Академический Документы

Профессиональный Документы

Культура Документы

LO Procedure Sample

Загружено:

Nenad Spiki VukomanovicАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

LO Procedure Sample

Загружено:

Nenad Spiki VukomanovicАвторское право:

Доступные форматы

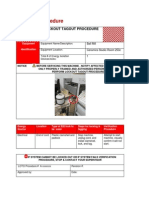

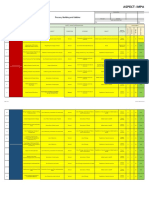

LOCKOUT / TAGOUT PROCEDURES

DEPT:

ASSET NO.

EQUIPMENT IDENTIFICATION

ASSET NAME:

RELATED EQUIPMENT:

DPT050

PPP021

ENERGY SOURCES AND MAGNITUDE

TYPE

NO.

SOURCES

ELECTRICAL

PNEUMATIC

HYDRAULIC

CHEMICAL

WATER

STORED ENERGY

NATURAL GAS

1

1

ELECTRICAL

480VAC

100PSI

TURN OFF POWER AND

LOCK AND TAG OUT

WITH LOCK.

LOCATED ON SIDE

OF MACHINE

PNEUMATIC

TYPE

AMOUNT

TURN OFF MAIN

PADLOCK AND TAG

LG. PLUG LOCKOUT

AIR COUPLING LOCKOUT

SM. BALL VALVE LOCK

LG. BALL VALVE LOCK

BREAKER LOCK

BLOCKING DEVICE

AIR SUPPLY DUMP VALVE,

LOCK AND TAGOUT

WITH LOCK.

LOCATED ON BACK

OF MACHINE

APPROVED BY:

John Doe

PUNCH PRESS 55 TON

LOCATIONS AND LOTO DEVICE TYPE NEEDED

LARGEST

MAGNITUDE

EQUIPMENT NEEDED TO LOCKOUT OR CONTROL

IDENTIFIED ENERGY SOURCE

REVISION:

(date)

REVIEWED 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015

LOCKOUT/TAGOUT WORK INSTRUCTIONS

1

NOTIFY OPERATOR, SUPERVISOR AND ANY AFFECTED PERSONNEL OF IMPENDING WORK TO BE PERFORMED.

CLEAR MACHINE OF ALL MATERIALS/PRODUCT AND TURN MACHINE OFF BY DEPRESSING THE "OFF" OR "E-STOP" BUTTON/S

TURN OFF MAIN ELECTRICAL DISCONNECT AND LOCKOUT.

TURN OFF MAIN AIR DUMP VALVE AND LOCK OUT. WAIT TILL AIR BLEEDS FROM SYSTEM.

WHEN THE ABOVE STEPS ARE COMPLETED TRY TO START THE MACHINE USING THE START OR ON BUTTONS TO VERIFY THAT

THE MACHINE IS CORRECTLY LOCKED OUT. AFTER VERIFICATION DEPRESS THE STOP BUTTONS AGAIN.

MAKE ABSOLUTELY SURE ALL PERSONNEL AND TOOLS ARE REMOVED FROM THE EQUIPMENT.

CONFIRM ALL GUARDS AND COVERS ARE ON AND ALL ELECTRICAL ENCLOSURES ARE CLOSED.

WHEN ALL THE ABOVE STEPS ARE COMPLETE THE AUTHORIZED EMPLOYEE WHO PLACED THE LOCKOUT DEVICE/S ON THE

MACHINE MAY NOW REMOVE THEM AND PROCEDE WITH START-UP AND/OR TEST.

AFTER SUCCESSFUL TEST THE AUTHORIZED EMPLOYEE NOTIFIES THE OPERATOR AND/OR AFFECTED PERSONNEL THAT THE

MACHINE IS READY FOR USE.

