Академический Документы

Профессиональный Документы

Культура Документы

Oil Pressure Equipment

Загружено:

Nguyễn Văn Quý0 оценок0% нашли этот документ полезным (0 голосов)

7 просмотров13 страницOil Pressure Equipment

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документOil Pressure Equipment

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

7 просмотров13 страницOil Pressure Equipment

Загружено:

Nguyễn Văn QuýOil Pressure Equipment

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 13

HYZ-1. 6-6. 3

mk RF

Aur TA THANG Kw 3b FI

OIL PRESSURE EQUIPMENT

FOR VIETNAM TA THANG POWER PLANT

Hw W +

INSTRUCTION BOOK

. S |

ERRATA EAE RBA

CHONGQING waTuR! TUR SINE WORKS CO. LTD.

CHONG QING SPEED GOVERNOR FACTORY

seat Address: ERPSRELKAH 1005

Wis Tel: 023- 62856826 (4A Fax)

Y84% Zip code: 400054

A _HYZ-1663 WIKRE He

1, BGA

YH E268 AAI DF AP EK FE, AH

FAR MAA AAA HABE, KA Ak FR A BREAK TT

FBI SSA i FEL Jy EUR Hh 7 38) as

SEAM RE AL ASK, BITES AE ATR Jy MES Ae ee, SE

ALAR, BRUTE.

READY 6. 3MPa, RE LRA. EMT,

Fae, FR DAR RI S88. ERE, RE

Sah, RAE. RARE. EST REA OAL

ih.

2. EBSR

C1). Mie Po=6.3MPa

(2) . FRAME V=1.6m*

(3). FLAT AA Vmax=2.16m?

C4) 5 uA Q=3L/s

(5) . pL W=30kw

(6). Hs AE Be} Q345R

CD. Dr Rta BE T=+5°C~50°C

1, General

Oil pressure equipment mainly provides pressure oil source

for many devices. At present, it is wildly used for water turbine

governor system, control system of other units, large pump station,

inlet valve and relief valve, and for others which need pressure

energy source.

The oil pressure equipment is of combined structure, which

consists of oil return tank and pressure tank. This structure is good

for layout as well as convenient for installation.

Working pressure of the equipment is 6.3 MPa. There are

main output oil pipe and stand-by oil pipe set on the equipment.

te HYZ1.663 WME He

Magnetic liquid level signal device, air safety valve, pressure

signal device, pressure control device and pressure gauge are set

on pressure tank. Working medium is compressed air and turbine

oil 46#.

2. Main parameter

(1) Rated oil pressure P,=6.3 MPa

(2) Volume of pressure tank V=1.6m*

(3) Max. volume of oil return tank Vmax=2.16 m°

(4) Output of oil pump Q=3L/s

(5) Motor power W=30kW

(6) Main material of pressure tank Q345R

(7) Medium temperature T=+5°C~50°C

Fe TE ik FES WL YO940-02 HEA ASC, [laa

Ae — RRA, (LA A Te a RAR BE

MEAT Jy tit, SGML i HB ae. RE, AT

FGA. Aone, TIAA (7) ieee

R (5) MNRMARA, BAP aL (4) TT

BA), WMP ARIE BERR 70 (13) 6

2h ORE Fs Be BET EAT EE — BMA — BAL R,

RAGAN, AMR, CRORE, Pieri

FAT A I AE PE. CEES TB REFER 1/3 BY

FRCP LAN 2/3 EAR MAAEAL, R aR AAD 96 A Bea a eT

JHE IR. Ay LWA Ay ARTHAS tt 11)»

FY Gawd, = (14) RA, ATURE UMMA Ho 5 URE

LAUT (10) tH, BIA aA, Tel Zeta ERY (9)

SIP MANS, MANE (6) MIB ARAG MK, AA

BARRAKAK Hie, WE SH

Ay RELA A NTP, Be Tie See, lA

PY YATE ict en BRI, CEA Be fee 3 Rey HA a A a

®UER GD).

se HYZ16-63 WIRE te

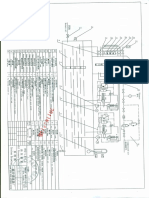

3, See work principle of oil equipment in Drawing Y0440B-02 Oil

Pressure Device System Drawing. Two screw pumps are set on oil

return tank. After it filtered by filter mesh, oil in return tank flows

into pressure tank via screw pump and stop valve, and then to oil-

using equipment via main output pipes. So a closed oil circuit

comes into being. Detailed working procedure is :clear oil in oil

return tank (7) are sucked into oil sucking pipe of screw pump(5),

motor(4) drives screw pump by coupling joint, oil is sucked into

stop valve by screw pump and then enters into pressure tank(13).

