Академический Документы

Профессиональный Документы

Культура Документы

Anti-Surge Valve Piping For Gas Compressor

Загружено:

iaftОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Anti-Surge Valve Piping For Gas Compressor

Загружено:

iaftАвторское право:

Доступные форматы

Anti-Surge Valve Piping for Gas

Compressor

0

1. Introduction to Anti-Surge Valve:

The anti-surge valve piping is the recycle loop that connects the discharge of the compressor (generally downstream of the

discharge cooler) back to the suction side(generally upstream of the scrubber). This allows the compressor to flow through

bypass and keeps the compressor from surging (reverse flow thru compressor). The anti-surge (control) valve is installed in

this line.

2. Process Description:

The performance of a process system depends a lot upon the quality of the layout engineering. The gas compressor surge

control piping is critical for any gas compression plant and needs to be given due care during the design of piping.

The basic elements of a compressor surge control system are the flow measurement (on the suction side of compressor),

pressure and temperature measurement on suction and discharge side of the compressor, discharge check valve, anti-surge

valve and its actuation system and the surge control system controller.

Typically the surge control system has an Independent recycle loop for each compressor train and the surge controller for

each compressor assures that adequate control is provided for every operation scenario which includes upsets in the

compressor downstream gas system. Each compressor train also has an individual check valve for effective surge control.

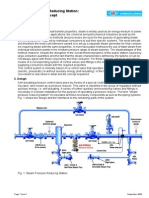

A typical schematic flow diagram generally followed is attached in Appendix-I which depicts the surge control system of a gas

compressor.

3. Layout Guidelines

Recommendations in the designing of the layout of a surge control piping system are as follows:

The check valve on the downstream of the gas compressor discharge cooler outlet line shall be located at a

minimum distance from the cooler outlet flange.

The anti-surge line shall be connected immediately upstream of the check valve and the anti-surge valve shall be

located at minimum distance from the discharge line. The performance of the surge control system is greatly dependent

on the piping volume downstream of the compressor and upstream of the check valve, discharge shutdown valve and

anti-surge valve being minimum.

It may be noted that the requirement of the hot gas bypass may be avoided if the minimum pipe volume as

described in the para above is ensured. Process shall check and confirm the requirement of hot gas bypass by

performing a proper dynamic simulation.

The branch connection for the pipe taking gas from discharge for the anti surge valve shall be located on the top of

the discharge line.

The anti-surge valve shall be located at a high point in the piping such that the upstream and downstream piping

is free draining into the suction and discharge lines and is without any pockets which may cause slug formation.

The temperature transmitters (TITs) on the discharge cooler outlet shall beprovided on the common discharge line

i.e. before the tapping for anti-surgeline. This is to ensure that the correct temperature is monitored during recycling of

the gas through the anti-surge valve.

Straight pipe lengths upstream and downstream of the anti-surge valve shallbe provided as per the

recommendations of the Vendor to limit noise and pipevibrations. Normally, this should be about 10 times the pipe

diameter on the upstream side and 5 times the pipe diameter on the downstream side.

Any other specific requirements of the compressor Vendor shall be compliedwith.

An alternative typical schematic flow diagram is shown in Appendix-II. In this the tapping for anti-surge valve inlet is taken

from the upstream of the compressor outlet cooler and the outlet of anti-surge valve is connected to upstream of compressor

inlet cooler, instead of directly connecting to scrubber.

The actual piping arrangement shall be followed as indicated in the P&IDs.

Appendix III depicts a typical piping arrangement for the anti-surge valve piping.

Appendix I:Typical Schematic Drawing for Surge Control System

Appendix II:Typical Schematic Drawing for Surge Control System (Alternative arrangement)

Appendix III:Typical Piping Arrangement of Anti-Surge Valve Piping

Вам также может понравиться

- AntisurgeДокумент6 страницAntisurgesch203Оценок пока нет

- Centrifugal Compressor Surge Control Methods PDFДокумент1 страницаCentrifugal Compressor Surge Control Methods PDFBalaji KrishnanОценок пока нет

- System Overview Digital Turbine Control SystemsДокумент56 страницSystem Overview Digital Turbine Control SystemsAshutosh Yadav100% (2)

