Академический Документы

Профессиональный Документы

Культура Документы

Exp 1 Transportation Engineering

Загружено:

Saad UllahОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Exp 1 Transportation Engineering

Загружено:

Saad UllahАвторское право:

Доступные форматы

Highway and Traffic Engineering

2015

EXPERIMENT NO. 1

Determination of flakiness and elongation index for the given aggregate

sample.

Flaky particle:

A flaky particle is the one whose least dimension (thickness) is less than 0.6

times the mean size.

Elongated particle:

These are the particles having length considerably larger than the other two

dimensions and it is the particle whose greater dimension is 1.8 times its

mean size.

SCOPE & SIGNIFICANCE:

This test is used to determine the particle shape of the aggregate and each

particle shape being preferred under specific conditions.

The significance of flakiness & elongation index is as follows;

The degree of packing of the particles of one size depends upon their

shape.

Due to high surface area to volume ratio, the flaky and elongated

particles lower the workability of concrete mixes.

Flaky and elongated particles are considered undesirable for base

coarse construction as they may cause weakness with possibilities of

braking down under heavy loads.

BS-1241 specifies a Flakiness index not exceeding 30% irrespective of

the aggregate size.

Maximum permitted Elongated index is 35, 40 or 45% for aggregate

sizes 2 2, 1 & 3/8.

Both Flakiness and Elongation tests are not applicable to sizes smaller

then 6.3mm i.e. sieve.

RELATED THEORY:

SHAPES OF PARTICLES

The usual shapes of the particles are;

i - Rounded (river gravel)

ii - Flaky (laminated rock)

iii - Elongated

Department of Civil Engineering

The University of Lahore

Highway and Traffic Engineering

2015

iv - Angular( crushed rock)

PREFERRED USE OF EACH SHAPE

Rounded aggregates are preferred in concrete roads (rigid

pavements) as the workability of concrete increases due to the

less friction between the surfaces.

Angular shape of the particles is desirable in granular base

coarse (flexible pavement) due to better interlocking and

increased stability.

Flaky and Elongated particles are considered as

a source of weakness.

APPARATUS:

Thickness/Flakiness Index Gauge

Length/Elongation Index Gauge

Aggregate sample to be tested

FLAKY

A flaky particle is the one whose least dimension (thickness) is than 0.6

times the mean size.

These are the materials of which the thickness is small as compared to the

other two dimensions.

Limit of flaky particles in the mixes is 30%. If the flaky particles are

greater than 30% then the aggregate is considered undesirable for the

intended use.

FLAKINESS INDEX

It is the percentage by weight of flaky particles in a sample.

Department of Civil Engineering

The University of Lahore

2 1/2 2

2015

2 1 1/2

1 1 1/2

1 3/4

3/4 1/2

3/8

Highway and Traffic Engineering

1 1/4 1

Thickness/Flakiness Index Gauge

Procedure

Perform the sieve analysis on the given aggregate sample

The aggregates are then arranged in the into a number of closely limited

particle size groups -stored orted on the test sieves into a number of closely

limited particle size groups 2 2, 1 & 3/8

Each group (fraction) is weighed and tested for thickness on appropriate

opening of the thickness gauge by passing each particle through slot of

specified thickness along least dimension.

The weight of particles passing the thickness gauge is recorded for each

fraction. This is the weight of flaky particles.

The flakiness index is calculated by expressing the weight of flaky particles

as a percentage of total weight of the sample.

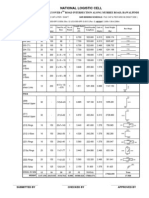

Calculation for Sieve Analysis:

Sieve Size

Weight Percentage Cumulative Percentage

weight

passing

Passing Retained Retained Retained

(kg)

(%)

retained

(%)

(in.)

(in.)

(%)

2

1

1

3/8

1

1

3/8

Pan

=

Department of Civil Engineering

The University of Lahore

Highway and Traffic Engineering

2015

Calculation for Flaky Particles:

Sieve Size

Weight Percentage Weight Individual Weighted

of Flaky Flakiness Flakiness

Passing Retained Retained Retained

(gm)

(%)

Particles

Index

Index

(in.)

(in.)

(kg)

(%)

(%)

2

1

1

3/8

1

1

3/8

Pan

=

ELONGATED PARTICLES

These are the particles having length considerably larger than the other two

dimensions and it is the particle whose greater dimension is 1.8 times its mean size.

Limit of elongated particles in the mixes is 45%. Thus, if the elongated

particles are greater than 45%, then the aggregate is considered undesirable for

the intended use.

ELONGATION INDEX

It is the percentage by weight of elongated particles in a sample. The

Elongated index is calculated by expressing the weight of Elongated

particles as percentage of total weight of the sample.

