Академический Документы

Профессиональный Документы

Культура Документы

2886-Stud Fitting & Removal PDF

Загружено:

syllavethyjimОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2886-Stud Fitting & Removal PDF

Загружено:

syllavethyjimАвторское право:

Доступные форматы

GEOMETER explains -

S T U D F TTING

A ND REMO VAL

at times, when space is limited., is

their only disadvantageyb compartson

with setscrews, for with studs it is

essential there is distance to present

components squarely.

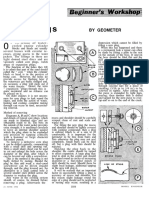

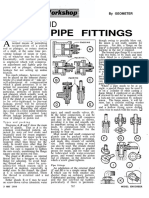

Employing a pair of nuts, A ,

locked tightly with spanners, a stud

may be fitted turning on the top one,

or removed turning on the bottom

one. On the stud being in place in

fitting, the bottom nut should be

slackened rather than the top one, to

obviate the tendency to loosening.

When studs are numerous, as on a

motor cylinder block, the tool at B

is useful. This consists of a sleeve

fitting over studs and havmg at the.

bottom an eccentrically-mounted

knurled roller feeding and gripping

automaticall

y on turning the tool with

a tommy bar. Several holes in the

roller provide for shifting its position

0

E

0

D

ASSEMBLIES

where bolts would

be impracticable, studs are an

alternative to setscrews and,

being permanently fitted, possess

advantages.

Obviously there is no wear of

threads in holes fitted with studs, nor

possibility of mistakes in assemblies

where different lengths of setscrews

would be needed-mistakes such as

the fitting of too-short setscrews with

the danger of stripped threads, or the

opposite, over-long setscrews which

bottom m the holes.

With studs, too, once they are

fitted there is no chance of foreign

matter entering their holes, as can

occur when setscrews are removed.

Studs also provide location for the

components fitted on them-which,

N

13 SEPTEMBER 1956

GUIDE

PLATE

371

as the knurling wears. The tool marks

studs on which it is used, the same as

would grips or pliers, so it is not

always advisable to use it.

A hole to take a stud should be

slightly chamfered to avoid the beginning of the thread lifting; and if

the material is light-alloy it should

not be overlooked that studs may

have different threads at opposite

ends-course threads (Whit.) to screw

into the component, fine threads

(B.S.F.) to take the nuts.

A stud tight to remove may be

lightly hammered on the end to

break adhesion from rust or corrosion,

and treated with paraffin or penetrating oil.

Broken studs

The end of a broken stud which

cannot be gripped by pliers can

sometimes be turned with a centre

punch and hammer.

Normally,

however, drilling out is necessary. If

rough and sloping, the broken end

should be filed, or levelled by chiselling,

C, then, with a centre punch, carefully

centred, D.

To begin the hole; a small drill is

advisable, changing it for another

sufficiently substantial to drill without

the risk of breakage, and enlarging on

this if the stud demands it.

An attempt atremoval may be made

using the tang of a file which has been

ground to sharpen the corners. This

is tapped into the hole, E, and a

spanner used on it. The stud remaining firm, discretion is needed not to

wring off the tang in the hole. Extreme

caution is also necessary when using

Easy-Out stud removal tools of the

type having a left-hand taper spiral

which bites into the hole.

The top component can afford a

guide when centring and drilling if a

lathe is available for drilling mildsteel holders, F, to take a silver-steel

centre punch and small drill, which

latter can be soldered in.

These

ensure that the hole is commenced

and drilled centrally, G, and afterwards,

if it has to be enlarged, there is little

chance of its moving eccentrically.

Alternatively, a guide plate,, H, can be

made to clamp from an adjacent stud.

When the threads in a stud hole are

stripped and it cannot be deepened,

the choice rests between the next

size larger stud, if possible, a special

stepped stud, I, or a threaded bush J,

to return the hole to standard size.

