Академический Документы

Профессиональный Документы

Культура Документы

Delrin Low Emissions For Auto Applications

Загружено:

ashkansoheylОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Delrin Low Emissions For Auto Applications

Загружено:

ashkansoheylАвторское право:

Доступные форматы

DUPONT DELRIN ACETAL RESIN

E-GRADES FOR LOW VOC AUTOMOTIVE APPLICATIONS

DUPONT DELRIN E-GRADES FOR LOW EMISSIONS

DuPont Delrin acetal resin, the worlds first acetal polymer,

is a highly versatile engineering polymer which offers an

excellent balance of desirable properties that bridges the gap

between metals and ordinary plastics. Acetal polymers are

commonly referred to as polyoxymethylene or POM and parts

are commonly identified with the part marking code >POM< for

recycling purposes.

All POM Delrin E-grades for low emissions meet the automotive

industrys demanding requirements for the use of plastics

in vehicle interiors. This extends the scope of application for

Delrin acetal resins in vehicles to include plastic components in

interiors, where high resistance to impact load is required.

Product Line

Delrin E-grades for low emissions are available in several basic

melt flow series: 100, 300, and 500. These differ primarily in

melt viscosity with 100 being the most viscous and 500 being

the most fluid. A wide range of Delrin E-grades acetal resin

are available to meet specific customer needs for demanding

applications:

Unreinforced resins (PE-grades)

Toughened and super tough resins (TE-grades)

UV-stabilized grades (UVE-grades)

Spring element made of DuPont Delrin 100PE for

steering column

As is typical for all Delrin acetal resins, the new low

emission grades combine high impact resistance, even at low

temperatures, with high stiffness, strength and elongation. It

provides high surface hardness, very low wear and friction,

resiliency and a high resistance to chemicals and solvents.

Testing by the SGS Institut Fresenius GmbH in Germany,

in accordance with the VDA standard 275, confirms that all

E-grades of Delrin meet the demanding emission requirements

of the worlds major automotive manufacturers. The SGS testing

revealed emissions of below 2 mg/kg for all grades, while internal

testing showed their strength, stiffness and impact resistance to

be similar or better than the standard grades.

Applications

Delrin E-grades for low emissions are suitable for applications

such as:

fasteners

seatbelt components

headrest adjusters

levers

brackets

gears

switches

buckles

latches

components with snap-in joints

Bearing plate of safety belt retractor from Autoliv

made of DuPont Delrin 300TE

DUPONT DELRIN E-GRADES FOR LOW EMISSIONS

PE Grades

DuPont Delrin PE grades for low emissions are unreinforced grades that are very suitable for applications located within

the vehicles interior as they offer less than 2 mg/kg emission of volatile particles per VDA275, meeting the requirements

of the global automotive industry and performing as well as standard Delrin products.

Delrin 100PE

Delrin 500PE

high viscosity

medium viscosity

maximum toughness without impact modification

optimum mechanical performance

enhanced version of Delrin 500P with extremely

low emissions

high heat deflection temperature

improved processing thermal stability

good balance of melt flow vs. mechanical properties

Delrin 300PE

medium-high viscosity

greater design flexibility and freedom

high mechanical properties with ease of process in mind

enables wall thicknesses reduction with good resin flow in

complex parts

improved weld line strength

UV Stabilized Grades

DuPont Delrin UVE grades for low emissions are UV stabilized acetal resins and are available in 3 different viscosities:

Delrin 127 UVEhigh viscosity

Delrin 327 UVEmedium-high viscosity

Delrin 527 UVEmedium viscosity

As Delrin PE grades, UVE grades offer less than 2 ppm emission of volatile particles.

Units

Delrin

100PE

NC010

Delrin

300PE

NC010

Delrin

500PE

NC010

Delrin

127UVE

NC010

Delrin

327UVE

NC010

Delrin

527UVE

NC010

ISO 527

MPa

72

72

74

71

71

72

Yield Strain

ISO 527

25

20

15

25

20

15

Nominal Strain at Break

ISO 527

45

35

25

45

40

25

Tensile Modulus

ISO 527

MPa

3100

3200

3300

2900

3000

3100

Flexural Modulus

ISO 178

MPa

2900

3100

3100

2800

3000

Notched Charpy Impact Strength, 30 C

ISO 179/1eA

KJ/m

12

10

Notched Charpy Impact Strength, 23 C

ISO 179/1eA

KJ/m

15

11

10

14

10

Unnotched Charpy Impact Strength, 23 C

ISO 179/1eU

KJ/m2

380

300

300

390

350

280

Deflection Temperature, 1.8 MPa

ISO 75-1/-2

96

95

100

91

91

93

Melt Flow Rate, 2.16 kg/190 C

ISO 1133

g/10 min

2.3

14

2.5

15

Density

ISO 1183

kg/m

1420

1420

1420

1420

1420

1420

VOC Emissions

VDA 275

mg/kg

<2

<2

<2

<2

<2

<2

Property

Test

Method

Yield Stress

DUPONT DELRIN E-GRADES FOR LOW EMISSIONS

TE and STE Grades

Delrin 100STE

DuPont Delrin TE grades for low emissions are toughened grades

offering less than 2 mg/kg emission of volatile particles. They are

available in 3 different viscosities and different levels of toughener while

keeping the same performance as standard toughened Delrin grades.

