Академический Документы

Профессиональный Документы

Культура Документы

Forklift Pre-Operational Inspection Checklist: Operator #1 Operator #2 Operator #3 Operator #4 Operator #5

Загружено:

Dayang Sari AndrianiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Forklift Pre-Operational Inspection Checklist: Operator #1 Operator #2 Operator #3 Operator #4 Operator #5

Загружено:

Dayang Sari AndrianiАвторское право:

Доступные форматы

Model: __________________

Forklift Pre-Operational Inspection Checklist

Operator #1

Operator #2

Operator #3

Truck #: _________________

Operator #4

Operator #5

Operator Name

Hour Meter Reading

Date (Month/Day/Year)

Operators Signature

Certified Forklift Operator: Complete this form, before each use. Check OK if the items are in good condition/operation or check

the Repair Required if the item is not in proper order. IMPORTANT: The forklift must not be utilized if there are any items that

require repairs. Have a service company repair prior to use. Note to Supervisors: It is your responsibility to ensure your operators are

continually performing and documenting their pre-use inspections.

Operator #1

Workplace Inspection

Criteria

Ground Conditions

Drop-offs, holes, debris, etc.

Overhead Hazards

Structures, utility pipes, fans, lights, etc.

Unauthorized Access

People, vehicles, equipment, etc.

Safety Items

Fire extinguisher, PPE, eye wash, first aid kit, etc.

Key Off (Visual Check)

Criteria

General Overview

Parking brake, fluid leaks on floor, damage, etc.

Forks/Attachment, Backrest

Bent, cracked, locking pins, worn, mismatched

Mast, Lift Chains, Rollers

Broken welds, cracks, bent, greased, rust

Hydraulic Cylinders/Hoses

Leaks, damaged, bubbles/cuts on hose

Tires/Wheel All Tires

Lug nuts, rim damage, sidewall, tread, pressure

Overhead Guard All Sides

Broken welds, missing bolts, damaged areas

Capacity Plate/Safety Decals

Legible, attached to unit

Seatbelt/Operator Restraint

Worn, damage, working, locks when attached

Controls and Pedals

Hydraulic controls and pedals move freely

Counterweight

Propane Cylinder

Operator #3

Operator #4

Operator #5

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

Bolts, damage, cracks in exhaust/radiator

N/A

Mounted properly, damage, leaks, date

Fluid Checks (All Accessible)

Engine oil/hydraulic/brake/transmission/coolant

Battery

Secure, cell caps, leaks, corrosion, cables

Key On (Oper. Checks)

Criteria

Seatbelt

Seatbelt is engaged prior to any motion

Gauges

All warning lights and gauges

Warning Devices/Lights

Horn, backup alarm, all lights working

Parking and Service Brake/

Deadman Pedal

Parking brake holds when in gear, service brakes

works travelling forward and reverse, stops unit

Proper operation and no leak through full range

of motion: lift, lower, tilt, side-shift, reach, etc.

All Hydraulic Operations

Steering

Operator #2

OK

No unusual noise, excessive free-play

Supervisors Initials

Use the section below to indicate any items that need repair or special attention. If required, tag the unit out of service.

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Model: __________________

RT Forklift Pre-Operational Inspection Checklist Truck #: _________________

Operator #1

Operator #2

Operator #3

Operator #4

Operator #5

Operator Name

Hour Meter Reading

Date (Month/Day/Year)

Operators Signature

Certified Forklift Operator: Complete this form, before each use. Check OK if the items are in good condition/operation or check

the Repair Required if the item is not in proper order. IMPORTANT: The forklift must not be utilized if there are any items that

require repairs. Have a service company repair prior to use. Note to Supervisors: It is your responsibility to ensure your operators are

continually performing and documenting their pre-use inspections.

Operator #1

Workplace Inspection

Criteria

Ground Conditions

Drop-offs, holes, obstructions, etc.

Wind and Weather

High wind speeds, harsh weather conditions

Overhead Hazards

Structures, MAD, utility pipes, fans, lights, etc.

Unauthorized Access

People, vehicles, equipment, etc.

Safety Items

Fire extinguisher, PPE, eye wash, first aid kit, etc.

