Академический Документы

Профессиональный Документы

Культура Документы

23 - Well Control Worksheet-Surface BOP

Загружено:

Aseem PandeyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

23 - Well Control Worksheet-Surface BOP

Загружено:

Aseem PandeyАвторское право:

Доступные форматы

Name of Company:

WELL CONTROL

WORK SHEET

ell Name & Number:

Microsoft Excel 97 Date: November 6, 2016

WELL GEOMETRY

WAIT

WAIT &

& WEIGHT

WEIGHT Method

Method -- Surface

Surface

BOP

BOP Stack

Stack

SEC 1

SEC 2

SEC 3

SEC 4

SEC 5

SEC 6

SEC 7

Length, ft? =

Hole Size, in? =

Pipe OD, in? =

Pipe ID, in? =

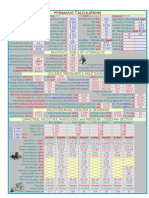

PRE-KICK INFORMATION

MUD PUMP

Present or Old Mud Weight, ppg? =

TVD of Integrity Test @ Last Shoe, ft? =

Integrity Test @ Last Shoe, ppg? =

Slow Rate Pump Pressure? =

Slow Pump Rate, spm? =

Volume in Active Mud Pits, bbls? =

KICK INFORMATION

TVD of Well, ft? =

Stabilized Shut-in Drill Pipe Pressure? =

Stabilized Shut-in Casing Pressure? =

Pit Gain, bbls? =

CALCULATE A TVD

Liner Size, in? =

Stroke Length, in? =

Rod Size, in? =

0

Efficiency (1-100)? =

Triplex, bbl/stk

0.0000

NOTES

Angle Last Survey? =

MD Last Survey? =

TVD Last Survey? =

MD for New TVD? =

TVD Result, ft

1. Enter Well Geometry from the bottom of the hole starting in SEC 1.

2. The mud pump defaults to a Duplex when the rod size greater than

zero.

3. The result in cell J27 is the TVD to spot a mud weight equal to the last

Integrity Test @ Shoe to generate a BHP equal to a hole full of KWM.

4. A red triangle in upper right hand corner of cell is a comment for the

user.

Move cursor over cell for viewing.

KILL RESULTS

New Mud Weight Required for Kill,

Initial Circulating Drill Pipe Pressur

Final Circulating Drill Pipe Pressure

Surface to Bit, stks

Surface to Surface, stks

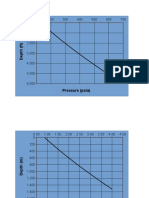

Drill Pipe Pressure

Schedule

0.00

0

0

0

0

0.00

Mud Weight For a 100 psi Trip Margin, ppg

#DIV/0!

Estimated Length of Kick Material, ft

#DIV/0!

Estimated Density of Kick Material, ppg

Maximum Allowable Casing Pressure, psi

0

Minimum Depth to Run Drill Pipe For a Kill Off-Bo

0

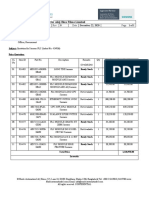

SUMMARY OFDRILL

RESULTS

PIPEFOR

SUMMARY

DRILL PIPE SECTION

Strokes

0

0

Pressure

0

0

Minutes

#DIV/0!

#DIV/0!

Capacity, bbls

Displacement, bbls

Surface to Bit, strokes

0

0

0

0

0

0

0

0

0

0

0

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

Measured Depth or Length of Drill String, ft

Capacity, bbls

Bit to Surface, strokes

0

0

0

0

0

0

0

0

0

0

0

0

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

Bit to Surface, minutes

Density of Kick < 6 ppg = Gas Present

SUMMARY OF RESULTS FOR ANNULUS SECTION

BARITE REQUIREMENTS

Barite Required to Weight-Up 100 Barrels of Mud, sacks

Barite Required To Weight-Up System, sacks

Mud Volume Increase Due To Weighting-Up, bbls

Minimum Mixing Rate, sacks/min

0

0

0

0.00

DRILL PIPE RESULTS BY SECTION

SEC 1

SEC 2

SEC 3

SEC 4

SEC 5

SEC 6

SEC 7

ANNULUS RESULTS BY SECTION

SEC 1

SEC 2

SEC 3

SEC 4

SEC 5

SEC 6

SEC 7

Barrels

Strokes

Displacement, bbl

Barrels

Strokes

Annular Velocity, fpm

0.0

0

0.0

0.0

0

0

0.0

0

0.0

0.0

0

0

0.0

0

0.0

0.0

0

0

0.0

0

0.0

0.0

0

0

0.0

0

0.0

0.0

0

0

0.0

0

0.0

0.0

0

0

0.0

0

0.0

0.0

0

0

A. The Rule of Thumb to determine a kill rate is to consider an average annular velocity of 40 to 50 fpm around the drill collars.

