Академический Документы

Профессиональный Документы

Культура Документы

Steam Turbine 2

Загружено:

yuwarajaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Steam Turbine 2

Загружено:

yuwarajaАвторское право:

Доступные форматы

POLITEKNIK SULTAN SALAHUDDIN ABDUL AZIZ SHAH

Mechanical Engineering Department

WORK SHEET

Programme

Diploma Engineering in Mechanical

Course Code

DJJ2073 Thermodynamics 1

Title

Steam Turbine

Lab. No.

DJJ2073 - 2

CLO (COURSE LEARNING OUTCOMES)

1. Apply the fundamentals of thermodynamics to solve related problems ( C3,

PLO1)

2. Organize appropriately experiments in groups according to the

standard Operating Procedures (P4)

3. Demonstrate the ability to work in team to complete assigned tasks . ( A3)

ACTION

NAME & DESIGNATION

Prepared by:

Mohd Zulkarnaen Bin Mohd

Ibrahim

Checked by:

Approved by:

SIGNATURE

DATE

DJJ2073 THERMODYNAMICS

EXPERIMENT

TITLE

DURATION

PAGE

1.0

:

:

:

:

DJJ2073 2

STEAMTURBINE

15HOURS

10F 4

Experiment outcomes

At the end of the lab session students should be able:

1) Todemonstrate steam turbine

2) Todetermine the turbine shaft power and generated electrical power

3) Todeterminethe effect of steam temperature on turbine

2.0

Theory

A steam turbine is a device that converts the thermal energy of steam into

mechanical energy by using it to turn the blades of a rotor. High-temperature,

high-pressure steam passes through a nozzle or fixed blades and spurts out

and expands, or has its direction altered into a high-speed jet that is directed

against rotor blades which spin the shaft to which they are attached, creating

rotational energy. In simple terms, the steam turbine's rotors are turned by

the force of the steam in just the same way that a waterwheel is turned by

the force of the flowing water.

Prepared by : Mohd Zulkarnaen

Bin Mohd Ibrahim

DJJ2073 THERMODYNAMICS

EXPERIMENT

TITLE

DURATION

PAGE

:

:

:

:

DJJ2073 2

STEAMTURBINE

15HOURS

20F 4

Steam turbines used in electric power plants, factories, etc. use boilers

burning fossil fuels such as coal, fuel oil, or natural gas, or alternative fuels

such as biomass, refuse, or other waste materials, in order to produce large

quantities of superheated, high-pressure steam. This steam is channeled into

the turbine, where it is ejected from nozzles. At that instant, the

depressurization (expansion) of the steam creates a high-speed flow

(pressure is converted to velocity: Bernoulli's theorem). This jet of steam is

then directed against the turbine blades, causing them to revolve (velocity is

converted to kinetic energy).

Depending upon the behavior of the steam in the vicinity of the blades,

steam turbines are divided into two major classes: impulse turbines and

reaction turbines. In impulse turbines, high-velocity steam from fixed nozzles

impacts the blades, and this impulse drives the blades forward, causing the

rotor to turn. The main feature of these turbines is that the heat drop per

stage can be quite large, allowing for large blades and a smaller number of

stages. In reaction turbines, high-velocity steam from nozzles striking blades

also produces impulse, but the steam jet runs into the blades and the main

force turning the rotor is the reactive force produced by the expansion of

steam flowing off the rotor blades themselves. The main feature of this type

of turbine is that in contrast to the impulse turbine, the heat drop per stage is

lessened, so the blades become smaller and the number of stages increases.

Further sub classification of turbines is possible based upon the number of

rotor stages, steam extraction, direction of vapor flow, and so forth.

3.0

Apparatus/Equipments

1) Vapor Pressure Power Apparatus

2) Data Acquisition Software for LS-17123 Vapor Pressure Power Apparatus

3) 4LTapWater

4.0

Safety Precautions

1) Keep all body parts away from the boiler and system piping when in

2)

3)

4)

5)

6)

operation to avoid injury

Always use personal protective equipment (heat resistant gloves and

protection glasses) when operating this system.

