Академический Документы

Профессиональный Документы

Культура Документы

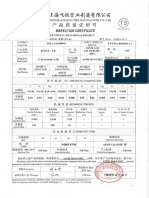

304L MTC Int PDF

Загружено:

Tanmoy DuttaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

304L MTC Int PDF

Загружено:

Tanmoy DuttaАвторское право:

Доступные форматы

AISI

304

DIN

1.4301 - X 5 CrNi 18 10

General characteristics

AFNOR

Z 6 CN 18 09

Austenitic stainless steel of intermediate corrosion resistance.

The high tolerance in carbon presents a risk for the precipitation of chromium carbides in the grain boundaries during

heat treatment. These carbides reduce the resistance to intergranular corrosion. In applications presenting the risk of

intergranular corrosion, the low carbon grade 304 L is preferably used.

In case of complex machining operation, due to the limited machinability of the steel 304, consider to use a free

machining grade (PX, 316 LS) or a modified 316 L grade (PM) when a high corrosion resistance is required.

For applications in chlorine environments or sea water, a molybdenum containing steel of type 316L is to be preferred.

For direct and prolonged contact with skin, the 316L type is preferred.

Machinability

Quench hardening

Polishing

Magnetic

Age hardening

Welding

no

no

no

MIG,TIG,WIG

Arc

Resistance

Autogenous

Laser

yes

yes

yes

yes

Chemical composition

C

Si

Mn

P

S

Cr

< 0.07

< 1.00

< 2.00

< 0.045

< 0.015*

17.0-19.5

*S < 0.03% for bars, wires, profiles and corresponding semi-products

Physical properties

Density

Electrical resistivity

r [Wm]

0.73

Coefficient of thermal expansion

r [kgm-3]

7'900

100 C

16.0

Annealed

Full hard

20C

200

965

100C

157

200C

127

Others

N < 0.11

Thermal conductivity

Cp [Jkg-1K-1]

500

l [Wm-1K-1]

15

Elastic modulus

E [GPa]

200 at 20C

Yield strength

Rp0.2 [MPa]

State

Ni

8.0 - 10.5

Specific heat

a [10-6C-1] between 20C and

300 C

400 C

500 C

600 C

17

18

18

18.5

Mechanical properties

200 C

17

Mo

-

700 C

18.5

Tensile

strength

Rm [MPa]

500-700

1275

300C

110

Elongation

A5 [%]

45

4

Vickers

Hardness

[HV]

160 - 200

390

Thermal treatments

Type

Annealing

Temperature

[C]

1020 -1080

Time

[minutes]

15 - 60

Protective atmosphere

H2 + N2 or cracked NH3

Surface treatments

Cooling

Quench (water, oil)

Type

Pickling

Passivation

Solution

Remarks

6 - 25 % HNO3 + 0.5 - 8 % HF

Only suitable in annealed condition, hot

20 - 50% HNO3

Hot

Fabrication characteristics

This steel can easily be cold rolled, drawn and stamped. Suitable tooling is required because of its high work hardening rate. This alloy becomes

slightly magnetic with increased cold working. This stainless steel should not be maintained for a long time between 500C and 900C, because of

possible precipitation of chromium carbides at grain boundaries. A consecutive annealing for carbide dissolution is necessary, followed by rapid

cooling to prevent a new precipitation. Quenching is recommended independently of the size of the pieces. This steel is relatively difficult to machine,

modified steels such as PX, 316LS or PM with the addition of chip breaking additives may be preferred.

Welding, brazing and soldering

This steel can easily be welded by any conventional joining technique, except the oxyacetylene torch.

and quenching are recommended after welding to prevent the risk of intergranular corrosion.

The grade 304 L is preferably used for welded constructions as this low carbon grade will not be sensitized.

Available products

Sheets, ribbons, wires, profiles, tubes, dimensions and tolerances on request.

The indications are basically founded on our actual know-how. This technical data sheet is without

commitment and not contracted.