REMOVING THE LOCKOUT/TAGOUT DEVICE

AUTHORIZED PERSONNEL

AFFECTED PERSONNEL

MACHINE OPERATORS

SETUP AND LEADHANDS

MAINTENANCE OR MANAGEMENT PERSONNEL

ALL PERSONNEL

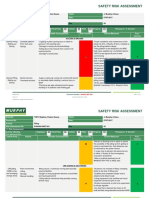

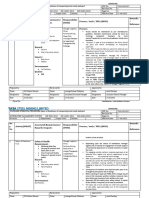

LOCKOUT / TAGOUT PROCEDURES

DEPT:

ASSET NO.

EQUIPMENT IDENTIFICATION

ASSET NAME:

RELATED EQUIPMENT:

DPT051

ASE014

ENERGY SOURCES AND MAGNITUDE

TYPE

NO.

SOURCES

ELECTRICAL

PNEUMATIC

HYDRAULIC

CHEMICAL

WATER

STORED ENERGY

NATURAL GAS

1

1

ELECTRICAL

480VAC

100PSI

BACK OR SIDE ON

CORD DROP

LARGE PLUG LOCKOUT

LOCK AND TAG

TYPE

AMOUNT

BACK OF WELDER

PADLOCK AND TAG

LG. PLUG LOCKOUT

AIR COUPLING LOCKOUT

SM. BALL VALVE LOCK

LG. BALL VALVE LOCK

BREAKER LOCK

BLOCKING DEVICE

LARGE PLUG LOCKOUT

LOCK AND TAG

John Doe

INLINE TIG WELDER

PNEUMATIC

APPROVED BY:

2/6/2007

LOCATIONS AND LOTO DEVICE TYPE NEEDED

LARGEST

MAGNITUDE

EQUIPMENT NEEDED TO LOCKOUT OR CONTROL

IDENTIFIED ENERGY SOURCE

REVISION:

(date)

REVIEWED 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015

LOCKOUT/TAGOUT WORK INSTRUCTIONS

1

NOTIFY OPERATOR, SUPERVISOR AND ANY AFFECTED PERSONNEL OF IMPENDING WORK TO BE PERFORMED.

CLEAR MACHINE OF ALL MATERIALS/PRODUCT AND TURN MACHINE OFF BY DEPRESSING THE "OFF" OR "E-STOP" BUTTON/S

UNPLUG 480 VOLT TWIST-LOCK. PLACE LARGE PLUG LOCKOUT DEVICE OVER MALE PLUG AND LOCK OUT.

UNHOOK 1/2" QUICK COUPLER. PLACE LARGE PLUG LOCKOUT OVER COUPLER AND LOCK OUT. CAN ALSO USE COUPLING LOCK.

WHEN THE ABOVE STEPS ARE COMPLETED TRY TO START THE MACHINE USING THE START OR ON BUTTONS TO VERIFY THAT

THE MACHINE IS CORRECTLY LOCKED OUT. AFTER VERIFICATION DEPRESS THE STOP BUTTONS AGAIN.

MAKE ABSOLUTELY SURE ALL PERSONNEL AND TOOLS ARE REMOVED FROM THE EQUIPMENT.

CONFIRM ALL GUARDS AND COVERS ARE ON AND ALL ELECTRICAL ENCLOSURES ARE CLOSED.

WHEN ALL THE ABOVE STEPS ARE COMPLETE THE AUTHORIZED EMPLOYEE WHO PLACED THE LOCKOUT DEVICE/S ON THE

MACHINE MAY NOW REMOVE THEM AND PROCEDE WITH START-UP AND/OR TEST.

AFTER SUCCESSFUL TEST THE AUTHORIZED EMPLOYEE NOTIFIES THE OPERATOR AND/OR AFFECTED PERSONNEL THAT THE

MACHINE IS READY FOR USE.

REMOVING THE LOCKOUT/TAGOUT DEVICE

AUTHORIZED PERSONNEL

AFFECTED PERSONNEL

MACHINE OPERATORS

SETUP AND LEADHANDS

MAINTENANCE OR MANAGEMENT PERSONNEL

ALL PERSONNEL

LOCKOUT/TAGOUT DOCUMENT REVISION TRACKING

DATE/REV.

