Академический Документы

Профессиональный Документы

Культура Документы

Lesson X: Large Porosity or Inclusions 3/64" To 1/16" DIAMETER OR LENGTH Maximum Number in Any 6" of Weld 8

Загружено:

crysОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lesson X: Large Porosity or Inclusions 3/64" To 1/16" DIAMETER OR LENGTH Maximum Number in Any 6" of Weld 8

Загружено:

crysАвторское право:

Доступные форматы

Lesson 10 - Reliability of Welding Filler Metals

1 dari 1

http://www.esabna.com/euweb/AWTC/Lesson10_14.htm

Lesson 1

The Basics of Arc

Welding

LESSON X

Lesson 2

Common Electric

Arc Welding

Processes

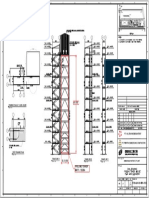

LARGE POROSITY OR INCLUSIONS

3/64" to 1/16" DIAMETER OR LENGTH

MAXIMUM NUMBER IN ANY 6" OF WELD = 8

Go To Test

Lesson 3

Covered Electrodes

for Welding

Mild Steels

Lesson 4

Covered Electrodes

for Welding Low

Alloy Steels

Lesson 5

Welding Filler Metals

for Stainless Steels

Glossary

FINE POROSITY OR INCLUSIONS

1/64" to 1/32" DIAMETER OR LENGTH

MAXIMUM NUMBER IN ANY 6" OF WELD = 30

SOUNDNESS TEST POROSITY AND INCLUSION STANDARDS

Figure 4

10.9.2.4

After the test plate has been radiographed, the all-weld-metal tension specimen,

and the charpy V-notch impact specimen are machined from the center of the plate as

Lesson 6

Carbon & Low Alloy

Steel Filler Metals GMAW,GTAW,SAW

Lesson 7

Flux Cored Arc

Electrodes Carbon

Low Alloy Steels

shown in Figure 3. Only the critical dimensions are shown in the sketches, and as you can

Turn Pages

see, they must be held to rather close tolerances to obtain accurate test results.

10.9.2.5

The .500 .010" diameter of the tension specimen is all weld metal since it is

machined from the center of the weld. The area of the impact specimens in which the

notch is machined is all weld metal also.

10.9.2.6

The tensile specimen is placed in a tensile testing machine and pulled until it

fractures. (Refer to Lesson I, "Yield Strength".) The yield strength and ultimate tensile

strength are recorded on the tensile tester. After fracture, the two halves of the broken

Lesson 8

Hardsurfacing

Electrodes

Current

Chapter

Table of

Contents

specimen are fitted back together in a jig, and the distance between the two center punch

marks is accurately measured. If this distance is now 2.500", it tells us that the specimen

has stretched .500" or 25% of its original length before breaking. This figure is recorded as

Search

Chapter

(Faster

Download)

Search

Document

(Slower

Download)

the elongation in a 2" length of the weld metal specimen.

Lesson 9

Estimating &

Comparing Weld

Metal Costs

10.9.2.7

The five impact specimens are broken in a Charpy Impact Tester, as described in

Lesson I, "Charpy Impacts", and the energy absorbed in breaking each of them is recorded. In calculating the average impact value, the specimens with the highest and lowest values are discarded. The average value of the three remaining specimens is recorded

Lesson 10

Reliability of Welding

Filler Metals

as the impact value.

COPYRIGHT 2000 THE ESAB GROUP, INC.