Two oil pumps are set for reliability, one for work and another

for standby. Two pumps should be periodically exchanged, and

two pumps can work synchronously within short time for special

conditions. In normal conditions, 1/3 turbine oil and 2/3

compressed air are filled in pressure tank. Supply and relieve of

compressed air shall to be done by no-return valve. In order to

directly indicate oil level in pressure tank, magnetic liquid level

annouciator (11) is set; (14) is pressure gauge used to observe

pressure in pressure tank. Oil source is output by stop valve (10),

to any oil-using position, and return oil returns to dirt oil area of oil

return tank by stop valve (9), and after it filtered by filter mesh (6),

it enters into clean oil area, and then sucked by screw pump

sending to pressure tank. Such moves are in cycles.

Oil level signal device is set to reflect oil level in oil return

tank, and it will send out signal if oil level exceeds the max. or min.

level. Still stop valve (1) is set for draining oil in oil return tank.

4, ERA

4.1, FRASER

AS fa AE eb BFE £8 00 Pb BA TG BET Sk PTTL, SORA

Jy L6MnR, HHP’ ARI ALAR, TLE BLE it

te _HYZ-1.6-63 WHORE

4.2.

4.3,

4.4,

4,

4.1

4.2

HALA RR ARTEL. CALIENTE TK

E

Tel yh Bee

ATTEN EF ARSE AE Jes AI A, A

ABT Th AT, PITT

Vlg AS Eat FF EER, ECB de Hock al se CE

J item L

BAR

Ach RS BS RAT HE, ELGG DA, eR

TB), SRE TE, WTA RAZ ME BRT

RN TARR, VES, PE, Aefirtk, fesse]

aah.

AAT

ALA ee, SRT. WR, EE. eh

BAS HD EE OTE FR 77 WE PJ RPE SOFA A,B LEHR

SR AMEE, SUR DRL ICYMEIN, 2242 A ahaT IT HE

WH, BURDAR ES, BARRA URUE, MBER, Fore

So SAUARARD A FAL RE 0h 2k JE FL LE

MATA SIRE PE, HOIST A RHEE, LAS)

SUES, A, HTML, POR AMI, 4

WAGASEW MW, Fyfe Sabante, mae Cea, wk

FUSE, ETE METAL TRE. SSL RR ta,

WER PIEM CER Ja, STE, FPR, (ERD

(i 09 Th 8 TE A A.

RALUNITE A EID 6. 43Mpa, 42 FF HR II 7. 31Mpa.

Structure

Pressure tank assembly

Pressure tank is formed by welding cylindrical barrel and

ellipse seal head, its material is 16MnR. Because it is the

vessel withstanding pressure, it has good welding quality and

has done pressure water test and flaws examination. It is fixed

on floor by foundation ring.

Return oil tank assembly

He_HYZ1.6-63 HRI He

Quadrate return oil tank is collection places of return oil after

oil-using system works, as well as oil source of oil-using

system clean oil. It is formed by steel plate welding.

Return tank upper cover is welded as a rigid frame by channel

steel, so it can be set directly or fixed on the floor of

powerhouse.

4.3 Screw pump

The device adopts vertical screw pump, compare with

horizontal type, the structure is simpler, and plane installation

area is smaller, more convenient for inspection, leakage oil in

pump body. Screw pump is with high efficiency, even

discharge and long life for use, and woks steadily and can

start instantaneously.

4. 4 Combined valve

Combined valve has the function of safety valve, unload

valve, no-return valve, by-pass valve. Safety valve can

guarantee pressure in pressure tank within allowable ranges.

When pressure is over allowable range, safety valve auto-

open to drain oil to prevent pressure rising. This is

mechanical-hydraulic device with spring reset and non-

electrical contact signal. Unload valve opens to drain whole oil

when oil pump start-up and motor speed can not meet rated

speed yet. After motor speed meets rated speed, unload valve

closed and open no-return valve to send oil to pressure tank;

Pressure signal device acts, oil pump stops rotating and no-

return valve is closed to prevent oil in pressure tank from

returning when oil pressure is normal. By-pass valve is also

protects pressure tank. When oil pressure is higher than

normal working pressure, by-pass valve opens to drain oil to

make oil pressure in pressure tank down to normal close.

Safety valve opening pressure: 6.43MPa, full opening

te HYZ-16-63 HRT se

pressure: 7.31MPa.

