Академический Документы

Профессиональный Документы

Культура Документы

Calculation 950122

Загружено:

fafcoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Calculation 950122

Загружено:

fafcoАвторское право:

Доступные форматы

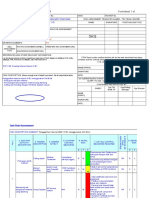

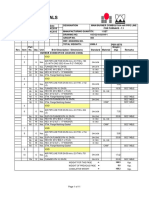

Bou Ali Sina Petrochemical Complex

Safety Valves Calculation Sheet

Document Title

Document Number

Page 1 of 36

Revision

D0

TD-950122

Code1

(Approved ) Vendor to submit " For Final" (No comment &

release for manufacturing)

( Approved with comments) : Vendor shall correct / revise &

Code2

resubmit it as " For Final " (Released for manufacturing if change

incorporated as indicated)

Safety Valves

EQUIPMENTNAME:

(Commented) : Vendor shall correct / revise & resubmit it as "

Code3

For Approval" of the date specified : ( Corrected documents to be

resubmitted before starting manufacturing )

ITEM NO.:

2

Code4

Not Acceptable quality (Reject)

CONTRACT NO.:

Above checking results by SADAF shall in no way relieve Vendor of any liability,

obligation and responsibility out of the purchase order and the mutual

agreement in writing.

Date:

Dept:

Signature:

Only for internal review

D0

19.Oct.2016

IFA

Rev.

Date

Class

POI

CV

PI

EL

IN

ME

MA

ST

BU

PR

SA

HV

TL

V. Khosronia

A. Mohammadi

A. Mohammadi

Prepared By

Checked By

Approved By

Vendor

Contractor Approved By

PGPIC Approval

Bou Ali Sina Petrochemical Complex

Safety Valves Calculation Sheet

Document Title

Document Number

Page 2 of 36

Revision

D0

TD-950122

Tabulation of Revised Page

Page

1

Revisions

00

01

02

03

04

05

06

07

Sheet

37

X

X

39

40

41

42

43

44

45

10

46

11

47

12

48

13

49

14

50

15

51

16

52

17

53

18

54

19

55

20

56

21

57

22

58

23

59

24

60

25

61

26

62

27

63

28

64

29

65

30

66

31

67

32

68

33

69

34

70

35

71

36

72

38

Revisions

00

01

02

03

04

05

06

07

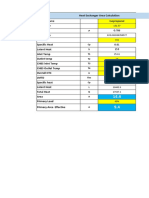

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Page: 3 of 36

Tag No.:PSV-21002

950122

1

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

P

paf

pae

Pu

T

Q

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

6.3

1.4

21

1.02

115

18405

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=W ((TZ)/M) / (CKdP1Kb)

1 Sizing Formula

2

3

4

5

6

7

8

9

10

11

12

13

Light End/Vapor

..

69.05

Kg/Kmol

1.125

Cp/Cv

22.28

Kg/m3

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

18405

Kg/h

0.888

1

1

388.15

K

8.643

Barg

0.02228

3.21

in2

4.1

in2

M

23,543.01

Kg/h

4" M 6"

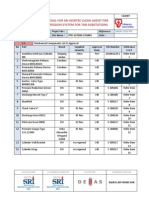

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 4 of 36

Tag No.:PSV-21002

Balanced Bellows

Full Nozzle

N.A.

Closed

Hard Seat

Bolted

No

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

4"

#300

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

6"

#150

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Page: 5 of 36

Tag No.:PSV-21003

950122

2

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

P

paf

pae

Pu

T

Q

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

13.4

1.4

10

1.02

133

55782

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=W ((TZ)/M) / (CKdP1Kb)

1 Sizing Formula

2

3

4

5

6

7

8

9

10

11

12

13

Light End/Vapor

..

