Академический Документы

Профессиональный Документы

Культура Документы

WT Catalog

Загружено:

Kaji Kelana UsopОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WT Catalog

Загружено:

Kaji Kelana UsopАвторское право:

Доступные форматы

www.actionmining.

com

Prices good through January 2016

Why recovery gets simpler, not more complex...

Positive means of recovering microscopic gold using mechanical means! Standing waves, skin effect,

inertia, and most importantly specific gravity, are all used in the recovery of gold, platinum, scheelite, copper,

zinc oxide, and many other minerals from their ores.

Replaces: centrifugal concentrators, flotation cells,

amalgamation, leaching, jigs, and a great deal more - Environmentally safer to use!

In todays environmentally-conscious world, extreme attention is being paid to operations using chemical means, including mercury, or even non-hazardous chemicals in the recovery of precious metals. Worldwide companies earnestly keep

their operations clean and safe, as today's miners are just as concerned about contamination as the general public.

Action Mining, many years ago, joined the ranks of concerned miners and mining companies referencing the use of

chemical means to extract precious metals. We felt that even the best concepts needed application, thus the Micron Mill Wave

Table was born. The mining industry can now eliminate worries regarding hazardous products or waste material. Action Minings Wave Tables use only water, and possibly some biodegradable surfactant. Again, everything is environmentally safe,

thus avoiding "chemical permits", arguments with government agencies, hazardous

waste disposal costs, and most

importantly, the headaches

connected with chemical extraction of gold, or other

metals. (See inside for

more information or

CALL 800 624-1511)

Environmentally

Safer to Use:

No chemicals needed

Uses recycled water

Recovers float material

No waste disposal costs

Safer for employees to operate

Actually recovers mercury from

ores & tailing piles

Mill Site Shown:

20 TPH

JUNE

2016

Improve

your fine

mineral

recovery!

Headquarters:

37390 Ruben Lane Sandy OR 97055

Phone:

Fax:

503 826-9330

503 826-1340

Order line:

800 624-1511 phone

E-mail: sales@actionmining.com

Web site: www.actionmining.com for secure online ordering & more!

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

How It Works:

The picture below shows the wave theory of

the

table.

Separating

by

specific

gravity, the

sand forms 2in drifts directly

www.actionmining.com

Prices good through January

2016

under

the

standing

wave

of

water.

Even

light

blond sand forms drifts, not

Simple operation washing away. Due to the Standing Wave principle, the heaviest particles

adjustable water flow

remain through the low motion area of the Standing Wave. The wave itself

adjustable table top bump

moves; the water directly beneath the wave tends to stand still. The further

adjustable table tilt

from the top of the wave, the less motion is in the water. Thus, the heavier

the particle the deeper it will ride and the less motion it will see. The Riffle

Pump attached to the top bar of the Riffle Bar assists in dropping float

gold to the table surface, enabling a faster production run without fear of

losing gold or other metals that normally would be lost on most tables.

In view of the fact that the table top moves back and forth, the micron particles of heavy material (gold, PGMs, scheelite,

copper, zinc oxide, etc.) sink to the bottom under the wave. The finer particles (-600 mesh and smaller) drop into a Skin

Effect area. That area is directly against the skin of the table top. The water in this area does not move with the flowing

water but rather sits almost still. The motion of the table causes this Skin Effect water to move in the opposite direction of

the flow. Thus the fine gold or mineral moves up the table and falls into the concentrate trough. The gold and/or

concentrates can then be washed automatically into a concentrate bucket or a security safe, or vacuumed off the table.

Ore should be classified according to size for efficient results.

The Secret lies at the Heart of the System:

Superior, top-of-the-line linear ball bearings: responsible for the precision back and forward

motion of the table top, preventing up and down vibration that causes gold or heaviest materials to

break loose and wash away. The bearings move back and forth on the high carbon alloy steel rods.

Highest Quality Fiberglass Top: vacuum-formed, sealed fiberglass top with a 1 thick base is built

to give several years of satisfactory results, conducive to not warping (store out of direct sunlight). The

finish blue color has been proven to be the best color contrast for gold viewing.

OPTIONAL UPGRADES - security cages, additional screens, stainless steel components, side feed troughs, IP55

motors and more!

The Micron Mill Wave Table can be fed from an overhead tank, slurry fed by conveyor belts, or by pipe,

depending on your setup requirements. Ask our technicians for suggestions. On-site table

adjustments after mill setup is available.

