Академический Документы

Профессиональный Документы

Культура Документы

P91 Welding Procedure Specification

Загружено:

Pepe SagitarioОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

P91 Welding Procedure Specification

Загружено:

Pepe SagitarioАвторское право:

Доступные форматы

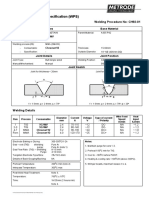

Welding Procedure Specification (WPS)

Welding Procedure No: CH9MVN-01

Consumables

Welding process (root):

Base Material

TIG (GTAW)

Parent Material:

Consumable:

9CrMoV-N

Specification:

BS EN: W CrMo 91

AWS: ER90S-B9

Welding process (fill):

A335 P91

ASME IX P-Number 5B

MMA (SMAW)

Consumable:

Chromet 9MV-N

Thickness:

15-60mm

Specification:

BS EN, E CrMo 91 B

Outside Diameter:

16 NB (406mm OD)

Joint Details

Joint Position

Joint Type:

Butt single sided

Manual/Mechanised:

Manual

Welding Position:

ASME: 5G

BS EN: PF

Joint Sketch

Joint for thickness < 20mm

Joint for thickness > 20mm

f = 1-3mm; g = 2-4mm; = 70

f = 1-3mm; g = 2-4mm; = 70; = 20

Welding Details

Run

Process

Consumable

Diameter

mm

Current

A

Voltage

V

Type of current

/ Polarity

Wire Feed

Speed

m/min

Heat

Input

kJ/mm

1

2-3

4-7

Rem

TIG

TIG

MMA

MMA

9CrMoV-N

9CrMoV-N

Chromet 9MV-N

Chromet 9MV-N

2.4

2.4

3.2

4.0

70-110

80-140

90-130

120-170

~12

~12

~24

~25

DCDCDC+

DC+

NA

NA

NA

NA

~1.2

~ 1.2

~ 1.0

~ 1.2

Notes:

Electrode Baking or Drying:

Gas root (TIG)

shielding:

purge:

Gas Flow Rate (TIG) Shielding:

Purge:

Tungsten Electrode Type/Size:

300-350 C/1-2h

Pure Ar

Pure Ar (note 1)

8-15 l/min

4-10 l/min

2% Th/2.4mm

3. Cool to ~100 C before PWHT.

Details of Back Gouging/Backing:

NA

4. Heating & cooling rate <100 C/h (above 300C).

Preheat Temperature:

200 C min (note 2)

2. Preheat 150 C min for TIG.

o

o

o

Interpass Temperature:

300 C max

Post-Weld Heat Treatment:

Note 3.

Temperature:

760 C 10 C

Time:

1h/25mm (2 hours min)

Note 4.

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

1. Maintain purge for runs 1-3.

5. Stringer beads, maximum weave 3 x .

Welding Procedure Specification (WPS)

Welding Procedure No: CH9MVN-02

Consumables

Welding process (root):

Base Material

NA

Consumable:

Specification:

Welding process (fill):

Parent Material:

A335 A217 C12A ((cast)

ASME IX P-Number 5B

MMA (SMAW)

Consumable:

Chromet 9MV-N

Thickness:

15-60mm

Specification:

BS EN, E CrMo 91 B

Outside Diameter:

Joint Details

Joint Position

Joint Type:

Butt/groove

Manual/Mechanised:

Manual

Welding Position:

ASME, 1G

BS EN, PA

Joint Sketch

R =8-12mm; = 20-30

Welding Details

Run

Process

Consumable

Diameter

mm

Current

A

Voltage

V

Type of current

/ Polarity

Wire Feed

Speed

m/min

Heat

Input

kJ/mm

MMA

MMA

MMA

Chromet 9MV-N

Chromet 9MV-N

Chromet 9MV-N

3.2

4.0

5.0

90-135

130-180

160-240

~23

~24

~25

DC+

DC+

DC+

NA

NA

NA

~ 1.2

~ 1.4

~ 1.8

Electrode Baking or Drying:

Gas root (TIG)

shielding:

purge:

Gas Flow Rate (TIG) Shielding:

Purge:

Tungsten Electrode Type/Size:

300-350 C/1-2h

NA

NA

NA

NA

NA

Details of Back Gouging/Backing:

NA

Preheat Temperature:

200 C min

Interpass Temperature:

300 C max

Post-Weld Heat Treatment:

Note 1.