09/12/2013 14:40

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Pt. Intan Anugrah PersadaДокумент1 страницаPt. Intan Anugrah PersadacrysОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Pt. Intan Anugrah Persada: Void VoidДокумент1 страницаPt. Intan Anugrah Persada: Void VoidcrysОценок пока нет

- 328 PDFДокумент1 страница328 PDFcrysОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Pt. Intan Anugrah PersadaДокумент1 страницаPt. Intan Anugrah PersadacrysОценок пока нет

- Pt. Intan Anugrah PersadaДокумент1 страницаPt. Intan Anugrah PersadacrysОценок пока нет

- Pt. Intan Anugrah PersadaДокумент1 страницаPt. Intan Anugrah PersadacrysОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Cipta Sukses, PT.: Pt. Intan Anugrah PersadaДокумент1 страницаCipta Sukses, PT.: Pt. Intan Anugrah PersadacrysОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Vac 112 PDFДокумент1 страницаVac 112 PDFcrysОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Vac 110 PDFДокумент1 страницаVac 110 PDFcrysОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Cipta Sukses, PT.: Pt. Intan Anugrah PersadaДокумент1 страницаCipta Sukses, PT.: Pt. Intan Anugrah PersadacrysОценок пока нет

- Piping Color CodesДокумент12 страницPiping Color CodescrysОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Sdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadaДокумент1 страницаSdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadacrysОценок пока нет

- Vac 105 PDFДокумент1 страницаVac 105 PDFcrysОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Indonesia LNGДокумент22 страницыIndonesia LNGcrys100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Vac 113 PDFДокумент1 страницаVac 113 PDFcrysОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Single 'V' Butt Joint Carbon Steel: Pt. Alphacon ValfindoДокумент20 страницSingle 'V' Butt Joint Carbon Steel: Pt. Alphacon Valfindocrys0% (1)

- ITP Installation of Boiler - R1Документ14 страницITP Installation of Boiler - R1crys100% (4)

- Assembling Flanged Joints Procedure1 PDFДокумент34 страницыAssembling Flanged Joints Procedure1 PDFcrysОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- RFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFДокумент23 страницыRFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFcrysОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Equipment PhotoДокумент6 страницEquipment PhotocrysОценок пока нет

- Instalation Genset CSTS 36 Unit 23-1-2019Документ1 страницаInstalation Genset CSTS 36 Unit 23-1-2019crysОценок пока нет

- PASCAL Check Valves CatalogueДокумент19 страницPASCAL Check Valves Cataloguecrys100% (1)

- Overall Heat Transfer CoefficientДокумент22 страницыOverall Heat Transfer CoefficientcrysОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Master Document Register ListДокумент10 страницMaster Document Register ListcrysОценок пока нет

- Pneumatic TestДокумент10 страницPneumatic TestcrysОценок пока нет

- List Equipment JC Periode 2018Документ1 страницаList Equipment JC Periode 2018crysОценок пока нет

- Prilling TowerДокумент1 страницаPrilling TowercrysОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Supplier Deliverable Register (SDR) : - Document TitleДокумент11 страницSupplier Deliverable Register (SDR) : - Document TitlecrysОценок пока нет

- Railway Engineering-3c - Permanent Way - Track & Track StressesДокумент41 страницаRailway Engineering-3c - Permanent Way - Track & Track Stressesraghav VarmaОценок пока нет

- Foundation Engineering. 02 Soil Compressibilty. Edited. 15 Feb 2020Документ8 страницFoundation Engineering. 02 Soil Compressibilty. Edited. 15 Feb 2020sammy lopezОценок пока нет

- Solidification of Iron Castings - 314983Документ1 страницаSolidification of Iron Castings - 314983Ankur PatelОценок пока нет

- Https Eapplication - Nitrkl.ac - in Nitris Student Examination Results Internal Grade Card UG - Aspx Guttr 324432JHGFD67 MTQ2MTI - m9kQIZdicXMДокумент2 страницыHttps Eapplication - Nitrkl.ac - in Nitris Student Examination Results Internal Grade Card UG - Aspx Guttr 324432JHGFD67 MTQ2MTI - m9kQIZdicXMKalinga Prasad BeheraОценок пока нет

- Dispersion SystemДокумент25 страницDispersion Systempremkhandelwal147Оценок пока нет

- Chapter7 PPT SmithДокумент48 страницChapter7 PPT SmithApple Tiongco SantosОценок пока нет