3/8

1

26 20 mm 14 10 mm

2 1

50 37.5 mm

1 1

37.5 26 mm

20 14 mm

Length/Elongation Index Gauge

Department of Civil Engineering

3/8

10 6.3 mm

The University of Lahore

Highway and Traffic Engineering

2015

Calculation for Elongated Particles:

Sieve Size

Weight Percentage

Weight

Individual Weighted

of

Elongation Elongation

Passing Retained Retained Retained

(gm)

(%)

Elongated

Index

Index

(in.)

(in.)

(%)

(%)

Particles

(kg)

2

1

1

3/8

1

1

3/8

Pan

=

PRECAUTIONS:

1- While sieving, care must be taken that the particles that are chocked in the

sieve must not be forced down into the next sieve. Such particles should be

pushed back into the same sieve.

2- While placing different fractions on the table, place them some distance

apart so that no two fractions may get mixed.

3- Be careful while selecting the opening of the flakiness and elongation gauges

for any particular fraction.

COMMENTS:

Department of Civil Engineering

The University of Lahore

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- GroundДокумент1 страницаGroundSaad UllahОценок пока нет

- SBP BSC YPIP 7th Batch Sample PaperДокумент6 страницSBP BSC YPIP 7th Batch Sample PaperAmy 786Оценок пока нет

- Impact of SHRM On Org's PerformanceДокумент17 страницImpact of SHRM On Org's PerformanceShrikant PatelОценок пока нет

- Effect of Public Transport Change On Smoke Change A Case Study of Sahiwal CityДокумент1 страницаEffect of Public Transport Change On Smoke Change A Case Study of Sahiwal CitySaad UllahОценок пока нет

- Leveling for construction projectsДокумент60 страницLeveling for construction projectsSaad UllahОценок пока нет

- GIS Data TypeДокумент12 страницGIS Data TypeSaad UllahОценок пока нет

- Amina ResumeДокумент2 страницыAmina ResumeSaad UllahОценок пока нет

- Laila Khalid 2Документ2 страницыLaila Khalid 2Saad UllahОценок пока нет

- HBL Car Loan CalculatorДокумент1 страницаHBL Car Loan CalculatorSaad UllahОценок пока нет

- Asseement of Human Resources MangementДокумент2 страницыAsseement of Human Resources MangementSaad UllahОценок пока нет

- Public Transport Accessibility Level (Ptal) Based Mapping and Analysis of Rawalpindi and IslamabadДокумент2 страницыPublic Transport Accessibility Level (Ptal) Based Mapping and Analysis of Rawalpindi and IslamabadSaad UllahОценок пока нет

- Runway DesignДокумент50 страницRunway DesignSaad UllahОценок пока нет

- MS Thesis GuidelinesДокумент9 страницMS Thesis GuidelinesSaad UllahОценок пока нет

- CASE Registration FormДокумент2 страницыCASE Registration FormSaad UllahОценок пока нет

- 8-Compaction TestДокумент4 страницы8-Compaction TestSaad UllahОценок пока нет

- Specific GravityДокумент3 страницыSpecific GravitySaad UllahОценок пока нет

- 8-Compaction TestДокумент4 страницы8-Compaction TestSaad UllahОценок пока нет

- Digital Library Registration RequirementsДокумент1 страницаDigital Library Registration Requirementsasher_tfm1693Оценок пока нет

- 1 Sieve AnalysisДокумент2 страницы1 Sieve AnalysisSaad UllahОценок пока нет

- Ms Dos: Presented by Muhammad SaadullahДокумент6 страницMs Dos: Presented by Muhammad SaadullahSaad UllahОценок пока нет

- Application Form For EmploymentДокумент4 страницыApplication Form For EmploymentSaad UllahОценок пока нет

- Field Study Report For Traffic SignsДокумент15 страницField Study Report For Traffic SignsSaad UllahОценок пока нет

- ACAD Residential DesignДокумент46 страницACAD Residential DesignSaad UllahОценок пока нет

- Programming in CДокумент150 страницProgramming in CSaad UllahОценок пока нет

- PIER 07 (GRID # 08) Bar BendingДокумент2 страницыPIER 07 (GRID # 08) Bar BendingSaad UllahОценок пока нет

- University of Lahore ProspectusДокумент143 страницыUniversity of Lahore ProspectusSaad Ullah0% (2)

- L05 IdeologicalFoundationsДокумент95 страницL05 IdeologicalFoundationsSaad UllahОценок пока нет

- Construction Instructions for Anchorage Housing PlotsДокумент2 страницыConstruction Instructions for Anchorage Housing PlotsSaad UllahОценок пока нет