The last when fitted should be fixed

with a locking screw as shown., in a

hole drilled and tapped half m the

bush, half in the component.

q

MODEL ENGINEER

Вам также может понравиться

- 2873-Cotters & Wedges PDFДокумент1 страница2873-Cotters & Wedges PDFsyllavethyjimОценок пока нет

- 149-Workshop Hints & TipsДокумент1 страница149-Workshop Hints & TipssyllavethyjimОценок пока нет

- 149-Workshop Hints & Tips PDFДокумент1 страница149-Workshop Hints & Tips PDFsyllavethyjimОценок пока нет

- 2847-Keys & Driving PinsДокумент1 страница2847-Keys & Driving PinssyllavethyjimОценок пока нет

- 3 in 1 MachineДокумент5 страниц3 in 1 Machinemarandan85100% (1)

- Contours 1: Hile It CannotДокумент1 страницаContours 1: Hile It CannotsyllavethyjimОценок пока нет

- WWMM Lumber Storage CartДокумент9 страницWWMM Lumber Storage CartjlpicardОценок пока нет

- Table Saw AlingmentДокумент8 страницTable Saw AlingmentEd BozmanОценок пока нет

- Lathe ToolslideДокумент2 страницыLathe ToolslideFrenchwolf420Оценок пока нет

- South Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007Документ16 страницSouth Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007asdfОценок пока нет

- Auto-Powered Arc Welder: by Norman E. SchuttzДокумент60 страницAuto-Powered Arc Welder: by Norman E. SchuttzPierre799es100% (1)

- Longworth Chuck PDFДокумент6 страницLongworth Chuck PDFBen Gerez100% (2)

- Operating: Maintenance ManualДокумент18 страницOperating: Maintenance ManualAnonymous reYe6iCCОценок пока нет

- Quorn: Tool and Cutter GrinderДокумент3 страницыQuorn: Tool and Cutter GrinderDan HendersonОценок пока нет

- Milling Attachment With 3 FunctionsДокумент3 страницыMilling Attachment With 3 FunctionsKarthickОценок пока нет

- Lapping tapers and seatings to improve fit and finishДокумент1 страницаLapping tapers and seatings to improve fit and finishsyllavethyjimОценок пока нет

- Ian Bradley Talks LatheToolsДокумент3 страницыIan Bradley Talks LatheToolsAnonymous mKdAfWifОценок пока нет

- Different pump typesДокумент1 страницаDifferent pump typesDinkalai WaronfireОценок пока нет

- Louis Belet Cutting Tools Watchmaking Jura Suisse Vendlincourt Switzerland Brochure Hob Cutters enДокумент16 страницLouis Belet Cutting Tools Watchmaking Jura Suisse Vendlincourt Switzerland Brochure Hob Cutters enLogan RaoОценок пока нет

- Atlas Mill AccessoriesДокумент1 страницаAtlas Mill AccessoriesGary RepeshОценок пока нет

- 32 Insert Jig Raised PanelsДокумент1 страница32 Insert Jig Raised PanelsDavid TuaineОценок пока нет

- 33 - Making Clocks PDFДокумент65 страниц33 - Making Clocks PDFBruno DelsupexheОценок пока нет

- Thread Basics - GO-No GoДокумент2 страницыThread Basics - GO-No GoKundan Kumar MishraОценок пока нет

- Quorn: Tool and Cutter GrinderДокумент4 страницыQuorn: Tool and Cutter GrinderDan Henderson100% (1)

- 2943-Port & Valve TimingДокумент1 страница2943-Port & Valve TimingVinoth Kumar VinsОценок пока нет

- Metal LatheДокумент25 страницMetal Lathebogesz68Оценок пока нет

- 47158Документ16 страниц47158Rosania SanchesОценок пока нет

- 09 SuspensionДокумент27 страниц09 SuspensionOsvaldo Fernandez100% (1)

- Cowells Manuals PDFДокумент16 страницCowells Manuals PDFpedjaОценок пока нет

- Quorn User ManualДокумент31 страницаQuorn User ManualGeorge Stright100% (5)

