Академический Документы

Профессиональный Документы

Культура Документы

Catlouge of Ring Granulator - TRF Make

Загружено:

Vijayakumar AtthuluriИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Catlouge of Ring Granulator - TRF Make

Загружено:

Vijayakumar AtthuluriАвторское право:

Доступные форматы

A TATA Enterprise

Ring Granulator

Technical Features

Specially designed for high capacity crushing of coal and lignite (range from 40 to 1700 TPH).

Unique crushing action results in higher output and lower power consumption.

Maximum feed size up to 500 mm.

Ideal for product size of (-) 20 mm, with uniform granular product.

Crushing action involves minimum attrition and hence produces minimum fines.

Maximum accessibility is provided to ease the routine inspections.

Easy replacement of wear and spare parts.

ATATA Enterprise

Ring Granulator

TRF's Ring Granulators are rugged, dependable units, specially designed for continuous high

capacity crushing of ROM coal and other medium hard friable materials. These are ideal machines

for crushing coal to a size suitable for pulverisation, in power stations. The unique crushing action by

combining impact and rolling compression in a Ring Granulator results in higher output with lower

power consumption. They offer better overall economy in terms of power consumption and

maintenance. Ring Granulators are available with operating capacities from 40 to 1700 tonnes per

hour and feed size up to 500 mm. Positive adjustment of clearance between the cage and the path of

the rings is provided to compensate for wear and to adjust or maintain product gradation. Internal

parts such as breaker plate, cage bars or screen plate, crushing rings and liners are made of abrasion

and shock resistant steels for optimum working life.

SPECIAL FEATURES

Positive Adjustability -Quick, easy external adjustment of the cage assembly can be done while the

crusher is running

Longer Parts Life - screen plate or cage bar wear compensated by simple adjustment to desired clearance

Automatic Removal of Tramp iron - rear access door allows fast, easy removal of debris

Hinged Cage - adjustable concentricity with the rotor balances wear evenly among all cage bars

Wide Hopper Opening - results in uniform, even feeding no bridges and material build-up

Ring Granulator

ATATA Enterprise

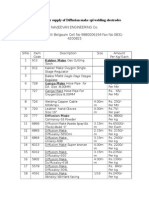

GeneralData

ModelNo.

TR24

TR33

TR36

TR41

TR42

TR120X270

TRM53

TRM54

TR160X330

TR180X330

HammerCircle RotorSpeed

Dia.(mm)

(RPM)

610

700

765

1120

1120

1210

1370

1350

1600

1800

720

720

720

720

720

720

720

720

720

600

Max.Feed

Size(mm)

Approximate

Capacity(TPH)

Wt.ofHeaviest

part.(Kg)

Total

weight(kg.)

200

200

300

275

275

300

350

300

400

400

120150

250300

450500

550600

600700

7501000

9001050

10501200

13001800

18002400

820

2100

4100

5750

6400

9000

12000

14000

15000

16000

44,00

6000

11,000

15,000

15,000

21,000

30,000

32,000

35,000

43000

ATATA Enterprise

Ring Granulator

Frame

Fabricated from heavy steel plates with large inspection front

and rear doors, fitted with dust tight seals. Access for further

maintenance is provided on the top. Doors on the sides

above the rotor shaft facilitate removal of the rotor without

completely dismantling the machine. Hydraulic door opening

arrangement (optional) can be provided, if required

Frame and Hopper Liners

Replaceable abrasion-resistant steel.

Rotor Assembly

Statically/dynamically balanced to operate with

minimum of vibration and noise. Weight concentrated

within rotor eliminates the external fly-wheels.

Rotor Shaft

Forged and heat treated alloy steel.

Suspension Bars

Duplex suspension bars are provided in all models.

Crushing Rings

Heavy cast Mn-steel toothed and/or plain Crushing

Rings depending upon applications.