Annealing

Вам также может понравиться

- MTC - Astm A36 - Jis400 - Q235Документ2 страницыMTC - Astm A36 - Jis400 - Q235nayeemОценок пока нет

- Test Certificate: (, Phone: 26751763 MillДокумент1 страницаTest Certificate: (, Phone: 26751763 MillQc QatarОценок пока нет

- MTC, Test Report & Packing ListДокумент63 страницыMTC, Test Report & Packing Listjubair100% (1)

- Al Jazeera Steel Products MTC ReportДокумент1 страницаAl Jazeera Steel Products MTC ReportKyОценок пока нет

- 16 MM MS Plate 355 JR - India-MTCДокумент1 страница16 MM MS Plate 355 JR - India-MTCQc QatarОценок пока нет

- Test CertificateДокумент1 страницаTest CertificateAvinash JadhavОценок пока нет

- Mag General Business: Mill Test CertificateДокумент1 страницаMag General Business: Mill Test CertificateRaul Sebastiam100% (1)

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdДокумент1 страницаTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocОценок пока нет

- Mill Test Certificate: Zibo Camel Material Co., LTDДокумент1 страницаMill Test Certificate: Zibo Camel Material Co., LTDJoseph Arturo SolisОценок пока нет

- 1.20mm T.C - Mehta SteelsДокумент1 страница1.20mm T.C - Mehta SteelsRonak FireОценок пока нет

- Mill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037Документ1 страницаMill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037yugandhar100% (2)

- MTC - Plate 2mx12m - 8mmДокумент4 страницыMTC - Plate 2mx12m - 8mmValesh Monis100% (1)

- Sau - MTC 0001-002163 - Acc.aºcºДокумент24 страницыSau - MTC 0001-002163 - Acc.aºcºrosa aurora montesano somarribaОценок пока нет

- MTC 4500528257 Iii - 210209Документ3 страницыMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasОценок пока нет

- Hebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEДокумент1 страницаHebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEAnonymous TPoO5u8MeОценок пока нет

- En 8Документ3 страницыEn 8ajaykrishnaaОценок пока нет

- Quality Certificated 123Документ1 страницаQuality Certificated 123Zaid Raslan Ayoub100% (1)

- Varilla B7 3-8 X 144 MT (B7)Документ1 страницаVarilla B7 3-8 X 144 MT (B7)Carlos Lluen AquinoОценок пока нет

- 025 - Guard Zinc Phosphate Epoxy PrimerДокумент3 страницы025 - Guard Zinc Phosphate Epoxy PrimerBalgo BalgobinОценок пока нет

- 30 MM Round Bar - EN8 - MTCДокумент1 страница30 MM Round Bar - EN8 - MTCMohammad Adil0% (1)

- TubacexДокумент1 страницаTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSОценок пока нет

- Material TCДокумент1 страницаMaterial TCgmbakshiОценок пока нет

- Assure Solutions: Hydro Test ReportДокумент1 страницаAssure Solutions: Hydro Test ReportKailas NimbalkarОценок пока нет

- MTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Документ3 страницыMTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Saul Omar Fernandez RojasОценок пока нет

- Hyundai Steel Mill TestДокумент1 страницаHyundai Steel Mill TestJamesОценок пока нет

- Test Certificate Hot Rolled, Medium High Tensile Steel: SailДокумент3 страницыTest Certificate Hot Rolled, Medium High Tensile Steel: SailJignesh Jagjivanbhai PatelОценок пока нет

- MOE Simplex - 24.06.2016 PDFДокумент4 страницыMOE Simplex - 24.06.2016 PDFSabyasachi BangalОценок пока нет

- Vendor ListДокумент2 страницыVendor ListfarjadulhaqОценок пока нет

- MAG General Business Mill Test CertificateДокумент1 страницаMAG General Business Mill Test CertificateRaul Sebastiam67% (3)

- BF20112602 English MTC PDFДокумент2 страницыBF20112602 English MTC PDFSvetlana VujovićОценок пока нет

- Material Test Report: Cse. Chiang Sung Enterprise Co., LTDДокумент3 страницыMaterial Test Report: Cse. Chiang Sung Enterprise Co., LTDChethan Nagaraju KumbarОценок пока нет

- IS 4923 Chemical CompositionДокумент1 страницаIS 4923 Chemical CompositionTulasidas MalajiОценок пока нет