super tough, high viscosity

superior impact resistance

best combination of stiffness and impact

resistance at very low temperature

use in easy-to-fill molds

Delrin 100TE

toughened, high viscosity resin

Delrin 500TE

outstanding impact resistance and good moldability

toughened, medium viscosity

good friction partner in gear applications

high impact resistance

designed for highly stressed parts where outstanding

toughness is required

optimized flow properties and impact performance

good friction partner in gear applications

low noise properties

Delrin 300TE

toughened, medium-high viscosity

very good balance of melt flow and impact properties

low noise properties

Test Method

Units

Delrin 100STE

NC010

Delrin 100TE

NC010

Delrin 300TE

NC010

Delrin 500TE

NC010

Yield Stress

ISO 527

MPa

43

54

54

52

Yield Strain

ISO 527

35

25

20

20

Nominal Strain at Break

ISO 527

>50

>50

35

35

Tensile Modulus

ISO 527

MPa

1300

1850

2000

2150

Flexural Modulus

ISO 178

MPa

Notched Charpy Impact Strength, 30 C

ISO 179/1eA

Notched Charpy Impact Strength, 23 C

Property

1250

1850

1900

2050

KJ/m

17

14

10

ISO 179/1eA

KJ/m

90

25

18

11

Unnotched Charpy Impact Strength, 23 C

ISO 179/1eU

KJ/m

No Break

No Break

No Break

Deflection Temperature, 1.8 MPa

ISO 75-1/-2

64

71

71

76

Melt Flow Rate, 2.16 kg/190 C

ISO 1133

g/10 min

2.3

2.2

10

Density

ISO 1183

kg/m3

1330

1370

1380

1370

VOC Emissions

VDA 275

mg/kg

<2

<2

<2

<2

North America

DuPont Performance Polymers

Wilmington, Delaware

Tel +1 302 999-4592

South America

DuPont do Brasil, S.A.

Barueri, SP Brasil

Tel +55 11 4166 8531/8647

Asia Pacific

DuPont China Holding Co., Ltd.

DuPont Kabushiki Kaisha

Shanghai, China

Tokyo, Japan

Tel +86 21 3862 2888

Tel +81 3 5521 8500

Europe/Middle East/Africa

DuPont International Operations Sarl

Geneva, Switzerland

Tel +41 22 717 51 11

plastics.dupont.com

Copyright 2013 DuPont. The DuPont Oval Logo, DuPont , The miracles of science, and Delrin are trademarks or registered trademarks of E.I. du Pont de Nemours and Company or its affiliates. All rights reserved.

DuPont (NYSE: DD) has been bringing world-class science and engineering to the global marketplace in the form of innovative products, materials, and services since 1802. The company believes that by

collaborating with customers, governments, NGOs, and thought leaders we can help find solutions to such global challenges as providing enough healthy food for people everywhere, decreasing dependence on

fossil fuels, and protecting life and the environment. For additional information about DuPont and its commitment to inclusive innovation, please visit www.dupont.com.

(10/13)

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- T 176Документ9 страницT 176ashkansoheylОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Wwii Aircraft Vol 2Документ50 страницWwii Aircraft Vol 2Virág Árpád100% (5)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Week 8 Sheet Metal FormingДокумент69 страницWeek 8 Sheet Metal FormingashkansoheylОценок пока нет

- Professional CV FormatДокумент2 страницыProfessional CV FormatShawn ParkerОценок пока нет

- Geothermal Project TimelinesДокумент10 страницGeothermal Project TimelinesAldwin EncarnacionОценок пока нет

- FMEA Ford PDFДокумент32 страницыFMEA Ford PDFashkansoheyl100% (2)

- CCNA - Access List QuestionsДокумент3 страницыCCNA - Access List QuestionsBaaska214Оценок пока нет

- Research Proposal GuidelinesДокумент8 страницResearch Proposal Guidelineskomal khalidОценок пока нет

- MBR Presentation LatestДокумент12 страницMBR Presentation LatestRuchi GuptaОценок пока нет

- Hytrel Extrusion Manual PDFДокумент28 страницHytrel Extrusion Manual PDFashkansoheylОценок пока нет