Cage Frame

Breaker Plate

Replaceable abrasion resistant steel, depending on

requirement.

Cage Adjustment

Cage assembly can be easily moved by a ratchet

wrench and worm gear assembly either towards or

away from the path of crushing rings. Adjustment

which can be made while the granulator is in

operation, provides control over the product size

within permissible limits. The cage hinge bearing is

so located that in any adjusted position all parts of

cage face are practically equidistant from the rotor

assembly. This ensures even wear.

Tramp Iron Pocket

Tramp iron and uncrushables are prevented from

continuing around and back into the crushing

zone by a heavy deflector plate. The debris is

collected in a pocket and removed from access

door

Bearing

Heavy duty double row spherical roller bearings

with cast steel split type bearing housings with

labyrinth type seals.

Fabricated from heavy steel plate and supported from Lubrication

heavy hinged cage shaft at top and provided with adjusting Grease lubrication for small and medium size

mechanism at the bottom.

granulators. Oil splash lubrication system for

bigger models.

Cage Bars or Screen Plate

Trapezoidal cage bars are of replaceable, ensuring free

discharge. Screen plates are made from abrasion resistant Drive

steel. Selection of cage bars or screen plates depends on Direct coupled drives are recommended. For

smaller models V- Belts drive may be used.

application.

Ring Granulator

ATATA Enterprise

OverallDimensions

ModelNo.

TR24

TR33

TR36

TR41

TR42

TR53

TR54

TR120X270

TR160X330

TR180X330

2160

2490

2670

3390

3810

4840

5150

4312

5180

5180

810

1044

1250

1556

1500

1925

1925

1820

2185

2436

1380

1830

1970

2140

2140

2740

2740

2680

3082

3380

380

485

585

780

780

965

965

865

1090

1230

1276

1338

1455

2010

2300

3150

3410

2980

3490

3490

455

575

660

610

610

750

730

668

882

972

1288

1370

1510

2040

2360

3140

3470

2980

3530

3530

1070

1600

1760

1710

610

2130

2135

2313

2477

2780

1748

1990

2130

3,000

3,290

4,100

4,400

3,652

4,504

4504

NoteAlldimensionsareinmm.

Вам также может понравиться

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshОт EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshОценок пока нет

- Alwasy Step Ahead in TechnologyДокумент3 страницыAlwasy Step Ahead in TechnologyjtpmlОценок пока нет

- Fluid Coupling (Scoop Type) PST - Rating - SelectionДокумент2 страницыFluid Coupling (Scoop Type) PST - Rating - Selectionpravash2526100% (1)

- Aditya Tech Diary PDFДокумент155 страницAditya Tech Diary PDFSiddhant Satpathy100% (1)

- Wagon Tippler With Side Arm ChargerДокумент4 страницыWagon Tippler With Side Arm ChargerMRITUNJAYОценок пока нет

- ELECON GEAR Elign CouplingДокумент14 страницELECON GEAR Elign Couplingsatish kumar reddy100% (1)

- Barrel Reclaimers TRFДокумент4 страницыBarrel Reclaimers TRFkaustavОценок пока нет

- CHP SpecifictionДокумент36 страницCHP SpecifictionVaibhav Jain100% (1)

- RDSO Guidelines G-33 Rev.1Документ29 страницRDSO Guidelines G-33 Rev.1Ashish Goswami86% (7)

- Premium All Products 2019 PricelistДокумент35 страницPremium All Products 2019 PricelistShyam J VyasОценок пока нет

- Elecon ET Catalogue PDFДокумент42 страницыElecon ET Catalogue PDFVisnu Sankar86% (7)

- Elecon Standard Gear PresentationДокумент69 страницElecon Standard Gear Presentationeakinci6968100% (4)

- Geared MotorДокумент96 страницGeared MotorSaurabh jain50% (2)

- SIDE ARM CHARGER Design-R0 PDFДокумент8 страницSIDE ARM CHARGER Design-R0 PDFSripara KrishnaОценок пока нет

