Академический Документы

Профессиональный Документы

Культура Документы

DRAM (Dynamic Random Access Memory) Leakage Path Analysis

Загружено:

Rio CarthiisОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DRAM (Dynamic Random Access Memory) Leakage Path Analysis

Загружено:

Rio CarthiisАвторское право:

Доступные форматы

http://www.paper.edu.

cn

DRAM(Dynamic Random Access Memory)Leakage

Path Analysis

Abstract

DRAM is one of the key products used for high-density data storage. Data retention

performance is key item of DRAM product yield, This paper present three possible

leakage current path that can downgrade data retention performance in IC process.

Keywords: DRAM,Leakage path,Junction leakage,GIDL,Subthreshold leakage

http://www.paper.edu.cn

Introduction

DRAM product can be fabricated in large volumes with given fabrication process. Process problems

result in failing memory cells. And yield Limitation is the key point for DRAM product mass

production profit. The control of the retention time is the key issue for realizing high density DRAM

because the refresh time doubles with each successive generation [1] The retention time can be

defined as the duration until the stored signal can be read out. There are several leakage current paths,

by which the stored charge flowed out from the storage capacitor.

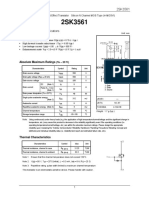

Fig.1 shows schematic of a 0.20 um Stack type CUB (Capacitor Under Bit line)DRAM device, Cell

Capacitors top and bottom plates are poly silicon material, Nitride-Oxide structure is for capacitor

dielectric.Rogered poly was deposited on bottom poly silicon to increase the area of plates which can

enlarge cell capacitance to store more charge. Tungsten(W) was used as bit line and bit line contact to

charge sense amplifier. When positive voltage is applied on poly gate (Vpp,usually 3.1~3.3V),cell

transistor will be turned on ,charges stored in cell capacitor flow out ,this can cause the voltage on bit

line have a drop or jump change, sense amplifier will catch this change and judge the capacitor stored

information is one or zerologic.Automatically ,when transistor is turned on, charges in capacitor

will be refreshed(recharged). During the period, charge will leak through some paths, we will

investigate age e three kinds of leakage current path with example of this stacked type DRAM.

Here are major possible leakage path as shown in Fig.1:

(1) Reverse Junction leakage current from the storage node

(2) Gate Induced drain leakage (GIDL) current

(3) Subthreshold leakage current of NMOS transistor

Bitline

Bitline Contact

Capacitor

N-

(3)

(2)

N-

(1)

P-Sub

Fig.1 Schematic of stack type DRAM device

http://www.paper.edu.cn

Leakage current Paths analysis

2.1 Junction leakage

The fabrication process of node p-n junction of DRAM device is as follows.Firstly,well formation

steps: Boron was implanted in order to form the p-well. The acceleration energy was

180Kev.Followed by anti punch through implant, Boron was implant with 80Kev acceleration energy.

The implantation dose was changed in order to vary the boron concentration of the p-well. MeV

implantation can be used to implant a minority carrier diffusion barrier between the ends of the

junction, which functions in a similar manner to a retrograde well used to improve data retention time.

After capacitor contact hole was formed,concact implant to reduce the resistance is performed.

Phosphorous with acceleration energy 80kv was implanted under the capacitor contact .The storage

node of the capacitor consist of n- diffused layer p-n junction is formed under capacitors. Fig2&Fig3

shows the implanted material depth distribution profile by SIMS.

Fig.2 Phosphorous

implant distribution

profile

Fig.3 Boron implant

distribution profile

We will explain junction current with reverse applied voltage, and this condition is DRAM cell storage

1condition. Fig.4 shows the measured feature of the current-voltage (I-V) characteristics with

Aglient 4156C, the leakage current increases exponentially as the applied reverse voltage increases.

http://www.paper.edu.cn

This characteristic cannot be explained neither by diffusion current nor G-R current. Diffusion current

Diffusion current does not depend on the applied voltage because the concentration of the minority

carrier at the depletion layer edge remains constant even if the reverse bias change.

Generation-Recombination current has a square root relationship to the applied voltage. These two

kinds of relationship are different from the I-V characteristics shown in Fig.4.

