Академический Документы

Профессиональный Документы

Культура Документы

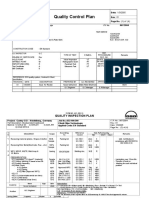

Sequence of Inspection

Загружено:

Romi Abdul RahmanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sequence of Inspection

Загружено:

Romi Abdul RahmanАвторское право:

Доступные форматы

PT UNITED SINDO PERKASA

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

Document Number

Document Title

USP-NC-SOI-002

SEQUENCE OF INSPECTION

Page

1 of 7

Rev

Date

05 APRIL 2010

SEQUENCE OF INSPECTION

Project

KINOA 4307

Company

NAVTECH KELOA/KINOA INVESTMENT S.A.

Contractor

PT. UNITED SINDO PERKASA

Document no

USP-NC-SOI-002

Document revision

status

Rev

For Submission

Date

Description

QA

Project

Manager

ABS

Client

Prepared

Reviewed

Reviewed

Approved

PT UNITED SINDO PERKASA

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

Document Number

Document Title

USP-NC-SOI-002

SEQUENCE OF INSPECTION

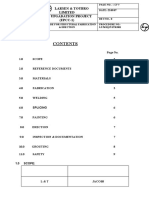

TABLE OF CONTENTS

1.

Material / Equipment Identification Check

2.

Sequence of Inspection

3.

Flow chart Hull Construction work Inspection

4.

Flow chart Piping work Inspection

5.

Communication Practice

Page

2 of 7

Rev

Date

05 APRIL 2010

PT UNITED SINDO PERKASA

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

Document Number

Document Title

USP-NC-SOI-002

SEQUENCE OF INSPECTION

Page

3 of 7

Rev

Date

05 APRIL 2010

1. Material / Equipment Identification Check

a.

Purpose

This procedure is providing a general guidance on the inspection of materials /

equipment prior to the fabrication process / installation on board.

b.

Time for Inspection.

This is prepared one day prior to the inspection time

c.

Procedure

Material / Equipment must be check by the Supervisor previously

Material / Equipment must be recorded by the Supervisor

The QC Inspector will invite the Class / Owner Surveyor one day before the

day of inspection.

2. Sequence of Inspection.

a.

Purpose

This is aimed at identification stages of inspection performed during the ship

building process

b.

Stages of Inspection.

This stages of inspection is a enclosed flow chart.

c.