- ORLENOIL Folder Przemyslowy en 2014Документ45 страницORLENOIL Folder Przemyslowy en 2014Handerson PanjaitanОценок пока нет

- Heat and Mass TransferДокумент31 страницаHeat and Mass TransferRavi RaneОценок пока нет

- Synthesis and Characterization of Co2FeAl Heusler Alloy NanoparticleДокумент5 страницSynthesis and Characterization of Co2FeAl Heusler Alloy Nanoparticlekarthik kaonОценок пока нет

- Iso 10684Документ26 страницIso 10684Jay GaneshОценок пока нет

- EEE-ETI 3208 ELECTROMAGNETICS III ExamДокумент3 страницыEEE-ETI 3208 ELECTROMAGNETICS III ExamHenry Kabasa100% (1)

- ch14 1Документ7 страницch14 1jiholee1117Оценок пока нет

- Steelwork Design Guide To BS 5950-1-2000. Volume 2. Worked Examples. Part 2 - Example 2 Simply Supported Restrained Beam.Документ11 страницSteelwork Design Guide To BS 5950-1-2000. Volume 2. Worked Examples. Part 2 - Example 2 Simply Supported Restrained Beam.Yilin ZuoОценок пока нет

- STEM - Physics 1 CG - With Tagged Sci EquipmentДокумент15 страницSTEM - Physics 1 CG - With Tagged Sci EquipmentAndres Kalikasan Sara100% (8)

- Timber Ridge Beam Calculation Report 2Документ5 страницTimber Ridge Beam Calculation Report 2CartecSyriaОценок пока нет

- Physical Chemistry (III)Документ32 страницыPhysical Chemistry (III)GraceОценок пока нет

- Q Switching and Mode LockingДокумент25 страницQ Switching and Mode Lockinganon_344429691100% (1)

- Env Law End TermДокумент13 страницEnv Law End TermSadhvi SinghОценок пока нет

- AutoclaveДокумент17 страницAutoclavesushil kumar100% (2)

- Ijmet 11 07 002Документ8 страницIjmet 11 07 002Siranjeevi AbimanyuОценок пока нет

- Multiple Choice Question Material ScienceДокумент2 страницыMultiple Choice Question Material Sciencemanish_agr8567% (3)

- KSB Technical DatasheetДокумент4 страницыKSB Technical DatasheetJj Oredina50% (2)

- Main Exam Paper Nov08, Smt211tДокумент6 страницMain Exam Paper Nov08, Smt211tPortia ShilengeОценок пока нет

- Notes Chapter 18-1Документ65 страницNotes Chapter 18-1Biruk BtОценок пока нет

- Assignment Questions For All UnitsДокумент10 страницAssignment Questions For All UnitsPiyush BhandariОценок пока нет

- X-Ray Diffraction: Dr. Mukesh KumarДокумент31 страницаX-Ray Diffraction: Dr. Mukesh Kumarhimanshu singhОценок пока нет

- Lehninger PPT Ch13 2Документ45 страницLehninger PPT Ch13 2송정근0% (2)

- Solidstatephysics PDFДокумент608 страницSolidstatephysics PDFTomislav Octenjak100% (1)

- Casting Simulation & Study CaseДокумент37 страницCasting Simulation & Study CaseRosalina KeziaОценок пока нет

- Use of Ambient Dose Equivalent, Directional DoseДокумент15 страницUse of Ambient Dose Equivalent, Directional DoseMuhammad NaveedОценок пока нет

- Laws of UX: Using Psychology to Design Better Products & ServicesОт EverandLaws of UX: Using Psychology to Design Better Products & ServicesРейтинг: 5 из 5 звезд5/5 (9)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneОт EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneРейтинг: 4.5 из 5 звезд4.5/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОт EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОценок пока нет

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureОт EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureРейтинг: 4.5 из 5 звезд4.5/5 (2)