Temperature:

745 C 10 C

Time:

8 hours

o

o

Note 2.

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

Notes:

o

1. Cool to ~100 C before PWHT.

o

2. Heating & cooling rate <100 C/h (above 300C).

Welding Procedure Specification (WPS)

Welding Procedure No: CH9B9-01

Consumables

Welding process (root):

Base Material

TIG (GTAW)

Parent Material:

Consumable:

9CrMoV-N

Specification:

AWS ER90S-B9 (note 1).

Welding process (fill):

A335 P91

ASME IX P-Number 5B

MMA (SMAW)

Consumable:

Chromet 9-B9

Thickness:

15-60mm

Specification:

AWS E9015-B9 (note 2).

Outside Diameter:

16 NB (406mm OD)

Joint Details

Joint Position

Joint Type:

Butt single sided

Manual/Mechanised:

Manual

Welding Position:

ASME, 5G

BS EN, PF

Joint Sketch

Joint for thickness < 20mm

Joint for thickness > 20mm

f = 1-3mm; g = 2-4mm; = 70

f = 1-3mm; g = 2-4mm; = 70; = 20

Welding Details

Run

Process

Consumable

Diameter

mm

Current

A

Voltage

V

Type of current

/ Polarity

Wire Feed

Speed

m/min

Heat

Input

kJ/mm

1

2-3

4-7

Rem

TIG

TIG

MMA

MMA

9CrMoV-N

9CrMoV-N

Chromet 9-B9

Chromet 9-B9

2.4

2.4

3.2

4.0

70-110

80-140

90-130

120-170

~12

~12

~24

~25

DCDCDC+

DC+

NA

NA

NA

NA

~ 1.2

~ 1.2

~ 1.0

~ 1.2

Notes:

Electrode Baking or Drying:

Gas root (TIG)

shielding:

purge:

Gas Flow Rate (TIG) Shielding:

Purge:

Tungsten Electrode Type/Size:

300-350 C/1-2h

Pure Ar

Pure Ar (note 3)

8-15 l/min

4-10 l/min

2% Th/2.4mm

3. Maintain purge for runs 1-3.

Details of Back Gouging/Backing:

NA

4. Preheat 150 C min for TIG.

Preheat Temperature:

200 C min (note 4)

Interpass Temperature:

300 C max

Post-Weld Heat Treatment:

Note 5.

Temperature:

760 C 10 C

Time:

1h/25mm (2 hours min)

2. ASME IX, QW-442 A-number 5.

5. Cool to ~100 C before PWHT.

6. Heating & cooling rate <100 C/h (above 300C).

Note 6.

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

1. ASME IX, QW-432 F-number 4.

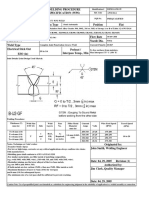

Welding Procedure Specification (WPS)

Welding Procedure No: CMM91-01

Consumables

Welding process (root):

Base Material

TIG (GTAW)

Parent Material:

Consumable:

9CrMoV-N

Specification:

BS EN: W CrMo 91

Welding process (fill):

A335 P91

ASME IX P-Number 5B

MIG (GMAW)

Consumable:

Cormet M91 (MCW)

Thickness:

15-60mm

Specification:

AWS: ER90C-G

Outside Diameter:

Joint Details

Joint Position

Joint Type:

Butt single sided

Manual/Mechanised:

Manual

Welding Position:

ASME, 1G

BS EN, PA

Joint Sketch

Joint for thickness < 20mm

Joint for thickness > 20mm

f = 1-3mm; g = 2-4mm; = 70

f = 1-3mm; g = 2-4mm; = 70; = 20

Welding Details

Run

Process

Consumable

Diameter

mm

Current

A

Voltage

V

Type of current

/ Polarity

Wire Feed

Speed

m/min

Heat

Input

kJ/mm

15

-

TIG

MCW

MCW

9CrMoV-N

Cormet M91

Cormet M91

2.4

1.2

1.6

70-110

240-280

270-330

~12

~28

~29

DCDC+ (note 1)