5. SS

WPA ARE TAT ERE PE TH Bee BT, HCH KP

SAEUETT ICU RRMNAT ANIA, YR ea HS TAT PE Bi FE ae

AF, FEF 46 SCHL, FASO EAC. ERT A

HEARD A, ABEND EE Wh BARS TE

5.1, SRE INR

CL) . RAPES PLR, FPR), BER

HANG, Whe RMA.

(2) . EPR SDI, SEER, AE ALE

PBR ARR.

5.2, SNR — Ua)

(2). EAA LY CHU-46) ARCBLIS FERRAT ARB

FAS 7 Wi 19 BA Ae BAT FF

(2). FABSUGAR, BOAO HERE TT,

ARF AGES BL Fe aE 9 i Ba 2

0. SMpa WF, FFF hd tal Er Fs Jy EO 2 LE MAL. ZE

EINTRAG LA, FAT HR

Bo PAT IPE AGUIAR, FETA Jy EE RHEE 0. TMpa,

HEATED, PR eT Be TO EE

SWART. KALA, BAAR, AGAR TT

Fic RAIMA HRSA IK, FAIR IME EBLE)»

TFs Ja ARS AGRE, NTL HE eh ae LE AE TS

WFR

5 Installation and Adjustment

Before installing all spare parts of oil pressure device at site ,

do dismantling them according to related drawing. First clean them

by kerosene, then blowdry all pipelines by compressed air, and

then lubricate by 46# turbine oil, and assembly according to

requirements in drawings. While cleaning, only use silk or gauze,

cotton yarn and hair sheding goods are forbidded.

se HYZ-1.663 HMR He

5.1 Installation notices

(1) After screw pump is connected with motor by coupling, turn it

by hand, and it should rotate flexibly without block.

(2) Connection of screw pump and oil sucking pipe should be

close with well seal, any air suction is forbidded.

5.2 The first start-up after installation

(1 ) Fill oil return tank with enough (HU - 46) turbine oil; Open al

| valves from screw pump to pressure tank.

(2) Start-up screw pump in spot-move way, inspect rotation

direction of motor which should be the same as direction of arrow

on the screw pump. Start-up oil pump to supply oil for pressure oil

tank to 0.5MPa oil pressure, then control oil pump by hand to

supply oil for pressure oil tank to rated oil level. During the period,

observe oil pump totation. And then open air non-return valve, fill

pressure tank with compressed air to 0.7Mpa,close all stop valves,

ckeck oil pipeline and connection seal of each element, air

leakage and oil leakage are not allowed. If find problems, solve

them immediately and do not rise pressure. Only when system is

normal,continue to rise pressure until pressure of oil pressure tank

rises to rated pressure.

The compressed air supplied to pressure tank should be dry

air seperated by air filter.

6, MAREE SES

6.1. FAY HJSEEE Ay GB-11120 *P 46 SYHCHLI, MIE EA 10°C ~

50°C

6.25 HARE ERS AGET PJ BET BE A a THB

FETE a.

6. 35. Psa AAP He ah FY we TA RE.

se HYZ-1.6-63 HAE He

6 Maintenance of the oil pressure device

6.1 Oil quanlity meets No. 46 turbine oil of GB - 11120, oil

temerature scope is within 10°C ~50°C

6.2 After oil pressure device first put into operation for one

month, it ought to use new clean oil or filter used oil before

use it again.

6.3 Oil filter mesh in oil return tank ought to be periodically

cleaned or changed.

10-0604

ad unss01d 110

x03 Surmesq Buy] TP1SUL

KNB IRE BE

wenn ARE

saeeeea aa

eave

‘1qBL UOI}Sog 0915130

[iowa wee vais aa ane]

eRe VT | SUTHeIa woasss

wee

[oo porsen aamsoag Th

HRW

69-9 I-24

380024 BE Xo

a ey a

oi

Joc: sea

Contactor | 5

Insulation electricity-resistance inspection

SBMA, 2000vDY, >20K0,

QED BS XYK-IB atso11 pao

(ve)

7

* i

a

ie

a

™

Ry

«

Re ,

oF Tey

= zl

El om eaae

Вам также может понравиться

- Dien Tu Cong Suat - Ebookbkmt - Removed PDFДокумент498 страницDien Tu Cong Suat - Ebookbkmt - Removed PDFNguyễn Văn QuýОценок пока нет

- YK-103 Oil Pump Control Assembly Drawing PDFДокумент12 страницYK-103 Oil Pump Control Assembly Drawing PDFNguyễn Văn QuýОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Pack 1Документ1 страницаPack 1Nguyễn Văn QuýОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- PackДокумент1 страницаPackNguyễn Văn QuýОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- YK-103 Oil Pump Control Assembly Drawing PDFДокумент12 страницYK-103 Oil Pump Control Assembly Drawing PDFNguyễn Văn QuýОценок пока нет