Always ensure that the boiler vessel is filled with water until half full

before operating to prevent heater burnout.

Ensure that the boiler valves are kept closed when the system is in

operating.

Keep all body parts and objects away from the relief valve blowdown line.

Keep all body parts and objects away from the moving mechanical parts of

the turbine and generator.

Prepared by : Mohd Zulkarnaen

Bin Mohd Ibrahim

DJJ2073 THERMODYNAMICS

EXPERIMENT

TITLE

DURATION

PAGE

5.0

:

:

:

:

DJJ2073 2

STEAMTURBINE

15HOURS

30F 4

Procedures

1. Connect the water inlet port at the bottom of the boiler to a water supply.

2. Connect the outlet port at the top of the boiler, relief valve blowdown line

and the discharge port to a drain.

3. Open the lower valve and the throttling valve. Fill the boiler vessel with

tap water until half full. Ensure that the heater cartridge is completely

submerged in water.

4. Close both of the valves.

5. Switch on the mains switch.

6. Set the temperature to 160C and switch on heater

7. Once the boiler temperature reaches 90C, slowly open the upper valve

on the boiler. This is to remove any air deposit in the boiler. Once steam

flows out steadily from the top outlet, fully close the upper valve.

8. Run the Data Acquisition Software and press start to begin data logging.

9. Once the boiler reaches a pressure of at least 4.0 bar (g), slowly open the

turbine valve. Allow theturbine speed to gradually pick up.

10. Fully open the turbine valve.

11. One by one, switch on lamps on the load bank until all four lamps are

switched on. Between switching on each lamp, allow the turbine to run for

5 to 10 seconds at the same time write down the value of temperature,

pressure, speed, torque, volt and amp.

12. Switch off all the lamps.

13. Switch off the heater and the mains switch.

6.0

Result/Data

No. of lamp

Temperature

Pressure

Speed

Torque

Voltage

Ampere

Prepared by : Mohd Zulkarnaen

Bin Mohd Ibrahim

DJJ2073 THERMODYNAMICS

EXPERIMENT

TITLE

DURATION

PAGE

7.0

:

:

:

:

DJJ2073 2

STEAMTURBINE

15HOURS

40F 4

Discussion

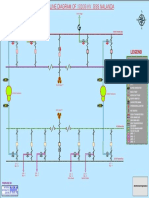

1. Draw the schematic of the component used in thisexperiment.

2. From the observations during the experiment, discuss and explain the

operating principles of the steam turbine.

3. From the data obtained, discuss the data comparison between all four

lamps that were on during the experiment.

4. If the amount of water in the boiler is low, will itcause any effect to the

experiment data? Discuss.

8.0

Conclusion and Recommendation

Your conclusion should be related to your practical and theoretical

understanding on the related topic.

9.0

References

Yunus A. Cengel,MichaelA. Boles(1998) Thermodynamics: An Engineering

Approach.

McGrawHill

Easteop,T.D &McConkey. , Applied Thermodynamics For Engineering

Technologist ,

5

th

Edition,Pearson&Prentice Hall,Singapore.

Sonntag,R. E.,Borgnakke,C.,and VanWylen,G. J.,2003. FUNDAMENTALS OF

THERMODYNAMICS, 6

th

Edition,JohnWiley&Sons,Inc.

John P. OConnell,J.M. Haile(2005) Thermodynamics:Fundamentals Of

Applications,

Cambridge UniversityPress.

Prepared by : Mohd Zulkarnaen

Bin Mohd Ibrahim

Вам также может понравиться

- Conzerv em 6400 Series Power Meter User ManualДокумент68 страницConzerv em 6400 Series Power Meter User ManualMukesh Kumar Gupta33% (3)

- Encyclopedia of Controlled Drug Delivery (2 Vols) - E. Mathiowitz (Wiley, 1999) WWДокумент903 страницыEncyclopedia of Controlled Drug Delivery (2 Vols) - E. Mathiowitz (Wiley, 1999) WWCiontu Valentin100% (4)

- Refining & Chemicals: Training CoursesДокумент185 страницRefining & Chemicals: Training CoursesJean-Louis KouassiОценок пока нет