Contact implant dosage Vs Data Retention Time(ms)

300

250

200

150

100

50

Data

Retention

Time(ms)

0

6.00E+ 7.00E+ 8.00E+ 9.00E+ 1.00E+ 1.10E+ 1.20E+ 1.30E+ 1.40E+

03

03

03

03

04

04

04

04

04

Fig.5 Experiment of different

Fig.4 p-n Junction I-V

contact implant dosage vs data

characteristic with

Thermal Field Emission current has an exponential relationship to theretention

appliedtime

voltage. Thermal

reverse voltage

emission rate from a deep level is enhanced by tunneling effect due to the strong electric filed in the

depletion region. There, the conduction mechanism of the leakage current of p-n junction formed on

P+ type substrate is thermionic field emission, When no bias is applied to the junction, diffusion

current flows at the n+/p-well junction, when the reverse bias is applied to the junction, diffusion

current disappears and TFE current can be observed. Different from diffusion current, the junction

leakage current increases as the boron concentration of the n-/p-well increases. The electric field in the

depletion layer is enhanced when the Phosphorous/boron concentration of the p-well increases. It

leads to the enhancement of the tunneling probability of electron. Therefore, the thermal emission of

electron from a deep level also increases.Fig.5 is process experiment with different contact implant

dosage result. From the result ,we have the conclusion: higher node dosage of n-p junction can

decrease the data retention time because of higher junction dosage induced higher electrical field. This

give us the clue to improve DRAM product data retention time.

Because reverse junction leakage usually is less than 10-12order,the junction leakage direct

measurement on the wafer is not sensitivity for High-density DRAM product; a useful method to

evaluate the leakage performance of DRAM product is tail bits distribution. The distribution can be

divided into two distributions: Main Distribution and Tail Distribution The retention time of

almost all the memory cells belonged to Main Distribution. However, there are a few memory cell

whose retention time does not belong to Main Distribution: We defined this shorter retention time

http://www.paper.edu.cn

distribution as Tail Distribution that follows 6rules. Tail Distribution dominates the refresh

characteristics of DRAM. [2] Usually, the DRAM products have redundancy capacity design for

normal tail bits, by using laser repair, the tail bits will be replaced by redundancy cells. If the tail bits

count appear beyond redundancy repair capability in less than designed data retention time, this chip

will be categorized as Non-Function chip.

A static retention test can be used on DRAM product to catch tail bits, the test methods is described as

follows: Write one(high level voltage) to the cell capacitor with word line fast operation ,Waiting for

some time with doing nothing, Read data from each cell with word line fast operation.The program

was created on Mosaid 4205 tester.This is a kind of general purpose memory engineering tester and

widely used on memory product electrical failure analysis. We can see from Fig6, with lower

Vbb(bulk bias voltage), tail bits increase more rapidly, this means worse data retention performance.

This result match I-V characterization shown on Fig.4, junction leakage increase with applied reverse

voltage.So,this give us the clue to evaluate the junction leakage more precisely.We can judge from

Fig7,the Vbb Vs Fail Bit Count curve,Condition1s fail tail bit count increase faster when Vbb

decrease compared with the other three which means high reverse junction leakage. Usually, Vbb is

set at 0.2V to suppress subthreshold leakage, and at the same time ,a low level reverse junction

leakage can be kept. We can use this kind of test methods to evaluate the junction leakage of different

DRAM process instead of insensitivity Direct Current measurement.

Fig.6 Tail bits distribution under

different Vbb condition.

Fig.7 Tail bits distribution under different

process condition when Vbb decrease.

