Академический Документы

Профессиональный Документы

Культура Документы

CV 655

Загружено:

Enrique Santiago BenavidesОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CV 655

Загружено:

Enrique Santiago BenavidesАвторское право:

Доступные форматы

MIG WELDERS

CV-655

Energy efficiency, reliability and exceptional performance are what set the CV-655

apart from the rest. Designed primarily for heavy-duty applications, the CV-655 is

an outstanding choice for MIG and flux-cored welding on mild steel, stainless steel,

aluminum and alloys.This sturdy, powerful DC power source handles CV semiautomatic submerged arc welding and arc gouging with ease. Equipped with electronic

and thermostatic protection, PC boards with built-in diagnostics and solid state

contactors, the CV-655 is built to last.

Processes

MIG

Description

Flux-Cored

Submerged Arc

Gouging

CV DC

Output

Input

60 50

PHASE

Hz

Hz

Advantage Lincoln

Recommended General Options

Calibrated output control lets operator accurately regulate

power levels.

Digital Meter Kit, Air Filter Kit, Dual Process Switch, Remote Output

Control, Remote Control Adapter, Undercarriage

Line voltage compensation maintains weld consistency, even

with line voltage changes of 10%.

Recommended Wire Feeders

115-volt duplex receptacle provides 20 amps of auxiliary

power.

LF-72, LN-742, LN-8, LN-9, LN-9 GMA, LN-10, DH-10, LN-15, LN23P, LN-25, NA-3, NA-4, NA-5, NA-5R, Cobramatic

Separate output studs allow the operator to select high or low

inductance.

Order

Panel switches allow operator to change settings at the power

source or wire feeder.

Solid state circuitry provides extra long life during repetitive

applications.

Three-year warranty on parts and labor.

K1480-1

K1480-5

K1481-1

K1481-2

K1481-4

K1481-5

CV-655

CV-655

CV-655

CV-655

CV-655

CV-655

230/460/3/60

575/3/60

230/400/3/50/60

380/500/3/50/60

200/400/3/50/60

415/3/50/60

Manufactured under a quality system certified to ISO 9001

requirements and ISO 14001 environmental standards.

Note: Cobramatic and Python are registered trademarks of MK Products, Inc.

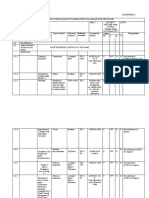

TECHNICAL SPECIFICATIONS

Product

Name

CV-655

(1)

Product

Number

Input Power

K1480-1

K1480-5

K1481-1

K1481-2

K1481-4

K1481-5

230/460/3/60

575/3/60

230/400/3/50/60

380/500/3/50/60

200/400/3/50/60

415/3/50/60

Rated Output

Current/Voltage/Duty Cycle(1)

Input Current @

Rated Output

650A/44V/100%

815A/44V/60%

94/47A

38A

94/54A

56/43A

107/54A

52A

Output Range

70-815A

13-44V

Max. OCV:

48V

Dimensions

HxWxD

inches (mm)

Net Weight

lbs.(kg)

27.5 x 22.2 x 38.0

(699 x 565 x 965)

670

(304)

NEMA Class I Rated Output. Based on a 10 minute period.

Publication E4.40 1/05

www.lincolnelectric.com

A CLOSER LOOK

PERFORMANCE

Provides line voltage compensation for maintaining weld consistency, even with changes of 10%.

Sub-arc welding with up to 5/64 (2.0mm) diameter electrodes.

Arc gouging up to 3/8 (10mm) carbons.

For heavy duty MIG and flux-cored applications.

FEATURES

Quick, simple 14-pin MS-type (Amphenol) wire feeder connection.

Low flat-top case can be placed under a workbench or stacked

on top of each other for smaller footprint.

Cold electrode with a solid state contactor when the trigger

is released for added safety.

Thermal trip indicator light.

1.

2.

3.

Key Controls

1.

Optional Voltmeter and Ammeter

2.

Output Voltage Control

3.

Pilot Light

4.