- Mechatronic Workshop Practice 1Документ15 страницMechatronic Workshop Practice 1Khairul AminОценок пока нет

- TEST Dbs1012Документ2 страницыTEST Dbs1012Rinz Raime100% (1)

- Practical Task 2 BearingДокумент2 страницыPractical Task 2 Bearingshirleyna saraОценок пока нет

- Sample For Students Mec435Документ6 страницSample For Students Mec435Syafiq FauziОценок пока нет

- MEC653 - Test 1 - Mac 2020 - EM220 8E4Документ11 страницMEC653 - Test 1 - Mac 2020 - EM220 8E4Nor Fitrey IbrahimОценок пока нет

- PT326-Round2 Expt3 Batch19Документ6 страницPT326-Round2 Expt3 Batch19Radhey MeenaОценок пока нет

- KUIZ 1 Workshop TechnologyДокумент1 страницаKUIZ 1 Workshop TechnologyMohd Azizee Bin SukorОценок пока нет

- Assignment Ethics 1Документ13 страницAssignment Ethics 1Fnur Fatihah0% (1)

- Introduction NadopodДокумент2 страницыIntroduction NadopodAinaaaa0% (1)

- Talking CalculaterДокумент18 страницTalking CalculateryuwarajaОценок пока нет

- JJ512 Hydraulic Lab 4Документ7 страницJJ512 Hydraulic Lab 42cekalОценок пока нет

- JJ512 Pneumatic PH 4 Lab SheetДокумент4 страницыJJ512 Pneumatic PH 4 Lab SheetIjal HaizalОценок пока нет

- EOC Chapter 2Документ1 страницаEOC Chapter 2Arief IzzОценок пока нет

- DJJ 10033-Chapter 6 NewДокумент43 страницыDJJ 10033-Chapter 6 NewAbbas SeuОценок пока нет

- DJF21012 Sand Casting 1006Документ15 страницDJF21012 Sand Casting 1006Sakinah KamalОценок пока нет

- Report Lab 4 Electro Hydrolic f1063Документ6 страницReport Lab 4 Electro Hydrolic f1063Syahzlan IskandarОценок пока нет

- Lec 4 Rotational Mechanical SystemДокумент14 страницLec 4 Rotational Mechanical SystemFelopateer EmadОценок пока нет

- Lab 1 DJJ30093 - em - Dis 2020Документ7 страницLab 1 DJJ30093 - em - Dis 2020khairul rizmanОценок пока нет

- Handbook JKM Mac 2021 Complete - CompressedДокумент130 страницHandbook JKM Mac 2021 Complete - CompressedSeekОценок пока нет

- Bearing: Service Manual MaintenanceДокумент9 страницBearing: Service Manual MaintenanceNazira NassОценок пока нет

- Lab Report 4 Electro-Hydraulic SystemДокумент18 страницLab Report 4 Electro-Hydraulic Systemamir sabrinОценок пока нет

- Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaДокумент8 страницFakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaThaneswaran BaluОценок пока нет

- Flow Through Venturi Tube and Orifice Plate 2021Документ17 страницFlow Through Venturi Tube and Orifice Plate 2021Arief HakeemОценок пока нет

- Mechanical Engineering Department: Djj3053 - Engineering Mechanics Lab: Velocity and AccelerationДокумент8 страницMechanical Engineering Department: Djj3053 - Engineering Mechanics Lab: Velocity and AccelerationMuhd AriffОценок пока нет

- Universiti Tun Hussein Onn Malaysia Department of Mechanical EngineeringДокумент11 страницUniversiti Tun Hussein Onn Malaysia Department of Mechanical EngineeringAriff ShasteraОценок пока нет

- Solid Modeling Project Sem 2 2014Документ5 страницSolid Modeling Project Sem 2 2014Matthew ShieldsОценок пока нет

- JJ102 Electrical Technology CHAPTER - 5 TansfomersДокумент17 страницJJ102 Electrical Technology CHAPTER - 5 TansfomersAh TiangОценок пока нет

- Test 1 Mekanik MesinДокумент8 страницTest 1 Mekanik MesinApek Suasana0% (1)