Another kind of junction leakage mechanism is defect related, either contamination or crystal defect

across node junction or LDD area can break down the barrier of p-n junction. Fig.8 is a failure

analysis case of high junction leakage, From the TEM(Transmission Electron Microscope) picture, a

http://www.paper.edu.cn

slice shape defect was observed ,and material analysis on the defect found abnormal Titanium peak,

This Titanium diffuse from the top of poly contact. This Ti contamination across Junction cause huge

junction leakage. Crystalline defects in the substrate can also cause junction leakage and degrade the

data retention property. Especially for downscaled devices, the probability of the failure due to the

defects are increased, because the junction layers become shallower. It is generally known that the

dislocation loops are generated at Ion implant, Poly etch, Spacer SiN deposition.Fig.9 shows

dislocation across the junction layer from the side-wall edge in transistor with LDD structures. This

pictures shows the cross-sectional TEM picture after poly etch at the sample with LDD structure. The

dislocation profiles were observed at the depth of 50nm. Usually,LDD thickness is 300~400A,this

dislocation depth is 500A,which is across the junction.

Fig.8 Ti contamination

caused junction leakage

Fig.9 Silicon crystal

defect across LDD area

2.2GIDL

A negative worline bias voltage usually named VNWL is used to reduce the subthreshold leakage of

deep submicron DRAM cell transistors. The sub threshold leakage of cell transistors poses a great

challenge for next generation cell transistor. Owing to the concern of junction leakage increase, the

cell transistors threshold voltage(Vt) cant be raised simply by increasing the dose of Vt adjustment

implant or arsenic implanted shallow junction[3].It is very difficult to control the process-induced

http://www.paper.edu.cn

point defects and rduce the channel doping concentration without degrading the subthreshold

characteristics of cell transistors.Fig.2 shows the Vt roll-off characteristics of cell transistors for

technology generation. It was found that the short channel effect (SCE) is getting serious with the

shrinkage.So,It is necessary to apply a negative worline bias voltage at the memory cell design in

order to gain the cell transistor on current while maintain desired off current. Although the sub

threshold characteristic of a DRAM cell can be improved by applying negative word line bias, the

GIDL can come serious. Saino et al. reported that GIDL current impacts tail retention time distribution

dominantly [4] When a 1signal stores in the storage capacitor, the junction near the capacitor is also

at high level. Therefore, if the gate is turned off at negative word line bias, the gate induced drain

junction leakage is serious because of the increased vertical electrical field as compared to ground

word line[5].

Fig.10.shows the schematic of cell device structure, and proposed GIDL current path. A negative

voltage is applied on the word line when the cell transistor is turned off. Depletion region border in the

p-well and the node-diffusion in the bias condition is marked b a dotted line. The rather high voltage

difference between gate and node-diffusion causes a strong field across the oxide in the overlap region.

If the electric filed becomes sufficiently large, the valence band electrons can tunnel to conduction

band and they are immediately swept laterally to the node-diffusion, which has a lower electron

potential. GIDL leakage can be reduced by tuning LDD implant recipe,Fig11 shows the Data

Retention performance under different LDD implant condition, The red curve stands the static data

retention characterization curve, the acceleration voltage is 30Kev with 2.5e13 dosage. Compared

with the blue curve with condition 20Kev and 2.5e13, high acceleration voltage shows better data

retention performance. This result can be explained as below: Higher implant energy can increase the

depth of Ion distribution, The LDD diffusion area depth under GOI will increase also, so the electrical

filed will decrease when same voltage dropped across the area.

http://www.paper.edu.cn

2.3Subthreshold Leakage

As the device shrinkage, the source and drain junction depletion length cant be ignored compared

with effect channel length ,short channel effect is significant when the channel length is in deep

submicron . Fig.12 is the device simulation result of threshold voltage (Vt) under different channel

length with Pocket (Halo) implant. Pocket implant is performed with the material same with bulk

substrate. It can increase the device Vt and roll off short channel effect, increase Poly gate dry etch

process window. In the DRAM fabrication, Poly gate etch CD control is critical for data retention

performance.When poly CD is lower than the target value, Vt will be lower which means subthreshold

leakage is beyondFig.10

designSchematic

value. of

Fig.11 Experiment of LDD

GIDL mechanism

implant to suppress GIDL

VT(V)

Channel Length(um) Vs Vt(V)

1.000

0.900

0.800

0.700

0.600

0.500

0.400

0.300

0.200

0.100

0.000

VT(V)

0.00

0.10

0.20

0.30

0.40

0.50

0.60

Channel Length(um)