Thermal Protection Light

5.

Input Power On/Off Switch

6.

Local/Remote Control Switch

7.

Output Terminals On/Remote Switch

4.

5.

6.

7.

QUALITY AND RELIABILITY

Electronic and thermostatic protection from current overload

or excessive temperatures.

Solid state circuitry provides extra long life during repetitive

applications.

PC boards have built-in diagnostic routines for quick and easy

troubleshooting.

Three-year warranty on parts and labor.

Circuit boards are protected with a specially insulated coating to

extend life and ensure reliable performance.

Manufactured under a quality system certified to ISO 9001

requirements and ISO 14001 environmental standards.

CSA approved for 60 Hz models.

SYSTEM SELECTION

Typical MIG Welding Systems

CV-655 / LF-72 Heavy Duty Wire Feeder

CV-655 Power Source

LF-72 Heavy Duty

600 Amp Weld Power Cable 10 ft.

Work Clamp

Harris Flowmeter Regulator and Gas Hose

K1480-1

K2327-3

K1842-10(2)

K910-2

K586-1

CV-655 / LN-742 Wire Feeder

Best for applications where more process control is required for

arc starting, welding and crater control!

CV-655 Power Source

K1480-1

LN-742 (Two Roll) Wire Feeder

K617-1

Control Cable - 10 ft.

K1819-10

.045 Drive Roll

KP653-052S

Universal Stand

K1524-1

Swivel Platform

K1557-1

Magnum 400 Gun & Cable Assembly

K2286-1(1)

600 Amp Weld Power Cable 10 ft.

K1842-10(2)

Work Clamp

K910-2

Harris Flowmeter Regulator and Gas Hose K586-1

CV-655 / LN-10 Wire Feeder

Where premium welding performance and control is demanded

this system delivers!

CV-655 Power Source

K1480-1

LN-10 wire feeder

K1559-1

Control Cable 10 ft.

K1501-10

.045 Drive Roll

KP1505-045S

Swivel Platform

KP557-1

Magnum 400 Gun & Cable Assembly

K471-21(1)

600 Amp Weld Power Cable 10 ft.

K1842-10(2)

Work Clamp

K910-2

Harris Flowmeter Regulator and Gas Hose K586-1

[2]

CV-655

www.lincolnelectric.com

A CLOSER LOOK

CV-655 / DH-10 Wire Feeder

For maximum welding flexibility select the DH-10 dual feeder.

Weld with two different types and sizes of wire with two different

welding procedures.

CV-655 Power Source

K1480-1

DH-10 wire feeder

K1499-1

Control Cable 10 ft.

K1501-10

.045 Drive Roll

KP1505-045S(2)

Magnum 400 Gun & Cable Assembly

K471-21(1)(2)

600 Amp Weld Power Cable 10 ft.

K1842-10(2)

Work Clamp

K910-2

Harris Flowmeter Regulator and Gas Hose K586-1

CV-655 / Cobramatic Wire Feeder

For aluminum welding, select the industries best aluminum feeding

system Cobramatic.

CV-655 Power Source

K1480-1

Cobramatic Wire Feeder

K2259-1

.035 Grooved Drive Roll (optional)

KP1594-035

Python Gun & Cable Assembly

K2211-2

600 Amp Weld Power Cable 10 ft.

K1842-10(2)

Work Clamp

K910-2

Harris Flowmeter Regulator and Gas Hose K586-1

(1)Fully assembled, no gun connector required.

(2)Two required.

RECOMMENDED OPTIONS

GENERAL OPTIONS

Remote Output Control

Consists of a control box with

choice of two cable lengths.

Permits remote adjustment of

output. 6 pin connection.

Order K857

for 25 ft. (7.6m).

Order K857-1

for 100 ft. (30m).

Digital Meter Kit

Displays amps and volts.

Order K1482-1

Air Filter Kit

Mounts on the front of the

machine and uses cleanable, all

metal air filters. Not compatible

with dual process switch.