B. The Minimum Mixing Rate result is based on the Slow Pump Rate.

A GENERAL WELL KILL PROCEDURE

1. Increase mud weight in active pits to KILL WEIGHT.

2. Zero stroke counters. Start pump and simultaneously open choke. Pressure on the choke initially should be the

shut-in casing pressure and this pressure should be maintained while the pump rate is brought up to the kill rate.

3. HOLD PUMP RATE CONSTANT and adjust choke so that the drill pipe pressure follows the calculated schedule.

If drill pipe pressure is too high, open the choke slightly; if it is too low, close choke slightly. Takes approximately

one second per thousand feet of hole to see a response at gauge when the choke setting is altered.

4. After the Kill Mud has filled the drill pipe, MAINTAIN CONSTANT PUMP RATE and CONSTANT DRILL PIPE

PRESSURE until the annulus is filled with the kill mud.

5. When kill weight mud reaches surface, stop the pump and shut well in. At this time, the casing pressure and drill pipe

pressure should be zero. If some pressure still exist on casing, open choke slightly and bleed a small amount or

volume of mud. If the well is dead, pressure should fall to zero and there should be no flow from well.

Reference: LSU Blowout Control School Manual, LSU - Baton Rouge, La.

THE END

Вам также может понравиться

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Документ2 страницыWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviОценок пока нет

- MACP and Well Control RecordДокумент6 страницMACP and Well Control RecordSudish BhatОценок пока нет

- Stimulation 4Документ27 страницStimulation 4DVScherbakovОценок пока нет

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Документ2 страницыWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviОценок пока нет

- 30 - WELL CONTROL DATA SHEET For DRILLER'S METHODДокумент2 страницы30 - WELL CONTROL DATA SHEET For DRILLER'S METHODAseem PandeyОценок пока нет

- 13 - Spot Heavy MudДокумент1 страница13 - Spot Heavy MudAseem PandeyОценок пока нет

- Well Control Preparation Class Final-Test: Name: Badge: DateДокумент16 страницWell Control Preparation Class Final-Test: Name: Badge: DateBoedi SyafiqОценок пока нет

- Basics of Well ControlДокумент45 страницBasics of Well ControlRocard NgomaОценок пока нет

- Well Control EquationsДокумент13 страницWell Control EquationsShaho Abdulqader Mohamedali100% (1)

- Spot Heavy MudДокумент1 страницаSpot Heavy MudstevebeardsleyОценок пока нет

- Filling The HoleДокумент1 страницаFilling The HolestevebeardsleyОценок пока нет

- 19 - Drill String DesignДокумент1 страница19 - Drill String DesignAseem PandeyОценок пока нет

- Tut-126 ProgramДокумент28 страницTut-126 Programhamdi1000Оценок пока нет

- Casing & Cementing ConventionalДокумент1 страницаCasing & Cementing ConventionalDeepak TandonОценок пока нет

- Wellbore Skematic DrawingsДокумент75 страницWellbore Skematic DrawingsJoy GОценок пока нет

- Subsea AccumulatorsДокумент4 страницыSubsea AccumulatorsAbdul Hameed OmarОценок пока нет

- Drilling Calculation SheetДокумент5 страницDrilling Calculation SheetDewy CoxОценок пока нет

- KILLSHTДокумент3 страницыKILLSHTscrbdgharaviОценок пока нет

- 20 - Filling The HoleДокумент1 страница20 - Filling The HoleAseem PandeyОценок пока нет

- Round Trip Ton-Miles CalculationДокумент2 страницыRound Trip Ton-Miles CalculationKenaouia BahaaОценок пока нет

- Surface BOP Stack Operations API - Deviated Well Kill SheetДокумент0 страницSurface BOP Stack Operations API - Deviated Well Kill Sheetjosesito_amoroso2005Оценок пока нет

