Академический Документы

Профессиональный Документы

Культура Документы

Acoustic Induced Vibration - Flare Systems PDF

Загружено:

sri9987Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Acoustic Induced Vibration - Flare Systems PDF

Загружено:

sri9987Авторское право:

Доступные форматы

Plant Asset Management

Acoustic Induced Vibration of Flare Systems

A flare study considers the following aspects:

Acoustic Fatigue due to shock noise

from the pressure relief and blowdown

valves

Flow Induced Vibration due to the

relatively high flow velocities in a flare

system flow turbulence can excite high

levels of vibration

Valve Transient due to the fast

acting nature of relief valves, high

transient forces can occur as the valve

opens

Plant Asset Management (PAM) provides design

and troubleshooting support for pressure relief

/ flare systems. The flare system for a plant is

a critical safety system and is exposed to

several sources of excitation, that if

inadequately designed could result in rapid

fatigue failures and loss of containment.

Sonic flow in tail pipes and headers

sonic flow can dramatically increase

the internal acoustic energy with in

flare systems

Local noise relief and blowdown

valves are inherently noisy, as part of a

flare study PAM predicts noise levels

local to such valves

At design or operational stage a flare system

study can be performed to highlight high risk

components of a flare system. For high risk

components further more detailed analysis can

be performed to quantify the risk, and/or

suitable remedial modifications can be

recommended to reduce the risk of failure.

Plant Asset Management is a leading international provider of intelligent asset integrity management solutions to the energy industry, with a

diverse customer portfolio including many of the worlds leading integrated, independent and national oil & gas companies.

For more information on our provision of asset integrity management solutions, please contact

pam@petrofac.com or visit our website www.petrofac.com.

www.petrofac.com

Plant Asset Management

Acoustic Induced Vibration of Flare Systems

The initial flare study is used to highlight

components within the flare system that have

a high risk of fatigue failure. For operational

plant PAM has a suite of more detailed

assessments that can be used to quantify the

risk of a failure, and then model potential

solutions.

Remedial Modification

Dependant on whether the plant is at design

or operational stage often determines the type

most applicable modification. At design stage

typical modifications to reduce the risk would

be:

Using more robust connections, such as

forged tees and sweepolets, rather

than fabricated tees or weldolets

Increasing pipe wall thickness

Increasing pipe diameter

Installing additional supports

At operational stage typical modifications are:

Bracing of high risk connections

Installation of stiffening rings to block

pipe ovalling modes

Additional

locally

to

pipe

PSVs

supports,

to

such

mitigate

transient load on valve opening

as

the

There are compelling benefits to be achieved from

undertaking piping vibration induced fatigue

assessments:

Reduce the risk of a fatigue failure/hydrocarbon

release to ALARP

Reduce the number of unplanned shutdowns

Increase the integrity of piping systems

Compliance with statutory duty

Improve safety and reliability

Minimise financial liabilities and lost production

Minimise time detracted from core business

Reduced insurance costs

Assessments to identify piping integrity risks

due to acoustic induced vibration will

deliver value at all stages of the plant

lifecycle. Plant Asset Management has the

expertise, the experience and the software

tools to undertake such assessments at the

design stage of new plants, for operating

plants and during de-bottlenecking.

Plant Asset Management is a leading international provider of intelligent asset integrity management solutions to the energy industry, with a

diverse customer portfolio including many of the worlds leading integrated, independent and national oil & gas companies.

For more information on our provision of asset integrity management solutions, please contact

pam@petrofac.com or visit our website www.petrofac.com.

www.petrofac.com

Вам также может понравиться

- Pulsation of Flow and Pressure in Piping of Reciprocating CompressorsДокумент26 страницPulsation of Flow and Pressure in Piping of Reciprocating CompressorsSuhas JoshiОценок пока нет

- ACHE Windmill DraftguardДокумент5 страницACHE Windmill DraftguardTIKSHALAОценок пока нет

- Product Bulletin - Puraspec 1173Документ1 страницаProduct Bulletin - Puraspec 1173elias100% (1)