- Fcu Install Maint PDFДокумент36 страницFcu Install Maint PDFMonica Santos60% (5)

- Flexible Pin Bush CouplingДокумент3 страницыFlexible Pin Bush Couplingsunilshinday1_456107Оценок пока нет

- Elecon KCN Gear BoxДокумент43 страницыElecon KCN Gear BoxGourav Choudhuri100% (12)

- Ash Handling System Spec.d1.8 Tce HZL BhelДокумент10 страницAsh Handling System Spec.d1.8 Tce HZL BhelShameer MajeedОценок пока нет

- BOBR Wagon DetailsДокумент4 страницыBOBR Wagon DetailsZahoor AhmedОценок пока нет

- Pulverizers 101 - Part IДокумент9 страницPulverizers 101 - Part Iabo1510Оценок пока нет

- Wagon Tippler DesignДокумент34 страницыWagon Tippler DesignAnku Pandey71% (7)

- L& T Wagon Tippler Mannual - HMEL Site PDFДокумент156 страницL& T Wagon Tippler Mannual - HMEL Site PDFranajoy71971Оценок пока нет

- Elecon Conveyor Idlers CatalogueДокумент10 страницElecon Conveyor Idlers CatalogueB DAS100% (1)

- Elecon GearboxДокумент19 страницElecon GearboxShirley Farrace100% (3)

- Overhauling Report of Mill - 2BДокумент19 страницOverhauling Report of Mill - 2BbhaskarОценок пока нет

- Iom DSM100-36Документ27 страницIom DSM100-36rogueatdoorОценок пока нет

- Diffusion Make Welding ElectrodeДокумент9 страницDiffusion Make Welding ElectrodeSarah FrazierОценок пока нет

- Enexco BrochureДокумент35 страницEnexco BrochureErin CraigОценок пока нет

- SKF Bearing DesignationsДокумент0 страницSKF Bearing DesignationsPatrick BaridonОценок пока нет

- Elecon EON Series GearboxДокумент70 страницElecon EON Series GearboxSumit Chugh0% (1)

- Gear Coupling 2014Документ4 страницыGear Coupling 2014Dado Maja ArseninОценок пока нет

- Elecon Gear Box CatalogueДокумент15 страницElecon Gear Box CatalogueKARTHIGEYAN.R79% (14)

- Flender GearboxesДокумент98 страницFlender GearboxesRahul RoyОценок пока нет

- Elecon Gear Box O&M ManualДокумент38 страницElecon Gear Box O&M ManualSrinivasa Rao PallelaОценок пока нет

- Mill Bearings and Lubrication (TST)Документ28 страницMill Bearings and Lubrication (TST)Diego Alejandro100% (2)

- CM-1 Girth Gear ReportДокумент4 страницыCM-1 Girth Gear Reportsivareddy143100% (2)

- Erection Manual For FRP 943 BOWL MILLДокумент88 страницErection Manual For FRP 943 BOWL MILLLALCHAND RAWANIОценок пока нет

- 6.utilisation of Submerged Scraper Conveyors For The Removal of Boiler Bottom AshДокумент16 страниц6.utilisation of Submerged Scraper Conveyors For The Removal of Boiler Bottom AshmsdoharОценок пока нет

- Failure Analysis and Prospects of Modification in Industrial Belt Conveyor SystemДокумент3 страницыFailure Analysis and Prospects of Modification in Industrial Belt Conveyor SystemGogyОценок пока нет

- Gear Coupling FGCДокумент4 страницыGear Coupling FGCMandar PundeОценок пока нет

- Instruction Manual: For Installation, Operation & MaintenanceДокумент40 страницInstruction Manual: For Installation, Operation & MaintenanceAvinash GamitОценок пока нет