- Ahu Hah 70701 AbДокумент14 страницAhu Hah 70701 AbEzrizalSaidinОценок пока нет

- Screw CompressorДокумент23 страницыScrew CompressorvaibhavОценок пока нет

- Control Valve SourcebookДокумент218 страницControl Valve SourcebookJuanita JitomateОценок пока нет

- Centrifugal Pump CharacteristicsДокумент27 страницCentrifugal Pump Characteristicskarioke mohaОценок пока нет

- System DescriptionДокумент28 страницSystem DescriptionGloria HamiltonОценок пока нет

- Air Fin Cooler Discharge Temperature Control OptionsДокумент13 страницAir Fin Cooler Discharge Temperature Control OptionsMuhammad ImranОценок пока нет

- Aspen Plus IGCC Model SimulationДокумент12 страницAspen Plus IGCC Model SimulationHAFIZ IMRAN AKHTERОценок пока нет

- Emergency ShutingdownДокумент11 страницEmergency ShutingdownOsama OmayerОценок пока нет

- PIPENET - Free Online Training-Webinar - Europe & AfricaДокумент1 страницаPIPENET - Free Online Training-Webinar - Europe & AfricaAnonymous a4Jwz14WОценок пока нет

- Barometric Leg DefinedДокумент1 страницаBarometric Leg DefinedHassan AssegafОценок пока нет

- Process Dynamics of AntiSurge SystemДокумент7 страницProcess Dynamics of AntiSurge SystemBodhisatya DasОценок пока нет

- Article Surge Control Analysis For Centrifugal CompressorsДокумент3 страницыArticle Surge Control Analysis For Centrifugal CompressorsHatem Ali100% (1)

- Protecting A Centrifugal Compressor From SurgeДокумент2 страницыProtecting A Centrifugal Compressor From SurgeDylanAdams100% (1)

- Tristation 1131: Turbomachinery Control SoftwareДокумент52 страницыTristation 1131: Turbomachinery Control Softwareali ibrahimОценок пока нет

- Compressor FormulaДокумент1 страницаCompressor FormulaMangal SinghОценок пока нет

- Compressor characteristic curveДокумент6 страницCompressor characteristic curveSyedMeherAliОценок пока нет

- Evaluating Boiler Efficiencies Using Direct and Indirect MethodsДокумент52 страницыEvaluating Boiler Efficiencies Using Direct and Indirect MethodsdebelaОценок пока нет

- Vibration and Noise Diagnosis in Centrifugal PumpsДокумент12 страницVibration and Noise Diagnosis in Centrifugal PumpsFahad MaqsoodОценок пока нет

- Analisis de Valvula Anti Surge y Fast StopДокумент17 страницAnalisis de Valvula Anti Surge y Fast Stopmcs21187Оценок пока нет

- APCI ProcessДокумент5 страницAPCI ProcessMario MontessoriОценок пока нет

- SP-2047 - Preparation & Content of Engineering DrawingsДокумент56 страницSP-2047 - Preparation & Content of Engineering Drawingsarjunprasannan7Оценок пока нет

- Closed Drain System - CompressДокумент166 страницClosed Drain System - CompressMiguel FОценок пока нет

- Understand Centrifugal CompressorДокумент16 страницUnderstand Centrifugal Compressorramanathan72-1100% (2)

- FlareДокумент8 страницFlarechem_ta100% (1)

- Compressor Surge Prevention and CCC Anti-Surge ControlДокумент12 страницCompressor Surge Prevention and CCC Anti-Surge ControlMuhd Fadzlee ZОценок пока нет

- APCДокумент25 страницAPCTawanda Precious SingiziОценок пока нет

- 1.1 Control Philosophy CAS-1 NMDCДокумент36 страниц1.1 Control Philosophy CAS-1 NMDCkoushik42000Оценок пока нет

- Emission Calculation SheetДокумент5 страницEmission Calculation SheetcindydianitaОценок пока нет

- Condenser Efficiency EngineeringДокумент9 страницCondenser Efficiency Engineeringโอม ปามาติกะ100% (2)

- Control Valves and Their Principles of OperationДокумент5 страницControl Valves and Their Principles of Operationgroshan20Оценок пока нет