- Barry Dooley Introducton-to-ACC-FAC-and-Cycle-ChemistryДокумент37 страницBarry Dooley Introducton-to-ACC-FAC-and-Cycle-Chemistrychemicalchouhan9303Оценок пока нет

- APGA Code of Practice For Upstream PE Gathering Lines in The CSG IndustryДокумент174 страницыAPGA Code of Practice For Upstream PE Gathering Lines in The CSG Industrydamian o'connorОценок пока нет

- ERCB - Inspection Manual001Документ60 страницERCB - Inspection Manual001bluesОценок пока нет

- Screening Reactor For Water HammerДокумент49 страницScreening Reactor For Water HammerYu GanОценок пока нет

- CRP Sampling Literature PDFДокумент8 страницCRP Sampling Literature PDFgullenariОценок пока нет

- Dynamic Testing of CheckvalveДокумент10 страницDynamic Testing of Checkvalveamirthraj74Оценок пока нет

- Improve Flaring OperationsДокумент4 страницыImprove Flaring Operationsaa dd qqОценок пока нет

- Integrated Training Program / Phase B - Flare Protection Systems Page 1 of 33Документ33 страницыIntegrated Training Program / Phase B - Flare Protection Systems Page 1 of 33metasoniko2014Оценок пока нет

- ISO 12213-3 Part 1 - Introduction and GuidelinesДокумент8 страницISO 12213-3 Part 1 - Introduction and GuidelinesserefbingolОценок пока нет

- Valves and Regulators - Turndown RatioДокумент3 страницыValves and Regulators - Turndown RatioklashincoviskyОценок пока нет

- Bondstrand 2416 / 3416 Glassfiber Reinforced Epoxy (GRE) Pipe Systems For and ServicesДокумент28 страницBondstrand 2416 / 3416 Glassfiber Reinforced Epoxy (GRE) Pipe Systems For and ServicesantoncanuckОценок пока нет

- Mokveld-Brochure Axial Check Valve enДокумент12 страницMokveld-Brochure Axial Check Valve enteacgОценок пока нет

- Thermal Fatigue Due To Statification in PipingДокумент16 страницThermal Fatigue Due To Statification in PipinghamadaniОценок пока нет

- Applications Guideline-Flashing (Water)Документ2 страницыApplications Guideline-Flashing (Water)strahor7492Оценок пока нет

- 10 Steps To Pump ReliabilityДокумент15 страниц10 Steps To Pump ReliabilityaqhammamОценок пока нет

- Calculation Methods For Thick Walled Components Under Creep Fatigue - Review and Advanced ConceptsДокумент9 страницCalculation Methods For Thick Walled Components Under Creep Fatigue - Review and Advanced ConceptsMarcus BaltesОценок пока нет

- Cavitational FlowДокумент11 страницCavitational FlowriemannОценок пока нет

- Samson: Evaluating The Calculation Accu-Racy Provided by The Relevant Noise Prediction Standards For Control ValvesДокумент12 страницSamson: Evaluating The Calculation Accu-Racy Provided by The Relevant Noise Prediction Standards For Control ValvesGopinath GunasekaranОценок пока нет

- Ethylene PipesДокумент8 страницEthylene Pipesingbarragan87Оценок пока нет

- User Guide FlowscannerДокумент137 страницUser Guide FlowscannerJDavid NavaОценок пока нет

- Article Properly Size Control Valves Fisher en 38152Документ4 страницыArticle Properly Size Control Valves Fisher en 38152Sergio Andres Villate UlloaОценок пока нет

- Numerically Efficient Modified Runge-Kutta Solver For Fatigue Crack Growth AnalysisДокумент8 страницNumerically Efficient Modified Runge-Kutta Solver For Fatigue Crack Growth AnalysisMuhammad Ahsan SaleemОценок пока нет

- Scandpower Fire Guidelines Version 2 PDFДокумент81 страницаScandpower Fire Guidelines Version 2 PDFliОценок пока нет

- The New 3rd Edition of The ALPEMA Plate-Fin Heat Exchanger StandardsДокумент3 страницыThe New 3rd Edition of The ALPEMA Plate-Fin Heat Exchanger StandardsvheshaghianОценок пока нет