- Gear CouplingДокумент10 страницGear CouplingKlmdaya BashisОценок пока нет

- IS Code For StackerДокумент20 страницIS Code For StackerManish VermaОценок пока нет

- Maintenance of Crushers: R S BaislaДокумент52 страницыMaintenance of Crushers: R S BaislaRavindranath BheemisettyОценок пока нет

- Bearing BasicsДокумент69 страницBearing BasicsHashem Mohamed HashemОценок пока нет

- Bucket ElevatorsДокумент6 страницBucket Elevatorskingathur26681Оценок пока нет

- GearboxДокумент85 страницGearboxTMDОценок пока нет

- Type SDFC Sizes 290 To 1040 - EngДокумент2 страницыType SDFC Sizes 290 To 1040 - EngKUNALJAYОценок пока нет

- HSMS DescriptionДокумент2 страницыHSMS DescriptionVũ Văn Thành100% (1)

- Tech Spec. of EOT CraneДокумент7 страницTech Spec. of EOT CraneSuresh MuttaОценок пока нет

- Ball and Race MillДокумент76 страницBall and Race Millsandeep19861986100% (2)

- Cema Standar 502-2001 PDFДокумент10 страницCema Standar 502-2001 PDFjavier alvarez100% (1)

- Diff Mill LayoutsДокумент40 страницDiff Mill Layoutsrazen_inОценок пока нет

- Bag Filter Himenviro - O&m - Cement MillДокумент51 страницаBag Filter Himenviro - O&m - Cement Millsambhu0% (1)

- Belt SwayДокумент29 страницBelt SwayNishantKumarGauravОценок пока нет

- 40867Документ6 страниц40867showvik_1962Оценок пока нет

- Single Roll CrushersДокумент8 страницSingle Roll CrushersRinaldi SaputraОценок пока нет

- Single RollДокумент8 страницSingle RolltashdashОценок пока нет

- CrushersДокумент6 страницCrushersNguyễn LinhОценок пока нет

- Coal Crushers: Optimal Solutions For ComminutionДокумент6 страницCoal Crushers: Optimal Solutions For ComminutionNguyễn LinhОценок пока нет

- Ash HandlingДокумент30 страницAsh Handlingichig0_89Оценок пока нет

- Presentations Made at IPS-2012 - Day-2 at PMI, NTPC, NOIDA, UP - Aurbindo Hall - Session-12 Challenges of Structures, Handling & Storage - Paper 3 ESP Ash EvacuationДокумент31 страницаPresentations Made at IPS-2012 - Day-2 at PMI, NTPC, NOIDA, UP - Aurbindo Hall - Session-12 Challenges of Structures, Handling & Storage - Paper 3 ESP Ash EvacuationVijayakumar AtthuluriОценок пока нет

- Health of ASH DYKEДокумент48 страницHealth of ASH DYKEVijayakumar Atthuluri100% (2)

- Dadri Ash MoundДокумент8 страницDadri Ash MoundVijayakumar AtthuluriОценок пока нет

- SS 316 (CF8M) & SS 316L (CF3M)Документ1 страницаSS 316 (CF8M) & SS 316L (CF3M)Vijayakumar Atthuluri100% (2)

- Cast Basalt Information SheetДокумент4 страницыCast Basalt Information SheetVijayakumar AtthuluriОценок пока нет

- SS 316 & SS316LДокумент3 страницыSS 316 & SS316LVijayakumar AtthuluriОценок пока нет

- CAESAR II - Pipe Stress AnalysisДокумент6 страницCAESAR II - Pipe Stress Analysisnguyentrungsonctm7Оценок пока нет

- Corrosion TableДокумент2 страницыCorrosion TableVijayakumar AtthuluriОценок пока нет

- Feed DispenserДокумент7 страницFeed DispenserFoo He XuanОценок пока нет

- ASME B16.28 Wrought Steel Buttwelding Short Radius Elbows and Returns 1994Документ20 страницASME B16.28 Wrought Steel Buttwelding Short Radius Elbows and Returns 1994Luis OrtizОценок пока нет