The Micron Mill Wave Table is beyond question a new development in the

recovery of micron particles or minerals of all kinds. This table can be adjusted to

separate virtually anything since it cleanly separates by specific gravity. Under most

circumstances it will replace flotation cells as well as other concentrating tables. Our theory

of operation and use differs quite widely from other concentration equipment. The inertia

Gold moves up the table

bump is in one direction and the flow of precious metals is in the opposite direction. The

Light sand moves away

recovery of micron particles as small as 5 microns (approx. 10,000 mesh) is happening daily!

Our trailblazing Tables rank near the top in order of importance in the recovery of

precious metal particles. Until the present, there has been no mechanical method of

Light sands at top of picture, black sands

recovering particles of gold finer than 150 mesh (106 microns). The only workable methods

in middle, gold moving forward &

for micron gold particles smaller than 150 mesh have been leaching and flotation. Now,

out of the black sands

recovery of finer particles can be accomplished without the environmental problems

associated with leaching and flotation. Notably, the cost factor of the Micron Mill Wave

Table recovery method is usually less than 1/10 the cost of leaching, flotation

or amalgamation.

NEW

Now available C2000 and CT8 (Commercial) series!

All the great features of the M series but

built for volume production of commercial

operations running 24/7 - featuring stainless

steel components & hardware, variable

speed controls, special feed trough, IP55

motors & controls, and more! See back page

for details.

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

The Tables must have all 4 legs bolted to a cement foundation and be level for best results, but may be mounted on a frame and weighted down, as

long as the table frames do not move or vibrate and the tops are level.

Alternate Production Configuration

M7s in production series - final concentration

on last M7 table

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

Our Production Size

M10 Table - 3-8 tph

average) * Special order item

A production table for making a

primary concentrate of a 10-20X

ratio which would then be fed

onto your finish table (M7) to

make the high grade

concentrate. The screening of

ore is not as critical as for a

finish table, thus you could run

-40 mesh material. The Riffle

Bar keeps float gold dropping to

the surface of the table, and

moving up to the concentrate

outlet.

Operating on the same principles as the 1 tph unit, using six 1 superior linear bearings & shafts

for smooth action to ensure steady production runs.

The heavy-duty electric Drive System works at a constant motion so the

amount of feed to the table can vary without a critical change in the mechanical

separation process on the table. (In other systems, if your feed changes, critical

changes occur that alter the separation process, thereby losing precious

metals.)

The Drive System comes with a variable speed control, with a digital RPM

display, for precise adjustments to obtain the correct bump to match your material.

Once youve determined the right bump for the best separation, easily memorize your

setting for optimum performance. (Remote control compatible - module sold

separately)

With this table, slime or recycled water can be used as long as it doesnt plug up

holes- still no float gold will be lost!

Solid heavy-duty metal feed trough takes plenty of abuse.

Riffle Bars and Feed Trough are adjustable; factory installed for 10 to 1 cut

SPECIFICATIONS FOR THE TABLE-M10:

3-8 tons of ore per hour, average. Examples:3tph of copper/lead/zinc ores; 8tph of simple quartz head ore

Recovery of gold particles ranges between 10 mesh and microscopic

Recovery of gold from classified black sand ranges from 80% to 99%

Water requirements are 5-20 gpm with 1 adjustable spray bar at top of table

Emergency stop switch mounted on main frame

3 HP, single or 3 phase, 50/60c, 220/460 VAC, IP55, with 15 ft cord to variable speed control box

Variable Speed Control UL, CSA, CE, NEMA 4X

Steel frame construction is positioned for easy gravity feeding from a trommel, chute, pipe, etc.

Feed Hopper is made from steel

Table top is constructed of fiberglass, gel-coated in finish blue

Adjustable table tilt & bump

Weight is 2000 lbs.

Crated Dimensions are 72 wide x 84 length x 42 high = 212.5 CU FT (182.9cm x 254cm x 129.5cm = 6.02 CU METERS)

Shipped by truck or sea freight

Cat #TABLE-M10

Base price $44,029.00 ($250 crating in U.S - $350 crating international)

Upgrade options available

Special COMBO pricing: Buy a set of TABLE-M10/TABLE-M7VS*, 110/220V, 60C for a special COMBO price $50,624

Or TABLE-M10/TABLE-M8VS*, IP55 240V, 50C OVERSEAS COMBO $50,738

* M7VS or M8VS with variable speed control

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

M10/C10

PRODUCTION MODEL

WAVE TABLE

Steel frame & adjustable feed trough

Sturdy fiberglass top

Electric drive system with emergency stop

switch & wall mounted variable speed control

Adjustable riffle bar, factory set 10 to 1

concentration

Feed trough

12

72

Spray bar

Discharge

12

16

Riffle bar assembly

46

30

Concentrate

outlet

71 base

18

Riffle bar & feed

trough adjustTilt adjustment

48 base

Production

rate

Water

requirement

3-8 TPH,

5-20 gpm,

average

(can be recycled);

depending on water feed (either

material run side hookup) miniExamples:

mum 3/4 pipe 30

Copper/lead

PSI;

ore about

3tph;