- Asme Steam Hammer CritiqueДокумент11 страницAsme Steam Hammer Critique이승원100% (1)

- As 3814-2009 Industrial and Commercial Gas-Fired AppliancesДокумент9 страницAs 3814-2009 Industrial and Commercial Gas-Fired AppliancesSAI Global - APACОценок пока нет

- Impulse 4.0 Users Guide SI PDFДокумент554 страницыImpulse 4.0 Users Guide SI PDFalberto fuentealbaОценок пока нет

- Api 931 Chapter 6 Dispersion of Gases PDFДокумент40 страницApi 931 Chapter 6 Dispersion of Gases PDFArcangelo Di TanoОценок пока нет

- Long Weld Necks 300 PDFДокумент1 страницаLong Weld Necks 300 PDFPedro Montes MarinОценок пока нет

- Valve Sizing and Selection: FREE ResourcesДокумент6 страницValve Sizing and Selection: FREE ResourcesSARATH KRISHNAKUMARОценок пока нет

- Methodology ArticleДокумент6 страницMethodology ArticleItalo AdottiОценок пока нет

- Heater Treater SeparatorДокумент2 страницыHeater Treater SeparatorMurat KalfaОценок пока нет

- Improved Analysis of External Loads On Flanged JointsДокумент1 страницаImproved Analysis of External Loads On Flanged JointsTiHoRОценок пока нет

- Fisher - Compressor Anti Surge ValveДокумент3 страницыFisher - Compressor Anti Surge ValveAlexa MouawadОценок пока нет

- PSV NoiseДокумент7 страницPSV NoiseJomer J SimpsonОценок пока нет

- Gas RegulationsДокумент168 страницGas RegulationsJijo GeorgeОценок пока нет

- Heat Transfer Problem 2014Документ240 страницHeat Transfer Problem 2014arminОценок пока нет

- KIRK KSME Axial Cyclone Swirl Mist Eliminators PDFДокумент4 страницыKIRK KSME Axial Cyclone Swirl Mist Eliminators PDFสิทธิไชย อรุณวํฒนชัยОценок пока нет

- In Line MixingДокумент4 страницыIn Line MixingKemas Ganesha MahendraОценок пока нет

- Process Engineering Course by IfluidsДокумент81 страницаProcess Engineering Course by IfluidsirfichemОценок пока нет

- Drains SystemsДокумент37 страницDrains SystemsKamal SkОценок пока нет

- Waha3 ManualДокумент186 страницWaha3 ManualsaifoaОценок пока нет

- Safe Chemical Reaction Scale Up: by Dennis C. Hendershot, Aaron SarafinasДокумент7 страницSafe Chemical Reaction Scale Up: by Dennis C. Hendershot, Aaron Sarafinasnitin_kheseОценок пока нет

- Gestra Technical Information 2021 enДокумент204 страницыGestra Technical Information 2021 enAdverОценок пока нет

- Improve Evaluation of Brittle Fracture Resistance For VesselsДокумент6 страницImprove Evaluation of Brittle Fracture Resistance For VesselsAnonymous 1XHScfCIОценок пока нет

- ABB Ie2 High EfficiencyДокумент4 страницыABB Ie2 High EfficiencyPARBATIОценок пока нет

- Basic Knowledge Safety Valves enДокумент7 страницBasic Knowledge Safety Valves enKarthik RaoОценок пока нет

- Materials Selection in Oil and Gas-An OverviewДокумент15 страницMaterials Selection in Oil and Gas-An OverviewAli AliОценок пока нет

- ClydeBergemannSootblowers PrinceGeorge06Документ36 страницClydeBergemannSootblowers PrinceGeorge06Arun YogaОценок пока нет

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsОт EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahОценок пока нет

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979От EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonОценок пока нет

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988От EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockОценок пока нет

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectОт EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectОценок пока нет

- Plant Engineering and Design The Ultimate Step-By-Step GuideОт EverandPlant Engineering and Design The Ultimate Step-By-Step GuideОценок пока нет