- IWCF Surface BOP: Kill SheetДокумент6 страницIWCF Surface BOP: Kill SheetMrSebollini0% (1)

- Exercise 1Документ16 страницExercise 1adeelsnОценок пока нет

- Well Control Data Sheet: Vertical WellsДокумент2 страницыWell Control Data Sheet: Vertical WellsscrbdgharaviОценок пока нет

- Drilling FormulasДокумент5 страницDrilling FormulasJoshua RosensteinОценок пока нет

- Henriksen, VibekeДокумент150 страницHenriksen, VibekeHamed SadeghiОценок пока нет

- Drillstring DesignДокумент1 страницаDrillstring DesignberrouiОценок пока нет

- Drill String DesignДокумент1 страницаDrill String DesignmalikshababОценок пока нет

- Leak Off TestДокумент2 страницыLeak Off TestLuisBlandónОценок пока нет

- Microsoft Word - Exercise 1Документ27 страницMicrosoft Word - Exercise 1KRОценок пока нет

- Directional Drilling CalcuationsДокумент43 страницыDirectional Drilling CalcuationsNourden Al100% (1)

- Assortment of Mini ApplicationsДокумент1 страницаAssortment of Mini ApplicationsAbdul Hameed OmarОценок пока нет

- Tech/drilling/Casing Design ExДокумент43 страницыTech/drilling/Casing Design ExSohaib RashidОценок пока нет

- Kill Sheet: Prerecorded Infromation Pump Strokes RequiredДокумент16 страницKill Sheet: Prerecorded Infromation Pump Strokes RequiredAbdul Hameed OmarОценок пока нет

- 19 Well ControlДокумент133 страницы19 Well ControlAvazdordi SadriОценок пока нет

- Surface Kill Sheet Exercise 2Документ3 страницыSurface Kill Sheet Exercise 2adeelsnОценок пока нет

- Drilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Документ1 страницаDrilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Abdul Hameed OmarОценок пока нет

- I WCF Formula SheetДокумент4 страницыI WCF Formula Sheethamdi1000Оценок пока нет

- Maximum Overpull Worksheet: Well:Grenadier EDC - 90Документ1 страницаMaximum Overpull Worksheet: Well:Grenadier EDC - 90islam atifОценок пока нет

- Microsoft Word - Exercise 3 Subsea P&PДокумент5 страницMicrosoft Word - Exercise 3 Subsea P&PKRОценок пока нет

- Bha & Drill ColarsДокумент6 страницBha & Drill Colarswasim78622Оценок пока нет

- Principles and Procedures: Rev.3 - November 2003Документ144 страницыPrinciples and Procedures: Rev.3 - November 2003Ibnu Rusdi SolomammaОценок пока нет

- Direcional Kill Sheet Blank FormДокумент6 страницDirecional Kill Sheet Blank FormClernard FerreiraОценок пока нет

- Hydraulics AnalyzedДокумент1 страницаHydraulics AnalyzedstevebeardsleyОценок пока нет

- Well Control Workbook For LinersДокумент23 страницыWell Control Workbook For Linerszerocool2kОценок пока нет

- (Training Documents) Strokes Bit To SurfaceДокумент2 страницы(Training Documents) Strokes Bit To SurfaceHeris SitompulОценок пока нет

- Kill Sheet Calculation Formulas Pressure & Gradient FormulasДокумент2 страницыKill Sheet Calculation Formulas Pressure & Gradient FormulasLucas NunesОценок пока нет

- Kill Sheet IWCFДокумент2 страницыKill Sheet IWCFMaria FernandaОценок пока нет

- (Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesДокумент7 страниц(Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesSasan AbbasiОценок пока нет

- Well Control Kill Sheet (Low Angle Wells) : (BBLS) Drillstring Volume Annular Volume (BBLS)Документ2 страницыWell Control Kill Sheet (Low Angle Wells) : (BBLS) Drillstring Volume Annular Volume (BBLS)scrbdgharaviОценок пока нет

- 12 Casing Running Speed - QuartzДокумент1 страница12 Casing Running Speed - QuartzRebarОценок пока нет

- Cameron Drilling Products Overview CatalogДокумент587 страницCameron Drilling Products Overview CatalogJayro LeninОценок пока нет