Discharge pipe 6

from bottom of

Black sands pipe to ground, on

about 4 tph;

center;

Power

240/460V

50/60 C

Length

Base

Width

Base

Totally enclosed

washdown motor,

IP55, Insulation

Class F, NEMA C,

UL CSA, Stainless

steel shaft, 3 HP,

Single/3 phase,

50/60 C,

208/460 VAC,

8.6/4.3 amps,

174-1740 RPM

48

71

Length

Table

top

61

Width

Table

top

80

(sketch not to scale)

Height

Weight

30, including 2000 lbs

feed trough, (909 KG)

working

height 18

(ground to

table top)

Variable Speed

Control

Simple quartz Concentrate pipe

UL,CSA,CE,

ore about 8 12 from bottom of

tph

pipe to ground, on NEMA 4X, Adjustable acceleration

center

0.1-180 seconds,

deceleration 0.3180 seconds, digital display

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

From high tech

production to low

tech small

operations the M or C series

combos are a

good fit for gravity

separation.

Ore feeds from ore bin onto conveyor belt which

feeds to the M10 for a primary concentrate, then

onto the M7 for the final concentrate.

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

31 years of proven success, the M7

Production Size Table also

serves as a Finish

Table.

While having the capability of acting

Separation on the M7

as a production table for a smaller mill or pilot

operation (concentrating approximately 1 ton of

simple quartz ore per hour), the M7 can be used as a

Finish Table producing a very high grade concentrate of

precious metals. Gold will separate efficiently and at a

high percentage from black sands - which is a statement

unheard of in mechanical separation considering the

specific gravity of black sands and gold are so close in

proximity! This Table will separate them!

As a Production Table, the same table that is used for

production can be used to clean the cons. The concentrates

produced can be reloaded onto the table for the finish (cleanup)

and can give almost pure gold or other metal when the water

flow is properly adjusted.

As a Finish Table, the concentrates coming off of the Production Table can

be run directly onto this table, offering a very efficient system for a mill operation.

The variable speed control on the Wave

Table enables the user to fine tune the separation.

Mounted directly on the table (or wall mounted),

the user can quickly adjust the separation of the

material with precision. This is especially helpful in

a lab environment where testing of different ore

bodies is performed. Minute changes in the speed of the table top movement are easily made to determine the most efficient and cost effective rate of speed and material

feed. Once calculations have been made, the control will hold the position.

2016

Model

Your 2016 M7/8 Wave Table comes with:

a specially designed Feed Hopper that holds a 20 mesh screen (included) to easily classify small batches of material while running the table. (Other mesh sizes available.)

a built-in hydraulic jack lift area (jack included) to easily and quickly adjust the height of the

concentrate end of the table.

2 Risers so that you can adjust each cons leg separately to level up the table for cleaner separation!

Double the number of superior linear bearings for a smoother performance & longer life

Variable Speed Control for precise separation adjustments

SPECIFICATIONS FOR TABLE-M7/8/9:

600 - 2500 pounds of head ore material per hour, Examples are approximate recovery

rates: 600 pph of copper/lead/zinc ore; 800 pph black sands; 2000+ pph of simple quartz ore

Recovery of gold particles ranges between 10 mesh and microscopic

Experience the wonder of

Recovery of gold from classified black sand ranges from 80% to 99%.

the Micron Mill Wave

Recovery of gold from small batches of classified black sands ranges from 92% to 99%.

Tables

Water requirements are 3 to 8 GPM, with 2 adjustable water spray bars

Call 503 826-9330 to schedule your

1/2 HP, 50/60 cycle, 110/240 VAC at 600 watts, IP55 Class F

appointment!! Receive a personal look

Steel frame construction is finished yellow with high corrosion-resistant baked-on,

at your own product run, in person or

powder coat epoxy paint.

by video & photos.

Table top and hopper are constructed of fiberglass, gel-coated in finish blue (proven to be

the best color for color contrast for gold)

Variable Speed Control 120/240V, 50/60C, NEMA 4X, LED display

Adjustable table top tilt & bump

Weight is 386 lbs, Dimensions are 61L x 32 W x 39 H. Crated weight 409 lbs; dimensional weight is 600 lbs. Crated dimensions are 64L x

36W x 38H. Can be shipped by truck or air or ocean freight

Cat #TABLE-M7VS Base price $7795.00 110V, 60C, IP55 Class F motor ($75 crating in U.S.)