66.24

Kg/Kmol

1.188

Cp/Cv

39.55

Kg/m3

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

55782

Kg/h

0.888

1

1

406.15

K

15.76

Barg

0.03955

5.17

in2

7.78

in2

P

83,936.36

Kg/h

4" P 6"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 6 of 36

Tag No.:PSV-21003

Balanced Bellows

Full Nozzle

N.A.

Closed

Hard Seat

Bolted

No

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

4"

#300

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

6"

#150

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Page: 7 of 36

Tag No.:PSV-21004

950122

3

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

P

paf

pae

Pu

T

Q

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

17.5

0

21

1.02

384.13

242.44

1

A=W ((TZ)/M) / (CKdP1Kb)

1 Sizing Formula

2

3

4

5

6

7

8

9

10

11

12

13

MPS/Vapor

..

18.02

Kg/Kmol

1.33

Cp/Cv

6.57

Kg/m3

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

242.44

0.888

1

1

657.28

22.195

0.00657

0.04

0.12

D

682.51

Kg/h

K

Barg

in2

in2

Kg/h

1" D 2"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 8 of 36

Tag No.:PSV-21004

Conventional

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

Plain

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1"

#300

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

2"

#150

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Water/Liquid

..

18.02

Kg/Kmol

--Cp/Cv

998

Kg/m3

P

paf

pae

Pu

T

Q

8

0

10

1.02

43.5

404.7

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=(11.78Q)/(KdKwKv)(G/(P1-Pb-101.3))

1 Sizing Formula

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

950122

4

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

2

3

4

5

6

7

8

9

10

11

12

13

Page: 9 of 36

Tag No.:TSV-21004

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

404.7

Kg/h

0.666

1

1

316.65

K

9.82

Barg

0.998

0.01

in2

0.12

in2

D

8,413.04

Kg/h

3/4" D 1"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 10 of 36

Tag No.:TSV-21004

Conventional

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

Plain

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

3/4"

NPTM

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1"

NPTF

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Page: 11 of 36

Tag No.:PSV-21005

950122

5

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

P

paf

pae

Pu

T

Q

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

29.8

1.4

21

1.02

201

16259

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=W ((TZ)/M) / (CKdP1Kb)

1 Sizing Formula

2

3

4

5

6

7

8

9

10

11

12

13

Hydr. Light End/Vapor

..

72.51

Kg/Kmol

1.278

Cp/Cv

161.6

Kg/m3

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

16259

0.888

1

1

474.15

37.078

0.1616

0.48

0.589

G

19,914.42

1 1/2" G

Kg/h

K

Barg

in2

in2

Kg/h

3"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 12 of 36

Tag No.:PSV-21005

Balanced Bellows

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

No

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1 1/2"

#300

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

3"

#150

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

Yes

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Water/Liquid

..

18.02

Kg/Kmol

--Cp/Cv

998

Kg/m3

P

paf

pae

Pu

T

Q

8

0

10

1.02

66

120.4

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=(11.78Q)/(KdKwKv)(G/(P1-Pb-101.3))

1 Sizing Formula

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

950122

6

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

2

3

4

5

6

7

8

9

10

11

12

13

Page: 13 of 36

Tag No.:TSV-21006

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

120.4

Kg/h

0.666

1

1

339.15

K

9.82

Barg

0.998

0.00

in2

0.12

in2

D

7,796.11

Kg/h

3/4" D 1"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 14 of 36

Tag No.:TSV-21006

Conventional

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

Plain

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

3/4"

NPTM

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1"

NPTF

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Page: 15 of 36

Tag No.:PSV-21007

950122

7

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

P

paf

pae

Pu

T

Q

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

11.5

1.4

10

1.02

126.8

15047

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=W ((TZ)/M) / (CKdP1Kb)

1 Sizing Formula

2

3

4

5

6

7

8

9

10

11

12

13

Hydr. Light End/Vapor

..