- Load Sharing Parallel Compressor Operation PDFДокумент3 страницыLoad Sharing Parallel Compressor Operation PDFVamsi MahantiОценок пока нет

- GTG PerformanceДокумент52 страницыGTG Performancerajan100% (2)

- High Fidelity Dynamic Simulation of Compressor SystemsДокумент9 страницHigh Fidelity Dynamic Simulation of Compressor SystemsTrần Quang ThắngОценок пока нет

- Condenser Vacuum Article From Power MagazineДокумент7 страницCondenser Vacuum Article From Power MagazineUdhayakumar VenkataramanОценок пока нет

- Turboexpander Compressors 2Документ5 страницTurboexpander Compressors 2Lidia JaraОценок пока нет

- Trisen TS160 TrainingДокумент105 страницTrisen TS160 TrainingGian ErzhaОценок пока нет

- 367 Steam Tracing GuidelinesДокумент1 страница367 Steam Tracing Guidelineslink2u_007Оценок пока нет

- Boiler Instrumentation and ControlsДокумент23 страницыBoiler Instrumentation and Controlshayat umar bhat100% (4)

- Running Performance: Service/Stage Data Performance OutputДокумент2 страницыRunning Performance: Service/Stage Data Performance OutputJose RattiaОценок пока нет

- Centrifugal Compressors Construction and TestingДокумент10 страницCentrifugal Compressors Construction and Testingmusaveer0% (1)

- Understanding Centrifugal Compressor Capacity ControlsДокумент5 страницUnderstanding Centrifugal Compressor Capacity Controlsjuancgr77100% (1)

- MIMO Control (Multiple Input Multiple Output)Документ17 страницMIMO Control (Multiple Input Multiple Output)Sohail Aziz Ahmad MalikОценок пока нет

- Reciprocating Compressor IIДокумент59 страницReciprocating Compressor IISagar NaduvinamaniОценок пока нет

- Density Compensation For Steam Drum Level MeasurementДокумент4 страницыDensity Compensation For Steam Drum Level MeasurementsaravananbscelecОценок пока нет

- E PR 460Документ37 страницE PR 460khorzooОценок пока нет

- MICROPROCESSOR-BASED COMPRESSOR CONTROLДокумент16 страницMICROPROCESSOR-BASED COMPRESSOR CONTROLSANTOSH KUMARОценок пока нет

- 10 WAYS TO MAXIMIZE YOUR COMPRESSOR'S ENERGY EFFICIENCYДокумент7 страниц10 WAYS TO MAXIMIZE YOUR COMPRESSOR'S ENERGY EFFICIENCYKamel NefziОценок пока нет

- Reading A Pump Curve: Pump Name and SpeedДокумент4 страницыReading A Pump Curve: Pump Name and SpeedganeshanОценок пока нет

- PSSCV ZixxingДокумент2 страницыPSSCV ZixxingShashi Kant KumarОценок пока нет

- TWO PHASE FLOW REGIMESДокумент25 страницTWO PHASE FLOW REGIMESAnant Joshi100% (1)

- CompressorДокумент29 страницCompressorShashi Naganur100% (1)

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979От EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonОценок пока нет

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationОт EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationОценок пока нет

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectОт EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectОценок пока нет

- Multiphase Flow 1995От EverandMultiphase Flow 1995A. SerizawaОценок пока нет

- Designing Steam Pressure Reducing StationsДокумент7 страницDesigning Steam Pressure Reducing StationsMohammed Hassan B KorainaОценок пока нет

- PrdsДокумент0 страницPrdssandi1111Оценок пока нет

- Basics of Pipe Stress Analysis A Presentation-Part 2 of 2Документ6 страницBasics of Pipe Stress Analysis A Presentation-Part 2 of 2iaftОценок пока нет

- Basics of Stress Analysis of Underground Piping in Caesar IIДокумент4 страницыBasics of Stress Analysis of Underground Piping in Caesar IIiaftОценок пока нет

- An Article On Tank Bulging Effect or Bulging Effect of Tank ShellsДокумент4 страницыAn Article On Tank Bulging Effect or Bulging Effect of Tank ShellsiaftОценок пока нет

- Stress Analysis of GRP GRE FRP Piping System Using Caesar IIДокумент5 страницStress Analysis of GRP GRE FRP Piping System Using Caesar IIiaftОценок пока нет