DC+ (note 2)

NA

~10

~7

~1.2

~ 1.6

~ 2.0

Notes:

Electrode Baking or Drying:

Gas (Cormet M91) shielding:

purge:

Gas Flow Rate Shielding:

Purge:

Tungsten Electrode Type/Size:

NA

Ar-2.5%CO2

Ar

15-25 l/min

4-10 l/min

2% Th/2.4mm

3. Preheat 150 C min for TIG.

Details of Back Gouging/Backing:

NA

4. Cool to ~100 C before PWHT.

Preheat Temperature:

200 C min (note 3)

Interpass Temperature:

300 C max

Post-Weld Heat Treatment:

Note 4.

Temperature:

760 C 10 C

Time:

1h/25mm (2 hours min)

2. Electrode stickout 15-25mm.

o

o

o

Note 5.

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

1. Electrode stickout 10-20mm.

5. Heating & cooling rate <100 C/h (above 300C).

Welding Procedure Specification (WPS)

Welding Procedure No: SCF91-01

Consumables

Welding process (root):

Base Material

TIG (GTAW)

Parent Material:

Consumable:

9CrMoV-N

Specification:

AWS: ER90S-B9

Welding process (fill):

A335 P91

ASME IX P-Number 5B

Thickness:

15-60mm

Joint Details

MMA

Consumable:

Chromet 9MV-N

Joint Type:

Single side butt weld

Specification:

AWS: E9015-B9

Manual/Mechanised:

Manual

Welding process (fill):

Joint Position

FCAW

Consumable:

Supercore F91 (Note 1)

Specification:

Welding Position:

ASME: 6G

BS EN: HL045

Joint Sketch

Welding Sequences

f = 1-2mm; g = 3-4mm; = 75; = 10-20

Welding Details

Run

Process

Consumable

Diameter

mm

Current

A

Voltage

V

Type of

current /

Polarity

Wire Feed

Speed

m/min

Heat

Input

kJ/mm

1

2-6

Fill

TIG

MMA

FCW

9CrMoV-N

Chromet 9MV-N

Supercore F91

2.4

3.2

1.2

80-120

90-110

160-190

~12

~22

25-27

DCDC+

DC+ (Note 2)

NA

NA

~6-8

~1.4

~1.0

~1.2

Notes:

Electrode Baking or Drying:

Gas root (TIG)

shielding:

purge:

Gas Flow Rate (TIG) Shielding:

Purge:

Tungsten Electrode Type/Size:

300-350C/1-2h

Argon

Argon (Note 3)

8-12 l/min

4-10 l/min

2% Th / 2.4mm

3. Maintain purge for at least first two runs.

Details of Back Gouging/Backing:

NA

4. Preheat 150C min for TIG.

Preheat Temperature:

200C min (note 4)

5. Cool to ~100C before PWHT.

Interpass Temperature:

300C

6. Heating & cooling rate <100C/h (above 300C).

Post-Weld Heat Treatment:

Note 5.

Temperature:

760C 10C

Time:

1 h/25mm (min 3 hours)

Note 6.

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

1. Shielding gas Ar-20%CO2 at 15-25 l/min.

2. Electrode stickout 15-25mm.

Welding Procedure Specification (WPS)

Welding Procedure No: SAW-P91-01

Consumables

Welding process (root):

Base Material

TIG (GTAW)

Parent Material:

A335 P91

25-75mm

Consumable:

9CrMoV-N

Thickness:

Specification:

BS EN, W CrMo 91

Outside diameter:

Welding process (hot pass):

ASME IX P-No. 5B

Joint Details

MMA (SMAW)

Consumable:

Chromet 9MV-N

Joint Type:

Butt single sided

Specification:

BS EN E CrMo 91 B

Manual/Mechanised:

Manual & mechanised

Welding process (fill):

Joint Position

SAW

Consumable:

9CrMoV-N + LA491 (flux)

Specification:

BS EN S CrMo 91 (wire).