65.52

Kg/Kmol

1.161

Cp/Cv

33.34

Kg/m3

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

15047

Kg/h

0.888

1

1

399.95

K

13.67

Barg

0.03334

1.65

in2

1.95

in2

K

17,740.55

Kg/h

3" K 4"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 16 of 36

Tag No.:PSV-21007

Balanced Bellows

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

No

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

3"

#300

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

4"

#150

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

Yes

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Page: 17 of 36

Tag No.:PSV-21008

950122

8

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

P

paf

pae

Pu

T

Q

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

17.5

0

21

1.02

383.93

109.2

1

A=W ((TZ)/M) / (CKdP1Kb)

1 Sizing Formula

2

3

4

5

6

7

8

9

10

11

12

13

MPS/Vapor

..

18

Kg/Kmol

1.33

Cp/Cv

6.57

Kg/m3

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

109.2

0.888

1

1

657.08

22.195

0.00657

0.02

0.12

D

682.23

Kg/h

K

Barg

in2

in2

Kg/h

1" D 2"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 18 of 36

Tag No.:PSV-21008

Conventional

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

Plain

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1"

#300

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

2"

#150

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Water/Liquid

..

18.02

Kg/Kmol

--Cp/Cv

998

Kg/m3

P

paf

pae

Pu

T

Q

8

0

10

1.02

41

77.7

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=(11.78Q)/(KdKwKv)(G/(P1-Pb-101.3))

1 Sizing Formula

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

950122

9

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

2

3

4

5

6

7

8

9

10

11

12

13

Page: 19 of 36

Tag No.:TSV-21009

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

77.7

Kg/h

0.666

1

1

314.15

K

9.82

Barg

0.998

0.00

in2

0.12

in2

D

7,796.11

Kg/h

3/4" D 1"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 20 of 36

Tag No.:TSV-21009

Conventional

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

Plain

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

3/4"

NPTM

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1"

NPTF

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

P

paf

pae

Pu

T

Q

Hydr. Light End/Liquid

..

78.7

Kg/Kmol

--Cp/Cv

572.5

Kg/m3

3.5

0.4

10

1.02

65

61.1

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=(11.78Q)/(KdKwKv)(G/(P1-Pb-101.3))

1 Sizing Formula

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

950122

10

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

2

3

4

5

6

7

8

9

10

11

12

13

Page: 21 of 36

Tag No.:TSV-21010

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

61.1

Kg/h

0.666

1

1

338.15

K

4.87

Barg

0.5725

0.00

in2

0.12

in2

D

3,697.16

Kg/h

3/4" D 1"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 22 of 36

Tag No.:TSV-21010

Conventional

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

No

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

3/4"

NPTM

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1"

NPTF

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

P

paf

pae

Pu

T

Q

Hydr. Light End/Liquid

..

78.7

Kg/Kmol

--Cp/Cv

572.5

Kg/m3

3.5

0.4

10

1.02

65

49

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=(11.78Q)/(KdKwKv)(G/(P1-Pb-101.3))

1 Sizing Formula

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

950122

11

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

2

3

4

5

6

7

8

9

10

11

12

13

Page: 23 of 36

Tag No.:TSV-21012

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

49

Kg/h

0.666

1

1

338.15

K

4.87

Barg

0.5725

0.00

in2

0.12

in2

D

3,697.16

Kg/h

3/4" D 1"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 24 of 36

Tag No.:TSV-21012

Balanced Bellows

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

No

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

3/4"

NPTM

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1"

NPTF

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

P

paf

pae

Pu

T

Q

Hydr. Light End/Liquid

..