Fig.12 Simulation result of

Channel length vs. Vt

Fig.13 Correlation

between Vt vs. Yield

Fig14,is wafer map of a DRAM product, the red area means fail dies that suffer a test item disturb

fail, the disturb test is to detect subthreshold leakage of the DRAM transistor. Wafer bottom suffer

serious disturb fail. Fig13 is correlation analysis of two parameters Vt vs. Wafer Yield ,from the

result we can see the wafer yield have correlation vs. transistor Vt .Fig14 is the VT measurement value

at different region of wafers. Where there are disturb fail die, Vt is lower that of good dies.

http://www.paper.edu.cn

Fig.15 Wafer map that

Fig.14 WAT

3.Conclusion

hasdisturbfailed die in it

measurement found VT

We analyze three major DRAM

device

leakage

paths,Junction

Leakage,GIDL

Leakage,and Subthreshold

lower at failed region

leakage.And studied the current mechanism and how to evaluation and diagnose the current path. .With

device shrinkage, due to shallow junction ,Gate Oxide tunneling, short channel effect etc. transistor leakage

is becoming more and more serious.How to quickly and precisely identify leakage path and process issue in

DRAM fabrication is very important.More efficient and useful Electrical,Physical failure analysis and data

analysis methods is always great challenge for DRAM data retention analysis.

Acknowledgement

Thanks the great instruction and help from Dr. Qiyu Huang and Shirla Cheng of School of

Microelectronics,Shanghai Jiao Tong University.

References

[1]

T.Hamamoto,S.Sugiura,and S. Sawada,Well Concentration:A novel scaling limitation factor

derived from dram retention time and its modeling,in IEDM Tech.Dig,.1995,915-918 .

[2]

El-Bakry, H.M (2001) Human Iris Detection Using Fast Cooperative Modular Neural Nets. Neural Networks,

[3]

S.KamoharaStatistical PN Junction Leakage Model with Trap level Flucuation for

Tref(Retention)-Orientied DRAM DesignIEDM.PP.549-541, 1999

A.Chatterjee et al.,A pass transistor design methodology for 256Mbit DRAM and beyond,in

Proc.Synp.VLSI TechnolDtg.Tech.Papers,1999,PP.137-138

K.Saino et al.,Impact of gate-induced drain leakage current on the tail distribution of DRAM

[4]

http://www.paper.edu.cn

[5]

data retention time,in IEDM Tech.Dtg.2000,pp.837-840.

Minchen Chang etcImpact of Gate Induced Drain Leakage on Retention Time Distribution of

256Mbit DRAM With Negative Wordline BiasIEEE Transactions on electron

Devices,VOL.50,NO.4,APRIL.2003

10

Вам также может понравиться

- Impact of Gate Induced Drain Leakage On Overall Leakage of Submicrometer CMOS VLSI CircuitsДокумент10 страницImpact of Gate Induced Drain Leakage On Overall Leakage of Submicrometer CMOS VLSI Circuits275108006Оценок пока нет

- A Low-Power 8-Read 4-Write Register File DesignДокумент4 страницыA Low-Power 8-Read 4-Write Register File DesignEdmund LeongОценок пока нет

- Low Power Design and Simulation of 7T SRAM Cell Using Various Circuit TechniquesДокумент6 страницLow Power Design and Simulation of 7T SRAM Cell Using Various Circuit TechniquesseventhsensegroupОценок пока нет

- Low Power SramДокумент5 страницLow Power SramPromit MandalОценок пока нет

- Leakage Current Reduction 6TДокумент3 страницыLeakage Current Reduction 6Tshoaib nadeemОценок пока нет

- Sram 2nd PhaseДокумент26 страницSram 2nd PhaseSanjay ChОценок пока нет

- Low Power ThesisДокумент6 страницLow Power Thesistiffanybarbermobile100% (2)

- PXC 3873796Документ6 страницPXC 3873796Sai PraveenОценок пока нет

- DecapДокумент6 страницDecapayyannagaraga1Оценок пока нет

- Maximum Leakage Power Estimation For CMOS CircuitsДокумент9 страницMaximum Leakage Power Estimation For CMOS Circuitsowais74Оценок пока нет

- Thesis MfadtДокумент6 страницThesis Mfadtgj9zvt51100% (1)