Detail of inspection shall be describe in Inspection and Test Plan

PT UNITED SINDO PERKASA

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

Document Number

Document Title

USP-NC-SOI-002

SEQUENCE OF INSPECTION

Page

4 of 7

Rev

Date

05 APRIL 2010

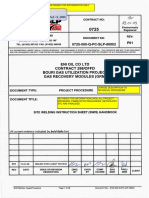

3. FLOW CHART HULL CONSTRUCTION WORK INSPECTION

PHASE

ACTIVITY

STORE HOUSE

IDENT MATERIAL

INSPECTION

USP Supervisor

QC USP

MATERIAL HANDLING

AUTO SHOT BLASTING &

SHOP PRIMER

FABRICATION SHOP

MARKING

CUTTING

QC Subcontractor

USP Supervisor

QC USP

QC Subcontractor

USP Supervisor

QC USP

QC Subcontractor

USP Supervisor

QC USP

BENDING

QC Subcontractor

USP Supervisor

QC USP

JOINT PLATE

QC Subcontractor

USP Supervisor

QC USP

MARKING & DIMENSIONAL

CHECK

QC Subcontractor

USP Supervisor

QC USP

FITTING SMALL PART

QC Subcontractor

USP Supervisor

QC USP

FIT UP PART

WELDING

. QC Subcontractor

USP Supervisor

QC USP

PT UNITED SINDO PERKASA

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

Document Number

Document Title

USP-NC-SOI-002

SEQUENCE OF INSPECTION

PHASE

ASSEMBLY

ACTIVITY

STAGE

MAKING BLOCK

FIT UP

Page

5 of 7

Rev

Date

05 APRIL 2010

INSPECTION

QC Subcontractor

USP Supervisor

QC USP

SCANTLING , LEVELLING &

DIMENSIONAL CONTROL

QC Subcontractor

USP Supervisor

QC USP

WELDING & NDT

QC Subcontractor

USP Supervisor

QC USP

DIMENSIONAL CONTROL

FAIRING

BLOCK INSPECTION

ERECTION STAGE

ADJUSTING

JOINT BLOCK

QC Subcontractor

USP Supervisor

QC USP

QC Subcontractor

USP Supervisor

QC USP

QC Subcontractor

USP Supervisor

QC USP

CLASS & CLIENT

QC Subcontractor

USP Supervisor

FIT UP BLOCK

QC Subcontractor

USP Supervisor

QC USP

CLASS

WELDING & NDT

QC Subcontractor

USP Supervisor

QC USP

DIMENSIONAL CHECK

FINAL INSPECTION

AIR TEST/STRUCTURAL TEST

FINAL PAINTING

QC Subcontractor

USP Supervisor

QC USP

QC Subcontractor

USP Supervisor

QC USP

CLASS & CLIENT

QC Subcontractor

USP Supervisor

QC USP

CLASS & CLIENT

QC Subcontractor

USP Supervisor

QC USP

PAINT REP & CLIENT

PT UNITED SINDO PERKASA

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

Document Number

Document Title

USP-NC-SOI-002

SEQUENCE OF INSPECTION

Page

6 of 7

Rev

Date

05 APRIL 2010

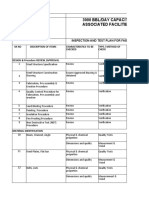

3. FLOW CHART PIPING WORK INSPECTION

PHASE

STORE HOUSE

ACTIVITY

INSPECTION

MATERIAL IDENTIFICATION

MATERIAL HANDLING

FABRICATION SHOP

MARKING

QC Subcontractor

USP Supervisor

CUTTING

QC Subcontractor

FITTING

QC Subcontractor

USP Supervisor

QC USP

WELDING & NDT

ON BOARD

INSTALLATION

FITTING

WELDING & NDT

FINAL LINE CHECK

FINAL HYDRO TEST

USP Supervisor

QC Subcontractor

USP Supervisor

QC USP

CLASS & CLIENT

QC Subcontractor

USP Supervisor

QC USP

QC Subcontractor

USP Supervisor

QC USP

CLASS & CLIENT

QC Subcontractor

USP Supervisor

QC

CLASS & CLIENT

QC Subcontractor

USP Supervisor

QC USP

CLASS & CLIENT

PT UNITED SINDO PERKASA

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

Document Number

Document Title

USP-NC-SOI-002

SEQUENCE OF INSPECTION

PHASE

ACTIVITY

FLUSHING

FINAL PAINTING

4.

Page

7 of 7

Rev

Date

05 APRIL 2010

INSPECTION

QC Subcontractor

USP Supervisor

QC USP

QC Subcontractor

USP Supervisor

QC USP

CLASS & CLIENT

Communication Practice

To perform official inspection activities, Client Representative should be accompanied

by QA/QC Engineer and / or QA/QC Inspector of the project. All comments and / or

recommendation should be address to the QA/QC Engineer as the contact person in

charge and will be informed to the Client Representative and Class Surveyor prior to

the inspection.

Вам также может понравиться

- Inspection & Test Plan: Sub-Contractor Con - Tractor Saudi AramcoДокумент1 страницаInspection & Test Plan: Sub-Contractor Con - Tractor Saudi AramcoDelta akathehusky100% (1)

- Control of Welding ConsumablesДокумент6 страницControl of Welding ConsumablesRakesh RanjanОценок пока нет

- Welding Procedure QualificationДокумент23 страницыWelding Procedure QualificationHosam AhmedОценок пока нет

- NDT MatrixДокумент2 страницыNDT MatrixPanagiotis Chatzakos100% (1)

- Welding Inspector Job and ResponsilbilitiesДокумент5 страницWelding Inspector Job and ResponsilbilitiesFelix GomintongОценок пока нет

- Obite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureДокумент22 страницыObite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureeetuaОценок пока нет

- IQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFДокумент11 страницIQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFAli MajeedОценок пока нет

- Section 5 - Supplier Quality Surveillance: 1.0 GeneralДокумент3 страницыSection 5 - Supplier Quality Surveillance: 1.0 Generalanishgirme100% (1)