- The Advance Metalworking LatheДокумент6 страницThe Advance Metalworking LathePronina100% (1)

- Metal Working Processes, Tools, and Machines: (Sheet and Small Section Steel)Документ35 страницMetal Working Processes, Tools, and Machines: (Sheet and Small Section Steel)Carlo Damião100% (2)

- Riding Mower PartsДокумент17 страницRiding Mower PartsDwight MorrisonОценок пока нет

- Mechanisms For Projects Drawings PR PDFДокумент10 страницMechanisms For Projects Drawings PR PDFstaticfactory9281Оценок пока нет

- More Tricks With The: "Quorn"Документ5 страницMore Tricks With The: "Quorn"Dan HendersonОценок пока нет

- Balanci GrindingДокумент18 страницBalanci GrindingAnonymous JzEb8CXErОценок пока нет

- Mini Bike LightДокумент2 страницыMini Bike LightperacОценок пока нет

- Quorn: Tool and Cutter GrinderДокумент3 страницыQuorn: Tool and Cutter GrinderDan HendersonОценок пока нет

- c14ae533-c88e-4356-9f4b-3f4995ffa658Документ20 страницc14ae533-c88e-4356-9f4b-3f4995ffa658Ramius HamdaniОценок пока нет

- 04 80 PDFДокумент272 страницы04 80 PDFRahmat Budi PermanaОценок пока нет

- Care and Use of Boyar Schultz Model 6-12 Surface GrinderДокумент11 страницCare and Use of Boyar Schultz Model 6-12 Surface GrinderRandyWilsonОценок пока нет

- Quorn: Tool and Cutter GrinderДокумент4 страницыQuorn: Tool and Cutter GrinderDan HendersonОценок пока нет

- Quorn: Tool and Cutter GrinderДокумент4 страницыQuorn: Tool and Cutter GrinderDan HendersonОценок пока нет

- Kearney and Trecker Installation ManualДокумент12 страницKearney and Trecker Installation Manualaa987100% (1)

- Racing Gas Engine: Building A Twin CylinderДокумент12 страницRacing Gas Engine: Building A Twin Cylinder2n Tv100% (1)

- Penny Engine Micro Air Powered EngineДокумент10 страницPenny Engine Micro Air Powered Enginemarius_danila8736Оценок пока нет

- CatalogДокумент235 страницCatalogcustomerx50% (4)

- Asme B5.11-1964 (2018)Документ16 страницAsme B5.11-1964 (2018)vijay pawarОценок пока нет

- DIYMetalBrake 1Документ4 страницыDIYMetalBrake 14U6ogj8b9snylkslkn3nОценок пока нет

- Reaming processes and toolsДокумент1 страницаReaming processes and toolsvikash kumarОценок пока нет

- Engmod2T: The Multi-Cylinder Two-Stroke Engine SimulatorДокумент8 страницEngmod2T: The Multi-Cylinder Two-Stroke Engine SimulatorByndy95Оценок пока нет

- GraderДокумент2 страницыGraderFrenchwolf420Оценок пока нет

- Lathe Chuck Backplate FittingДокумент2 страницыLathe Chuck Backplate FittingAnonymous iYKTkmhpZ100% (3)

- SphericalturninglathetoolДокумент14 страницSphericalturninglathetoolFrenchwolf420Оценок пока нет

- 1946 Rusnok Mill Heads CatДокумент25 страниц1946 Rusnok Mill Heads CatfgrefeОценок пока нет

- Shaper Used As Surface GrinderДокумент1 страницаShaper Used As Surface Grinderradio-chaserОценок пока нет

- Very Much ImprovedДокумент5 страницVery Much ImprovedAndy LОценок пока нет

- IMP Workshop ManualДокумент336 страницIMP Workshop Manualsyllavethyjim67% (3)

- 2890-Nuts & Spanners PDFДокумент1 страница2890-Nuts & Spanners PDFsyllavethyjimОценок пока нет

