Академический Документы

Профессиональный Документы

Культура Документы

Gruppe 040 en

Загружено:

Marco MaximilianoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Gruppe 040 en

Загружено:

Marco MaximilianoАвторское право:

Доступные форматы

Service Manual

SUBGROUP - INDEX

Group

Type

SCR system

040.025.1

R 966 - R 980

Coupling

040.030.1

R 956 - R 980

MKA pump distributor gear

040.045.1

R 956 - R 960

R 966 - R 980

LFR/en/Edition: 09/2014

Section

040.000.1

MJFCIFSS

LFR/en/Edition: 09/2014

Service Manual

040.000.2

MJFCIFSS

Service Manual

SCR system

Design

SCR system

1

Design

The SCR system (Selective Catalytic Reduction) reduces the nitrogen oxides (NOx) content in the

exhaust gases.

LFR/en/Edition: 07/2014

2.1

Function

General diagram and components list

Fig. 1

General diagram - coolant and diesel exhaust fluid

040.025.1

copyright by

MJFCIFSS

SCR system

Service Manual

Function

----

Diesel exhaust fluid system (hoses with ____

heating resistance)

Coolant system

A770

Diesel exhaust fluid pump

Y770

Circulation solenoid valve

A772

Level and temperature sensor

Y771

Injector

Fig. 2

General diagram of the exhaust system

----

Diesel exhaust fluid system (hoses with ____

heating resistance)

Coolant system

A770

Diesel exhaust fluid pump

B773

Outside temperature sensor

A772

Level and temperature sensor

D9508 Engine

B726

NOx-sensor / inlet

Y770

Circulation solenoid valve

B727

NOx-sensor / outlet

Y771

Injector

LFR/en/Edition: 07/2014

Hydrolysis: diesel exhaust fluid injected in exhaust gases forms ammonia (NH3) and carbon

dioxide (CO2).

Ammonia synthesis: when ammonia reacts with nitrogen oxides (NOx), it becomes nitrogen (N2)

and water (H2O).

040.025.2

copyright by

MJFCIFSS

Service Manual

SCR system

Function

2.2

Arrangement of the components

Fig. 3

2.3

Arrangement of the components

Description of the components

UDL control unit and diesel exhaust fluid pump A770

The UDL control unit monitors the following temperatures: diesel exhaust fluid in the tank, coolant

and outside temperature. It controls the solenoid valve Y771.

Diesel exhaust fluid hoses with heating resistance

The resistances of the hoses are the following:

from the pump to the injector = about 7,2

from the tank to the pump = about 42

LFR/en/Edition: 07/2014

NOx-sensors

B726 is at the inlet of the SCR system. It measures the NOx at the engine outlet and determinates

the diesel exhaust fluid content.

B727 is at the outlet of the SCR system. It measures the NOx content at the exhaust outlet and

checks the efficiency of the reaction in the system.

Circulation solenoid valve Y770

The solenoid valve is active in the following cases:

diesel exhaust fluid temperature is under -10C

outside temperature is under 5C

040.025.3

copyright by

MJFCIFSS

SCR system

Service Manual

Maintenance

The solenoid valve is inactive in the following cases:

pump temperature is over 55C

diesel exhaust fluid temperature is over 58C

Diesel exhaust fluid injector Y771

It injects the diesel exhaust fluid at about 8 bar.

2.4

Electrical diagram

(see 110 electrical system)

Maintenance

(see 030 Maintenance)

LFR/en/Edition: 07/2014

(see SCR system menu, in 190.600 Sculi Wizard utility)

040.025.4

copyright by

MJFCIFSS

Service Manual

Coupling

Design

Coupling

1

Design

Fig. 1

Design of the coupling

Elastic coupling

Mounting bolt

Disk

Flywheel

Hub

Intermediate housing

Riveted disks

1000 Diesel engine

Pressure spring

The elastic coupling 1 is mounted between the Diesel engine 1000 and the pump assembly.

LFR/en/Edition: 03/2014

The disk 2 is screwed to the flywheel 7 of the Diesel engine 1000. The disks 4 are riveted onto the

hub 3. The hub 3 is driven axially by the riveted disks 4. The pressure springs 5 are inserted into the

disks 2 and 4.

Function

The elastic coupling 1 compensates for misalignment of the crankshaft with the drive shaft and

dampens torque peaks in the event of load variations, imbalance or Diesel engine vibrations. It

prevents premature wearing of the flanged components.