- Checklist for Chapter VIII of ASME B31.3 for Category M PipingДокумент5 страницChecklist for Chapter VIII of ASME B31.3 for Category M PipingiaftОценок пока нет

- A Brief Description of Sway Brace, Strut and Snubber (Dynamic Restraints) For Pipe Supporting For Process IndustriesДокумент7 страницA Brief Description of Sway Brace, Strut and Snubber (Dynamic Restraints) For Pipe Supporting For Process IndustriesiaftОценок пока нет

- Cold Springing (Cold Pull) In Piping SystemsДокумент5 страницCold Springing (Cold Pull) In Piping SystemsiaftОценок пока нет

- Few Points On "Selection of Bolts"Документ2 страницыFew Points On "Selection of Bolts"iaftОценок пока нет

- Slug Flow Analysis Using Dynamic Spectrum Method in Caesar II-20150911Документ6 страницSlug Flow Analysis Using Dynamic Spectrum Method in Caesar II-20150911iaftОценок пока нет

- Upstream - 2016-06-24 PrintДокумент1 страницаUpstream - 2016-06-24 PrintiaftОценок пока нет

- Dynamic Slug Time History Analysis Load ReportsДокумент2 страницыDynamic Slug Time History Analysis Load ReportsiaftОценок пока нет

- What's New in CAESAR II, 2016 (Version 8.0)Документ5 страницWhat's New in CAESAR II, 2016 (Version 8.0)iaftОценок пока нет

- What's New in CAESAR II, 2016 (Version 8.0)Документ5 страницWhat's New in CAESAR II, 2016 (Version 8.0)iaftОценок пока нет

- Welding Processes Fcaw, Gmaw, Gtaw, Smaw, SawДокумент2 страницыWelding Processes Fcaw, Gmaw, Gtaw, Smaw, SawiaftОценок пока нет

- What Are Universal & Hinged Expansion JointsДокумент4 страницыWhat Are Universal & Hinged Expansion JointsiaftОценок пока нет

- Balance Pressure Steam TraДокумент3 страницыBalance Pressure Steam TraiaftОценок пока нет

- Types of Pipe FittingsДокумент3 страницыTypes of Pipe FittingsiaftОценок пока нет

- What Causes Corrosion in MetalsДокумент2 страницыWhat Causes Corrosion in MetalsiaftОценок пока нет

- Fatigue PDFДокумент1 страницаFatigue PDFiaftОценок пока нет

- What Causes Corrosion in MetalsДокумент2 страницыWhat Causes Corrosion in MetalsiaftОценок пока нет

- What Is Pipe Schedule Explanation and Pipe Schedule ChartsДокумент4 страницыWhat Is Pipe Schedule Explanation and Pipe Schedule ChartsiaftОценок пока нет

- Winterization Protection Against Low Ambient TemperatureДокумент8 страницWinterization Protection Against Low Ambient TemperatureiaftОценок пока нет

- Underground Piping Stress Analysis Procedure Using Caesar IIДокумент7 страницUnderground Piping Stress Analysis Procedure Using Caesar IIiaftОценок пока нет

- Ball Valve Based On Body Construction TypeДокумент2 страницыBall Valve Based On Body Construction TypeiaftОценок пока нет

- PDTSMetricWeight BookДокумент13 страницPDTSMetricWeight BookGrant NelsonОценок пока нет

- Auxiliary Units of CompressorДокумент5 страницAuxiliary Units of CompressoriaftОценок пока нет

- Equipment Layout ChecklistДокумент35 страницEquipment Layout ChecklistjkahamedОценок пока нет

- Air Cooled Heat ExchangerДокумент24 страницыAir Cooled Heat Exchangeriaft100% (2)

- Additional Technical Requirements For Pipes & FittingsДокумент2 страницыAdditional Technical Requirements For Pipes & FittingsiaftОценок пока нет

- Ans: DДокумент10 страницAns: DVishal FernandesОценок пока нет

- Fundamental analysis of ACC Ltd and India's cement industryДокумент5 страницFundamental analysis of ACC Ltd and India's cement industryDevika SuvarnaОценок пока нет