- Strength Lab Report (Exp 2) Update 1Документ14 страницStrength Lab Report (Exp 2) Update 1Syafiq RonaldoОценок пока нет

- Report Lab 2Документ6 страницReport Lab 2Adid Punya0% (1)

- Engin2423424234242423424eering Statisti342342342342cs CompletedДокумент10 страницEngin2423424234242423424eering Statisti342342342342cs CompletedSaiful AzrieОценок пока нет

- Tudung Saji InovasiДокумент4 страницыTudung Saji InovasiAly Rajaie Anna RusliОценок пока нет

- Group 1 - Lab Report Concept of Free VibrationДокумент15 страницGroup 1 - Lab Report Concept of Free VibrationAmeer AimanОценок пока нет

- Gantt Chart (Fabrication and Testing Durian Crepe Folding Machine)Документ1 страницаGantt Chart (Fabrication and Testing Durian Crepe Folding Machine)Akmal HassanОценок пока нет

- JJ310 STRENGTH OF MATERIAL Chapter 1 (A) Forces On MaterialДокумент18 страницJJ310 STRENGTH OF MATERIAL Chapter 1 (A) Forces On MaterialAh Tiang100% (1)

- Lathe Machine ReportДокумент10 страницLathe Machine ReportSyahirahОценок пока нет

- Business Plan Template - UniklДокумент14 страницBusiness Plan Template - UniklcertifiedCrazyOZ HemaОценок пока нет

- Djj3103: Strength of Materials Lab ReportДокумент15 страницDjj3103: Strength of Materials Lab ReportSyfull musicОценок пока нет

- JF611 Manufacturing EconomyДокумент8 страницJF611 Manufacturing EconomyNuqmanKhanОценок пока нет

- DJF 3012 - Manufacturing Workshop Practice 2Документ7 страницDJF 3012 - Manufacturing Workshop Practice 2Leeahna JkОценок пока нет

- Lab 4 Logic Gate (Lab Report)Документ4 страницыLab 4 Logic Gate (Lab Report)Izzat IkramОценок пока нет

- Mecha Lab Report (Pneumatics Results and Discussion)Документ3 страницыMecha Lab Report (Pneumatics Results and Discussion)Shamni KarthegesuОценок пока нет

- Contoh WATER JET PDFДокумент17 страницContoh WATER JET PDFWAN AHMAD FARISH DANIAL WAN HUSNIОценок пока нет

- Course Jj618 Engineering Plant TechnologyДокумент6 страницCourse Jj618 Engineering Plant Technologyweafareez100% (1)

- Det1022 PW3Документ9 страницDet1022 PW3Muhammad FaissalОценок пока нет

- Report BengkelДокумент5 страницReport BengkelAkmal HazimОценок пока нет

- Lab 3 Deflection On The Beam GroupingДокумент6 страницLab 3 Deflection On The Beam GroupingMuhd AriffОценок пока нет

- Algorithm and Flowchart To Convert A Number From °celsius To °fahrenheitДокумент10 страницAlgorithm and Flowchart To Convert A Number From °celsius To °fahrenheitSai PreethamОценок пока нет

- Observations and FindingsДокумент2 страницыObservations and FindingsJustin Mark AgtingОценок пока нет

- Lab ReportДокумент4 страницыLab Reportshareen tanОценок пока нет

- DBM20023-Topic 1-Indices and LogarithmsДокумент29 страницDBM20023-Topic 1-Indices and LogarithmsNaqiuddin MuhamadОценок пока нет

- Note CHP 1-Material Science 281 Uitm Em110Документ59 страницNote CHP 1-Material Science 281 Uitm Em110bino_rye100% (3)

- Lab 5Документ6 страницLab 5AimiWaniОценок пока нет

- Broom Manufacture Machine: StartДокумент62 страницыBroom Manufacture Machine: StartHaziq PazliОценок пока нет

- Phy Report Exp2Документ5 страницPhy Report Exp2audiliciousОценок пока нет

- For The Full Essay Please WHATSAPP 010-2504287Документ15 страницFor The Full Essay Please WHATSAPP 010-2504287Simon RajОценок пока нет