- SDU Ver142beta1 - Demo Print 1 PDFДокумент12 страницSDU Ver142beta1 - Demo Print 1 PDFreza khОценок пока нет

- Gas Lift Valve SpacingДокумент23 страницыGas Lift Valve SpacingLuis Carlos SaavedraОценок пока нет

- PETE 661: Drilling EngineeringДокумент50 страницPETE 661: Drilling Engineeringcmrig74Оценок пока нет

- Volumetric MethodДокумент1 страницаVolumetric MethodscrbdgharaviОценок пока нет

- Drill EssДокумент95 страницDrill EssandrewОценок пока нет

- EXTENDED Well Control ChecklistДокумент14 страницEXTENDED Well Control ChecklistAdam InesОценок пока нет

- Well Control PresentationДокумент57 страницWell Control PresentationmissaouiОценок пока нет

- 35 - Casing CementingДокумент8 страниц35 - Casing CementingAseem PandeyОценок пока нет

- 40 - Squeeze Cementing JobДокумент1 страница40 - Squeeze Cementing JobAseem PandeyОценок пока нет

- 28 - Kill Sheet1Документ2 страницы28 - Kill Sheet1Aseem PandeyОценок пока нет

- 31 - WELL CONTROL DATA SHEET For VERTICAL WELLS Wt. & Wt. METHODДокумент2 страницы31 - WELL CONTROL DATA SHEET For VERTICAL WELLS Wt. & Wt. METHODAseem PandeyОценок пока нет

- 33 - Well ControlДокумент46 страниц33 - Well ControlAseem PandeyОценок пока нет

- 29 - WELL CONTROL DATA SHEET For DIRECTIONAL WELLS Wt. & Wt. METHODДокумент2 страницы29 - WELL CONTROL DATA SHEET For DIRECTIONAL WELLS Wt. & Wt. METHODAseem PandeyОценок пока нет

- 21 - Volumetric MethodДокумент1 страница21 - Volumetric MethodAseem PandeyОценок пока нет

- Basic Mud Reportv1.5Документ21 страницаBasic Mud Reportv1.5Anonymous MxwCc4Оценок пока нет

- 18 - Critical Rotary SpeedДокумент1 страница18 - Critical Rotary SpeedAseem PandeyОценок пока нет

- Well Control Kill Sheet (Low Angle Wells) : Drillstring Volume Annular Volume (BBLS) (BBLS)Документ2 страницыWell Control Kill Sheet (Low Angle Wells) : Drillstring Volume Annular Volume (BBLS) (BBLS)Samad Ali SiddiquiОценок пока нет

- 19 - Drill String DesignДокумент1 страница19 - Drill String DesignAseem PandeyОценок пока нет

- 17 - Maximum Casing Pressure and Pit GainДокумент1 страница17 - Maximum Casing Pressure and Pit GainAseem PandeyОценок пока нет

- 14 - Mud Motors, Jets & SurveysДокумент1 страница14 - Mud Motors, Jets & SurveysAseem PandeyОценок пока нет

- 13 - Spot Heavy MudДокумент1 страница13 - Spot Heavy MudAseem PandeyОценок пока нет

- 20 - Filling The HoleДокумент1 страница20 - Filling The HoleAseem PandeyОценок пока нет

- 02 Drilling CalculationДокумент53 страницы02 Drilling CalculationMohammad Kamal Habbaba100% (2)

- 15 - Floating CasingДокумент1 страница15 - Floating CasingAseem PandeyОценок пока нет

- 05 - SRB Hydraulic ProgramsДокумент22 страницы05 - SRB Hydraulic ProgramsAseem PandeyОценок пока нет

- 16 - Lubricate and Bleed ProcedureДокумент1 страница16 - Lubricate and Bleed ProcedureAseem PandeyОценок пока нет

- 10 - Simple Mud Engineerv1.22Документ22 страницы10 - Simple Mud Engineerv1.22Aseem PandeyОценок пока нет

- 07 - Nowsco Calculation SheetsДокумент26 страниц07 - Nowsco Calculation SheetsAseem PandeyОценок пока нет

- Hydraulics CalculationДокумент1 страницаHydraulics CalculationSudish BhatОценок пока нет