- 3.2 Develop The Material Control PlanДокумент9 страниц3.2 Develop The Material Control Planjesus_bs100% (1)

- Qa Inspection and Test PlanДокумент1 страницаQa Inspection and Test Planit4scribdОценок пока нет

- 652-100-FINAL (ITP) Rev1Документ4 страницы652-100-FINAL (ITP) Rev1Anonymous AdofXEYAgEОценок пока нет

- Standard PracticeДокумент14 страницStandard PracticeRomi Abdul RahmanОценок пока нет

- PQP EpldtДокумент8 страницPQP Epldtmartin leeОценок пока нет

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Документ19 страницHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefОценок пока нет

- MATERIAL TRACEABILITY ReportДокумент16 страницMATERIAL TRACEABILITY ReportKandregula Mohan BabuОценок пока нет

- The Welding Inspection Services Are Define in Three Stages As BelowДокумент9 страницThe Welding Inspection Services Are Define in Three Stages As BelowdeliОценок пока нет

- Fabrication ProcedurДокумент7 страницFabrication ProcedurHarry PangestuОценок пока нет

- Construction Quality Plan G16BДокумент8 страницConstruction Quality Plan G16BDavid SeeОценок пока нет

- Cold Forming ProcedureДокумент5 страницCold Forming ProcedureMassimo FumarolaОценок пока нет

- Quality Control Checklist: Steel RepairДокумент2 страницыQuality Control Checklist: Steel RepairDilhara WickramaarachchiОценок пока нет

- Inspection Test Plan For FabricationДокумент4 страницыInspection Test Plan For FabricationAshwani Dogra100% (9)

- QCP For Control of Welding ConsumablesДокумент9 страницQCP For Control of Welding ConsumablesUmair Awan100% (1)

- Inspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationДокумент3 страницыInspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationKhaled GamalОценок пока нет

- Fabricatin Inspection Testing of Structural ProductДокумент44 страницыFabricatin Inspection Testing of Structural ProductwalitedisonОценок пока нет

- Re: Procurement & Material Storage: ProcedureДокумент4 страницыRe: Procurement & Material Storage: ProcedureAkash Singh TomarОценок пока нет

- TGN-BC-01 Tack Welding of Reinforcement BarДокумент8 страницTGN-BC-01 Tack Welding of Reinforcement BarFerhat KahveciОценок пока нет

- Asme Sec Ix (Welder Qualification)Документ39 страницAsme Sec Ix (Welder Qualification)VinodОценок пока нет

- Control of Welding ConsumableДокумент6 страницControl of Welding ConsumableRaja Rathinam100% (1)

- Welding InspectionДокумент7 страницWelding Inspectionzahid_497100% (1)

- General Format For Girder Fabrication Check ListДокумент4 страницыGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryОценок пока нет

- Material Grade S275Документ3 страницыMaterial Grade S275Tran Van DaiОценок пока нет

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Документ5 страницA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableОценок пока нет

- Corrective and Preventive Action On High Rejection RateДокумент1 страницаCorrective and Preventive Action On High Rejection RateRakeshОценок пока нет

- SOP - 01 - Structure Organization ChartДокумент10 страницSOP - 01 - Structure Organization ChartSuci YatiningtiyasОценок пока нет

- Job Description NDTДокумент4 страницыJob Description NDTNDTInstructorОценок пока нет

- Welding Control ProcedureДокумент9 страницWelding Control ProcedureRomi Abdul RahmanОценок пока нет

- W QC A 004 Rev1, WQT ProcedureДокумент15 страницW QC A 004 Rev1, WQT ProcedureAlif Rahmat FebriantoОценок пока нет

- 01 Procedure For Structural SteelДокумент9 страниц01 Procedure For Structural Steelpunitg_2Оценок пока нет

- Ok-Hydraulic Oil Flushing at Terminal AreaДокумент4 страницыOk-Hydraulic Oil Flushing at Terminal AreaEric TingОценок пока нет

- Weld Fit Up Inspection Employee TrainingДокумент10 страницWeld Fit Up Inspection Employee TrainingviswamanojОценок пока нет

- Quality Record Control ProcedureДокумент5 страницQuality Record Control ProcedureGomathyselviОценок пока нет