- Fila TableДокумент2 страницыFila TableSyafiq AimanОценок пока нет

- Lab Sheet 2 PDFДокумент13 страницLab Sheet 2 PDFmalaОценок пока нет

- AT 0 Lab Report PDFДокумент7 страницAT 0 Lab Report PDFerlanggasulaiman90Оценок пока нет

- Fossil Fuel - Compressor and Turbine WorkДокумент13 страницFossil Fuel - Compressor and Turbine WorkVinoth K VelauthamОценок пока нет

- Lab Refrigeration N Cooling TowerДокумент21 страницаLab Refrigeration N Cooling TowerShahran IezzatОценок пока нет

- (Technical Paper) TMR - A New Frontier For Magnetic Sensing - NTNДокумент8 страниц(Technical Paper) TMR - A New Frontier For Magnetic Sensing - NTNyuwarajaОценок пока нет

- 1Документ3 страницы1yuwarajaОценок пока нет

- Logic PDFДокумент36 страницLogic PDFyuwarajaОценок пока нет

- Force TableДокумент3 страницыForce TableMohammed Yousif AbdualjabbarОценок пока нет

- BPA Falling Hazards & PPEДокумент75 страницBPA Falling Hazards & PPEyuwarajaОценок пока нет

- Assignment1 Duedate5mac2020Документ1 страницаAssignment1 Duedate5mac2020yuwarajaОценок пока нет

- Bab 1Документ23 страницыBab 1yuwarajaОценок пока нет

- Calender 201'8Документ3 страницыCalender 201'8yuwarajaОценок пока нет

- SelangorДокумент3 страницыSelangoryuwarajaОценок пока нет

- Untitled 11Документ39 страницUntitled 11yuwarajaОценок пока нет

- Chapter 4 Multistage Amplifier1Документ25 страницChapter 4 Multistage Amplifier1yuwarajaОценок пока нет

- Cooling SystemДокумент7 страницCooling SystemyuwarajaОценок пока нет

- Introduction To ShurikenДокумент2 страницыIntroduction To ShurikenyuwarajaОценок пока нет

- Hydraulics and Pnuematics SymbolsДокумент9 страницHydraulics and Pnuematics SymbolsRockingRayGОценок пока нет

- Lab Sheet 01Документ5 страницLab Sheet 01yuwarajaОценок пока нет

- Mini Project (Engineering Design)Документ6 страницMini Project (Engineering Design)yuwarajaОценок пока нет

- PneumaticДокумент9 страницPneumaticyuwarajaОценок пока нет

- Administrative Assistant: Professional ExperienceДокумент2 страницыAdministrative Assistant: Professional ExperienceyuwarajaОценок пока нет

- Signal Processing DevicesДокумент11 страницSignal Processing DevicesyuwarajaОценок пока нет

- LT TR IndemnityДокумент3 страницыLT TR IndemnityAhmad NaqiuddinОценок пока нет

- Applicationform 2010Документ6 страницApplicationform 2010Pejuang KehidupanОценок пока нет

- Chapter 6Документ26 страницChapter 6yuwarajaОценок пока нет

- Learning Objectives Upon Completion of This Chapter, Student Should Be Able ToДокумент54 страницыLearning Objectives Upon Completion of This Chapter, Student Should Be Able ToSalvador JovenОценок пока нет

- Lab 1 Cell and OsmosisДокумент5 страницLab 1 Cell and OsmosisyuwarajaОценок пока нет

- DJJ3103 Strength of Materials: Azunaidi B. Abdul Aziz Mechanical Eng. Dept. PolimasДокумент16 страницDJJ3103 Strength of Materials: Azunaidi B. Abdul Aziz Mechanical Eng. Dept. PolimasyuwarajaОценок пока нет

- DJJ3103 Strength of Materials: Azunaidi B. Abdul Aziz Mechanical Eng. Dept. PolimasДокумент10 страницDJJ3103 Strength of Materials: Azunaidi B. Abdul Aziz Mechanical Eng. Dept. PolimasyuwarajaОценок пока нет