Welding Position:

ASME, 1G (1GR; note 6).

BS EN, PA (note 6).

Joint Sketch

f = 13mm; g = 2-4mm; = 70; = 20

Welding Details

Run

Process

Consumable

Diameter

mm

Current

A

Voltage

V

Type of

current /

Polarity

Travel

Speed

mm/min

Heat

Input

kJ/mm

1

2-3

4-7

Rem

TIG

TIG

MMA

SAW (note 1)

9CrMoV-N

9CrMoV-N

Chromet 9MV-N

9CrMoV-N

2.4

2.4

3.2

2.4

70-110

80-140

90-130

350-450

~12

~12

~24

~30

DCDCDC+

DC+

NA

NA

NA

400-500

~ 1.0

~ 1.2

~ 1.2

~ 2.0

Notes:

Electrode & Flux Drying:

Gas root (TIG)

shielding:

purge:

Gas Flow Rate (TIG) Shielding:

Purge:

Tungsten Electrode Type/Size:

300-350 C/1-2h

Pure Ar

Pure Ar (note 2)

8-15 l/min

4-10 l/min

2% Th/2.4mm

2. Maintain purge for runs 1-3.

Details of Back Gouging/Backing:

NA

3. Preheat 150 C min for TIG.

Preheat Temperature:

200 C min (note 3)

Interpass Temperature:

300 C max

Post-Weld Heat Treatment:

Note 4.

~20mm wire extension, ~30mm flux depth.

4. Cool to <100 C before PWHT.

5. Heating & cooling rate <100 C/h (above 300C).

6. For rotated pipe, head to be 10 before TDC

o

760 C 10 C

Time:

1h/25mm (2 hours min)

Note 5.

Temperature:

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

1. SAW flux LA491.

perpendicular to pipe.

Вам также может понравиться

- P91 Profile WpsДокумент6 страницP91 Profile WpsZead Ali Adal100% (2)

- WPS P91Документ6 страницWPS P91JoseAlbertoNeyraОценок пока нет

- WPS - EngineerДокумент20 страницWPS - Engineerhunghoanglong100% (1)

- Loading Unloading Temperature Welding ProgressionДокумент5 страницLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- P 91 - Welding WPSДокумент2 страницыP 91 - Welding WPSSuhailshah123475% (4)

- Superduplex Welding Procedure Specification (WPSДокумент4 страницыSuperduplex Welding Procedure Specification (WPSClaudia Mms100% (3)

- 1035 03Документ2 страницы1035 03Anuj ShahiОценок пока нет

- P91 Profile WpsДокумент6 страницP91 Profile WpsManzar KhanОценок пока нет

- WPS PQR 12Документ9 страницWPS PQR 12Ranjan KumarОценок пока нет

- Wps Is 2062 GR B Butt-OkДокумент2 страницыWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- WPS, PQR & WPQTДокумент14 страницWPS, PQR & WPQTSky RОценок пока нет

- P91 Welding ProcedureДокумент1 страницаP91 Welding ProcedureJaymin100% (2)

- Welding Procedure SpecificationДокумент3 страницыWelding Procedure SpecificationGodwin A.udo-akanОценок пока нет

- Preliminary WPS for 12.7mm SMAW WeldingДокумент3 страницыPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- Wps p91 - BhelДокумент2 страницыWps p91 - BhelAshish Gupta100% (4)

- MIZAT PWHT Procedure Ensures Welded Joints Meet StandardsДокумент9 страницMIZAT PWHT Procedure Ensures Welded Joints Meet StandardsM. R. Shahnawaz KhanОценок пока нет

- Super Duplex Stainless SteelДокумент1 страницаSuper Duplex Stainless SteelUma Shankar100% (1)

- P numbers welding guideДокумент20 страницP numbers welding guideMOHANОценок пока нет

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSДокумент2 страницыSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSsuria qaqcОценок пока нет

- Welder Visual Inspection ReportsДокумент24 страницыWelder Visual Inspection ReportsKyОценок пока нет