78.7

Kg/Kmol

--Cp/Cv

572.5

Kg/m3

3.5

0.4

10

1.02

65

16.3

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=(11.78Q)/(KdKwKv)(G/(P1-Pb-101.3))

1 Sizing Formula

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

950122

12

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

2

3

4

5

6

7

8

9

10

11

12

13

Page: 25 of 36

Tag No.:TSV-21013

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

16.3

Kg/h

0.666

1

1

338.15

K

4.87

Barg

0.5725

0.00

in2

0.12

in2

D

3,697.16

Kg/h

3/4" D 1"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 26 of 36

Tag No.:TSV-21013

Balanced Bellows

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

No

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

3/4"

NPTM

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1"

NPTF

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Page: 27 of 36

Tag No.:PSV-21014

950122

13

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

P

paf

pae

Pu

T

Q

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

17.5

0

10

1.02

215

41077.5

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=W ((TZ)/M) / (CKdP1Kb)

1 Sizing Formula

2

3

4

5

6

7

8

9

10

11

12

13

MPS/Vapor

..

18

Kg/Kmol

1.42

Cp/Cv

8.6

Kg/m3

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

41077.5

Kg/h

0.888

1

1

488.15

K

20.27

Barg

0.0086

6.45

in2

7.78

in2

P

49,529.07

Kg/h

4" P 6"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 28 of 36

Tag No.:PSV-21014

Conventional

Full Nozzle

N.A.

Closed

Hard Seat

Bolted

Plain

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

4"

#300

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

6"

#150

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Page: 29 of 36

Tag No.:PSV-21020

950122

14

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

P

paf

pae

Pu

T

Q

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

7.6

1.4

10

1.02

165.2

56626.5

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=W ((TZ)/M) / (CKdP1Kb)

1 Sizing Formula

2

3

4

5

6

7

8

9

10

11

12

13

Hydr. Light End/Vapor

..

84.57

Kg/Kmol

1.12

Cp/Cv

28.41

Kg/m3

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

56626.5

Kg/h

0.888

1

1

438.35

K

9.38

Barg

0.02841

8.53

in2

12.16

in2

Q

80,709.10

Kg/h

6" Q 8"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 30 of 36

Tag No.:PSV-21020

Balanced Bellows

Full Nozzle

N.A.

Closed

Hard Seat

Bolted

No

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

6"

#300

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

8"

#150

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Page: 31 of 36

Tag No.:PSV-21021

950122

15

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

P

paf

pae

Pu

T

Q

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

17.5

0

21

1.02

383.9

177.1

1

A=W ((TZ)/M) / (CKdP1Kb)

1 Sizing Formula

2

3

4

5

6

7

8

9

10

11

12

13

MPS/Vapor

..

18

Kg/Kmol

1.33

Cp/Cv

6.57

Kg/m3

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

177.1

0.888

1

1

657.05

22.195

0.00657

0.03

0.12

D

682.25

Kg/h

K

Barg

in2

in2

Kg/h

1" D 2"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 32 of 36

Tag No.:PSV-21021

Conventional

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

Plain

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1"

#300

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

2"

#150

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Water/Liquid

..

18.02

Kg/Kmol

--Cp/Cv

998

Kg/m3

P

paf

pae

Pu

T

Q

8

0

10

1.02

44.4

19

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=(11.78Q)/(KdKwKv)(G/(P1-Pb-101.3))

1 Sizing Formula

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

950122

16

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

2

3

4

5

6

7

8

9

10

11

12

13

Page: 33 of 36

Tag No.:TSV-21022

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

19

Kg/h

0.666

1

1

317.55

K

9.82

Barg

0.998

0.00

in2

0.12

in2

D

7,796.11

Kg/h

3/4" D 1"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 34 of 36

Tag No.:TSV-21022

Conventional

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

Plain

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

3/4"

NPTM

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1"

NPTF

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Calculation Sheet For Safety Relief Valves

Request No

Doc. No.: TD950122

Project No.: 950122

General Info

1 Project Number

2 Item Number

3 Sizing Code

4 Quantity of Safety Valve

Sizing -Medium

1 Fluid & State

2 Formula

3 Molecular Weight

4 Specific heat ratio

5 Relief Density

Water/Liquid

..