- 2003 Expedition/Navigator 4WD Systems Workshop Manual DiagnosisДокумент18 страниц2003 Expedition/Navigator 4WD Systems Workshop Manual DiagnosisAngelina IsaacsОценок пока нет

- Torts - Damages by UribeДокумент4 страницыTorts - Damages by UribeJolas BrutasОценок пока нет

- Page 34-45 BLK PicДокумент12 страницPage 34-45 BLK PicMihir MehraОценок пока нет

- Tutorial Question 4 TORTДокумент2 страницыTutorial Question 4 TORTNBT OOОценок пока нет

- Itc Diversification Case SolutionДокумент40 страницItc Diversification Case SolutionDivya PujariОценок пока нет

- Parliamentary Procedure in The Conduct of Business MeetingДокумент14 страницParliamentary Procedure in The Conduct of Business MeetingEstephanie SalvadorОценок пока нет

- Homework 7 Traffic Accident Data AnalysisДокумент5 страницHomework 7 Traffic Accident Data AnalysisRagini P0% (1)

- 330-350W / 72 Cells / 5 Bus Bars Polycrystalline Module: GreenДокумент2 страницы330-350W / 72 Cells / 5 Bus Bars Polycrystalline Module: GreenCARLOS JAVIER COTRINA SAAVEDRAОценок пока нет

- 1 ST QTR MSlight 2023Документ28 страниц1 ST QTR MSlight 2023Reynald TayagОценок пока нет

- Charles L. Mader - Numerical Modeling of The Deflagration-to-Detonation TransitionДокумент21 страницаCharles L. Mader - Numerical Modeling of The Deflagration-to-Detonation TransitionSteemWheelОценок пока нет

- Approved Term of Payment For Updating Lower LagunaДокумент50 страницApproved Term of Payment For Updating Lower LagunaSadasfd SdsadsaОценок пока нет

- Docu31515 VNXe3100 VNXe3150 Replacing A Solid State Disk (SSD)Документ6 страницDocu31515 VNXe3100 VNXe3150 Replacing A Solid State Disk (SSD)john malloyОценок пока нет

- AR15 Forging ReceiverДокумент105 страницAR15 Forging ReceiverNO2NWO100% (10)

- Banking Fundamentals QuizДокумент5 страницBanking Fundamentals QuizPhương Nghi LêОценок пока нет

- DSKH Riviera Q2 101Документ10 страницDSKH Riviera Q2 101Viết HảiОценок пока нет

- Set Up A Mail Server On LinuxДокумент56 страницSet Up A Mail Server On Linuxammurasikan6477Оценок пока нет

- Covid-19 Vaccine (Argumentative Essay) By: Karr GelladoДокумент2 страницыCovid-19 Vaccine (Argumentative Essay) By: Karr GelladoKesha May GelladoОценок пока нет

- Oracle Payslip PDFДокумент2 страницыOracle Payslip PDFVaishnavi DappureОценок пока нет

- Calculus Early Transcendentals 10th Edition Anton Solutions ManualДокумент35 страницCalculus Early Transcendentals 10th Edition Anton Solutions Manualcrenate.bakshish.7ca96100% (16)

- Impact of Digitalisation Online FinalДокумент72 страницыImpact of Digitalisation Online FinalBanon KekeОценок пока нет

- Book Shop Automation SystemДокумент36 страницBook Shop Automation SystemThe Tech ExpertОценок пока нет

- Cambridge O Level: English Language 1123/21Документ8 страницCambridge O Level: English Language 1123/21Fred SaneОценок пока нет

- Blackbook Project On IT in Insurance - 163417596Документ75 страницBlackbook Project On IT in Insurance - 163417596Dipak Chauhan57% (7)

- Mazda2 Brochure August 2009Документ36 страницMazda2 Brochure August 2009Shamsul Zahuri JohariОценок пока нет

- Check List: For Processing of RA Bills @Документ9 страницCheck List: For Processing of RA Bills @pvnОценок пока нет

- Annexure CДокумент63 страницыAnnexure CSandeep VermaОценок пока нет

- Financial Analysis P&GДокумент10 страницFinancial Analysis P&Gsayko88Оценок пока нет

- Leak Proof Engineering I PVT LTDДокумент21 страницаLeak Proof Engineering I PVT LTDapi-155731311Оценок пока нет