- Denso Pipe Wrapping SolutionsДокумент8 страницDenso Pipe Wrapping SolutionsVinoth MechОценок пока нет

- Inspode Quality Assurance ManualДокумент53 страницыInspode Quality Assurance ManualKeneth Del CarmenОценок пока нет

- Method Statement For Welding Control System: Sohar Refinery Improvement ProjectДокумент14 страницMethod Statement For Welding Control System: Sohar Refinery Improvement Projectmansih457100% (1)

- Procedure For WQTДокумент13 страницProcedure For WQTdevikar8umОценок пока нет

- Con-011 Instruction For Painting Work Rev.0Документ11 страницCon-011 Instruction For Painting Work Rev.0monchai_626Оценок пока нет

- KON 8.2 QA PRO 0020 C1 Welding Control ProcedureДокумент15 страницKON 8.2 QA PRO 0020 C1 Welding Control ProcedureAlizamin Salmanov100% (1)

- Method Statement For Fabrication of Steel WorksДокумент10 страницMethod Statement For Fabrication of Steel WorksB S ArunОценок пока нет

- 03 Welding Control Procedure - Asf QC WCP 001Документ7 страниц03 Welding Control Procedure - Asf QC WCP 001el_sharkawy2011100% (1)

- Welding Consumable Handling Storage & Issue Control ProcedureДокумент19 страницWelding Consumable Handling Storage & Issue Control ProcedureFerdie OSОценок пока нет

- 5 Contractor Quality Control Plan For Steel StructureДокумент3 страницы5 Contractor Quality Control Plan For Steel Structurebehzad esОценок пока нет

- OCTGДокумент1 страницаOCTGMurugananthamParamasivam100% (1)

- Transmittal SampleДокумент1 страницаTransmittal SamplekokocdfОценок пока нет

- Site Welding Instruction Sheet (SWIS) HandbookДокумент36 страницSite Welding Instruction Sheet (SWIS) HandbookNuwan RanaweeraОценок пока нет

- 2 QUALITY CONTROL Manual FINALДокумент8 страниц2 QUALITY CONTROL Manual FINALBilisumman Hawwe BeekaОценок пока нет

- NG-018-XX-PNL-430926 - Rev04 Weld Numbering System and Procedure UnsignedДокумент20 страницNG-018-XX-PNL-430926 - Rev04 Weld Numbering System and Procedure UnsignedFolarin Ayodeji100% (1)

- NG-018-XX-PNL-430949 - Rev04closure Weld Procedure and Examination UnsignedДокумент10 страницNG-018-XX-PNL-430949 - Rev04closure Weld Procedure and Examination UnsignedFolarin AyodejiОценок пока нет

- Material Receiving ProcedureДокумент7 страницMaterial Receiving ProcedureRomi Abdul Rahman100% (3)

- S-900-1670-581 - 1 - (Inspection and Test Plan For Rotating Machinery (Pumps and Air Compressors) )Документ10 страницS-900-1670-581 - 1 - (Inspection and Test Plan For Rotating Machinery (Pumps and Air Compressors) )Alif Rahmat Febrianto100% (3)

- Sc13003-p5003-q03-0003 - Itp Sea Water Intake SystemДокумент17 страницSc13003-p5003-q03-0003 - Itp Sea Water Intake SystemDwi Mulyanti DwimulyantishopОценок пока нет

- WPS KinoaДокумент31 страницаWPS KinoaRomi Abdul RahmanОценок пока нет

- Welding Control ProcedureДокумент9 страницWelding Control ProcedureRomi Abdul RahmanОценок пока нет

- Standard PracticeДокумент14 страницStandard PracticeRomi Abdul RahmanОценок пока нет

- Welding Control ProcedureДокумент9 страницWelding Control ProcedureRomi Abdul RahmanОценок пока нет

- Material Receiving ProcedureДокумент7 страницMaterial Receiving ProcedureRomi Abdul Rahman100% (3)

- NCR Control ProcedureДокумент6 страницNCR Control ProcedureRomi Abdul Rahman100% (5)

- Flame Straightening ProcedureДокумент7 страницFlame Straightening ProcedureRomi Abdul RahmanОценок пока нет

- Coating StandardДокумент40 страницCoating Standardkendo_qn100% (8)