Key Off (Visual Check)

Criteria

General Overview

Parking brake, fluid leaks on floor, damage, etc.

Forks/Attachment, Backrest

Bent, cracked, locking pins, worn, mismatched

Boom

Broken welds, cracks, bent, greased, rust

Hydraulic Cylinders/Hoses

Leaks, damaged, bubbles/cuts on hose

Tires/Wheel All Tires

Lug nuts, rim damage, sidewall, tread, pressure

Overhead Guard All Sides

Broken welds, missing bolts, damaged areas

Capacity Plate/Safety Decals

Legible, attached to unit

Seatbelt/Operator Restraint

Worn, damage, working, locks when attached

Controls and Pedals

Hydraulic controls and pedals move freely

Counterweight

Bolts, damage, cracks in exhaust/radiator

Fluid Checks (All Accessible)

Engine oil/hydraulic/brake/transmission/coolant

Battery

Secure, leaks, corrosion, cables

Key On (Oper. Checks)

Criteria

Seatbelt

Seatbelt is engaged prior to any motion

Gauges

All warning lights and gauges

Warning Devices/Lights

Horn, backup alarm, all lights working

Parking and Service Brake

All Hydraulic Operations

Steering

Operator #2

Operator #3

Operator #4

Operator #5

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

Parking brake holds when in gear, service brakes

works travelling forward and reverse, stops unit

Proper operation and no leak through full range

of motion: lift, lower, tilt, side-shift, reach, etc.

No unusual noise, excessive free-play

Supervisors Initials

Use the section below to indicate any items that need repair or special attention. If required, tag the unit out of service.

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Model: __________________

Loader Pre-Operational Inspection Checklist

Unit #: __________________

`

Operator #1

Operator #2

Operator #3

Operator #4

Operator #5

Operator Name

Hour Meter Reading

Date (Month/Day/Year)

Operators Signature

Certified Loader Operator: Complete this form, before each use. Check OK if the items are in good condition/operation or check

the Repair Required if the item is not in proper order. IMPORTANT: The loader must not be utilized if there are any items that

require repairs. Have a service company repair prior to use. Note to Supervisors: It is your responsibility to ensure your operators are

continually performing and documenting their pre-use inspections.

Operator #1

Workplace Inspection

Criteria

Underground Utilities

Call Before You Dig

Ground Conditions

Drop-offs, holes, obstructions, etc.

Overhead Hazards

MAD, structures, etc.

Unauthorized Access

People, vehicles, equipment, etc.

Safety Items

Fire extinguisher, PPE, eye wash, first aid kit, etc.

Key Off (Visual Check)

Criteria

General Overview

Park-brake, fluid leaks on ground, damage, etc.

Bucket/Attachment

Bent, cracked, locking pins, worn, capacity

Lift Arms

Broken welds, cracks, bent, greased, rust

Hydraulic Cylinders/Hoses

Leaks, damaged, bubbles/cuts on hose

Tires/Wheel/Tracks All

Lug nuts, rim damage, sidewall, tread, pressure

ROPS/FOPS All Sides

Broken welds, missing bolts, damaged areas

Capacity Plate/Safety Decals

Legible, attached to unit

Seatbelt/Operator Restraint

Worn, damage, working, locks when attached

Controls and Pedals

Hydraulic controls and pedals move freely

Counterweight

Bolts, damage, cracks in exhaust/radiator

Fluid Checks (All Accessible)

Engine oil/hydraulic/brake/transmission/coolant

Battery

Secure, cell caps, leaks, corrosion, cables

Key On (Oper. Checks)

Criteria

Seatbelt

Seatbelt is engaged prior to any motion

Gauges

All warning lights and gauges

Warning Devices/Lights

Horn, backup alarm, all lights working

Parking and Service Brake

All Hydraulic Operations

Steering

Operator #2

Operator #3

Operator #4

Operator #5

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

Parking brake holds when in gear, service brakes

works travelling forward and reverse, stops unit

Proper operation and no leak through full range

of motion: lift, lower, tilt, reach, etc.

No unusual noise, excessive free-play

Supervisors Initials

Use the section below to indicate any items that need repair or special attention. If required, tag the unit out of service.