- FinFET-Based SRAM DesignДокумент6 страницFinFET-Based SRAM DesignAnil KulshresthaОценок пока нет

- Stop Fried Boards, Garbled Data: Proper Surge ProtectionДокумент2 страницыStop Fried Boards, Garbled Data: Proper Surge ProtectionMansoor AbbasОценок пока нет

- VLSI Antenna Ratio Definition Improves Detection of Plasma DamageДокумент5 страницVLSI Antenna Ratio Definition Improves Detection of Plasma DamageShin Tsz JianОценок пока нет

- Decoder2001 Armatur HorowitzДокумент10 страницDecoder2001 Armatur HorowitzNK NKОценок пока нет

- Reliability of 3D NAND Memories PDFДокумент35 страницReliability of 3D NAND Memories PDFJeff Wank100% (1)

- DFT For SRAMДокумент9 страницDFT For SRAMsuneeldvОценок пока нет

- ANALOG-DIGITAL CONVERSION: Understanding Capacitor ParasiticsДокумент6 страницANALOG-DIGITAL CONVERSION: Understanding Capacitor ParasiticsalpcruzОценок пока нет

- Lpvlsi Unit VДокумент27 страницLpvlsi Unit Vlanug channelОценок пока нет

- PVT Sensitive Sleep For SRAM Core: Piyush Jain, Jitendra Dasani and Ashish KumarДокумент4 страницыPVT Sensitive Sleep For SRAM Core: Piyush Jain, Jitendra Dasani and Ashish KumarAshish KumarОценок пока нет

- Circuit Characterization and ModelingДокумент9 страницCircuit Characterization and Modelingbikash routОценок пока нет

- A Novel Power Efficient 8T SRAM Cell: Ankush Sindwani Suman SainiДокумент5 страницA Novel Power Efficient 8T SRAM Cell: Ankush Sindwani Suman SainiBanu KiranОценок пока нет

- 05682957Документ4 страницы05682957Praveenkumar ViswanathanОценок пока нет

- Use of Nano-Mechanical Relays For FPGA Power ReductionДокумент6 страницUse of Nano-Mechanical Relays For FPGA Power ReductionMegha Gupta ChaudharyОценок пока нет

- Printed Circuit Board TechniquesДокумент6 страницPrinted Circuit Board TechniquesA. VillaОценок пока нет

- Low Power VLSI Circuits QuestionsДокумент31 страницаLow Power VLSI Circuits QuestionsPallavi Ch71% (7)

- PP 59-64 Superiority of Current Mode Over Voltage Mode InterconnectsДокумент6 страницPP 59-64 Superiority of Current Mode Over Voltage Mode InterconnectsEditorijset IjsetОценок пока нет

- 279 E317 PDFДокумент6 страниц279 E317 PDFJubin JainОценок пока нет

- High Speed Layout AnalogДокумент4 страницыHigh Speed Layout AnalogMahendra SakreОценок пока нет

- Frequently Asked VLSI Interview Questions and AnswersДокумент6 страницFrequently Asked VLSI Interview Questions and AnswersbhargatejaОценок пока нет

- 9 PDFДокумент10 страниц9 PDFrajОценок пока нет

- Analysis of Write Power Consumption For Single Gate and Dual Gate MOS Based SRAMДокумент6 страницAnalysis of Write Power Consumption For Single Gate and Dual Gate MOS Based SRAMresearchinventyОценок пока нет

- Vlsi 2-Marks With AnswerДокумент23 страницыVlsi 2-Marks With Answerk poornimaОценок пока нет

- A 32 KB 10T Sub-Threshold Sram Array With Bit-Interleaving and DiДокумент10 страницA 32 KB 10T Sub-Threshold Sram Array With Bit-Interleaving and DiSreyas MohanОценок пока нет

- Mtech Vlsi Short Answer QuestionsДокумент8 страницMtech Vlsi Short Answer QuestionsRachit NemaОценок пока нет

- Design of A Class F Power Amplifier: Piers O V NДокумент4 страницыDesign of A Class F Power Amplifier: Piers O V NstepannpОценок пока нет