- MTC Details-MS: Client:-Spacemaker P.O.No: JOB No.: 1122/19 Report No-1122/01Документ6 страницMTC Details-MS: Client:-Spacemaker P.O.No: JOB No.: 1122/19 Report No-1122/01sankarapandianОценок пока нет

- CBH-21-007 Stud Bolt M6 X 1000 ZC3 8.8Документ1 страницаCBH-21-007 Stud Bolt M6 X 1000 ZC3 8.8qualityОценок пока нет

- IS 2062 Structural Steel GuideДокумент10 страницIS 2062 Structural Steel GuideJagjeet SinghОценок пока нет

- Al Jazeera Steel Mill Test ReportДокумент1 страницаAl Jazeera Steel Mill Test Reportsnehalmdeshmukh100% (1)

- MTC Annexure (6 Inch)Документ16 страницMTC Annexure (6 Inch)maheshОценок пока нет

- KBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3Документ4 страницыKBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3kamlОценок пока нет

- Offshore A312A358 R2Документ1 страницаOffshore A312A358 R2Prathamesh OmtechОценок пока нет

- MTC - Al JazeeraДокумент1 страницаMTC - Al JazeeraArmağan DemirelОценок пока нет

- Plate A36 t.8mm Dan 16mm MTC Topsco Baja 12531Документ3 страницыPlate A36 t.8mm Dan 16mm MTC Topsco Baja 12531Ganjar Samiaji100% (1)

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Документ2 страницыMill'S Test Certificate ACC. TO EN 10204 / 3.1Durulsan MakinaОценок пока нет

- Mill Test Certificate 91Документ1 страницаMill Test Certificate 91Zaid Raslan Ayoub100% (1)

- MTC PDFДокумент170 страницMTC PDFShoukat Zaki0% (2)

- Test Certificate: CM/L-NO:5530357Документ10 страницTest Certificate: CM/L-NO:5530357TARUNKUMARОценок пока нет

- Mill Test Certificate: Din 125 Washer Electro Zinc PlatedДокумент1 страницаMill Test Certificate: Din 125 Washer Electro Zinc PlatedFodor ZoltanОценок пока нет

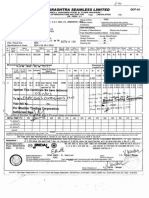

- MAHARASHTRA SEAMLESS LIMITED CERTIFICATE OF MANUFACTURE AND TEST FOR PIPESДокумент1 страницаMAHARASHTRA SEAMLESS LIMITED CERTIFICATE OF MANUFACTURE AND TEST FOR PIPESPetroPower OilandgasОценок пока нет

- 14mm Gr60Документ1 страница14mm Gr60alshaya steelОценок пока нет

- Sample Valve Material CertificatesДокумент18 страницSample Valve Material CertificatesFLOW VALVE AUTOMATION100% (2)

- Lish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFДокумент1 страницаLish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFliving goodОценок пока нет

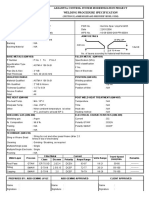

- WPS-2 InchДокумент2 страницыWPS-2 InchKarthikeyan MpОценок пока нет

- Inc 800 MTC - FlangeДокумент1 страницаInc 800 MTC - Flangeranjith_007100% (1)

- Material QuivalentДокумент4 страницыMaterial QuivalentUma SankarОценок пока нет

- 65X M L - 211224 - 180120 - Converted - by - AbcdpdfДокумент1 страница65X M L - 211224 - 180120 - Converted - by - AbcdpdfVidhyarthi Photocopy KhargoneОценок пока нет

- MTCДокумент3 страницыMTCziashaukatОценок пока нет

- TV 100x100x5#S235JRДокумент5 страницTV 100x100x5#S235JRRazvan CristeaОценок пока нет

- Vedanta Limited Integrated Field Plan Inspection ReportsДокумент23 страницыVedanta Limited Integrated Field Plan Inspection ReportsPRAKASH PANDEYОценок пока нет

- Joining Stainless Steel by Soldering, Brazing and Resistance WeldingДокумент4 страницыJoining Stainless Steel by Soldering, Brazing and Resistance WeldingA K SinghОценок пока нет

- Acero MadridДокумент46 страницAcero MadridviyfОценок пока нет

- Acerto Steel 2Документ51 страницаAcerto Steel 2viyfОценок пока нет

- Is 341-1973Документ18 страницIs 341-1973Karishma Prabhu100% (1)