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Model: __________________

Aerial Lifts Pre-Operational Inspection Checklist Truck #: _________________

Operator #1

Operator #2

Operator #3

Operator #4

Operator #5

Operator Name

Hour Meter Reading

Date (Month/Day/Year)

Operators Signature

Certified Aerial Lift Operator: Complete this form, before each use. Check OK if the items are in good condition/operation or

check the Repair Required if the item is not in proper order. IMPORTANT: The aerial lift must not be utilized if there are any items

that require repairs. Have a service company repair prior to use. Note to Supervisors: It is your responsibility to ensure your

operators are continually performing and documenting their pre-use inspections.

Operator #1

Workplace Inspection

Criteria

Ground Conditions

Drop-offs, holes, debris, etc.

Wind and Weather

High wind speeds, harsh weather conditions

Overhead Hazards

Structures, MAD, utility pipes, fans, lights, etc.

Unauthorized Access

People, vehicles, equipment, etc.

Safety Items

Fire extinguisher, PPE, eye wash, first aid kit, etc.

Key Off (Visual Check)

Criteria

Fall Protection

Worn, damage, working, locks when attached

General Overview

Emergency stop, fluid leaks on floor, damage, etc.

Guardrail System/Platform

Bent, cracked, door/safety chain latches, welds

Boom, Lift Arms, Chains

Broken welds, cracks, bent, greased, rust

Hydraulic Cylinders/Hoses

Leaks, damaged, bubbles/cuts on hose

Tires/Wheel All Tires

Lug nuts, rim damage, sidewall, tread, pressure

Turret/Base All Sides

Broken welds, missing bolts, damaged areas

Capacity Plate/Safety Decals

Legible, attached to unit, manuals present

Controls and Pedals

Hydraulic controls and pedals move freely

Counterweight

Propane Cylinder

Operator #3

Operator #4

Operator #5

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

OK

Repair

Reqd.

Bolts, damage, etc.

N/A

Mounted properly, damage, leaks, date

Fluid Checks (All Accessible)

Engine oil/hydraulic/coolant, etc.

Battery

Secure, cell caps, leaks, corrosion, cables

Key On (Oper. Checks)

Criteria

Emergency Controls

Emergency lowering and auxiliary controls

Warning Devices

Horn, backup alarm, slope warning

Fall Protection

Engaged prior to any motion when in platform

Ground/Platform Controls

Proper operation and no leak through full range

of motion: lift, lower, tilt, reach, extension, etc.

Gauges

Brake, Foot/Hand Switch

Steering

Operator #2

OK

All warning lights and gauges

Brake holds when released, brakes works

travelling forward and reverse, stops unit

No unusual noise, excessive free-play

Supervisors Initials

Use the section below to indicate any items that need repair or special attention. If required, tag the unit out of service.

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Вам также может понравиться

- Inspection Checklist ForkliftДокумент1 страницаInspection Checklist ForkliftpigooyОценок пока нет

- Pallet Jack Safety TrainingДокумент21 страницаPallet Jack Safety TrainingIndranil Mitra100% (2)

- Form-162-Scissor Lift Daily Inspection ChecklistДокумент1 страницаForm-162-Scissor Lift Daily Inspection Checklistshamroz khan100% (2)

- Monthly Forklift Inspection Checklist OHS PR 009 FM 01 0412Документ1 страницаMonthly Forklift Inspection Checklist OHS PR 009 FM 01 0412cmrig74100% (2)

- Heavy Equipment Inspection ChecklistДокумент18 страницHeavy Equipment Inspection ChecklistJuned Hamid Khan89% (9)

- HSE Objectives 2015Документ2 страницыHSE Objectives 2015Anonymous iI88Lt100% (2)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Forklift TruckДокумент1 страницаForklift TruckShazaley AbdullahОценок пока нет

- Title: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Документ5 страницTitle: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Adeyinka MichealОценок пока нет

- Forklift Safety Policy and ProcedureДокумент3 страницыForklift Safety Policy and ProcedureChristian Auditor Rivera100% (1)

- Forklift Operator - Competency AssessmentДокумент5 страницForklift Operator - Competency AssessmentMohammed YousufОценок пока нет