- EI2301 IE Notes FullДокумент103 страницыEI2301 IE Notes FullVenkatesan SatheeswaranОценок пока нет

- A 409 GOPS W Adaptive and Resilient Domino Register File2Документ13 страницA 409 GOPS W Adaptive and Resilient Domino Register File2emmasustechОценок пока нет

- On Chip VariationДокумент4 страницыOn Chip VariationsarvoscribОценок пока нет

- Waleed K. Al-Assadi Anura P. Jayasumana Yashwant K. Malaiya Technical Report CS-96-102Документ10 страницWaleed K. Al-Assadi Anura P. Jayasumana Yashwant K. Malaiya Technical Report CS-96-102RajasekharVenkataОценок пока нет

- Ec1461 Vlsi DesignДокумент17 страницEc1461 Vlsi DesignArunkumarОценок пока нет

- Nonvolatile D Flip-Flop with 3.4 pJ FeRAM for Energy Harvesting SystemsДокумент28 страницNonvolatile D Flip-Flop with 3.4 pJ FeRAM for Energy Harvesting SystemsaanbalanОценок пока нет

- Nanometer MOSFETДокумент12 страницNanometer MOSFETSibi ManojОценок пока нет

- VLSI CAT2 SolvedДокумент13 страницVLSI CAT2 SolvedTrinayan PathakОценок пока нет

- Dheeraj ReportДокумент15 страницDheeraj ReportGirdhar Gopal GautamОценок пока нет

- Gate Level LeakageДокумент4 страницыGate Level LeakageMadu KumarОценок пока нет

- Flyback Converter Without SnubberДокумент2 страницыFlyback Converter Without SnubberReena ElangovanОценок пока нет

- Layout-Aware Pattern Generation For Maximizing Supply Noise Effects On Critical PathsДокумент6 страницLayout-Aware Pattern Generation For Maximizing Supply Noise Effects On Critical PathsJagadish BaluvuОценок пока нет

- Improved LDMOS For ESD Protection of High Voltage BCD ProcessДокумент4 страницыImproved LDMOS For ESD Protection of High Voltage BCD ProcessNguyen Van ToanОценок пока нет

- Study On Trapped Charge SONOS NVSM With Effect of VG and Vds Programming State VariationДокумент5 страницStudy On Trapped Charge SONOS NVSM With Effect of VG and Vds Programming State VariationdarОценок пока нет

- EI2301-IE - Unit 1 - Part A and Part B - With Answers PDFДокумент21 страницаEI2301-IE - Unit 1 - Part A and Part B - With Answers PDFsartpgitОценок пока нет

- Sub-Threshold Adiabatic Logic For Low Power ApplicationsДокумент7 страницSub-Threshold Adiabatic Logic For Low Power ApplicationsarcherselevatorsОценок пока нет

- Gate Oxide Leakage Current Analysis and Reduction For VLSI CircuitsДокумент12 страницGate Oxide Leakage Current Analysis and Reduction For VLSI CircuitsNK NKОценок пока нет

- Introducing The 5.5kV-5kA HPT IGCTДокумент6 страницIntroducing The 5.5kV-5kA HPT IGCTislam benyettouОценок пока нет

- Lectura 3 M PDFДокумент12 страницLectura 3 M PDFFlakita S MelcOchitaОценок пока нет

- High PSRR Ldo ThesisДокумент4 страницыHigh PSRR Ldo Thesisnibaditapalmerpaterson100% (1)

- Design of Low Power Sram: Presentation OnДокумент31 страницаDesign of Low Power Sram: Presentation Ondhanaji pawarОценок пока нет

- Tang DeltaДокумент4 страницыTang DeltaaderrlyОценок пока нет

- High-Performance D/A-Converters: Application to Digital TransceiversОт EverandHigh-Performance D/A-Converters: Application to Digital TransceiversОценок пока нет

- Signal Integrity: From High-Speed to Radiofrequency ApplicationsОт EverandSignal Integrity: From High-Speed to Radiofrequency ApplicationsОценок пока нет