Cat #TABLE-M8VS Base price $7909.00 220V, 50C, IP55 Class F motor ($150 crating for overseas)

Cat #TABLE-M9VS Base price $7909.00 220V, 60C, IP55 Class F motor ($150 crating for overseas)

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

M7/8/9VS

MID-SIZE MODEL

WAVE TABLE

pipe

1 pipe

43

33

Hydraulic lift

50

Production Rate

Water

requirements

600-2500

3-8 GPM

lbs wet slur- (can be recyry feed per

cled), 2 adhour

justable

depending

spray bars

on material

run

Supplied with

flex hoses

80-99% re- that attach to

covery 20

standard

mesh hose lines

5 microns

Separates

by specific

gravity

Power 60

cycle

(M7)

(M9)

HP variable

speed totally

enclosed motor, 1760 RPM,

110-220V

600 watts,

1.9 amps,

3 phase, IP55,

temperature

tolerance

class F

Variable

speed

control

120-240V, 3.6

amps, 50/60

Hz, single

phase, NEMA

4X, LED display,

Adjustable

acceleration/d

eceleration

time 0.3-20

seconds

Power 50

cycle

(M8)

Base

Length Width Height Weight Foundafoot print table table

tion

top

top

HP variable

50 x 26

speed totally

enclosed motor, Holes on

1760 RPM,

center

220V 600 watts,

47

x 24

1.9 amps,

for

securing

3 phase, IP55,

to concrete

temperature

floor

tolerance

class F

Variable

speed

control

Leveling

risers included for

all 4 legs

240V, 3.6 amps,

50/60 Hz, single phase,

NEMA 4X,

LED display,

Adjustable

acceleration/de

celeration time

0.3-20 seconds

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

61

32

43

386 lbs

Including feed

trough

with

screen

Working

height

33

(ground

to table

top)

Minimum

5 x 3

4 slab

Ideally 12

x 9 for

working

space

Built-in

hydraulic jack

lift

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

Accessories & Upgrades for Wave Tables

Service Parts Kits - (not shown) weve put together kits of wear parts.

M7/8 Kit Cat #M7SERVICEPARTS $ 540.00

M10 Kit Cat #M10SERVICEPARTS $1,698.00

Vacuum System - 2 sizes available

for vacuuming gold concentrates off

the table. If you are doing many

different runs, this vacuum system

works simply and efficiently. Vacuum

off the free gold or cons and smelt

them or send to a refiner.

5 gallon size Cat#TABLEM7VACUUM

$ 98.00

16 gallon size Cat#TABLEM7VACUUM15 $ 195.00

Surfactant - concentrated ProSurf GW surfactant, used by diluting

1 part of Concentrated ProSurf Gw to 10 parts water. Then diluting to

the recommended dosage of 100 ppm, which would be equivalent to 1

gallon of diluted ProSurf GW for every 10,000 gallons of water. For industrial and

research and development use only.

5 gallon pail Cat #SURFACTANTPS5

$310.00

1 liter bottle Cat #SURFACTANTPS51L

$ 55.00

Upgrades available for the M7/8/9 mid-sized tables:

Additional mesh size screens - $28

Special feed trough for the recycling industry - $825

Metal feed trough, rubber lined, permanent mount - $1100

Metal spray bars - $318 each (brass or ss)

IP55 ss waterproof motor & waterproof variable speed control - $7500

Stainless steel components & hardware - varies

Automatic grease system for bearings - $1200

Safety guard rails - $5400

Sealed 5/8 shafts & bearings eliminate all dirt/water contamination - $3645

Security cages - $3244

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

10

Security Cage Package for M7/8/9

Full security for your milling operation!

Concentrates travel directly from the table into

lock box via a connected pipe. Both ends of the

table are caged, with critical areas protected.

Workers can not reach the table surface without

opening the cages or removing feed trough.

The complete custom Security Cage Package consists of 2

lockable top cages and 1 lock box with hinged lockable door

for collecting concentrates. The table top metal framework

is manufactured with 14 gauge expanded metal screen with 3/4 diamond openings for easy viewing of table surface, but eliminates

access to the concentrates. The metal lock box holds 2 5-gallon buckets and can be moved by forklift. The undercarriage of the M7 is

modified with additional welded frame extensions for attaching the top cages which bolt and lock (locks not included) in place.

LOCK BOX: Open-wire design allows full visibility. Unit folds down

flat to stack for storage. Stacks up to 4 high to optimize available

storage space. Heavy-gauge wire and fully welded base. Drop gate

design allows easy access when unlocked (padlocks not included).