REASON FOR REVISION

3/20/2006 INITIAL LOCKOUT / TAG OUT INSTRUCTIONS

INITIALS

MSK

Вам также может понравиться

- Caramics LotoДокумент7 страницCaramics LotoAhmad MensaОценок пока нет

- 9C - MSDS FiberglassДокумент3 страницы9C - MSDS FiberglassSon TranОценок пока нет

- Fiberglass Cloth SdsДокумент5 страницFiberglass Cloth Sdslance boxОценок пока нет

- Hse Plan 2012Документ1 страницаHse Plan 2012Arief FirmansyahОценок пока нет

- Toolbox Talk 12 Banks Men Lifting GearДокумент2 страницыToolbox Talk 12 Banks Men Lifting GearSajid HussainОценок пока нет

- Emergency Plan CardsДокумент2 страницыEmergency Plan CardsJeremy NashОценок пока нет

- GEN-038 Balance Turbine Unit - All TypesДокумент3 страницыGEN-038 Balance Turbine Unit - All Typesacanbasri1980Оценок пока нет

- Osha 3761Документ1 страницаOsha 3761api-301892310Оценок пока нет

- BOMMI-PRD-03.0008-Rev.00 - Personal Protective EquipmentДокумент10 страницBOMMI-PRD-03.0008-Rev.00 - Personal Protective Equipmentfundatia_gaudeamusОценок пока нет

- Task Risk Assessment FormДокумент8 страницTask Risk Assessment FormNurpadmi KusbiantoroОценок пока нет

- Risk - Assessment - Form 14th Oct 2017Документ2 страницыRisk - Assessment - Form 14th Oct 2017hunstreteОценок пока нет

- Form Accident ReportДокумент4 страницыForm Accident ReportKarthik SОценок пока нет

- CL-07-02 Crane Lift Study ChecklistДокумент7 страницCL-07-02 Crane Lift Study Checklisthanes0% (1)

- Risk Assessment Hanging DoorsДокумент11 страницRisk Assessment Hanging DoorsMitchRappОценок пока нет

- Warehouse Risk Assessment Aldir II IWPPДокумент25 страницWarehouse Risk Assessment Aldir II IWPPMadhu MohanОценок пока нет

- Planned Job Observation Plan (Schedule) : Project Name: 380Kv DC Ohtl in Qiddiya Area ELEMENT 5.20.1Документ4 страницыPlanned Job Observation Plan (Schedule) : Project Name: 380Kv DC Ohtl in Qiddiya Area ELEMENT 5.20.1Shafie Zubier100% (1)

- Personal Protective EquipmentДокумент10 страницPersonal Protective EquipmentXozanОценок пока нет

- Sugeng Siswanto CV's May16Документ6 страницSugeng Siswanto CV's May16Sitole S SiswantoОценок пока нет

- All FormsДокумент18 страницAll FormsSuhendraОценок пока нет

- First Aid ENGДокумент46 страницFirst Aid ENGfaik395Оценок пока нет

- Safety Alert - Danger of Infection - January 2010Документ1 страницаSafety Alert - Danger of Infection - January 2010Meklo1Оценок пока нет

- Operating in Confined SpacesДокумент4 страницыOperating in Confined SpacesFaiqoh NahareyОценок пока нет

- Segregation of Paper and Cardboard Waste, Polymeric Materials Waste, Glass and TiresДокумент10 страницSegregation of Paper and Cardboard Waste, Polymeric Materials Waste, Glass and Tiresfaik395Оценок пока нет

- Loto Standard Operating Procedure Sop - Loto - : Lockout PointsДокумент2 страницыLoto Standard Operating Procedure Sop - Loto - : Lockout PointsK3L ULP Tanjung RedebОценок пока нет

- Hazardous Area Chart - BartecДокумент1 страницаHazardous Area Chart - BartecPutraSumatera100% (1)