- Significantly Regulated Organizations Added in February 2017Документ10 страницSignificantly Regulated Organizations Added in February 2017ashkansoheylОценок пока нет

- 154963guidance Consumer PDFДокумент90 страниц154963guidance Consumer PDFashkansoheylОценок пока нет

- Laboratory Glassware CatalogueДокумент52 страницыLaboratory Glassware CatalogueashkansoheylОценок пока нет

- Hytrel Product Reference GuideДокумент4 страницыHytrel Product Reference GuideashkansoheylОценок пока нет

- General Design Principles For Machining, Cutting and FinishingДокумент8 страницGeneral Design Principles For Machining, Cutting and FinishingashkansoheylОценок пока нет

- Crastin PBT and Rynite PET Design Info Module IV PDFДокумент67 страницCrastin PBT and Rynite PET Design Info Module IV PDFashkansoheyl100% (1)

- Extrusion Applications PDFДокумент23 страницыExtrusion Applications PDFashkansoheylОценок пока нет

- ME 4232: Fluid Power Controls Lab: Class #6 Hydraulic PumpsДокумент45 страницME 4232: Fluid Power Controls Lab: Class #6 Hydraulic Pumpsashkansoheyl100% (1)

- 7.sieve Analysis AhmedДокумент9 страниц7.sieve Analysis AhmedJin AhmedОценок пока нет

- User Manual For Online Super Market WebsiteДокумент3 страницыUser Manual For Online Super Market WebsiteTharunОценок пока нет

- Operaional Manual: YZBF-120LDДокумент16 страницOperaional Manual: YZBF-120LDMohamed AnwarОценок пока нет

- Payment Advice Outward Telegraphic Transfer: DateДокумент2 страницыPayment Advice Outward Telegraphic Transfer: DateRomanov DalsheОценок пока нет

- Riphah Project GuidelinesДокумент14 страницRiphah Project GuidelinesTanveer AhmedОценок пока нет

- Case Study of Improving Productivity in Warehouse WorkДокумент5 страницCase Study of Improving Productivity in Warehouse WorkRohan SharmaОценок пока нет

- Plug Design Case StudyДокумент24 страницыPlug Design Case StudyAnonymous EsZwKlnBОценок пока нет

- Opoc Engine ReportДокумент34 страницыOpoc Engine Reportapi-32792277367% (3)

- Void Acoustics 2017 BrochureДокумент28 страницVoid Acoustics 2017 BrochureCraig ConnollyОценок пока нет

- Padma Vibhushan Dr. G. Madhavan NairДокумент7 страницPadma Vibhushan Dr. G. Madhavan NairjishnusajiОценок пока нет

- Causes of Boiler Tube Leakage and MeasuresДокумент19 страницCauses of Boiler Tube Leakage and MeasuresNhật TuấnОценок пока нет

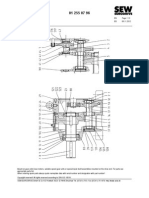

- Parts List 01 255 07 96: Helical Gear Unit R107Документ3 страницыParts List 01 255 07 96: Helical Gear Unit R107Parmasamy Subramani50% (2)

- Database Testing: Prepared by Sujaritha MДокумент21 страницаDatabase Testing: Prepared by Sujaritha Mavumaa22Оценок пока нет

- PAC4200 Product GuideДокумент4 страницыPAC4200 Product GuideHugo Alberto Malespin SolisОценок пока нет

- New DatabaseДокумент18 страницNew DatabaseShafiq RosmanОценок пока нет

- Scania TruckAndBus 2023Документ403 страницыScania TruckAndBus 2023Piotr ZiąbkowskiОценок пока нет

- Kendriya Vidyalaya, Tagore Garden Recruitment of Contractual Teachers For The Session 2013-14Документ8 страницKendriya Vidyalaya, Tagore Garden Recruitment of Contractual Teachers For The Session 2013-14ombidasarОценок пока нет

- CNC Grinding Notching and Marking Machine: AT 710 ENДокумент2 страницыCNC Grinding Notching and Marking Machine: AT 710 ENsmarjanОценок пока нет

- Core Insights: Advances in 12G-SDIДокумент3 страницыCore Insights: Advances in 12G-SDIHedsdasОценок пока нет

- Analysis of Business EnvironmentДокумент10 страницAnalysis of Business Environmentrashmi123vaish50% (2)

- Gardenia RedddДокумент44 страницыGardenia RedddYasmin Yvonne De Chavez100% (1)

- Draw 224-1Документ8 страницDraw 224-1Alther Dabon33% (3)

- Value Creation Through Project Risk ManagementДокумент19 страницValue Creation Through Project Risk ManagementMatt SlowikowskiОценок пока нет