- Bearing For GearboxДокумент32 страницыBearing For Gearboxeng13100% (1)

- Glenfield Air ValvesДокумент16 страницGlenfield Air ValvesTanmoy DuttaОценок пока нет

- Butterfly Valve ManualДокумент5 страницButterfly Valve ManualTanmoy DuttaОценок пока нет

- Datasheet Type 40104010HD enДокумент3 страницыDatasheet Type 40104010HD enTanmoy DuttaОценок пока нет

- Type 4010 and 4010HD non return valvesДокумент3 страницыType 4010 and 4010HD non return valvesTanmoy DuttaОценок пока нет

- Non Return Check Valves With Lever and Counterweight PDFДокумент7 страницNon Return Check Valves With Lever and Counterweight PDFhuyenthaigiaОценок пока нет

- STI/14846/1 Dec.2000Документ8 страницSTI/14846/1 Dec.2000Tanmoy DuttaОценок пока нет

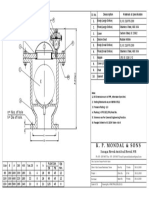

- K.P.Mondal & Sons: Works: Dasnagar, Howrah Amta Road, Howrah, West BengalДокумент1 страницаK.P.Mondal & Sons: Works: Dasnagar, Howrah Amta Road, Howrah, West BengalTanmoy DuttaОценок пока нет

- IS 5312 Part 1 Product ManualДокумент6 страницIS 5312 Part 1 Product ManualTanmoy DuttaОценок пока нет

- Butterfly Valve ManualДокумент5 страницButterfly Valve ManualTanmoy DuttaОценок пока нет

- Drawing1 Layout2 PDFДокумент1 страницаDrawing1 Layout2 PDFTanmoy DuttaОценок пока нет

- IS 14846 Product ManualДокумент5 страницIS 14846 Product ManualKrishna Prasad KanchojuОценок пока нет

- Product Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Документ5 страницProduct Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Tanmoy DuttaОценок пока нет

- CI Tamper Proffe-ModelДокумент1 страницаCI Tamper Proffe-ModelTanmoy DuttaОценок пока нет

- Assem1 - Sheet1Документ1 страницаAssem1 - Sheet1Tanmoy DuttaОценок пока нет

- Jis F7305Документ1 страницаJis F7305Tanmoy DuttaОценок пока нет

- Technical DetailsДокумент4 страницыTechnical DetailsTanmoy DuttaОценок пока нет

- Dual Plate 800 NB-ModelДокумент1 страницаDual Plate 800 NB-ModelTanmoy DuttaОценок пока нет

- Bill of Materials Cast Iron Double Door Foot ValveДокумент1 страницаBill of Materials Cast Iron Double Door Foot ValveTanmoy DuttaОценок пока нет

- Air Valve Kinetic 80 MM With ISVДокумент1 страницаAir Valve Kinetic 80 MM With ISVTanmoy DuttaОценок пока нет

- CI Sluice Valve With ActuatorДокумент1 страницаCI Sluice Valve With ActuatorTanmoy DuttaОценок пока нет

- DI Air Release Valve-ModelДокумент1 страницаDI Air Release Valve-ModelTanmoy DuttaОценок пока нет

- DJ Adaptor Body SpecificationДокумент1 страницаDJ Adaptor Body SpecificationTanmoy DuttaОценок пока нет

- MATERIALS FOR CAST IRON NON RETURN VALVEДокумент1 страницаMATERIALS FOR CAST IRON NON RETURN VALVETanmoy DuttaОценок пока нет

- Jis F7305Документ1 страницаJis F7305Tanmoy DuttaОценок пока нет

- Technical DetailsДокумент4 страницыTechnical DetailsTanmoy DuttaОценок пока нет

- 300 NRV ModelДокумент1 страница300 NRV ModelTanmoy DuttaОценок пока нет

- MaskДокумент1 страницаMaskTanmoy DuttaОценок пока нет

- Jis F7301Документ1 страницаJis F7301Tanmoy DuttaОценок пока нет

- Sec 1038Документ4 страницыSec 1038Lauren BowenОценок пока нет

- Media and Information LiteracyДокумент38 страницMedia and Information LiteracyRense Jun PunsalanОценок пока нет