Order K1486-1

Remote Control Adapter

Y connection adapter for connecting K857 Remote Output Control

(6 pin plug connection) and wire

feeder input cable (14 pin plug

connection) to power source 14

pin receptacle.

Order K864

Dual Process Switch

Mounts on front of machine and

provides polarity change or electrical isolation. Great for arc gouging applications and where two

separate feeders require different

output polarity or inductance

settings. Not compatible with air

filter.

Order K1528-1

Undercarriage

Platform undercarriage with

mountings for two gas cylinders

at rear of welder.

Order K842

[3]

CV-655

www.lincolnelectric.com

CV-655 ORDER FORM

PRODUCT DESCRIPTION

ORDER NUMBER

CV-655

CV-655

CV-655

CV-655

CV-655

CV-655

K1480-1

K1480-5

K1481-1

K1481-2

K1481-4

K1481-5

230/460/3/60

575/3/60

230/400/3/50/60

380/500/3/50/60

200/400/3/50/60

415/3/50/60

Recommended General Options

Digital Meter Kit

Air Filter Kit

Dual process Switch

Remote Output Control:

for 25 ft. (7.6m)

for 100 ft. (30m)

Remote Control Adapter

Undercarriage, Twin Cylinder

K857

K857-1

K864

K842

Recommended Wire Feeder Options

LF-72

LN-742

LN-8

LN-9

LN-9 GMA

LN-10

DH-10

LN-15

LN-23P

LN-25

NA-3

NA-4

NA-5

NA-5R

Cobramatic

See

See

See

See

See

See

See

See

See

See

See

See

See

See

See

QUANTITY

PRICE

K1482-1

K1486-1

K1528-1

publication

publication

publication

publication

publication

publication

publication

publication

publication

publication

publication

publication

publication

publication

publication

E8.11

E8.20

E8.30

E8.50

E8.50

E8.200

E8.200

E8.60

E8.90

E8.100

E9.10

E9.10

E9.30

E9.40

E8.300

TOTAL:

C U S T O M E R A S S I S TA N C E P O L I C Y

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the

needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond

to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability,

with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customers particular purpose, with respect to

such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has

been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility

of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

T H E L I N C O L N E L E C T R I C C O M PA N Y

22801 St. Clair Ave., Cleveland, OH 44117-1199 216.481.8100 www.lincolnelectric.com

Вам также может понравиться

- Idealarc DC-655: Stick, TIG, MIG, Flux-Cored, Submerged Arc, GougingДокумент2 страницыIdealarc DC-655: Stick, TIG, MIG, Flux-Cored, Submerged Arc, GougingJose Luis Sardinero GarciaОценок пока нет

- Invertec V275-S: For Stick and DC TIG WeldingДокумент4 страницыInvertec V275-S: For Stick and DC TIG WeldingPedro Ernesto Rodriguez RojasОценок пока нет

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Рейтинг: 2.5 из 5 звезд2.5/5 (3)

- Idealarc DC-600: Rugged Multi-Process Power For Industrial ManufacturingДокумент4 страницыIdealarc DC-600: Rugged Multi-Process Power For Industrial ManufacturingmoorthysanmukamОценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- CV - 400 PDFДокумент4 страницыCV - 400 PDFCarlos PadillaОценок пока нет

- Idealarc DC-600: Rugged Multi-Process Power For Industrial ManufacturingДокумент4 страницыIdealarc DC-600: Rugged Multi-Process Power For Industrial Manufacturingmkpasha55mpОценок пока нет

- Lincolin Weldig Transf.Документ4 страницыLincolin Weldig Transf.ahmedsaid85Оценок пока нет

- 275 S InvertecДокумент4 страницы275 S InverteclokopicОценок пока нет

- Invertec v350 ProДокумент4 страницыInvertec v350 ProJose Luis AroniОценок пока нет

- E6.32 Bulldog 5500Документ4 страницыE6.32 Bulldog 5500Noe Plancarte AndradeОценок пока нет