- BDVДокумент1 страницаBDVsri9987Оценок пока нет

- Valve ClassДокумент3 страницыValve Classsri9987Оценок пока нет

- TNEB Online Payment RekhaДокумент1 страницаTNEB Online Payment Rekhasri9987Оценок пока нет

- Valve ClassДокумент3 страницыValve Classsri9987Оценок пока нет

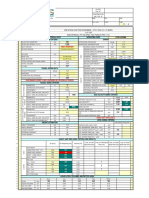

- Hazid/Envid/Dsr 1& Dsr2 /hazop /sil / Select Phase Action Tracking SheetДокумент6 страницHazid/Envid/Dsr 1& Dsr2 /hazop /sil / Select Phase Action Tracking Sheetsri9987Оценок пока нет

- Leaked ValveДокумент3 страницыLeaked ValveJosé Daniel ArenasОценок пока нет

- An Evaluation of General "Rules of Thumb" in Amine Sweetening UnitДокумент18 страницAn Evaluation of General "Rules of Thumb" in Amine Sweetening Unitrohl55Оценок пока нет

- Fluid Flow and Simulation SoftwaresДокумент57 страницFluid Flow and Simulation Softwaressri9987100% (1)

- Initiate SinglДокумент1 страницаInitiate Singlsri9987Оценок пока нет

- DcrerweДокумент1 страницаDcrerwesri9987Оценок пока нет

- Nutrition Science and Ways To EatДокумент18 страницNutrition Science and Ways To Eatsri9987Оценок пока нет

- IFE Modul 29092011Документ48 страницIFE Modul 29092011sri9987Оценок пока нет

- E ReceiptДокумент1 страницаE Receiptsri9987Оценок пока нет

- Liquid VS Distance PDFДокумент1 страницаLiquid VS Distance PDFsri9987Оценок пока нет

- Standard DocumentДокумент43 страницыStandard Documentsri9987100% (1)

- Flow AssuranceДокумент10 страницFlow Assurancesri9987Оценок пока нет

- RT PDFДокумент2 страницыRT PDFsri9987Оценок пока нет

- Mathcad Verticalseparatorsizing PDFДокумент8 страницMathcad Verticalseparatorsizing PDFGhilescu DaniilОценок пока нет

- Getting Started With Aspen HYSYS DynamicsДокумент42 страницыGetting Started With Aspen HYSYS Dynamicsjimbob8888Оценок пока нет

- Objective: Vessel Sizing Report Using ICARUSДокумент2 страницыObjective: Vessel Sizing Report Using ICARUSsri9987Оценок пока нет

- 5 L1 Aspen TutorialДокумент28 страниц5 L1 Aspen TutorialariefОценок пока нет

- Understanding Wax Problems Leads To Deepwater Flow Assurance SolutionsДокумент4 страницыUnderstanding Wax Problems Leads To Deepwater Flow Assurance SolutionsAndrea ZuritaОценок пока нет

- Separation Equipments Mod5Документ34 страницыSeparation Equipments Mod5msn1981Оценок пока нет

- Liquid VS Distance PDFДокумент1 страницаLiquid VS Distance PDFsri9987Оценок пока нет

- Liquid Vs DistanceДокумент1 страницаLiquid Vs Distancesri9987Оценок пока нет

- Cleaning Pig Designs and ApplicationsДокумент24 страницыCleaning Pig Designs and ApplicationsPasquale CutriОценок пока нет

- 1 IntroductionToArtificialLiftMethodsДокумент29 страниц1 IntroductionToArtificialLiftMethodsMahesh MahajanОценок пока нет

- Banchmark Olga Vs LedaДокумент79 страницBanchmark Olga Vs Ledasri9987100% (1)

- Oisd 226 For Pipeline IntegrityДокумент21 страницаOisd 226 For Pipeline IntegrityAmritesh Pandey100% (3)

- DistilationДокумент105 страницDistilationbahaaabdelnaserОценок пока нет

- Bipard Prashichhan (Gaya) - 87-2023Документ8 страницBipard Prashichhan (Gaya) - 87-2023tinkulal91Оценок пока нет

- CashflowДокумент3 страницыCashflowsikandar aОценок пока нет

- IBNR Reserves and Workers CompДокумент11 страницIBNR Reserves and Workers CompKirk HartleyОценок пока нет