- Carbon Steel GradesДокумент4 страницыCarbon Steel GradesKiky IchanafiОценок пока нет

- Welders Hand BookДокумент23 страницыWelders Hand Booksamyqatar100% (2)

- Dheeraj Resume ProductionДокумент4 страницыDheeraj Resume ProductionAmar AudichyaОценок пока нет

- 15 The Welding Simulation Solution GuidelinesДокумент152 страницы15 The Welding Simulation Solution GuidelinesFelipe ArceОценок пока нет

- GS 118-4 Storage and Control of Welding Consumables: August 1997Документ14 страницGS 118-4 Storage and Control of Welding Consumables: August 1997Mohd KhairulОценок пока нет

- Civl432 Bridge Design SummaryДокумент5 страницCivl432 Bridge Design SummarySheikh Mizanur RahmanОценок пока нет

- Mini Projects For Mechanical 10Документ12 страницMini Projects For Mechanical 10ZEESHANA001Оценок пока нет

- AESS GUIDE4thEditionДокумент28 страницAESS GUIDE4thEditionjaimin koratОценок пока нет

- Innershield NR-233 PDFДокумент3 страницыInnershield NR-233 PDFfernandojОценок пока нет

- Nwankwo Obi ReportДокумент23 страницыNwankwo Obi ReportWisdom Alaribe50% (4)

- JSPL Machinery Division Profile 1216Документ82 страницыJSPL Machinery Division Profile 1216Gurnam SinghОценок пока нет

- Date Sl. No Company Name WebsiteДокумент1 203 страницыDate Sl. No Company Name WebsiteSneha S100% (1)

- 40 Comparison of Vat WCT Rates For All StatesДокумент130 страниц40 Comparison of Vat WCT Rates For All StatesAbhishekVadadoriyaОценок пока нет

- MS Format-Tata Projects HosurДокумент19 страницMS Format-Tata Projects HosurSukhdeb BiswakarmaОценок пока нет

- Mid Term Report of InternshipДокумент16 страницMid Term Report of InternshipHafiz TalhaОценок пока нет

- Nuga Sigma Potenzia PDFДокумент30 страницNuga Sigma Potenzia PDFTriyonoОценок пока нет

- Tank ErectionДокумент13 страницTank Erectionsajay2010Оценок пока нет

- Abj Corporate Brochure - SmallsizeДокумент36 страницAbj Corporate Brochure - Smallsizeumer shafiqueОценок пока нет

- Resume SampleДокумент4 страницыResume SampleGokulPrasadОценок пока нет

- Manpower Planning - Final Assembly & ProcessingДокумент11 страницManpower Planning - Final Assembly & Processingsitam_nitj4202Оценок пока нет

- Itp For Structural Steel WorkДокумент12 страницItp For Structural Steel Worknguyen thangОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент21 страницаSaudi Aramco Inspection ChecklisthamidjoyiaОценок пока нет

- Inspection and Test PlanДокумент28 страницInspection and Test Planmfvallega88% (17)

- Fulima Steel Structure General Quality Control Program/Executive ManualДокумент51 страницаFulima Steel Structure General Quality Control Program/Executive ManualFULIMA Steel StructureОценок пока нет

- 60 M.bow String Girder-10411-7-RДокумент1 страница60 M.bow String Girder-10411-7-RkesharinareshОценок пока нет

- Descon News Spring-Summer 2009Документ36 страницDescon News Spring-Summer 2009Hassan Safdar MalikОценок пока нет

- Company Profile Details - OM Enterprise - Main PageДокумент15 страницCompany Profile Details - OM Enterprise - Main PagejaydeepОценок пока нет

- IEEE Guide To The Assembly and Erection of Metal Transmission Structures PDFДокумент44 страницыIEEE Guide To The Assembly and Erection of Metal Transmission Structures PDFjuanperezpintoОценок пока нет

- Fabrication of Steel StructureДокумент210 страницFabrication of Steel StructurePreeti goswamiОценок пока нет

- Vendor - Directory 01.07.19-31.12.19 PDFДокумент216 страницVendor - Directory 01.07.19-31.12.19 PDFsumitshyamal0% (1)

- EPT 09 T 04 Piping ConstructionДокумент30 страницEPT 09 T 04 Piping Constructionnwosu_dixon100% (1)