18.02

Kg/Kmol

--Cp/Cv

998

Kg/m3

P

paf

pae

Pu

T

Q

8

0

10

1.02

32.3

64.3

1

Barg

Barg

Barg

Barg

Barg

%

Barg

C

Kg/h

A=(11.78Q)/(KdKwKv)(G/(P1-Pb-101.3))

1 Sizing Formula

Required Capacity

Coefficient of Discharge

Capacity Correction Factor

Correction Factor

Temperature

Relieving Pressure

Specific Gravity

Calculated Discharge Area

Selected Discharge Area

Selected orifice

Maximum Flow

Nps Inlet Orifice NPS Outlet

Rev.

Date

Prep./Design by

Approved by

950122

17

API 520

1

M

K

Sizing - Service condition

1 Maximum Allowable Working Pressure

2 Set Pressure

3 Superimposed Back Pressure

4 Built Up Back Pressure

5 Back Pressure

6 Over Pressure

7 Enviromental Pressure

8 Reliving Temperature

9 Required Capacity

10 Rupture Disc Correction Factor

2

3

4

5

6

7

8

9

10

11

12

13

Page: 35 of 36

Tag No.:TSV-21023

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

T

P1

G

A

O

Qm

64.3

Kg/h

0.666

1

1

305.45

K

9.82

Barg

0.998

0.00

in2

0.12

in2

D

7,796.11

Kg/h

3/4" D 1"

Technical Data Safety Relief valves

Request No

Doc. No.: TD950122

Project No.: 950122

Valve - General

1 Design Type

2 Nozzle Type

3 Pilot Action Type

4 Bonnet Type

5 Seat Type

6 Cap Type

7 Lifting Lever

8 Test Gag

Page: 36 of 36

Tag No.:TSV-21023

Conventional

Full Nozzle

N.A.

Closed

Hard Seat

Screwed

Plain

No

Inlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

3/4"

NPTM

RF

Outlet connection

1 Connection Standard

2 DN/NPS

3 PN/PR

4 Flange Facing

Acc. to ANSI B16.5

1"

NPTF

RF

Code & Basis

1 Basis

2 Seat Tightness

3 Shell Test

4 Comply with API 526

5 Comply with Nace

Acc. to ASME Sec. VIII;

Acc. to API 527

Acc. to ASME B16.34

Yes

No

Painting

1 Primer

2 Middle

3 Final

Epoxy Zinc Rich

Epoxy Polyamide

Poly Urethane

Rev.

Date

Prep./Design by

Approved by

D0

19-Oct-2016

V.Khosronia

A.Mohamadi

Вам также может понравиться

- Ipsco-Oem Catalog SMДокумент48 страницIpsco-Oem Catalog SMAvdhesh Yadav100% (1)

- CO2 SnuffingДокумент2 страницыCO2 SnuffingJagan BoseОценок пока нет

- CO2 SnuffingДокумент1 страницаCO2 SnuffingFadhila Ahmad AnindriaОценок пока нет

- Htri B51GUHXEReport PDFДокумент42 страницыHtri B51GUHXEReport PDFjesus_manrique2753Оценок пока нет

- Buku Pintar MigasДокумент108 страницBuku Pintar Migasandraprima100% (1)

- Design Data: 2" Threadolet CalculationДокумент2 страницыDesign Data: 2" Threadolet Calculationgrabetty50% (2)

- Flare Calc Sheet API RP 521Документ11 страницFlare Calc Sheet API RP 521dursosonoОценок пока нет

- MSS SP-68 High Pressure Butterfly Valves With Offset Design PDFДокумент9 страницMSS SP-68 High Pressure Butterfly Valves With Offset Design PDFmohamed ahmedОценок пока нет

- ASME PCC-1 Bolted Flange Joint AssemblyДокумент1 страницаASME PCC-1 Bolted Flange Joint Assemblykhaireddin75% (4)