3-7/8" underclearance allows easy movement by fork trucks with 4way entry access. Load capacity 1500 lbs. 19L x 32W x 16H easily holds a couple of 5 gallon pails or large tank.

Cat #SECURITY7

Price $3244.00

M5 Stand - metal stand for mounting M5 up to

working height. Cat #M5STAND $749.95

Photo shows M5

mounted on Stand

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

11

Micron Mill Wave Table M5 Field or Lab Bench Model

The newest bench model, M5, is a mini-me of our production models. Blue fiberglass top,

removable riffle bar, top-of-the-line linear bearings, heavy metal frame with adjustable risers

for table tilt, and feed trough to hold our small classifier screens (unit comes with -20 mesh

screen; other mesh sizes available). The M5 stands 19 high and can be split into 2 pieces

and bolted together by 8 bolts in about 15 minutes. Great for packing in to a remote location!

Lab model in 110V/220V with variable speed

adjustment. Perfect for running small samples in a lab environment to determine ease

of specific gravity separation and optimum

classification size of materials. Through-put

is around a 5 gallon bucket (9 liters) of material, hand fed, per hour. Water use around

2 gallons (10 liters) per minute and can be

dirty water recycled.

Weight: 130 lbs CRATED 170

LBS. Dimensions: 43l x 17w x

20 h; crated 46x24x24

Power supply: 12 volt battery or

battery charger (not included) Cat

#TABLE-M5 Price:$3975.00 ($75

crating charge)

110/220V 50/60Hz UL, CSA, Class B with variable speed control

Cat #TABLE-M5110/220V Price $4148.00 ($75 crating charge)

220V 50/60Hz IP55, UL, CSA, CE, Class F with NEMA 4X variable speed control

Cat #TABLE-M5220CV Price $4484.00 ($75.00 crating charge)

Gettin

g great

M5 110/220V

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

review

s!

Photos of M5 110V shown mounted on a

stand in our lab. Stand is NOT included.

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

12

Lab (110/220V or 220CV) or Field (12V battery run) Model M5 Wave Table

M5 110/220V

20

26

16

Shown with new riffle

bar & feed trough

Production Rate

Water requirements

Power

12 volt

(Field work)

37

Base

foot

print

Length Width Height Weight

table top table

top

Foundation

110/220V

50/60C

(Lab work)

220CV

50/60C

For testing2-5 GPM

hand feed 5 (10-25 liters)

gallon bucket

can be

(9 liters) per

recycled

hour

Supplied

80-99% recov- with 2 adjustery 20 mesh - able spray

5 microns

bars,

flex hoses &

Separates by pipe unit that

specific gravi- attaches to

ty

standard

hose lines

(Lab work)

12V battery or

battery charger

(not included)

110/220V

50/60C

HP Motor,

1700 RPM,

3.4/1.7 amps,

UL,CSA,

Class B, VS

control

220CV 50/60C

HP Motor,

1655 RPM, 1.2

amps,IP55,

UL,CSA,CE,

Class F, NEMA

4X VS control

37 x 16

43

Holes on Table top is

center

removable

34 x for transport14 for

ing by unsecuring bolting the

to conmotor

crete floor

mount

frame

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

17

26

Including

feed

trough

20 Working height

(ground

to table

top)

130 lbs

No permanent foundation needed,

although

mounting

holes provided for securing to bench

503 826-9330 customerservice@actionmining.com

www.actionmining.com

ls

onia

m

i

t

es

Prices good through January 2016

13

TESTIMONIALS:

Thank you for designing a product that actually works well. I have been processing taunna (arrasta) tailings from areas in Mexico. These small operations loose up to 70% of their gold and throw 10-15% of their mercury into the tailings piles. Your table not only catches the lost gold, but captures almost all of the mercury.

Thanks, D Peterson, California

Thanks for the great tipswe are getting to know the table (M8s) - and implementing a lot of what you

have said has helped enormously. We have quite a bit of pyrite at the moment but can get a clear line between

gold, pyrite, and ballmill steel/magnetite. We are still getting a lot of mercury coated gold in the system and amalgam balls as the previous owner put in quite a bit into the ball mills. We see this on the tables. We are having a

few issues on getting screening right. We notice in the book that the 4 tables are set at very narrow screening intervals. At the moment we have 0.25-1.00m going over the table and it seems to work although we find a bit of the

mercury gold in among the sand (top area) and not getting to the front. Guess it is because some of this has been

flattened by the ball mills and partly digested by the mercury. So overall happy so far on table runs, were just

kicking in the bigger ball mills so will let you know on results of more of the commercial sized production runs.