- 2Документ5 страниц2yuwarajaОценок пока нет

- Lab Report 1Документ6 страницLab Report 1yuwarajaОценок пока нет

- Report MIG WeldingДокумент12 страницReport MIG Weldingyuwaraja0% (2)

- SIEMENS Price List2009Документ60 страницSIEMENS Price List2009Goutam MandalОценок пока нет

- Quiz3 2015 SolutionsДокумент8 страницQuiz3 2015 SolutionsGerald RattichОценок пока нет

- WattsUp July2021Документ16 страницWattsUp July2021Muhammad Nadzri HamzahОценок пока нет

- Fault Current CalculationДокумент3 страницыFault Current CalculationfarhanajnОценок пока нет

- Univerity of West Indies Lab ReportДокумент12 страницUniverity of West Indies Lab ReportvrajendraupadhyayОценок пока нет

- Alice A Bailey - Cosmic Law 2Документ11 страницAlice A Bailey - Cosmic Law 2StevanОценок пока нет

- Wind EnergyДокумент31 страницаWind EnergySeek seekОценок пока нет

- Hitachi Steam Condenser InstallationДокумент6 страницHitachi Steam Condenser InstallationselviraОценок пока нет

- Samsung VRF HEAT PUMP - AM100AXVANH - TL - Samsung Business IndiaДокумент4 страницыSamsung VRF HEAT PUMP - AM100AXVANH - TL - Samsung Business Indiachandravadiyaketan1504Оценок пока нет

- AC Pasco Power SupplyДокумент4 страницыAC Pasco Power SupplyLohith NBОценок пока нет

- AG12V100FДокумент2 страницыAG12V100FDanilo Armando Silva Lévano100% (1)

- 18 Mar 2017 1003043576765NIAXAnnexure-BriefNoteДокумент5 страниц18 Mar 2017 1003043576765NIAXAnnexure-BriefNotesambhuОценок пока нет

- P&D Chemistry 1Документ7 страницP&D Chemistry 1AndersonMitchell100% (2)

- Importance and Conduct of Grid Impact StudyДокумент24 страницыImportance and Conduct of Grid Impact StudyJCuchapinОценок пока нет

- Hydrogen and Fuel Cells: Opportunities For Growth: A Roadmap For The UKДокумент55 страницHydrogen and Fuel Cells: Opportunities For Growth: A Roadmap For The UKMeredith GreyОценок пока нет

- Certificate of Conformity: SGS Tecnos, S.AДокумент1 страницаCertificate of Conformity: SGS Tecnos, S.Afiras abou sharafОценок пока нет

- 7SS522 CT RequirementДокумент4 страницы7SS522 CT RequirementAnonymous 9EV0OmkОценок пока нет

- Calculating Capasitor Filter PDFДокумент4 страницыCalculating Capasitor Filter PDFKusmara MarmarОценок пока нет

- TEG 500W Thermoelectric Power GeneratorДокумент1 страницаTEG 500W Thermoelectric Power GeneratorčuvarОценок пока нет

- Timeline: Chemtou TunisiaДокумент2 страницыTimeline: Chemtou TunisiasudhirОценок пока нет

- PSS21/A DSE 7310: Package Standby SystemsДокумент20 страницPSS21/A DSE 7310: Package Standby SystemsBaciu NicolaeОценок пока нет

- Ha35 41 en ScreenДокумент48 страницHa35 41 en ScreenmagycОценок пока нет

- SLD GSS NalandaДокумент1 страницаSLD GSS NalandaRahul KumarОценок пока нет

- Protective Relaying QuizДокумент3 страницыProtective Relaying QuizCattleya Tabor PeñalosaОценок пока нет

- AB Power Eng'gДокумент16 страницAB Power Eng'gHarlyn Joy LuciОценок пока нет

- Generac Spec Sheet 9kw and 11kwДокумент6 страницGenerac Spec Sheet 9kw and 11kwRichard WiksОценок пока нет

- Chemistry: Fifth Class of Science Biological BranchДокумент220 страницChemistry: Fifth Class of Science Biological BranchMahd madreОценок пока нет