- Markdown For Jupyter Notebooks Cheatsheet - IBM Watson Data - MediumДокумент3 страницыMarkdown For Jupyter Notebooks Cheatsheet - IBM Watson Data - MediumRio CarthiisОценок пока нет

- EeL Proceedings FInalДокумент173 страницыEeL Proceedings FInalRio CarthiisОценок пока нет

- Wikipedia - LaTeX Symbols - WikipediaДокумент9 страницWikipedia - LaTeX Symbols - WikipediaRio CarthiisОценок пока нет

- Markdown For Jupyter Notebooks Cheatsheet - IBM Watson Data - MediumДокумент3 страницыMarkdown For Jupyter Notebooks Cheatsheet - IBM Watson Data - MediumRio CarthiisОценок пока нет

- 5239 PB XC7Z007S 1CLG225C V11aДокумент2 страницы5239 PB XC7Z007S 1CLG225C V11aRio CarthiisОценок пока нет

- Electronics 08 00292 v3 PDFДокумент66 страницElectronics 08 00292 v3 PDFRio CarthiisОценок пока нет

- Installation Guide ETAP19.0.1Документ2 страницыInstallation Guide ETAP19.0.1Rio CarthiisОценок пока нет

- EQEDITOR Use the Equation EditorДокумент11 страницEQEDITOR Use the Equation EditorpanchopanzaОценок пока нет

- Installation Guide ETAP19.0.1 PDFДокумент2 страницыInstallation Guide ETAP19.0.1 PDFRio CarthiisОценок пока нет

- Perry - EKДокумент1 страницаPerry - EKRio CarthiisОценок пока нет

- A Survey On CNN and RNN ImplementationsДокумент7 страницA Survey On CNN and RNN ImplementationsRio CarthiisОценок пока нет

- LM 741Документ16 страницLM 741Ismael PalmaОценок пока нет

- NVIDIA DLI Catalog Published March 17 2019Документ15 страницNVIDIA DLI Catalog Published March 17 2019Rio CarthiisОценок пока нет

- Complex NumbersДокумент25 страницComplex NumbersRio CarthiisОценок пока нет

- A3967 DatasheetДокумент15 страницA3967 DatasheetJonathanDaysОценок пока нет

- Moderation of Module MarksДокумент3 страницыModeration of Module MarksRio CarthiisОценок пока нет

- Professional Engineers (Code of Professional Conduct and Ethics) RulesДокумент5 страницProfessional Engineers (Code of Professional Conduct and Ethics) RulesRio CarthiisОценок пока нет

- MBR20100CT DДокумент4 страницыMBR20100CT DcsclzОценок пока нет

- xl4016 DatasheetДокумент10 страницxl4016 DatasheetEduardo Jose Torres HernandezОценок пока нет

- RT Box ManualДокумент48 страницRT Box ManualRio CarthiisОценок пока нет

- Sensors 17 01942Документ12 страницSensors 17 01942Rio CarthiisОценок пока нет

- mbrb20 Datasheet PDFДокумент7 страницmbrb20 Datasheet PDFRio CarthiisОценок пока нет

- 2-Texas Instruments TPS92001EVM-628 Evaluation ModuleДокумент2 страницы2-Texas Instruments TPS92001EVM-628 Evaluation ModuleRio CarthiisОценок пока нет

- 05272410Документ5 страниц05272410Rio CarthiisОценок пока нет

- EM Made EasyДокумент3 страницыEM Made EasyRio CarthiisОценок пока нет

- New Homework To Be Posted This Weekend Project Phase 3 Launched Next WeДокумент20 страницNew Homework To Be Posted This Weekend Project Phase 3 Launched Next WeRio CarthiisОценок пока нет

- 107 Isda2004Документ5 страниц107 Isda2004Rio CarthiisОценок пока нет

- MindShare Intro To USB 3.0Документ20 страницMindShare Intro To USB 3.0alexchuahОценок пока нет

- Amf Ind t1119Документ61 страницаAmf Ind t1119Rio CarthiisОценок пока нет

- Silicon Carbide Power MOSFET E-Series Automotive: N-Channel Enhancement ModeДокумент10 страницSilicon Carbide Power MOSFET E-Series Automotive: N-Channel Enhancement ModeDidac MessОценок пока нет