- Panel Accessories CatalogueДокумент176 страницPanel Accessories CataloguemrithulakannanОценок пока нет

- Invertec V160-T: Stick, TIG, Pulsed TIG K1845-1 See Back For Complete SpecsДокумент2 страницыInvertec V160-T: Stick, TIG, Pulsed TIG K1845-1 See Back For Complete Specsapi-237777038Оценок пока нет

- Mcs Miniature Contactors Selection Guide: The Miniature Modular Control System Small in Dimensions - Big in PerformanceДокумент36 страницMcs Miniature Contactors Selection Guide: The Miniature Modular Control System Small in Dimensions - Big in PerformanceRichard WiltsieОценок пока нет

- UniGear ZS1Документ8 страницUniGear ZS1SOUMENОценок пока нет

- Panel Accessories Catalogue R1Документ184 страницыPanel Accessories Catalogue R1supermannon0% (1)

- Abb Disconnector Gw54 1yva000105 Reva enДокумент8 страницAbb Disconnector Gw54 1yva000105 Reva enerkamlakar2234Оценок пока нет

- NA-5 Control and Heads: Flux-Cored, Submerged Arc K356-2Документ4 страницыNA-5 Control and Heads: Flux-Cored, Submerged Arc K356-2Cornel NoiaОценок пока нет

- Circuit Breaker LTB D 72.5 - 170 KV FSA Spring Operating MechanismsДокумент8 страницCircuit Breaker LTB D 72.5 - 170 KV FSA Spring Operating MechanismsRazvan Mares0% (1)

- Fiche Technique Lincoln Vintage 500Документ8 страницFiche Technique Lincoln Vintage 500ludgeissОценок пока нет

- TC Media Tension Abb - ELECTRICAДокумент2 страницыTC Media Tension Abb - ELECTRICAagvega69109Оценок пока нет

- Specifier's Guide: Line Installation and Protective Equipment Master Catalog 5 KV - 35 KV Electrical Distribution SystemsДокумент64 страницыSpecifier's Guide: Line Installation and Protective Equipment Master Catalog 5 KV - 35 KV Electrical Distribution Systemssincos1983Оценок пока нет

- Abb Transfer Şalteri̇Документ56 страницAbb Transfer Şalteri̇AdemEfeОценок пока нет

- L&T CHANGEOVER SW C-Line Catalogue PDFДокумент15 страницL&T CHANGEOVER SW C-Line Catalogue PDFchidambaram kasi67% (3)

- Brochure - CB 123kVДокумент6 страницBrochure - CB 123kVHùng HuyОценок пока нет

- Sabre Vacuum Circuit Breaker Ring Main Unit Up To 24kV: With Automation and Remote Control OptionsДокумент16 страницSabre Vacuum Circuit Breaker Ring Main Unit Up To 24kV: With Automation and Remote Control OptionsArlone ManaladОценок пока нет

- RMU Sabre BrochureДокумент16 страницRMU Sabre BrochurehansamvОценок пока нет

- Seccionadores ABB PDFДокумент8 страницSeccionadores ABB PDFLuisManuelTrujilloMartínezОценок пока нет

- Centre-Break Disconnectors Type SGF 72.5: For Outdoor InstallationДокумент8 страницCentre-Break Disconnectors Type SGF 72.5: For Outdoor InstallationRorrachoОценок пока нет

- 6000 BR 1205Документ40 страниц6000 BR 1205Carlos BenavidesОценок пока нет

- ABB DisconnectorДокумент8 страницABB DisconnectoridundoviОценок пока нет

- Current Transformer Iosk 1Документ8 страницCurrent Transformer Iosk 1Dumitru Tănase0% (1)

- Unigear 550: 12 - 17.5 KV, Arc-Proof, Air Insulated Switchgear For Power ApplicationsДокумент48 страницUnigear 550: 12 - 17.5 KV, Arc-Proof, Air Insulated Switchgear For Power ApplicationsMohd Nawawi Ab AzizОценок пока нет