- SOP of ForkДокумент15 страницSOP of ForkGyanendra Narayan NayakОценок пока нет

- Health and Safety Check CateringДокумент5 страницHealth and Safety Check CateringDayang Sari AndrianiОценок пока нет

- Medical Records in Family PracticeДокумент22 страницыMedical Records in Family PracticenurfadillahОценок пока нет

- AMS 48 - 2000-n - D0114354 - 055 - 00Документ116 страницAMS 48 - 2000-n - D0114354 - 055 - 00wanhall100% (1)

- Forklift RAДокумент5 страницForklift RAFachri HidayatОценок пока нет

- 9.5 Forklift Daily InspectionДокумент1 страница9.5 Forklift Daily InspectionArshad MahmoodОценок пока нет

- Forklift Truck/Powered Indutrial Truck: I. ObjectiveДокумент4 страницыForklift Truck/Powered Indutrial Truck: I. ObjectiveprinceОценок пока нет

- Forklift Daily Checklist ElectricДокумент2 страницыForklift Daily Checklist Electricmikel derrickОценок пока нет

- Safety Checklist of Safety BeltДокумент1 страницаSafety Checklist of Safety BeltA S YadavОценок пока нет

- Forklift Inspection ChecklistДокумент2 страницыForklift Inspection ChecklistZeinullah 026100% (1)

- Scissor Lift Pre-Use Inspection Checklist 2Документ1 страницаScissor Lift Pre-Use Inspection Checklist 2Harun SaniОценок пока нет

- S-OS-21-01 Hand Tool Inspection RegisterДокумент1 страницаS-OS-21-01 Hand Tool Inspection RegisterCharles Lamb100% (1)

- 5 Weekly Check List JCBДокумент4 страницы5 Weekly Check List JCBsamiran RouthОценок пока нет

- Excavator ChecklistДокумент1 страницаExcavator ChecklistEleonor MaderazoОценок пока нет

- 30682417-Forklift Safety ChecklistДокумент2 страницы30682417-Forklift Safety ChecklistWaqas GujjarОценок пока нет

- Forklift Inspection RecordДокумент1 страницаForklift Inspection Record7twofourОценок пока нет

- Excavator Weekly Inspection ChecklistДокумент2 страницыExcavator Weekly Inspection ChecklistSiyadarakkalmajeed ArakkalmajeedОценок пока нет

- Safety Harness ChecklistДокумент2 страницыSafety Harness ChecklistTilak RajОценок пока нет

- Forklift Accident Case StudiesДокумент30 страницForklift Accident Case Studieschaitanya_kumar_13Оценок пока нет

- Ladder Inspection Checklist: General Condition OK Needs Repair Not ApplicableДокумент1 страницаLadder Inspection Checklist: General Condition OK Needs Repair Not ApplicableWaqas Khan100% (1)

- FORM PDI ForkliftДокумент2 страницыFORM PDI ForkliftAkbar100% (1)

- Checklist ForkliftДокумент4 страницыChecklist ForkliftAris100% (2)

- Concrete Pump (Static) ChecklistДокумент1 страницаConcrete Pump (Static) ChecklistKannan JaganОценок пока нет

- Safe Forklift Operation ManualДокумент32 страницыSafe Forklift Operation ManualMauricio Bulla ValenciaОценок пока нет

- Fork Lift Daily Check: (Only For FL Operated by Batery)Документ1 страницаFork Lift Daily Check: (Only For FL Operated by Batery)Martin CabelloОценок пока нет

- LOLER Inspection Checklist - 7 Free TemplatesДокумент7 страницLOLER Inspection Checklist - 7 Free TemplatesernestozagОценок пока нет

- HSE-BMS-013 Color Coding and InspectionДокумент30 страницHSE-BMS-013 Color Coding and InspectionSatya Naidu100% (1)

- A Guide To Personal Protective Equipment: N.C. Department of LaborДокумент30 страницA Guide To Personal Protective Equipment: N.C. Department of LaboramaliaОценок пока нет

- 30 - 2.4 - Ladder Register & InspectionДокумент4 страницы30 - 2.4 - Ladder Register & InspectionsalmanОценок пока нет