The permanent coupling 1 transfers the torque of the Diesel engine 1000 directly and continuously

to the pump assembly.

040.030.1

R 956 - R 980

copyright by

MJFCIFSS

Coupling

Service Manual

Repair

The hub 3 can move radially to the disk 2. The pressure springs 5 ensure an elastic connection

between the disks 4 that are tightly fixed to the hub 3.

The drive shaft of the pump assembly is connected to the hub 3 and the coupling 1 through the spline

mesh.

The power from the Diesel engine 1000 is transmitted to the pump assembly through the flywheel 7,

the mounting bolts 6, the disk 2, the pressure springs 5, the disks 4 with the hub 3 and the drive shaft.

The torque peaks are dampened by the compression and release of the springs 5. The torsional

vibrations transmitted from the Diesel engine 1000 to the pump assembly are greatly reduced.

3.1

Repair

Removing the coupling

Fig. 2

Removing the coupling

Elastic coupling

Intermediate housing

Mounting bolt

1000 Diesel engine

Flywheel

2000 Pump assembly

Remove the pump assembly 2000 from the intermediate housing 8 of the Diesel engine 1000.

(see 040.045 MKA pump distributor gear)

Note the positioning of the coupling 1.

040.030.2

R 956 - R 980

copyright by

MJFCIFSS

LFR/en/Edition: 03/2014

Service Manual

Coupling

Repair

Loosen and remove the mounting bolts 6.

Remove the coupling 1 from the flywheel 7 of the Diesel engine 1000.

3.2

Installing the coupling

LFR/en/Edition: 03/2014

Fig. 3

Cross sectional drawing of a coupling

Disk

Flywheel

Hub

Intermediate housing

Riveted disks

Drive shaft

Pressure spring

1000 Diesel engine

Mounting bolt

Control measure

Machine

Control measure A (in mm)

R956 - R960 SME

about 48

R966 - R970 SME

about 47.5

R976 - R980 SME

about 47.5

Tab. 1

Control measure A for correct positioning

040.030.3

R 956 - R 980

copyright by

MJFCIFSS

Coupling

Service Manual

Repair

Caution!

Incorrect installation of the coupling!

Damage to the Diesel engine and pump assembly.

Position the coupling 1 properly on the flywheel 7, see Fig. 3.

If the control measure does not correspond to any position: contact the manufacturer.

Put the coupling 1 in position on the flywheel 7.

Insert two diametrically opposed mounting bolts 6.

Measure the distance between the intermediate housing 8 and the hub 3 and compare it with the

control measure A (see Tab. 1).

If the distance corresponds to the control measure A, the coupling 1 is properly installed.

If the distance does not correspond to the control measure A: turn the coupling 1 around and

check the control measure A again.

Insert the remaining mounting bolts 6 and tighten them with the prescribed torque.

Install the pump assembly 2000. (see 040.045 MKA pump distributor gear)

3.3

Checking concentricity and evenness

Fig. 4

Checking concentricity and evenness

Measure the concentricity E at the outer diameter of the hub 3 with a suitable measuring tool (dial

indicator) (tolerance = 0.1 mm).

LFR/en/Edition: 03/2014

Check the surface of the coupling 1 for evenness F with a suitable measuring tool (dial indicator)

(tolerance = 0.05 mm).

040.030.4

R 956 - R 980

copyright by

MJFCIFSS

Service Manual

MKA pump distributor gear

Design

MKA pump distributor gear

1

Design

Fig. 1

MKA pump distributor gear

2000 Pump distributor gear

Drive shaft

Primary output

Intermediate gear

Auxiliary output

The pump distributor gear 2000 is a spur gear unit installed between the Diesel engine and the

hydraulic pumps.

It is directly energized by the Diesel engine through a flexible coupling and transmits the power of the

Diesel engine to the hydraulic pumps.

LFR/en/Edition: 01/2014

The different gear transmission ratios to the primary outputs 2 of working pumps and to the auxiliary

output 3 of swing pump allow an accurate adaptation of the flows for the operating movements.