- Data Sheet Fuel Gas Filter Rev 0Документ22 страницыData Sheet Fuel Gas Filter Rev 0Bowo Edhi WibowoОценок пока нет

- Rumus Internal External PressureДокумент6 страницRumus Internal External PressureDidi SudiprayitnaОценок пока нет

- Level 2 Risk Assessment Front Sheet: Operations/WJ West AssetДокумент14 страницLevel 2 Risk Assessment Front Sheet: Operations/WJ West AssetAndi Yanuar50% (2)

- Perhitungan Pressure Vessel LengkapДокумент70 страницPerhitungan Pressure Vessel LengkapReo Aditya MahesaОценок пока нет

- Ambient Crude Oil StorageДокумент13 страницAmbient Crude Oil StorageSrihari KodimelaОценок пока нет

- Heat Exchanger Sizing AC-6050 #1Документ2 страницыHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleОценок пока нет

- PSV Capacity ConversionДокумент4 страницыPSV Capacity Conversionaw_aeОценок пока нет

- Attachment C - HAZOP WorksheetДокумент18 страницAttachment C - HAZOP Worksheetwibowo wibowo50% (2)

- PSV Sizing - Two Phase (Two-Points)Документ2 страницыPSV Sizing - Two Phase (Two-Points)Saeid Rahimi MofradОценок пока нет

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterДокумент2 страницыHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc Nguyen100% (1)

- Ejector Data SheetДокумент5 страницEjector Data SheetFatih FıratОценок пока нет

- Burst PR Calculation PDFДокумент1 страницаBurst PR Calculation PDFAranga KeerthiОценок пока нет

- Quick Opening ClosuresДокумент4 страницыQuick Opening ClosureseduinОценок пока нет

- Nozzle CalculationДокумент13 страницNozzle Calculationaqilah liyanaОценок пока нет

- Knock Out KO Drum SizingДокумент10 страницKnock Out KO Drum SizingJermaine HeathОценок пока нет

- Sizing Pressure RelievingДокумент20 страницSizing Pressure RelievingNuch NapapornОценок пока нет

- Vent&BlowdownCatalog PDFДокумент19 страницVent&BlowdownCatalog PDFktsnl100% (1)

- 40863-001 Calc - Inline Heater PDFДокумент3 страницы40863-001 Calc - Inline Heater PDFomar equihuaОценок пока нет

- Pig Calc PDFДокумент286 страницPig Calc PDFJaroslaw KoniecznyОценок пока нет

- Cp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Документ1 страницаCp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Triana Rosma Fikriyati DinaОценок пока нет

- N2 Regulator and Gauges DatasheetДокумент4 страницыN2 Regulator and Gauges DatasheetpavanОценок пока нет

- Flare Stack Sizing CalculationДокумент2 страницыFlare Stack Sizing CalculationSumit BudhiaОценок пока нет

- PSV Sizing CalculationДокумент3 страницыPSV Sizing CalculationMurali MohanОценок пока нет

- KG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.0Документ6 страницKG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.0sumit kumar100% (1)

- Data Sheet FOR Pig Signal: Cikande - Bitung Distribution Pipeline Project Pt. Perusahaan Gas Negara Data SheetДокумент3 страницыData Sheet FOR Pig Signal: Cikande - Bitung Distribution Pipeline Project Pt. Perusahaan Gas Negara Data Sheetalfa vimalaОценок пока нет

- Compressor Settleout Pressure Temperature EstimationДокумент3 страницыCompressor Settleout Pressure Temperature EstimationFahad Maqsood100% (1)

- 081201X V3533 PDFДокумент59 страниц081201X V3533 PDFClemente Rafael Marval Escalona50% (2)

- PSV Calculation and PhilosophyДокумент33 страницыPSV Calculation and PhilosophysbmmlaОценок пока нет

- Pump Sizing Fire Hydrant MojoДокумент2 страницыPump Sizing Fire Hydrant MojoAnonymous 6S9tcbhОценок пока нет