- LUCY SwitchgearДокумент8 страницLUCY SwitchgearHillary McgowanОценок пока нет

- GAVE 099CA00567.05EN - LowДокумент32 страницыGAVE 099CA00567.05EN - LowRahmat Nur IlhamОценок пока нет

- Info Condensadores VarplusCanДокумент28 страницInfo Condensadores VarplusCanjhoansilvaОценок пока нет

- Gas Insulated Switchgear Design, Technical Data, Testing & AdvantagesДокумент9 страницGas Insulated Switchgear Design, Technical Data, Testing & AdvantagesBhaskar1411Оценок пока нет

- Switch On To The Best: Cam Operated Rotary SwitchesДокумент32 страницыSwitch On To The Best: Cam Operated Rotary Switchesbagastc100% (1)

- Busducts: Low and Medium VoltageДокумент14 страницBusducts: Low and Medium VoltagesaturasatuОценок пока нет

- 72 - 800 Gas Insulated Switchgear SiemensДокумент10 страниц72 - 800 Gas Insulated Switchgear Siemensamir17012076Оценок пока нет

- PW Acdc 1000Документ24 страницыPW Acdc 1000Aleiser Quevedo AcuñaОценок пока нет

- Surface Tension Transfer (STT) : ProcessДокумент4 страницыSurface Tension Transfer (STT) : ProcessBorn ToSinОценок пока нет

- SeccionadoraABB XLP EasyLine GB ScreenДокумент28 страницSeccionadoraABB XLP EasyLine GB ScreenGeorg AugustoОценок пока нет

- W-SLC Medium Voltage Fused Contactor Truck: A Safe, Reliable and Effi Cient Motor StarterДокумент12 страницW-SLC Medium Voltage Fused Contactor Truck: A Safe, Reliable and Effi Cient Motor StartercyuenkОценок пока нет

- CA Powercube PBF (En) B 1vcp000253 1201aДокумент20 страницCA Powercube PBF (En) B 1vcp000253 1201aPrashanth ChandrashekarОценок пока нет

- Brochure ANSIДокумент40 страницBrochure ANSIDaniel PalaciosОценок пока нет

- 3AP1 DTC en - V9 - Epost PDFДокумент8 страниц3AP1 DTC en - V9 - Epost PDFjoan75Оценок пока нет

- 145Документ8 страниц145Стоян ТеневОценок пока нет

- LTB E CB BrochureДокумент6 страницLTB E CB BrochureMidhun VargheseОценок пока нет

- Single-Phase Step Voltage Regulators: Technical Data 225-10Документ8 страницSingle-Phase Step Voltage Regulators: Technical Data 225-10sincos1983Оценок пока нет

- MoellerДокумент39 страницMoellerMilagros Arteaga GonzalezОценок пока нет

- Switchgear Smart Grid - LV Mortor Control Centre BrochureДокумент8 страницSwitchgear Smart Grid - LV Mortor Control Centre BrochureNOJAPowerОценок пока нет

- 03 Evolis MV Vacuum Circbreak CatДокумент74 страницы03 Evolis MV Vacuum Circbreak CatGryndiОценок пока нет

- Ln25pro PDFДокумент8 страницLn25pro PDFNapoleón Ortíz CárdenasОценок пока нет

- DS CB DB NewДокумент8 страницDS CB DB NewMichael Parohinog GregasОценок пока нет

- Finite Element PrimerДокумент81 страницаFinite Element PrimerAnonymous ntE0hG2TPОценок пока нет

- Design an overhead crane beamДокумент95 страницDesign an overhead crane beamEnrique Santiago BenavidesОценок пока нет

- SSPC SP7 PDFДокумент5 страницSSPC SP7 PDFMelissa Edith Vega Reynoso100% (1)

- Astm A325m (2005)Документ7 страницAstm A325m (2005)THUFAIL RASHEEDОценок пока нет

- A 285547Документ39 страницA 285547Enrique Santiago BenavidesОценок пока нет

- Penstock ManualДокумент159 страницPenstock Manualstudent_bl95% (21)