- Company ProfilesДокумент14 страницCompany ProfilesKeiser MonteroОценок пока нет

- Sa 312Документ1 страницаSa 312babis1980Оценок пока нет

- Technical Specifications For Peb For Pune Ware House 17.10.11Документ21 страницаTechnical Specifications For Peb For Pune Ware House 17.10.11chepurthiОценок пока нет

- Company Survey ReportДокумент2 страницыCompany Survey ReportPradip Tapan BanerjeeОценок пока нет

- ACROW Bridges - Vehicular BridgesДокумент2 страницыACROW Bridges - Vehicular BridgesAbhisek BasnyatОценок пока нет

- BibliographiesДокумент2 страницыBibliographiesVa LicОценок пока нет

- Unist Coolube 2210ALДокумент2 страницыUnist Coolube 2210ALMann Sales & MarketingОценок пока нет

- Sample FRP Tank SpecificationДокумент8 страницSample FRP Tank Specificationapparaokr100% (1)

- Ajanta Pharma Ltd. Status of Export OverduesДокумент60 страницAjanta Pharma Ltd. Status of Export Overduesananda_joshi5178Оценок пока нет

- MLTC CATRAM Market Study Container Terminals West and Central AfricaДокумент133 страницыMLTC CATRAM Market Study Container Terminals West and Central AfricazymiscОценок пока нет

- Bangalore IT Directors Contact ListДокумент4 страницыBangalore IT Directors Contact ListDeep sharmaОценок пока нет

- Chhattisgarh Technical University Civil Engineering SchemeДокумент19 страницChhattisgarh Technical University Civil Engineering SchemeNeeraj Kumar ThakurОценок пока нет

- Stud Rails ESR-2494Документ3 страницыStud Rails ESR-2494Bruno PilieciОценок пока нет

- History of Canadian AirportsДокумент51 страницаHistory of Canadian Airportssyed.imamОценок пока нет

- Air DeccanДокумент50 страницAir DeccanAngita KumariОценок пока нет

- A Project Report On Logistics Management in VRL Logistics LTD VarurДокумент95 страницA Project Report On Logistics Management in VRL Logistics LTD VarurBabasab Patil (Karrisatte)81% (16)

- M8 Router Handling Instructions GuideДокумент68 страницM8 Router Handling Instructions GuideyoranvaneekelenОценок пока нет

- Surface Vehicle Standard: Rev. FEB2004 J434Документ12 страницSurface Vehicle Standard: Rev. FEB2004 J434Douglas RodriguesОценок пока нет

- Transportation Laws Notes - Atty. Zarah Villanueva-CastroДокумент15 страницTransportation Laws Notes - Atty. Zarah Villanueva-CastroLex Talionis Fraternitas83% (12)

- Introduction To Petroleum Engineering - Final - Oil and Gas TransportationДокумент12 страницIntroduction To Petroleum Engineering - Final - Oil and Gas TransportationshanecarlОценок пока нет

- Blacksmithing 101 - How To Make A Forge and Start Hammering Metal - Popular MechanicsДокумент6 страницBlacksmithing 101 - How To Make A Forge and Start Hammering Metal - Popular MechanicsByram JОценок пока нет

- A 93 1Документ14 страницA 93 1jkhgvdj mnhsnjkhgОценок пока нет

- Cathelco C-Shield ICCP BrochureДокумент12 страницCathelco C-Shield ICCP BrochureHerik AziziОценок пока нет

- The Importance of Proper Rotation TechniqueДокумент2 страницыThe Importance of Proper Rotation Techniqueaske7sp8055Оценок пока нет

- B 747 400 Master MelДокумент229 страницB 747 400 Master MelSece Mejia FrancoОценок пока нет

- W&C Sec 7 Issue 5Документ68 страницW&C Sec 7 Issue 5tvsameel7208Оценок пока нет

- CESPL Brochure PDFДокумент73 страницыCESPL Brochure PDFAshiniBatraОценок пока нет

- 4.0 Manpower Mobilization Plan (TA)Документ7 страниц4.0 Manpower Mobilization Plan (TA)anjangandak2932100% (1)