- 2884-Panel Beating PDFДокумент1 страница2884-Panel Beating PDFsyllavethyjim100% (1)

- 2887-Broken Drills & Taps PDFДокумент1 страница2887-Broken Drills & Taps PDFsyllavethyjimОценок пока нет

- 2885-Dent & Bulge Removal PDFДокумент1 страница2885-Dent & Bulge Removal PDFsyllavethyjimОценок пока нет

- 2879-Clamping & Holding PDFДокумент1 страница2879-Clamping & Holding PDFsyllavethyjimОценок пока нет

- 2888-Oblique Drilling PDFДокумент1 страница2888-Oblique Drilling PDFsyllavethyjimОценок пока нет

- 2889-Further Drilling Methods PDFДокумент1 страница2889-Further Drilling Methods PDFsyllavethyjimОценок пока нет

- 2880-Supporting & Steadying PDFДокумент1 страница2880-Supporting & Steadying PDFsyllavethyjimОценок пока нет

- 2881-Radii Functions and Checking PDFДокумент1 страница2881-Radii Functions and Checking PDFsyllavethyjimОценок пока нет

- 2883-Metal Working PDFДокумент1 страница2883-Metal Working PDFsyllavethyjimОценок пока нет

- Contours 1: Hile It CannotДокумент1 страницаContours 1: Hile It CannotsyllavethyjimОценок пока нет

- 2872-Circular Clips #2 PDFДокумент1 страница2872-Circular Clips #2 PDFsyllavethyjimОценок пока нет

- 2878-Chains & Sprockets PDFДокумент1 страница2878-Chains & Sprockets PDFsyllavethyjimОценок пока нет

- 2876-Belt Fasteners PDFДокумент1 страница2876-Belt Fasteners PDFsyllavethyjimОценок пока нет

- 2875-Belt Drives PDFДокумент1 страница2875-Belt Drives PDFsyllavethyjimОценок пока нет

- 2871-Circular Clips #1 PDFДокумент1 страница2871-Circular Clips #1 PDFsyllavethyjimОценок пока нет

- Roller Chains and Sprockets GuideДокумент1 страницаRoller Chains and Sprockets GuidesyllavethyjimОценок пока нет

- 2874-Fitting Core Plugs PDFДокумент1 страница2874-Fitting Core Plugs PDFsyllavethyjimОценок пока нет

- 2869-Fitting & Joining Pipes PDFДокумент1 страница2869-Fitting & Joining Pipes PDFsyllavethyjimОценок пока нет

- 2870-Simple Screw Assembly PDFДокумент1 страница2870-Simple Screw Assembly PDFsyllavethyjimОценок пока нет

- 2866-Hardening & Tempering PDFДокумент1 страница2866-Hardening & Tempering PDFsyllavethyjimОценок пока нет

- 2868-Glands & Pipe Fittings PDFДокумент1 страница2868-Glands & Pipe Fittings PDFsyllavethyjimОценок пока нет

- 2861-Wheel & Shaft PullersДокумент1 страница2861-Wheel & Shaft PullersSandra Barnett CrossanОценок пока нет

- 2864-Poppet Valves & Seating PDFДокумент1 страница2864-Poppet Valves & Seating PDFsyllavethyjimОценок пока нет

- 2867 Case HardeningДокумент1 страница2867 Case HardeningEr Sukhwinder SinghОценок пока нет

- 2865-Testing & Facing Valves PDFДокумент1 страница2865-Testing & Facing Valves PDFsyllavethyjimОценок пока нет

- 2863-Valve Seating Tools PDFДокумент1 страница2863-Valve Seating Tools PDFsyllavethyjimОценок пока нет

- March 17, 2016 Strathmore TimesДокумент24 страницыMarch 17, 2016 Strathmore TimesStrathmore TimesОценок пока нет

- Psychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)Документ48 страницPsychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)sfrtr100% (1)

- MEETING 7 OPINIONSДокумент2 страницыMEETING 7 OPINIONSLeonie Irina MutiaraОценок пока нет