- Compressed Gas Cylinders ChecklistДокумент2 страницыCompressed Gas Cylinders ChecklistPerwez21100% (1)

- Alabama Homebuilders Self Insurers Fund: Lift Truck Operator Training ProgramДокумент61 страницаAlabama Homebuilders Self Insurers Fund: Lift Truck Operator Training ProgramMalathy Sekar100% (1)

- Safety & Maintenance Checklist Underground Trucks PDFДокумент1 страницаSafety & Maintenance Checklist Underground Trucks PDFGustavoОценок пока нет

- Forklift Service ReportДокумент1 страницаForklift Service ReportBarathОценок пока нет

- Form Inspeksi Bar Cutter Bar Bender - Fix (SfileДокумент1 страницаForm Inspeksi Bar Cutter Bar Bender - Fix (Sfilerajatua dramaga.projectОценок пока нет

- Bar Cutting MachineДокумент1 страницаBar Cutting Machinesaurav roy100% (1)

- Material Safety Data Sheet: 1. Information of The Substance / CompanyДокумент6 страницMaterial Safety Data Sheet: 1. Information of The Substance / CompanyDiego MОценок пока нет

- Daily Observation Report PDFДокумент44 страницыDaily Observation Report PDFp kishorОценок пока нет

- Ppe Matrix - FTДокумент1 страницаPpe Matrix - FTAkhilesh Pandey100% (2)

- Hand Pallet Truck-VL25Документ2 страницыHand Pallet Truck-VL25sutanuprojectsОценок пока нет

- Environment Management System ManualДокумент5 страницEnvironment Management System ManualtoanvmpetrologxОценок пока нет

- Daily EHS Inspection Checklist: Date: General Yes No CommentsДокумент2 страницыDaily EHS Inspection Checklist: Date: General Yes No CommentsWaqasОценок пока нет

- Weekly Tower Light Check ListДокумент1 страницаWeekly Tower Light Check ListpjosesmОценок пока нет

- SWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. AДокумент1 страницаSWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ACliffordОценок пока нет

- SAMPLE Forklift Safety ProgramДокумент5 страницSAMPLE Forklift Safety ProgramHerry PrakosoОценок пока нет

- MPBA Acop Lorry LoadersДокумент22 страницыMPBA Acop Lorry LoadersRichu PaliОценок пока нет

- 9 Forklift Pre-Operational ChecklistДокумент2 страницы9 Forklift Pre-Operational ChecklistandrewhwОценок пока нет

- SFPSG-Rescue Persons From MEWPsДокумент10 страницSFPSG-Rescue Persons From MEWPsLyle KorytarОценок пока нет

- Uperform - Pallet Truck PDFДокумент52 страницыUperform - Pallet Truck PDFMohd Asrul Abu Harirah100% (2)

- Hierarchy of ControlsДокумент2 страницыHierarchy of ControlsAbhash AryanОценок пока нет

- SG-14 Safety Guideline For Work On Electric Overhead Travelling (EOT) CraneДокумент19 страницSG-14 Safety Guideline For Work On Electric Overhead Travelling (EOT) CraneAbhishek GadatiaОценок пока нет

- SANY Rough-Terrain Crane 30 Ton (SRC300C)Документ15 страницSANY Rough-Terrain Crane 30 Ton (SRC300C)Deni FebriantoОценок пока нет

- Forklift OperationsДокумент16 страницForklift Operationsnomi buttОценок пока нет

- Verb BaseДокумент21 страницаVerb BaseDayang Sari AndrianiОценок пока нет

- BBS by OhsaДокумент14 страницBBS by OhsaDayang Sari AndrianiОценок пока нет

- Surat LamaranДокумент1 страницаSurat LamaranDayang Sari AndrianiОценок пока нет

- PMI Framework Processes PresentationДокумент17 страницPMI Framework Processes PresentationAakash BhatiaОценок пока нет

- Dungeon World ConversionДокумент5 страницDungeon World ConversionJosephLouisNadeauОценок пока нет

- Benzil PDFДокумент5 страницBenzil PDFAijaz NawazОценок пока нет

- Employment Offer: 1. Employer InformationДокумент2 страницыEmployment Offer: 1. Employer InformationnavidОценок пока нет