- Welding Procedure PreparationДокумент122 страницыWelding Procedure Preparationthe_badass1234100% (21)

- 3d Stress TutДокумент6 страниц3d Stress TutUpender DhullОценок пока нет

- ASNT Handbook Volume 2 Liquid Penetrant TestingДокумент498 страницASNT Handbook Volume 2 Liquid Penetrant TestingJosé Juan Jiménez Alejandro94% (32)

- 07Документ58 страниц07Enrique Santiago BenavidesОценок пока нет

- Red River Floodway Expansion Project Design and Construction of The Outlet Structure PDFДокумент60 страницRed River Floodway Expansion Project Design and Construction of The Outlet Structure PDFEnrique Santiago BenavidesОценок пока нет

- Vehicle Crash Worthiness CompleteДокумент388 страницVehicle Crash Worthiness Completemuscogiuri100% (3)

- MacroElementMethod PDFДокумент53 страницыMacroElementMethod PDFEnrique Santiago BenavidesОценок пока нет

- 07Документ58 страниц07Enrique Santiago BenavidesОценок пока нет

- ViewДокумент233 страницыViewEnrique Santiago BenavidesОценок пока нет

- Case1328021324 PDFДокумент145 страницCase1328021324 PDFChrista Epifani SebayangОценок пока нет

- Ijmer 45012642 PDFДокумент17 страницIjmer 45012642 PDFEnrique Santiago BenavidesОценок пока нет

- Design an overhead crane beamДокумент95 страницDesign an overhead crane beamEnrique Santiago BenavidesОценок пока нет

- Vehicle Crash Worthiness CompleteДокумент388 страницVehicle Crash Worthiness Completemuscogiuri100% (3)

- Nav 009Документ10 страницNav 009Vishnu Vardhan Reddy YerasiОценок пока нет

- Practical Discussion On Fatigue PDFДокумент5 страницPractical Discussion On Fatigue PDFEnrique Santiago BenavidesОценок пока нет

- AY1314 IRP Jaime PedretДокумент103 страницыAY1314 IRP Jaime PedretEnrique Santiago BenavidesОценок пока нет

- ASME Section VIII Div 1 Pressure Vessel Design GuideДокумент103 страницыASME Section VIII Div 1 Pressure Vessel Design GuideJaeup YouОценок пока нет

- Automated Metal-Removal System: Arcair-Matic N6000Документ1 страницаAutomated Metal-Removal System: Arcair-Matic N6000Enrique Santiago BenavidesОценок пока нет

- PQR Test Results Summary - Tensile, Bend, Visual & Fillet Weld TestsДокумент2 страницыPQR Test Results Summary - Tensile, Bend, Visual & Fillet Weld TestsEnrique Santiago BenavidesОценок пока нет

- 1Документ2 страницы1Enrique Santiago BenavidesОценок пока нет

- Report of Radiographic Examination of Welds ProjectДокумент1 страницаReport of Radiographic Examination of Welds ProjectEnrique Santiago BenavidesОценок пока нет

- Report of Radiographic Examination of Welds ProjectДокумент1 страницаReport of Radiographic Examination of Welds ProjectEnrique Santiago BenavidesОценок пока нет

- Stud Welding Procedure Specification WpsДокумент2 страницыStud Welding Procedure Specification WpsEnrique Santiago BenavidesОценок пока нет

- c9001 Chartered Financial Modeling Professional CFMP Brochure 1Документ11 страницc9001 Chartered Financial Modeling Professional CFMP Brochure 1Shit A Brick “Om Tegank”Оценок пока нет

- Framework Profitability Smarthveer Sidana 1Документ1 страницаFramework Profitability Smarthveer Sidana 1adityaОценок пока нет

- Maruti suzuki Ambal Auto ExperienceДокумент26 страницMaruti suzuki Ambal Auto Experience18UGCP078 SUJITHОценок пока нет

