science in Pharmaceutical Sciences - 2018 CurriculumДокумент3 страницыBachelor of Science in Pharmaceutical Sciences - 2018 CurriculummarkflianceОценок пока нет

- Classification of Retail Formats ExplainedДокумент36 страницClassification of Retail Formats ExplainedpraveennaikОценок пока нет

- Value Chain AnalysisДокумент33 страницыValue Chain AnalysisM ManjunathОценок пока нет

- Tilak High School English Project Yr12Документ3 страницыTilak High School English Project Yr12rosheel100% (1)