- 03 - Assortment of Mini ApplicationsДокумент1 страница03 - Assortment of Mini ApplicationsAseem PandeyОценок пока нет

- 01 - General FormulaeДокумент10 страниц01 - General FormulaescrbdgharaviОценок пока нет

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Документ2 страницыLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulОценок пока нет

- SDS ERSA Rev 0Документ156 страницSDS ERSA Rev 0EdgarVelosoCastroОценок пока нет

- Structural Design Basis ReportДокумент31 страницаStructural Design Basis ReportRajaram100% (1)

- Manhole Head LossesДокумент11 страницManhole Head Lossesjoseph_mscОценок пока нет

- MATM1534 Main Exam 2022 PDFДокумент7 страницMATM1534 Main Exam 2022 PDFGiftОценок пока нет

- WWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeДокумент8 страницWWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeDestiny EasonОценок пока нет

- Service Quality Dimensions of A Philippine State UДокумент10 страницService Quality Dimensions of A Philippine State UVilma SottoОценок пока нет

- CIPD L5 EML LOL Wk3 v1.1Документ19 страницCIPD L5 EML LOL Wk3 v1.1JulianОценок пока нет

- JUnit 5 User GuideДокумент90 страницJUnit 5 User GuideaawaakОценок пока нет

- Work Energy Power SlidesДокумент36 страницWork Energy Power Slidessweehian844100% (1)

- RSW - F - 01 " ": Building UtilitiesДокумент4 страницыRSW - F - 01 " ": Building Utilities62296bucoОценок пока нет

- Scrum Exam SampleДокумент8 страницScrum Exam SampleUdhayaОценок пока нет

- Title: Smart Monitoring & Control of Electrical Distribution System Using IOTДокумент27 страницTitle: Smart Monitoring & Control of Electrical Distribution System Using IOTwaleed HaroonОценок пока нет

- SSC Gr8 Biotech Q4 Module 1 WK 1 - v.01-CC-released-09May2021Документ22 страницыSSC Gr8 Biotech Q4 Module 1 WK 1 - v.01-CC-released-09May2021Ivy JeanneОценок пока нет

- .CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADOДокумент782 страницы.CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADOMarcelo JesusОценок пока нет

- CPD - SampleДокумент3 страницыCPD - SampleLe Anh DungОценок пока нет

- ChatGPT & EducationДокумент47 страницChatGPT & EducationAn Lê Trường88% (8)

- Importance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesДокумент61 страницаImportance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesjrtnОценок пока нет

- MLX90614Документ44 страницыMLX90614ehsan1985Оценок пока нет

- Control ValvesДокумент95 страницControl ValvesHardik Acharya100% (1)

- "Organized Crime" and "Organized Crime": Indeterminate Problems of Definition. Hagan Frank E.Документ12 страниц"Organized Crime" and "Organized Crime": Indeterminate Problems of Definition. Hagan Frank E.Gaston AvilaОценок пока нет

- Configuration Guide - Interface Management (V300R007C00 - 02)Документ117 страницConfiguration Guide - Interface Management (V300R007C00 - 02)Dikdik PribadiОценок пока нет

- Đề Tuyển Sinh Lớp 10 Môn Tiếng AnhДокумент11 страницĐề Tuyển Sinh Lớp 10 Môn Tiếng AnhTrangОценок пока нет

- Rsi r2 Super Rsi FaqДокумент14 страницRsi r2 Super Rsi FaqChandrasekar Chandramohan100% (1)

- BSS Troubleshooting Manual PDFДокумент220 страницBSS Troubleshooting Manual PDFleonardomarinОценок пока нет

- EPW, Vol.58, Issue No.44, 04 Nov 2023Документ66 страницEPW, Vol.58, Issue No.44, 04 Nov 2023akashupscmadeeaseОценок пока нет

- CE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationДокумент32 страницыCE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationPROSPEROUS LUCKILYОценок пока нет

- Viscar Industrial Capacity LTD Company ProfileДокумент36 страницViscar Industrial Capacity LTD Company ProfileTechnician MwangiОценок пока нет

- Digital Systems Project: IITB CPUДокумент7 страницDigital Systems Project: IITB CPUAnoushka DeyОценок пока нет

- Technical Sheet Racloflex NTДокумент2 страницыTechnical Sheet Racloflex NTAnthony AngОценок пока нет