- READING 4 UNIT 8 Crime-Nurse Jorge MonarДокумент3 страницыREADING 4 UNIT 8 Crime-Nurse Jorge MonarJORGE ALEXANDER MONAR BARRAGANОценок пока нет

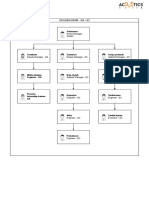

- Organogram - Qa / QC: Srinivasan SrinivasanДокумент4 страницыOrganogram - Qa / QC: Srinivasan SrinivasanGowtham VenkatОценок пока нет

- Potato Storage and Processing Potato Storage and Processing: Lighting SolutionДокумент4 страницыPotato Storage and Processing Potato Storage and Processing: Lighting SolutionSinisa SustavОценок пока нет

- Finite Element Analysis Project ReportДокумент22 страницыFinite Element Analysis Project ReportsaurabhОценок пока нет

- Answers To Your Questions About Circumcision and HIV/AIDSДокумент2 страницыAnswers To Your Questions About Circumcision and HIV/AIDSAlex BrownОценок пока нет

- Food and Beverage Control Systems Can Help You Introduce The Same Financial Rigour To Your Dining Establishment or Catering Company That YouДокумент11 страницFood and Beverage Control Systems Can Help You Introduce The Same Financial Rigour To Your Dining Establishment or Catering Company That Younarinder singh saini100% (4)

- Guides To The Freshwater Invertebrates of Southern Africa Volume 2 - Crustacea IДокумент136 страницGuides To The Freshwater Invertebrates of Southern Africa Volume 2 - Crustacea IdaggaboomОценок пока нет

- India Wine ReportДокумент19 страницIndia Wine ReportRajat KatiyarОценок пока нет

- Solo ParentsДокумент1 страницаSolo ParentsOZ CincoОценок пока нет

- ASOTДокумент4 страницыASOTemperors_nestОценок пока нет

- Covid-19 Mitigation PlanДокумент8 страницCovid-19 Mitigation PlanEkum EdunghuОценок пока нет

- Bhert - EoДокумент2 страницыBhert - EoRose Mae LambanecioОценок пока нет

- Report in Per Dev CorrectedДокумент34 страницыReport in Per Dev CorrectedJosh lyan RiveraОценок пока нет

- Cultivation Vaderstad Manual 2017Документ128 страницCultivation Vaderstad Manual 2017deroryОценок пока нет

- Refinería Kirkuk PDFДокумент11 страницRefinería Kirkuk PDFcesarinarragaОценок пока нет

- Model Probabilistik: "Variable Demand and Variable Lead Time" & Konsep Service LevelДокумент30 страницModel Probabilistik: "Variable Demand and Variable Lead Time" & Konsep Service LevelVladimir Hery WijannarkoОценок пока нет

- Marine Trans Owners Manual 1016313 RevH 0116 CDДокумент200 страницMarine Trans Owners Manual 1016313 RevH 0116 CDMarco Aurelio BarbosaОценок пока нет

- REV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Документ2 страницыREV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Bacano CapoeiraОценок пока нет

- CONTROLTUB - Controle de Juntas - New-Flare-Piping-Joints-ControlДокумент109 страницCONTROLTUB - Controle de Juntas - New-Flare-Piping-Joints-ControlVss SantosОценок пока нет

- Meat Plant FeasabilityДокумент115 страницMeat Plant FeasabilityCh WaqasОценок пока нет

- SanMilan Inigo Cycling Physiology and Physiological TestingДокумент67 страницSanMilan Inigo Cycling Physiology and Physiological Testingjesus.clemente.90Оценок пока нет

- Libro Resumenes 2012Документ735 страницLibro Resumenes 2012fdobonat613100% (2)

- Rooftop Rain Water Harvesting in An Educational CampusДокумент9 страницRooftop Rain Water Harvesting in An Educational CampusAkshay BoratiОценок пока нет

- Village Survey Form For Project Gaon-Setu (Village Questionnaire)Документ4 страницыVillage Survey Form For Project Gaon-Setu (Village Questionnaire)Yash Kotadiya100% (2)