- Strda9000es TWPДокумент33 страницыStrda9000es TWPfernando.pagnottaОценок пока нет

- Irfr 9120 NPBFДокумент11 страницIrfr 9120 NPBFdsafhОценок пока нет

- Lab 1 Schematic Tut 2014Документ43 страницыLab 1 Schematic Tut 2014Minu MathewОценок пока нет

- SILICA NXP Discretes Selection GuideДокумент86 страницSILICA NXP Discretes Selection Guidebuggy buggerОценок пока нет

- Components Code and Abbreviation On Laptop MotherbДокумент7 страницComponents Code and Abbreviation On Laptop MotherbDelwar HossainОценок пока нет

- LC Lab Manual Svuce EceДокумент116 страницLC Lab Manual Svuce EcePMVamsiОценок пока нет

- Power Electronics & Drives: Unit: 1 Power Semiconductor DevicesДокумент24 страницыPower Electronics & Drives: Unit: 1 Power Semiconductor DevicesTapobroto ChatterjeeОценок пока нет

- Audio Processor for Class-D Power AMPДокумент20 страницAudio Processor for Class-D Power AMPGiovani BragaОценок пока нет

- Si9407AEY: Vishay SiliconixДокумент5 страницSi9407AEY: Vishay SiliconixChristian Tubay MaciasОценок пока нет

- Unit 1 - CombinedДокумент194 страницыUnit 1 - CombinedNINJAОценок пока нет

- Infineon Bipolar AN20012 01 Technical Information An v1.0 enДокумент84 страницыInfineon Bipolar AN20012 01 Technical Information An v1.0 enflash_90697638Оценок пока нет

- Tcad EngДокумент147 страницTcad EngNeeraj GuptaОценок пока нет

- TE53N50EДокумент8 страницTE53N50EdavemcguireОценок пока нет

- Sem 3 Module 3Документ5 страницSem 3 Module 3Joshua HernandezОценок пока нет

- SPICE Module: User's GuideДокумент46 страницSPICE Module: User's GuidegkkumarОценок пока нет

- Switching Regulator Applications: Absolute Maximum RatingsДокумент2 страницыSwitching Regulator Applications: Absolute Maximum RatingsValdir KoxinhaprОценок пока нет

- 16f88 Brushless Controller SchematicДокумент1 страница16f88 Brushless Controller SchematicGiapy Phuc TranОценок пока нет

- BQ 20 Z 95Документ23 страницыBQ 20 Z 95Renato HernandezОценок пока нет

- DRV 103Документ24 страницыDRV 103Rahul SharmaОценок пока нет

- Triple High-Side Mosfet Driver: DescriptionДокумент13 страницTriple High-Side Mosfet Driver: DescriptionDan EsentherОценок пока нет

- VLSI- תרגול 0 - Mosfet CapacitanceДокумент2 страницыVLSI- תרגול 0 - Mosfet CapacitanceRonОценок пока нет

- YamadaДокумент37 страницYamadaayush guptaОценок пока нет

- 7 - Murphy Power Ignition - Mpi 16 - Install MaintenanceДокумент129 страниц7 - Murphy Power Ignition - Mpi 16 - Install MaintenanceGibi EstradaОценок пока нет

- Drmos BLN01G52 Aoz5311 RTX3070Документ18 страницDrmos BLN01G52 Aoz5311 RTX3070techgamebr85Оценок пока нет

- Amplificador Case D IC PAM8610Документ17 страницAmplificador Case D IC PAM8610TiToОценок пока нет

- Ap3105na BCDДокумент9 страницAp3105na BCDlcd_vinay34Оценок пока нет

- Synthesis Strategies and Nanoarchitectonics For High Performance Transition MetalДокумент11 страницSynthesis Strategies and Nanoarchitectonics For High Performance Transition MetalAwais AhmadОценок пока нет

- 04 - Second-Order Effects On MOSFET Small Signal ModelДокумент27 страниц04 - Second-Order Effects On MOSFET Small Signal ModelWinnie LahОценок пока нет

- Basic of CircuitsДокумент115 страницBasic of CircuitsPiyushsinhОценок пока нет