Tony, Mongolia

The Wave Table is one of the best, if not the best, Ive ever owned, and gets the real fine gold mostly on

the first pass, but some of the ore Im working with has a lot of cons in it, so Im having to run some of it 2 or 3

times to really get all I think there is in it. I had to re-bolt it to the floor in my shop to keep down vibrationit

works very well now that I have that done. James, Georgia

Just wanted to let you folks know that I finally got a chance to run about 80 lb of Nome concentrates

through the M4. Had already run it through a gold wheel and the wheel did surprisingly well, but the M4 pulled

some mighty fine gold out that the wheel missed, not a lot, but the M4 handled the material a lot faster and easier.

Cant wait to get it up to Nome this summer. Harold, Alaska

Since I unpacked my table, Ive run it about 4 or 5 hours getting used to it. I am quite satisfied with the

first results and the first recovery tests are positive. I am certain already that your table is the right recovery system that I was looking for and t his equipment will be very useful in my gold room. As you probably remember, I

need your table for daily clean ups of about 350 lbs of cons coming from my concentrator. The separation is effective and rapid, quite surprising I must say. Herwig, Fr Guyana

..........

Let me explain, for the last two years I am living on my mine site. Indeed, after so many years

and more than 1200 hours ( I have precise records) using your M8 table I am still a very satisfied and happy wave

table user. I sincerely believe that your wave table is a "must" for primary (hard

rock) mining. The finer the gold, the better the table behaves. To me it is always a

surprise to see how microscopic gold comes out first. Often I get a "cloud" of

floating gold on the surface of the water. Luckily this floating gold gets back to the

bottom when it reaches the hopper barrier of feeding water. The table that I purchased from you is now presently used by my son on his alluvial mine. I managed

to recuperate the second table that you've sold to Christian at the time. My son

has coarse gold and recuperates about 80 to 85% of his gold on the M8. It is a

fact that these tables work perfectly with microscopic and fine gold, they don't really perform at 100 % with coarse gold. Warmest regards, Herwig, Fr Guyana

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

14

Nancy, the 2 M7 Micron Wave tables that we are using have performed flawlessly. Due to the density of

the feed and the continuous operation, we had to make a few very minor changes to the tables. One table is being

used to recover metal values that our other recovery processes missed. The other M7 is being used to clean up the

mids from a full size Diester table. Both tables have been running 24/7 since 1996 with no breakdowns! The M7

tables are very efficient as far as low water consumption and are able to recover metal in the range of 5-44 microns, something that our large tables have trouble doing. The tables are very operator friendly and inexpensive

to maintain. Two of our tables are being used to make a clean product (tungsten carbide) of minus 400 mesh material. The feed rate for each table is about 75 lbs. per hour. The other table is used to scalp the tailings from 4

full size Wilfley tables and it has a feed rate of about 200 lbs. per hour. WC Mccuskey, Kennametal Corp., Nevada

Low water consumption and high grade micro mineral output. Rather perfect lab/production device to

work in the field away from any sufficient water sources. That's the way to go! From all Recovery devices I have

reviewed so far by distance the M7 is the most convincing one. Peru

Attached pic shows your M7 set up on a rather large concrete base. It works well, developing a black

sands line within 12-17 seconds after feeding a sample. I dont think Ill ever pan again

Craig, Oklahoma

First calibration/commissioning run of a single table. Steve S, UT

_I have performed clean ups of used/spent activated carbon on a M7/M8 Wave

Table(WT) and the results were mind blowing !....to say the least. The owners of the largest carbon stripping operation (toll treatment) in Australia brought me some samples and I ran them over my M8.

All they wanted, was to see if the M8 could separate the grit out of the carbon. Everyones eyes popped out when

they saw how easily the M8 separated the grit from the carbon granules - to such an extent that the plant operator was astonished at how much gold there was remaining in his large accumulation of spent carbon! In this grit

was heaps of gold! Ian Freeland, Australia

Dear Nancy, we are testing currently different mineral ores (gold, wolframite, tantalite). We will keep

you informed about the results. Best regards, Prof. Hermann Wotruba, RWTH University, Germany

Hi Nancy, Thanks very much for the follow-up note. As an aside: I particularly like that you had the

right table for our voltage in stock, and that we received it at the project in Paraguay within six days of our order. In getting our project underway, most articles have not been acquired so easily. The table has been working

well for us. I helped the gold room guys set it up myself, and I have operated the table personally for a few days.