- PSVs CalculationДокумент24 страницыPSVs Calculationionutlaur86100% (3)

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareДокумент127 страницPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresОценок пока нет

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetДокумент7 страницAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũОценок пока нет

- Tombo - Gasket - Genetal CatalogДокумент117 страницTombo - Gasket - Genetal CatalogAnh CaoОценок пока нет

- Maz - Design - Separator Capacity EvaluationДокумент5 страницMaz - Design - Separator Capacity EvaluationNaeem HussainОценок пока нет

- QIP-PDI-G.3 - Design Instruction For Standard Pipe Support SelectionДокумент1 страницаQIP-PDI-G.3 - Design Instruction For Standard Pipe Support Selectiondimas prasetyoОценок пока нет

- Heat Exchanger Area & Boilup Rate CalculationДокумент19 страницHeat Exchanger Area & Boilup Rate CalculationNitin KurupОценок пока нет

- Quick Opening ClosuresДокумент4 страницыQuick Opening ClosuresJuan CarvajalОценок пока нет

- Sizing of Pressure Safety Valve: Project Name ClientДокумент7 страницSizing of Pressure Safety Valve: Project Name ClientAmit Bansal100% (1)

- 5th Effect Large Nozzle CalcsДокумент5 страниц5th Effect Large Nozzle CalcsPROTOTYPE TESTОценок пока нет

- Heat Exchanger Rating Data Sheet Dumai UnitsДокумент1 страницаHeat Exchanger Rating Data Sheet Dumai UnitsagusnnnОценок пока нет

- Manual 8Документ21 страницаManual 8Vraja KisoriОценок пока нет

- Recip Compressor Calculations For GCP-3Документ4 страницыRecip Compressor Calculations For GCP-3Greg GolushkoОценок пока нет

- PSV D-103Документ24 страницыPSV D-103DIANTOROОценок пока нет

- Chemical & Process Technology - Requirements of SDV Bypass Pressurization Line PDFДокумент4 страницыChemical & Process Technology - Requirements of SDV Bypass Pressurization Line PDFvenkatrangan2003100% (1)

- Shell Entrance Area Calculation-R0Документ2 страницыShell Entrance Area Calculation-R0nagtummalaОценок пока нет

- Radiation and Dispersion Calculations: Vol% Vol%Документ9 страницRadiation and Dispersion Calculations: Vol% Vol%Maria Gabriela González CedeñoОценок пока нет

- LTJ-PGAS-GTLT-EN-DS-014 Vaporizer Data SheetДокумент15 страницLTJ-PGAS-GTLT-EN-DS-014 Vaporizer Data SheetsswahyudiОценок пока нет

- 008364-001-DS-I001 Dehydration Switching Valves Datasheet - Rev BДокумент17 страниц008364-001-DS-I001 Dehydration Switching Valves Datasheet - Rev BNaveen KumarОценок пока нет

- Datasheet For Ball ValveДокумент16 страницDatasheet For Ball ValveDamu JankerboyОценок пока нет

- APNEA-J-DSH-0002 Rev. 1Документ3 страницыAPNEA-J-DSH-0002 Rev. 1Michelle MartinezОценок пока нет

- Tank Calculation Kasikan Gs Rev BДокумент20 страницTank Calculation Kasikan Gs Rev BTrian Desta Rizal80% (5)

- PZ D CS Pi SP 015 02Документ60 страницPZ D CS Pi SP 015 02epbamdadОценок пока нет

- 8 - Mechanical Component List & AppovalДокумент17 страниц8 - Mechanical Component List & AppovalizamaiyusОценок пока нет

- BKDD00-ME-4M-87-001 Data Sheet Control Valve (Rev 0)Документ22 страницыBKDD00-ME-4M-87-001 Data Sheet Control Valve (Rev 0)nileshana100% (1)