- Chapter 7Документ10 страницChapter 7Eki OmallaoОценок пока нет

- Shahriar Zaman - MID ECO 1Документ5 страницShahriar Zaman - MID ECO 1Shahriar Zaman AsifОценок пока нет

- RFCL HDPE BagsДокумент9 страницRFCL HDPE BagsSandeep Goud ChatlaОценок пока нет

- Video Transcript Edc493Документ1 страницаVideo Transcript Edc493api-607892218Оценок пока нет

- Industrial Visit Report Visit Us at Management - Umakant.infoДокумент13 страницIndustrial Visit Report Visit Us at Management - Umakant.infowelcome2jungle0% (1)

- Topic 3 Long-Term Construction Contracts ModuleДокумент20 страницTopic 3 Long-Term Construction Contracts ModuleMaricel Ann BaccayОценок пока нет

- Pega CSSAДокумент851 страницаPega CSSAkollarajasekharОценок пока нет

- Sdoc 02 10 SiДокумент5 страницSdoc 02 10 Siمحي الدين محمدОценок пока нет

- GN Cement Industry 05022021 RevДокумент97 страницGN Cement Industry 05022021 RevNetaji Dasari100% (1)

- IGCSE Business Definitions GuideДокумент11 страницIGCSE Business Definitions GuideHibsОценок пока нет

- Senate Select Committee PaperДокумент62 страницыSenate Select Committee PaperForkLogОценок пока нет

- ANNE-A MQAP for PenstockДокумент3 страницыANNE-A MQAP for Penstocktarun kaushalОценок пока нет

- Assignment 1: On Formulation and Graphical MethodДокумент2 страницыAssignment 1: On Formulation and Graphical MethodI.E. Business SchoolОценок пока нет

- How To Use Oracle Hyperion Strategic FinanceДокумент6 страницHow To Use Oracle Hyperion Strategic FinancePrashantRanjan2010Оценок пока нет

- Unwomen What Is Local Government and How Is It OrganizedДокумент42 страницыUnwomen What Is Local Government and How Is It OrganizedHifsa AimenОценок пока нет

- 402 - Indian Ethos - Business EthicsДокумент237 страниц402 - Indian Ethos - Business Ethicssuraj chavanОценок пока нет

- Understanding Plants Abroad Functionality in SAP PDFДокумент3 страницыUnderstanding Plants Abroad Functionality in SAP PDFAnoop Rathod50% (2)

- Chapter 1Документ94 страницыChapter 1Narendran SrinivasanОценок пока нет

- How We Work With Suppliers: Upholding Apple's Values in Our Supply ChainДокумент18 страницHow We Work With Suppliers: Upholding Apple's Values in Our Supply ChainNguyễn Văn NghĩaОценок пока нет

- Bidding DocumentsДокумент82 страницыBidding DocumentsPalwasha GulОценок пока нет

- Chiller Water Treatment - TraneДокумент7 страницChiller Water Treatment - Tranetuatvq100% (4)

- Field Inspection Manual The Shell Petroleum Development Company of Nigeria LimitedДокумент31 страницаField Inspection Manual The Shell Petroleum Development Company of Nigeria LimitedMathias Onosemuode100% (1)

- 1-2 Math at Home Game TimeДокумент1 страница1-2 Math at Home Game TimeKarla Panganiban TanОценок пока нет

- Company Profile/ Profil Perusahaan MASKOD COMMUNICATIONДокумент20 страницCompany Profile/ Profil Perusahaan MASKOD COMMUNICATIONFranditya UtomoОценок пока нет

- An Appraisal On The Impact of Financial Planning and Control in The Profitability of An OrganizationДокумент156 страницAn Appraisal On The Impact of Financial Planning and Control in The Profitability of An OrganizationJamesОценок пока нет

- Real Estate Developer Revenue RecognitionДокумент2 страницыReal Estate Developer Revenue RecognitionEster SabatiniОценок пока нет

- Special Services Invoice SummaryДокумент1 страницаSpecial Services Invoice SummaryTQ Home Services100% (1)