- GHT 2001 Chino 12 Point Temperature Recorder EH3127 001Документ1 страницаGHT 2001 Chino 12 Point Temperature Recorder EH3127 001gawaОценок пока нет

- Torn MeniscusДокумент10 страницTorn MeniscusKrystal Veverka100% (3)

- Présentation Transportation ManagementДокумент14 страницPrésentation Transportation ManagementHiba Hmito100% (1)

- Answer Sheet FINAL LipidДокумент3 страницыAnswer Sheet FINAL LipidFaridah MagumparaОценок пока нет

- Weekly Report 52Документ196 страницWeekly Report 52Erceanu DanОценок пока нет

- Exercise Questions (Materials) .: BFT 112 Introduction To EngineeringДокумент1 страницаExercise Questions (Materials) .: BFT 112 Introduction To EngineeringSK DarsyanaaОценок пока нет

- Moral Theories: Presented By: Sedrick M. MallariДокумент27 страницMoral Theories: Presented By: Sedrick M. MallariAlyssa De PaduaОценок пока нет

- Vietnam & Angkor Wat (PDFDrive) PDFДокумент306 страницVietnam & Angkor Wat (PDFDrive) PDFChristine TranОценок пока нет

- Unit-2 Final KshitijДокумент108 страницUnit-2 Final KshitijShubham JainОценок пока нет

- STPM Chemistry Topic 16 Haloalkanes Short Notes PDFДокумент2 страницыSTPM Chemistry Topic 16 Haloalkanes Short Notes PDFbendanОценок пока нет

- AUS Triboard ManuaДокумент112 страницAUS Triboard ManuaWan RidsОценок пока нет

- CV of Shaila (Me)Документ4 страницыCV of Shaila (Me)Masud RanaОценок пока нет

- General Guidelines For Design and Construction of Concrete Diaphram (Slurry) WallsДокумент108 страницGeneral Guidelines For Design and Construction of Concrete Diaphram (Slurry) WallsharleyОценок пока нет

- DA1 Learning - Ans KeyДокумент4 страницыDA1 Learning - Ans KeyDolon DasОценок пока нет

- Class-III English Notes-WsДокумент6 страницClass-III English Notes-WsManu SinghОценок пока нет

- Elimination - Nursing Test QuestionsДокумент68 страницElimination - Nursing Test QuestionsRNStudent1100% (1)

- M700-70 Series Programming Manual (M-Type) - IB1500072-F (ENG)Документ601 страницаM700-70 Series Programming Manual (M-Type) - IB1500072-F (ENG)Mert SertОценок пока нет

- Genius+ Ba Cu en 1113Документ72 страницыGenius+ Ba Cu en 1113AlbertОценок пока нет

- داينمك الملزمة كاملةДокумент79 страницداينمك الملزمة كاملةarno assassin33% (3)

- WPS Ernicu 7 R1 3 6 PDFДокумент4 страницыWPS Ernicu 7 R1 3 6 PDFandresОценок пока нет

- Boston Acoustic PDFДокумент12 страницBoston Acoustic PDFAdam StarkОценок пока нет

- Multi Purpose StadiumДокумент130 страницMulti Purpose StadiumEmmanuel SolomonОценок пока нет

- Spcr-TagbayaganДокумент76 страницSpcr-TagbayaganReycia Vic QuintanaОценок пока нет

- Ichroma™ COVID-19 Ab (With Ichroma™ II Reader) Test SystemДокумент6 страницIchroma™ COVID-19 Ab (With Ichroma™ II Reader) Test SystemGopinath AgnihotramОценок пока нет

- Omcmle Physiology Workbook Part 5 PDFДокумент63 страницыOmcmle Physiology Workbook Part 5 PDFloiuse shepiralОценок пока нет

- Function and Definite Integrals ExplainedДокумент7 страницFunction and Definite Integrals Explainedana maharaniОценок пока нет

- Verbal ReasoningДокумент8 страницVerbal ReasoningyasirОценок пока нет