- D4251SS水轮机使用说明书Документ29 страницD4251SS水轮机使用说明书Nguyễn Văn QuýОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- He Thong Dieu Khien SCADA Trong He Thong Dien - Removed PDFДокумент142 страницыHe Thong Dieu Khien SCADA Trong He Thong Dien - Removed PDFNguyễn Văn QuýОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Sua Chua Quan Lai Dong Co Dien - Password - Removed PDFДокумент202 страницыSua Chua Quan Lai Dong Co Dien - Password - Removed PDFNguyễn Văn QuýОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- He Thong Dieu Khien SCADA Trong He Thong Dien - Removed PDFДокумент142 страницыHe Thong Dieu Khien SCADA Trong He Thong Dien - Removed PDFNguyễn Văn QuýОценок пока нет

- 1250KN Load Test Hydro Cylinder PDFДокумент12 страниц1250KN Load Test Hydro Cylinder PDFNguyễn Văn QuýОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- 2CY Type Gear Oil Pump Operation Instruction PDFДокумент7 страниц2CY Type Gear Oil Pump Operation Instruction PDFNguyễn Văn QuýОценок пока нет

- XWD Series Intelligent Itinerant Inspection Meter PDFДокумент13 страницXWD Series Intelligent Itinerant Inspection Meter PDFNguyễn Văn QuýОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- ZCT-ZCX Series Shaft Current Monitoring Device PDFДокумент5 страницZCT-ZCX Series Shaft Current Monitoring Device PDFNguyễn Văn QuýОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- XWT-122C Intelligent Digital Tempurature Regulating Instrument PDFДокумент12 страницXWT-122C Intelligent Digital Tempurature Regulating Instrument PDFNguyễn Văn QuýОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- ZXZ Series Speed Measure and Control Meter PDFДокумент9 страницZXZ Series Speed Measure and Control Meter PDFNguyễn Văn QuýОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- ZJCQ Type Turbine Oil Purifier Operation Instruction PDFДокумент15 страницZJCQ Type Turbine Oil Purifier Operation Instruction PDFNguyễn Văn QuýОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- MDM3051 Series Smart TransmittersДокумент29 страницMDM3051 Series Smart TransmittersNguyễn Văn QuýОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- DDF - Type Electric Buffterfly Valve PDFДокумент8 страницDDF - Type Electric Buffterfly Valve PDFNguyễn Văn QuýОценок пока нет

- ExDrawing PDFДокумент53 страницыExDrawing PDFNguyễn Văn QuýОценок пока нет

- Oil Pressure EquipmentДокумент13 страницOil Pressure EquipmentNguyễn Văn QuýОценок пока нет

- Stage Suction Piping Centrifuge Pump PDFДокумент15 страницStage Suction Piping Centrifuge Pump PDFNguyễn Văn QuýОценок пока нет

- Turck Follow Sensors PDFДокумент4 страницыTurck Follow Sensors PDFNguyễn Văn QuýОценок пока нет

- The Principle and User Manual For CVT-XX Digital Hydraulic Turbine Governor PDFДокумент71 страницаThe Principle and User Manual For CVT-XX Digital Hydraulic Turbine Governor PDFNguyễn Văn QuýОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Instruction For Installaion and Application PumpДокумент24 страницыInstruction For Installaion and Application PumpNguyễn Văn QuýОценок пока нет

- Installation & Operation Instructions Fo 100kv Power Transformer PDFДокумент28 страницInstallation & Operation Instructions Fo 100kv Power Transformer PDFNguyễn Văn QuýОценок пока нет

- Installation & Operation Instructions For Dry-Type Transformer PDFДокумент9 страницInstallation & Operation Instructions For Dry-Type Transformer PDFNguyễn Văn QuýОценок пока нет

- Indoor Hight Voltage Vacuum Circuit Breaker PDFДокумент25 страницIndoor Hight Voltage Vacuum Circuit Breaker PDFNguyễn Văn QuýОценок пока нет

- HYZ Oil Pressure Tank PDFДокумент12 страницHYZ Oil Pressure Tank PDFNguyễn Văn QuýОценок пока нет

- Installation & Operation Instructions For 100kv Dry-Type Transformer PDFДокумент9 страницInstallation & Operation Instructions For 100kv Dry-Type Transformer PDFNguyễn Văn QuýОценок пока нет

- Ex Outline of Ex-Work Test PDFДокумент17 страницEx Outline of Ex-Work Test PDFNguyễn Văn QuýОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)