- Outokumpu FlangesДокумент44 страницыOutokumpu FlangesHenrikОценок пока нет

- File1 229 152531320717Документ40 страницFile1 229 152531320717MEHDIОценок пока нет

- FOX 3F Water Combination Air Valve 11.2021Документ4 страницыFOX 3F Water Combination Air Valve 11.2021bre brilianОценок пока нет

- AD 360 - Movement Joints in Steel-Framed BuildingsДокумент1 страницаAD 360 - Movement Joints in Steel-Framed Buildingssymon ellimacОценок пока нет

- Understanding Brittle Fracture and How To Detect ItДокумент21 страницаUnderstanding Brittle Fracture and How To Detect ItOlusayoОценок пока нет

- SddsaДокумент11 страницSddsaAllswell ElleОценок пока нет

- Boxer BM 150 270415Документ72 страницыBoxer BM 150 270415visugue_26100% (1)

- Ansi B16.36 PDFДокумент27 страницAnsi B16.36 PDFgxbxbОценок пока нет

- SPECTRUM Horizontal Pumping SystemДокумент2 страницыSPECTRUM Horizontal Pumping SystemDirector TecnicoОценок пока нет

- D5 Rotary SootblowerДокумент4 страницыD5 Rotary SootblowerParmeshwar Nath TripathiОценок пока нет

- BS 4504 Slip On Flanges PDFДокумент7 страницBS 4504 Slip On Flanges PDFMaclean ArthurОценок пока нет

- Inspection & Testing Requirements Scope:: Test and Inspection PerДокумент2 страницыInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinОценок пока нет

- Krohne Optiflux 4000 ManualДокумент36 страницKrohne Optiflux 4000 ManualLuis SantosОценок пока нет

- Rotex Rotary ActuatorДокумент20 страницRotex Rotary ActuatorMayank Talwar100% (1)

- Spare Parts Catalog: Date: 04.12.2023 Language: enДокумент1 155 страницSpare Parts Catalog: Date: 04.12.2023 Language: enezgiulusoyy07Оценок пока нет

- Champak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoДокумент54 страницыChampak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoHabli MawardiОценок пока нет

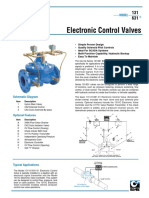

- Cla-Val Electronic Control ValvesДокумент6 страницCla-Val Electronic Control ValvesArelysSotilloОценок пока нет

- Powell Gate ValvesДокумент3 страницыPowell Gate Valveszguy360Оценок пока нет

- 12 Hidrostal 4ta. Bomba Io - M Book Rev. 1Документ82 страницы12 Hidrostal 4ta. Bomba Io - M Book Rev. 1Marcos Gonzales100% (1)

- Katalog Pumpi PDFДокумент26 страницKatalog Pumpi PDFBoro SaricОценок пока нет

- Manual 1008-1010Документ12 страницManual 1008-1010Edgar Eduardo Tellez RuizОценок пока нет

- Level 3: Machine Level 4: Component Level 5: Unit (1st Digit) Level 6: Unit (2nd Digit)Документ14 страницLevel 3: Machine Level 4: Component Level 5: Unit (1st Digit) Level 6: Unit (2nd Digit)Ace MiadzОценок пока нет

- 5 - API 570 Exam 100 QsДокумент25 страниц5 - API 570 Exam 100 QsSunny Thundil88% (32)

- AG RC Zero GovernorДокумент4 страницыAG RC Zero GovernorNemanja SušićОценок пока нет

- Bill of Materials: DIN-2458 DIN 2576 IS:1363 IS:1363Документ11 страницBill of Materials: DIN-2458 DIN 2576 IS:1363 IS:1363Roy ToledoОценок пока нет

- Sumitec CatalogДокумент90 страницSumitec CatalogIfan JSEОценок пока нет

- Design of Pressure VesselДокумент227 страницDesign of Pressure VesselLê Ngọc ThảoОценок пока нет