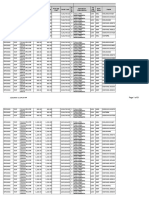

Technical data

Machine

Pump distributor gear

R 956 - R 960

R 966 - R 980

R956

type

R960

PVG 351 C 398

R966

R970

PVG 351 C 399

R976

R980

PVG 450 C 466

040.045.1

copyright by

MJFCIFSS

MKA pump distributor gear

Service Manual

Maintenance

Machine

R956

Weight of pump distributor gear

kg

R960

R966

198

Weight of working pumps

R970

250

Weight of swing pump

60

(2x) 153

28.5

46

73

93

Weight of servo control pump

3.5

type

Swing pump

Gear reduction to the working

pumps

ratio

Gear reduction to the swing

pump

R980

210

(2x) 125

Weight of fan drive pump

Working pumps

R976

LPV165

LPV250

A4VG71

A4VG90

A4VG125

0.83

0.7288

0.9285

0.6037

0.661

0.714

Maintenance

(see Maintenance and inspection schedule, in 030 Maintenance)

Repair

LFR/en/Edition: 01/2014

040.045.2

copyright by

MJFCIFSS

R 956 - R 960

R 966 - R 980

Service Manual

MKA pump distributor gear

Repair

Fig. 2

4.1

Removing and installing the pump distributor gear

Fire protection sheets

Diesel engine

Reinforcement

Diesel engines gearing

Shut-off valve

Drive shaft

Hydraulic tank

10

Pump distributor gear

Mounting bolts

11

Air line

Air filter

Removing the pump distributor gear

Remove the air filter 6 (for R956 and R960 only).

Remove the air line 11 (from R966 to R980 only).

Remove the fire protection sheets 1 and the reinforcement 2 (from R966 to R980 only).

Depressurize the hydraulic system. (See chapter 30, Working hydraulics system)

Place the hydraulic tank 4 under negative pressure with the vacuum pump.

Close the shut-off valve 3 on the hydraulic tank 4.

Place a suitable receptacle under the pump distributor gear 10.

Drain the oil out of the pump distributor gear 10. (See chapter 30, Drive group)

Drain the oil out of the suction line: remove the draining screw under the suction line (from R966

to R980 only).

Disconnect all oil lines from the pump distributor gear 10 and from the hydraulic pumps.

Disconnect all electrical connectors from the pump distributor gear 10 and from the hydraulic

pumps.

Attach the pump distributor gear 10 to a suitable slinging device and to a lifting crane.

Loosen and remove the mounting bolts 5 from the pump distributor gear 10.

Remove the pump distributor gear 10 from the Diesel engines gearing 8.

4.2

Repair

(See repair instructions PVG 450C462)

4.3

Installing the pump distributor gear

Make sure the sealing surfaces of the pump distributor gear 10 are clean and in good condition.

LFR/en/Edition: 01/2014

Apply grease on the drive shaft 9.

Move the pump distributor gear 10 closer to the Diesel engine 7 with the lifting crane.

Engage the drive shaft 9 in the Diesel engines gearing 8.

Put the mounting bolts 5 and tighten them to the approved torque.

Remove the slinging device and the lifting crane.

Connect all oil lines to the pump distributor gear 10 and to the hydraulic pumps.

Connect all electrical connectors of the pump distributor gear 10 and of the hydraulic pumps.

R 956 - R 960

R 966 - R 980

040.045.3

copyright by

MJFCIFSS

MKA pump distributor gear

Service Manual

Repair

Tighten the draining screw under the suction line (from R966 to R980 only).

Install the fire protection sheets 1 and the reinforcement 2 (from R966 to R980 only).

Install the air line 11 (from R966 to R980 only).

Install the air filter 6 (for R956 and R960 only).

Open the shut-off valve 3 on the hydraulic tank 4.

Pressurize the hydraulic tank 4 with the vacuum pump.

Bleed the air of the hydraulic pumps. (See chapter 30, Working hydraulics system)

Fill the pump distributor gear 10 with oil. (See chapter 30, Drive group)

Run the Diesel engine for some minutes.

Stop the Diesel engine.

Check the oil level in the pump distributor gear 10. (See chapter 30, Drive group)

LFR/en/Edition: 01/2014

Check the hydraulic system for leaks.