- TEST PILE Steel Schedules 6th RoadДокумент5 страницTEST PILE Steel Schedules 6th RoadSaad UllahОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Specifications: 1.write The Detail Technical Specification For Earthwork Excavation in Hard SoilДокумент5 страницSpecifications: 1.write The Detail Technical Specification For Earthwork Excavation in Hard SoilAnusha ChikmathОценок пока нет

- Safety Requirements for ScaffoldsДокумент16 страницSafety Requirements for ScaffoldschassasОценок пока нет

- The Basohil Cable Stayed BridgeДокумент7 страницThe Basohil Cable Stayed BridgeNagar NitinОценок пока нет

- Product DescriptionДокумент8 страницProduct DescriptionPatrisha SantosОценок пока нет

- Tunnel Formwork System GuideДокумент22 страницыTunnel Formwork System GuidesuvraОценок пока нет

- Dam Engineering HandoutДокумент135 страницDam Engineering Handoutthisisghostactual86% (7)

- GRC Durability PDFДокумент2 страницыGRC Durability PDFWissam AlameddineОценок пока нет

- Omun - 2018 - Data On Mixing and Curing Methods Effects On The Compressive Strength of ConcreteДокумент6 страницOmun - 2018 - Data On Mixing and Curing Methods Effects On The Compressive Strength of ConcreteEliasTalaAllcaОценок пока нет

- Basf Masteremaco t288 TdsДокумент2 страницыBasf Masteremaco t288 TdsJimmy ReeseОценок пока нет

- Chapter 3 Example Set 1Документ21 страницаChapter 3 Example Set 1alaa altaeeОценок пока нет

- Department of Civil Engineering Centre For Diploma Studies Material and Structure LaboratoryДокумент11 страницDepartment of Civil Engineering Centre For Diploma Studies Material and Structure LaboratoryHafizul Zaidan100% (1)

- BSR 2019 PDFДокумент143 страницыBSR 2019 PDFSujithОценок пока нет

- Marthon Jotun Marine PaintДокумент5 страницMarthon Jotun Marine PaintNishanthОценок пока нет

- Impact of Surkhi On GSB Layer As Replacement To The Stone DustДокумент10 страницImpact of Surkhi On GSB Layer As Replacement To The Stone DustVikas KumarОценок пока нет

- Pentron ProductsДокумент3 страницыPentron ProductsBabar AkbarОценок пока нет

- TTM Post TensioningДокумент103 страницыTTM Post Tensioninghorea67100% (2)

- Ecv 3 UnitДокумент8 страницEcv 3 UnitshakirОценок пока нет

- ASTM C 289 ASR Aggregates Chemical MethodДокумент7 страницASTM C 289 ASR Aggregates Chemical Methodsattiric100% (1)

- ICC-ES Evaluation Report ESR-1663Документ13 страницICC-ES Evaluation Report ESR-1663hectoriturbeОценок пока нет

- FMDДокумент6 страницFMDhazopmanОценок пока нет

- Optimum Design of Reinforced Concrete Raft Foundations Using Finite Element AnalysisДокумент78 страницOptimum Design of Reinforced Concrete Raft Foundations Using Finite Element AnalysisLaison GodloveОценок пока нет

- Building Survey Report SampleДокумент91 страницаBuilding Survey Report SampleabcОценок пока нет

- Cemwet SP 3000 (Pce 3)Документ2 страницыCemwet SP 3000 (Pce 3)Angry BoyОценок пока нет

- Checklist For Pre-Pour ConcretingДокумент1 страницаChecklist For Pre-Pour ConcretingDanish mallick100% (1)

- Seismic Analysis of Tall Concrete and Steel Diagrid Strucures Using Response Spectrum and Time History Method in E-TabsДокумент29 страницSeismic Analysis of Tall Concrete and Steel Diagrid Strucures Using Response Spectrum and Time History Method in E-TabsMullapudi Kiran Chowdary100% (1)

- MS - SikaWrap-231 C (Structural Strenghtening) (v.01.2018)Документ5 страницMS - SikaWrap-231 C (Structural Strenghtening) (v.01.2018)abdillah mursyidОценок пока нет

- Building Failure - Causes and Case StudiesДокумент14 страницBuilding Failure - Causes and Case Studiesresha bhatiaОценок пока нет

- High Performance Epoxy GroutДокумент2 страницыHigh Performance Epoxy Groutpravi3434Оценок пока нет

- DICT Sodium GluconateДокумент3 страницыDICT Sodium GluconatejimmyОценок пока нет

- Lecture 7 Portland CementДокумент13 страницLecture 7 Portland Cementsalil dubeyОценок пока нет