- DBS3900 GSM Technical Description (V100R012 - 06) (PDF) - enДокумент89 страницDBS3900 GSM Technical Description (V100R012 - 06) (PDF) - enadnantk01Оценок пока нет

- BS 6920-2.2.3-2000+a2-2014 PDFДокумент10 страницBS 6920-2.2.3-2000+a2-2014 PDFabdulkadir aliОценок пока нет

- Tyco Alarm ValveДокумент22 страницыTyco Alarm ValveMohammed BaquarОценок пока нет

- Tempconversion PDFДокумент6 страницTempconversion PDFPravat TiadiОценок пока нет

- Ba LabMaster E 2518902 200040 - 355 - 06Документ53 страницыBa LabMaster E 2518902 200040 - 355 - 06moriz52Оценок пока нет

- Global Flexible Power SolutionsДокумент8 страницGlobal Flexible Power SolutionsTBS Máy Phát ĐiệnОценок пока нет

- Our New Catalogue Now Includes All of The Latest EFENДокумент15 страницOur New Catalogue Now Includes All of The Latest EFENRaju ChowdhuryОценок пока нет

- Functional Gage and Fixture DesignДокумент8 страницFunctional Gage and Fixture DesignAnonymous 7ZTcBn0% (1)

- 938 K PDFДокумент36 страниц938 K PDFJuanОценок пока нет

- Afl Fsm-60s Splicer Spec SheetДокумент2 страницыAfl Fsm-60s Splicer Spec SheetFiberOpticStockCoОценок пока нет

- Web ProgrammingДокумент3 страницыWeb Programminghitesh5Оценок пока нет

- Final BB Internal AuditДокумент3 страницыFinal BB Internal Auditahmed salahОценок пока нет

- LM24A-F 2 0 en PDFДокумент6 страницLM24A-F 2 0 en PDFIsael Chavero CallejasОценок пока нет

- Oracle Enhanced RetroPayДокумент22 страницыOracle Enhanced RetroPayhamdy200150% (2)

- Switching Technologies-1Документ28 страницSwitching Technologies-1Ali Kamil AldulimyОценок пока нет

- OptiqRoute Load Balancer - Transparent Mode With FirewallДокумент13 страницOptiqRoute Load Balancer - Transparent Mode With FirewallJavier GomezОценок пока нет

- Crane Transportation DesignДокумент65 страницCrane Transportation Designdawit100% (1)

- Manual de Utilizare Concasor BB300Документ20 страницManual de Utilizare Concasor BB300lucianchiritaОценок пока нет

- FADesignManual v2 12 SPДокумент88 страницFADesignManual v2 12 SPmichael17ph2003Оценок пока нет

- MAZDA Tribute - Instrukcja Obslugi (2003) ENGДокумент245 страницMAZDA Tribute - Instrukcja Obslugi (2003) ENGjszbpОценок пока нет

- 2018assignment 2Документ3 страницы2018assignment 2Waqar RaoОценок пока нет

- Nas 3610Документ186 страницNas 3610onur onurОценок пока нет

- Export PDF TablesДокумент2 страницыExport PDF TablesMikeОценок пока нет

- Manual Del Operador altec-AM50-55-50E-55E-O PDFДокумент110 страницManual Del Operador altec-AM50-55-50E-55E-O PDFFabian Andres Cely67% (3)

- Kundan Switch Gear Private Limited Was Established in 2001Документ12 страницKundan Switch Gear Private Limited Was Established in 2001vivek_jangir2007Оценок пока нет

- Ba Elk 02 - En-UsДокумент132 страницыBa Elk 02 - En-UssldksОценок пока нет

- 1Ø Service Manual: Engineered For LifeДокумент76 страниц1Ø Service Manual: Engineered For LifejewettwaterОценок пока нет