The gold room guys are using it all the time. I liked that it is easy to set up and to run. We can adjust the 'hit' easily, and the concentrating performance responds to those adjustments. I learned in the first few minutes of playing

with it that by pushing or pulling against the table, you can change the 'hit' strength for a brief period, which can

be handy sometimes. We are struggling a bit to separate larger grains of hematite from our finer gold grains. The

coarse hematite typically wants to follow the gold. (Our material is already gravity concentrate from Falcon concentrators, that has then passed twice over a Deister table before getting to the small wave-table). We think the

way to resolve this better is by doing a lot more grain-size sorting before we get onto the wave table (20 mesh, 40

mesh, 80 mesh....). Anyway, the table has been easy to use and is pretty fast at bumping the gold to the leading

edge. It's working pretty well for us. Best regards, Miles, Paraguay

The M7 is an amazing piece of equipment. It does everything you said it wouldit now makes a lot of

other pieces of equipment obsolete and is going to change the way we (sample) the ground. We are seeing stuff

that we could not get with the pan. Even using the table to say yes/no as to if its worth sending any sample to the

lab justifies its use. Australia

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

15

I ran the old type tables and they just frankly, didnt inspire me. Your table does! Not only is the theory

fabulousit makes the operator strive to get the BEST separation possible. Sonot only do you have a successful

run..you feel damn good about it. Cheryl C, Oregon

The first test we ran on the M8 got a 70% recovery of the gold present. The WT had just be set up, the

ore was not ground properly, and we still got a good result. I am confident that I will get at least 75% recovery

rate when set up properly. Hans, Germany

There are many types of shaking tables on the market. Almost all have the cons reporting on the table

deck in a longitudinal direction.whereas the WT has the cons reporting transversely (across the deck). This is a

great advantage as it provides a cleaner separation, higher recovery of for example, gold (particularly, fine

gold).and allows gold to accumulate on the deck which is advantageous in clean-ups when you wish to wet vacuum off the gold. The general action of the Wave Table is superior to the other shaking tables. Hence, higher recoveries of the very fine gold are achieved. There are many other advantagessuch as size, lower water usage,

lower power usage and lower overall cost per unit of throughput. For the above reasons, I personally use WTs in

my two gold mines in Australia and they work extremely well. Ian Freeland, Australia

Arizona

Brazil

Philippines

Canada

Australia

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

French Guyana

503 826-9330 customerservice@actionmining.com

www.actionmining.com

Prices good through January 2016

16

C-series Wave Tables

Introducing the C series for commercial operations

running 24/7 or under rugged conditions!

Site-ready Fully Assembled Tables come standard with:

variable speed controls (remote control adaptability)

IP55 waterproof motors and switches

sealed 3/4 shafts, bearings, and shaft supports to eliminate dirt and water contamination

stainless steel components and hardware

metal spray bars

NEW

safety guards

extra seal and spare parts

PHOTOS COMING

SOON!

automatic greasers on linear bearings

stainless steel vacuum system (C2000-110 only)

safety protection assembly for power cords

metal feed trough, rubber-lined, permanently mounted to the base frame

metal guard rails around entire unit on mounting plates

self-adjusting chain drive (CT8 only)

Cat #TABLE-C2000-110

Cat #TABLE-C2000-220

Cat #TABLE-CT8

C2000 Service Kit

CT8 Service Kit

Base price (includes all of above features) $24,182.00

Single phase, 110V, 60Hz

Base price (includes all of above features) $24,298.00

Single phase, 220V, 50 or 60Hz

(depending on final destination)

Base price $99,500.00 3phase, 3KW, 220/440V, 60Hz

Cat #C2000SERVICEPARTS

Cat #CT8SERVICEPARTS

$2800.00

$6300.00

Price may vary depending on power requirements of final destination and customer specifications. Call us at 800 624-1511 or email for a quote!

Copyright 2016 ACTION Mining Services Inc. All Rights Reserved

503 826-9330 customerservice@actionmining.com

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

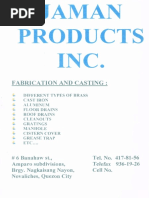

- Jaman Products Incorporated PDFДокумент37 страницJaman Products Incorporated PDFEppОценок пока нет

- Determination of The Effects of Biogenic Acidification On Concrete Antimicrobial Additives And/or Concrete ProductsДокумент13 страницDetermination of The Effects of Biogenic Acidification On Concrete Antimicrobial Additives And/or Concrete ProductsYoshi TaissonОценок пока нет

- Iso 10684Документ26 страницIso 10684Jay GaneshОценок пока нет

- Fastmarkets Risi Price Assessments All Forest MarketsДокумент287 страницFastmarkets Risi Price Assessments All Forest MarketsAkil KaziОценок пока нет