- Group Assignment Cover Sheet: Student DetailsДокумент9 страницGroup Assignment Cover Sheet: Student DetailsMinh DucОценок пока нет

- CH 2 - T.BДокумент25 страницCH 2 - T.BSAMOIERОценок пока нет

- LELE21M880POD22004331Документ4 страницыLELE21M880POD22004331Bhavik KakkaОценок пока нет

- STANDARD BANK Co Applicant Application FormДокумент4 страницыSTANDARD BANK Co Applicant Application Formpokipanda69100% (1)

- Application For Bank FacilitiesДокумент4 страницыApplication For Bank FacilitiesChetan DigarseОценок пока нет

- ConsolidateДокумент40 страницConsolidatePopeye AlexОценок пока нет

- Republic Vs CaguioaДокумент6 страницRepublic Vs CaguioaKim Lorenzo CalatravaОценок пока нет

- R.A. 9147 Wildlife Resources Conservation and Protection ActДокумент17 страницR.A. 9147 Wildlife Resources Conservation and Protection ActDennis S. SiyhianОценок пока нет

- AB Capital ConcallДокумент22 страницыAB Capital ConcallHarsimran SinghОценок пока нет

- IFRS 9 Training Slides For MLDC - DAY 1Документ43 страницыIFRS 9 Training Slides For MLDC - DAY 1Onche Abraham100% (1)

- Overview of Mutual Fund Ind. HDFC AMCДокумент67 страницOverview of Mutual Fund Ind. HDFC AMCSonal DoshiОценок пока нет

- NeekiДокумент2 страницыNeekiRamОценок пока нет

- Macro FinanceДокумент6 страницMacro FinanceSaurabhRoyОценок пока нет

- At January 2008 IssueДокумент68 страницAt January 2008 IssuejimfiniОценок пока нет

- Determinants of Profitability of Non Bank Financial Institutions' in A Developing Country: Evidence From BangladeshДокумент12 страницDeterminants of Profitability of Non Bank Financial Institutions' in A Developing Country: Evidence From BangladeshNahid Md. AlamОценок пока нет

- Iesco Online Billl PDFДокумент2 страницыIesco Online Billl PDFAsad AliОценок пока нет

- 1ed93719-2adb-4d95-979a-8a978e846df6Документ11 страниц1ed93719-2adb-4d95-979a-8a978e846df6jim912Оценок пока нет

- Bulkowsky PsicologiaДокумент41 страницаBulkowsky Psicologiaamjr1001Оценок пока нет

- Paper Individual ODCM - Kokoh RonaldДокумент17 страницPaper Individual ODCM - Kokoh RonaldAndy ZhengОценок пока нет

- ACC3022H+2021+Nov+2021 Scenario+and+RequiredДокумент13 страницACC3022H+2021+Nov+2021 Scenario+and+RequiredkateОценок пока нет

- SBT PDFДокумент9 страницSBT PDFrijulalktОценок пока нет

- HAJI ALI IMPORT EXPORT-Exim-Islampur-395Документ8 страницHAJI ALI IMPORT EXPORT-Exim-Islampur-395Eva AkashОценок пока нет

- Lesson 1 Definition of Finance Goals of The Financial ManagerДокумент14 страницLesson 1 Definition of Finance Goals of The Financial ManagerJames Deo CruzОценок пока нет

- The Great TakingДокумент107 страницThe Great TakingJohn100% (3)

- Safal Niveshak Stock Analysis Excel Ver 50 How To Use This Spreadsheet PDF FreeДокумент49 страницSafal Niveshak Stock Analysis Excel Ver 50 How To Use This Spreadsheet PDF Freeraj110Оценок пока нет

- A Design Measurement and Management Model: The DMI Design Value ScorecardДокумент7 страницA Design Measurement and Management Model: The DMI Design Value ScorecardDaz ArunabhОценок пока нет

- (C501) (Team Nexus) Assignment 1Документ14 страниц(C501) (Team Nexus) Assignment 1Mohsin Md. Abdul KarimОценок пока нет