040.045.4

copyright by

MJFCIFSS

R 956 - R 960

R 966 - R 980

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- C15 Industrial Engine (SEBP3815 - 70) - Documentation PDFДокумент2 страницыC15 Industrial Engine (SEBP3815 - 70) - Documentation PDFMarco Maximiliano0% (1)

- Gruppe 150 enДокумент28 страницGruppe 150 enMarco MaximilianoОценок пока нет

- C15 Industrial Engine (SEBP3815 - 70) - DocumentationДокумент2 страницыC15 Industrial Engine (SEBP3815 - 70) - DocumentationMarco MaximilianoОценок пока нет

- Ex 01Документ4 страницыEx 01Marco MaximilianoОценок пока нет

- Comp Araci OnДокумент31 страницаComp Araci OnMarco MaximilianoОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- PolydactylyДокумент43 страницыPolydactylyWara Samsarga GedeОценок пока нет

- Sop For Enlistment of Engineering ConsultantsДокумент1 страницаSop For Enlistment of Engineering Consultantssatheb319429Оценок пока нет

- Method StatementДокумент29 страницMethod StatementZakwan Hisyam100% (1)

- Biochem Nucleic Acid ReviewerДокумент5 страницBiochem Nucleic Acid ReviewerGabrielle FranciscoОценок пока нет

- The Vapour Compression Cycle (Sample Problems)Документ3 страницыThe Vapour Compression Cycle (Sample Problems)allovid33% (3)

- BV Lesson Plan 4Документ3 страницыBV Lesson Plan 4api-252119803Оценок пока нет

- Aldehydes, Ketones, Carboxylic Acids, and EstersДокумент11 страницAldehydes, Ketones, Carboxylic Acids, and EstersNATURE COMPUTERОценок пока нет

- BQ - Electrical Calibration Relay Bld803, NPBДокумент2 страницыBQ - Electrical Calibration Relay Bld803, NPBKazuya KasumiОценок пока нет

- Maxillofacial Notes DR - Mahmoud RamadanДокумент83 страницыMaxillofacial Notes DR - Mahmoud Ramadanaziz200775% (4)

- EP500 Standard Electropneumatic Positioner: Installation and Maintenance InstructionsДокумент28 страницEP500 Standard Electropneumatic Positioner: Installation and Maintenance InstructionsAlan ValdezОценок пока нет

- Indian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementДокумент44 страницыIndian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementArijit dasguptaОценок пока нет

- 6Документ2 страницы6Min Hsuan HsianОценок пока нет

- Gender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaДокумент53 страницыGender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaADBGADОценок пока нет

- Inlet Manifold Pressure - Test: Testing and AdjustingДокумент2 страницыInlet Manifold Pressure - Test: Testing and AdjustingAbdoulaye Boua BERTHEОценок пока нет

- Unit-3.1.2-Sleeve and Cotter JointДокумент18 страницUnit-3.1.2-Sleeve and Cotter JointAsvath Guru100% (2)

- Bisleri Water Industry: Project ReportДокумент53 страницыBisleri Water Industry: Project ReportJohn CarterОценок пока нет

- Procedure FireДокумент28 страницProcedure FireRichard D DuОценок пока нет

- Feeder BrochureДокумент12 страницFeeder BrochureThupten Gedun Kelvin OngОценок пока нет

- Comprehensive Safe Hospital FrameworkДокумент12 страницComprehensive Safe Hospital FrameworkEbby OktaviaОценок пока нет

- Service Manual: Multifunction Electrical Tester CalibratorДокумент106 страницService Manual: Multifunction Electrical Tester CalibratorJuan Carlos Ferrer OrtizОценок пока нет

- Outlook 2Документ188 страницOutlook 2Mafer Garces NeuhausОценок пока нет

- 41 Assignment Worksheets For SchoolДокумент26 страниц41 Assignment Worksheets For Schoolsoinarana456Оценок пока нет

- Those With MoonДокумент1 страницаThose With MoonRosee AldamaОценок пока нет

- EXP 2 - Plug Flow Tubular ReactorДокумент18 страницEXP 2 - Plug Flow Tubular ReactorOng Jia YeeОценок пока нет

- Heat Transfer ExampleДокумент4 страницыHeat Transfer Examplekero_the_heroОценок пока нет

- Intershield803 MDSДокумент4 страницыIntershield803 MDSSahanОценок пока нет

- Registration Statement (For Single Proprietor)Документ2 страницыRegistration Statement (For Single Proprietor)Sherwin SalanayОценок пока нет

- Installing Touareg R5 CamshaftДокумент1 страницаInstalling Touareg R5 CamshaftSarunas JurciukonisОценок пока нет

- Science 9 Q4 SML17 V2Документ15 страницScience 9 Q4 SML17 V2HotdogОценок пока нет

- READING 4 UNIT 8 Crime-Nurse Jorge MonarДокумент3 страницыREADING 4 UNIT 8 Crime-Nurse Jorge MonarJORGE ALEXANDER MONAR BARRAGANОценок пока нет