- Complete Amphetamine SyntheseДокумент14 страницComplete Amphetamine Synthesejtbrownstone100% (2)

- Def Stan 03-32 Part 4 Paint-Systems For Ferrous MetalsДокумент14 страницDef Stan 03-32 Part 4 Paint-Systems For Ferrous MetalsDeepto BanerjeeОценок пока нет

- 10 5923 J Jmea 20170704 07Документ5 страниц10 5923 J Jmea 20170704 07CK LING100% (1)

- New Brosur Beva Chainlink 2020 CompressedДокумент12 страницNew Brosur Beva Chainlink 2020 Compressedrani wulansariОценок пока нет

- MEP 15-018 - Eng - Rev PДокумент32 страницыMEP 15-018 - Eng - Rev PTAR AEROLINEASОценок пока нет

- A List of Most Common Glass Types in The Flat Glass IndustryДокумент11 страницA List of Most Common Glass Types in The Flat Glass IndustryShikha Aggarwal100% (1)

- 1 - Paper - Planta Piloto Absorcion H2S PDFДокумент7 страниц1 - Paper - Planta Piloto Absorcion H2S PDFSilas Calderon LuloОценок пока нет

- Characterization of New Cellulose Sansevieria Ehrenbergii Fibers For Polymer CompositesДокумент21 страницаCharacterization of New Cellulose Sansevieria Ehrenbergii Fibers For Polymer CompositesMartin ContardeОценок пока нет

- Fosroc Structuro W435: (Formerly Structuro RX Plus)Документ2 страницыFosroc Structuro W435: (Formerly Structuro RX Plus)Vincent JavateОценок пока нет

- Lintel Beam / Window Head Section Detail Parapet Section DetailДокумент1 страницаLintel Beam / Window Head Section Detail Parapet Section DetailDoroty CastroОценок пока нет

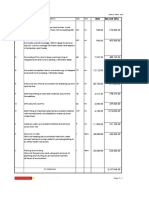

- Rate Amount (TZS) : Page 2 / 1Документ12 страницRate Amount (TZS) : Page 2 / 1SmartPave Construction Tanzania.50% (4)

- Cutting Department Work FlowДокумент3 страницыCutting Department Work FlowMandal SouvikОценок пока нет

- Electrolysis PlanДокумент7 страницElectrolysis PlanNatalia WhyteОценок пока нет

- Fleetguard Recycled Coolant: Fleetcool™ Recycled EG PremixДокумент48 страницFleetguard Recycled Coolant: Fleetcool™ Recycled EG PremixCesar G.Оценок пока нет

- Corrosion Resistance of Surface Treated 42crmo4 Steel: D. Kusmič, V. Hrubý, L. BachárováДокумент6 страницCorrosion Resistance of Surface Treated 42crmo4 Steel: D. Kusmič, V. Hrubý, L. BachárovárachidradouaniОценок пока нет

- Activity Sheet - Grade 8 PeriodicTable - Final As of April 19, 2018Документ105 страницActivity Sheet - Grade 8 PeriodicTable - Final As of April 19, 2018Daphnie Serate Nunez100% (1)

- Pouring Concrete 1floorДокумент2 страницыPouring Concrete 1floorNimas AfinaОценок пока нет

- @rin - Meow21 - Dudu The DuckДокумент7 страниц@rin - Meow21 - Dudu The DuckIsis Kuri100% (2)

- Alcohol EthoxylatesДокумент16 страницAlcohol Ethoxylatesjacky yeОценок пока нет

- Air Pollution ControlДокумент76 страницAir Pollution ControlSayyid Syafiq Syed MohamedОценок пока нет

- Carpet CleaningДокумент2 страницыCarpet CleaningmartenОценок пока нет

- 2012 Leatherman Military CatalogДокумент28 страниц2012 Leatherman Military CatalogMario LopezОценок пока нет

- Steel Grade AnaloguesДокумент8 страницSteel Grade AnaloguesandreahankОценок пока нет

- CES Selector Wrought Precipitation Hardened Stainless Steel: GeneralДокумент1 страницаCES Selector Wrought Precipitation Hardened Stainless Steel: GeneralCristhianGeovannyОценок пока нет

- European Regulations and Recommendations For Separation Between Solar Collector Fluids and Domestic WaterДокумент9 страницEuropean Regulations and Recommendations For Separation Between Solar Collector Fluids and Domestic Watermister_no34Оценок пока нет

- Hex Bonde A 9394 Structi L PDFДокумент2 страницыHex Bonde A 9394 Structi L PDFFlorian Le MaoОценок пока нет