- Utoc Preliminary Wps Shell Project 270807 PDFДокумент55 страницUtoc Preliminary Wps Shell Project 270807 PDFErick HoganОценок пока нет

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Документ2 страницыWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajОценок пока нет

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Документ2 страницы(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS API1104 A516 GR 70Документ1 страницаWPS API1104 A516 GR 70Erick HoganОценок пока нет

- Metrode - P92 WPS PDFДокумент3 страницыMetrode - P92 WPS PDFXing ChenОценок пока нет

- Metrode Dissimilar Consumable SelectorДокумент7 страницMetrode Dissimilar Consumable SelectorClaudia MmsОценок пока нет

- All Materials DocumentsДокумент1 страницаAll Materials DocumentsHarnish BariaОценок пока нет

- Hastelloy C-276 WeldingДокумент4 страницыHastelloy C-276 WeldingClaudia MmsОценок пока нет

- WPS PQR-01Документ9 страницWPS PQR-01Ranjan Kumar0% (1)

- Heat Treatment Procedure GuideДокумент15 страницHeat Treatment Procedure GuideVijay ShamОценок пока нет

- PQR 014 (Qualified Sa 106 GR BДокумент5 страницPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- PWHTДокумент13 страницPWHTcv100% (2)

- WPSДокумент3 страницыWPSKhurram Burjees100% (1)

- Electrode Selection ChartДокумент4 страницыElectrode Selection Chartsunitbhaumik100% (2)

- Welding of P91Документ37 страницWelding of P91Shyam Sundar GayenОценок пока нет

- Metrode Welding Duplex & Superduplex Stainless SteelsДокумент18 страницMetrode Welding Duplex & Superduplex Stainless SteelsClaudia Mms50% (2)

- QW-483 BlankДокумент2 страницыQW-483 BlankCraftyBob100% (1)

- Welding Procedure Specification For Storage Tank & Piping SystemДокумент3 страницыWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadОценок пока нет

- ASME 9 Calculator Approval RangesДокумент2 страницыASME 9 Calculator Approval RangesEmel Besir100% (1)

- WPS, PQR & WPQ - Duplex 2205Документ20 страницWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- Review WPS/PQR Road Map AcceptanceДокумент1 страницаReview WPS/PQR Road Map AcceptanceBaraa AzebОценок пока нет

- Pipe PWHTДокумент3 страницыPipe PWHTTridib Dey0% (1)

- Gmaw Complete Aws d1.6Документ1 страницаGmaw Complete Aws d1.6Silvia CardenasОценок пока нет

- OCS Engineering & Construction Visual Inspection ReportДокумент1 страницаOCS Engineering & Construction Visual Inspection ReportvinothОценок пока нет

- WPS Sa 335 P91 PipeДокумент3 страницыWPS Sa 335 P91 Pipecsankarananth50% (2)

- WPS - PQR (Sa516 GR.70)Документ4 страницыWPS - PQR (Sa516 GR.70)miltonangulomorrisОценок пока нет

- Multiple PQR QualificationДокумент4 страницыMultiple PQR QualificationKarthikeyan ShanmugavelОценок пока нет

- Welding Procedure SpecificationДокумент3 страницыWelding Procedure SpecificationAhmed saber100% (1)

- Welding of P91Документ37 страницWelding of P91nishant361100% (4)

- Electrodes ConsumablesДокумент2 страницыElectrodes Consumablesranjith_007100% (2)

- 3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFДокумент11 страниц3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFManoj Balla100% (1)

- WPS FormatДокумент1 страницаWPS FormatAbdullah AnsariОценок пока нет

- PQR-WPS-WPQR XXX Rev 0Документ6 страницPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Документ2 страницыWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyОценок пока нет

- Wps Sp14 Reva PDFДокумент9 страницWps Sp14 Reva PDFravi00098Оценок пока нет

- MPCC 20 WPS12Документ3 страницыMPCC 20 WPS12hekayat71Оценок пока нет

- Scan 0002Документ1 страницаScan 0002Marjolein VerhoevenОценок пока нет

- p22MNVMB MN Gtaw+Smaw (Pipe)Документ2 страницыp22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1Оценок пока нет