- GEN-021 Fact FindingДокумент3 страницыGEN-021 Fact Findingacanbasri1980Оценок пока нет

- Ohs-Pr-09-03-F10 (A) Planned Job Observation ReportДокумент1 страницаOhs-Pr-09-03-F10 (A) Planned Job Observation ReportShafie ZubierОценок пока нет

- OHS 5.3.1aPreventiveandCorrectiveActionFormДокумент1 страницаOHS 5.3.1aPreventiveandCorrectiveActionFormfcleong69Оценок пока нет

- RA - Ohl.019. Working in Close Proximity of OHL.Документ12 страницRA - Ohl.019. Working in Close Proximity of OHL.marvinОценок пока нет

- Risk Management and AssessmentДокумент50 страницRisk Management and Assessmentfaik395Оценок пока нет

- GoldenRules54StE Poster PDFДокумент1 страницаGoldenRules54StE Poster PDFAbdelkader BOUKHOUSОценок пока нет

- Safety Toolbox Meeting FormДокумент19 страницSafety Toolbox Meeting FormTuntun TatОценок пока нет

- 7 Global Golden Rules of Safety - Rule 4 - Machinery & Rotary Part Protection - DraftДокумент7 страниц7 Global Golden Rules of Safety - Rule 4 - Machinery & Rotary Part Protection - DraftPedro ViegasОценок пока нет

- Hazard DatabaseДокумент1 140 страницHazard DatabaseVero ColladoОценок пока нет

- Loto VeneervisionДокумент2 страницыLoto Veneervisionapi-362234935Оценок пока нет

- Confined Space ENGДокумент30 страницConfined Space ENGfaik395Оценок пока нет

- Lockout Procedure: Image Found and DisplayedДокумент2 страницыLockout Procedure: Image Found and DisplayedvanausabОценок пока нет

- Safety Alert Safety Alert: BackgroundДокумент1 страницаSafety Alert Safety Alert: BackgroundAnonymous h0yGTDQWZОценок пока нет

- BSA Alert 025 Grinder FatalityДокумент1 страницаBSA Alert 025 Grinder FatalitysubhanmusadiqОценок пока нет

- Blank A3 PPS Ver2Документ2 страницыBlank A3 PPS Ver2Lpitt56Оценок пока нет

- Safety Risk Assessment: THFC Stadium, Paxton House J. Murphy & Sons 07/07/2017 Piling POH0001/MST/001 Rev 00Документ14 страницSafety Risk Assessment: THFC Stadium, Paxton House J. Murphy & Sons 07/07/2017 Piling POH0001/MST/001 Rev 00nico AlpaОценок пока нет

- Risk Ass. - AD 417 - Installation of SocketДокумент6 страницRisk Ass. - AD 417 - Installation of SocketnsadnanОценок пока нет

- 4.5.3!01!06 First Aid Property Environmental ReportДокумент4 страницы4.5.3!01!06 First Aid Property Environmental Reportloveson709Оценок пока нет

- F006A CoSHH Assessment FormДокумент2 страницыF006A CoSHH Assessment FormShahlaОценок пока нет

- Aspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesДокумент4 страницыAspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesSir ZenОценок пока нет

- Site Management Form: Project Monthly SHEQ Wall Activity PlannerДокумент3 страницыSite Management Form: Project Monthly SHEQ Wall Activity PlannerParashuram PatilОценок пока нет

- Formas 300 OSHA - 2004Документ3 страницыFormas 300 OSHA - 2004violet HumeОценок пока нет

- PPE Matrix AgrocelДокумент2 страницыPPE Matrix AgrocelBhakti MahbubaniОценок пока нет

- Moving Convoy Wide Load - RA-R9-01-014-01Документ2 страницыMoving Convoy Wide Load - RA-R9-01-014-01cmrig74Оценок пока нет

- New Osha300form1 1 04Документ3 страницыNew Osha300form1 1 04Anonymous YTiBI3P3tОценок пока нет

- Safe Driving - Defensive DrivingДокумент20 страницSafe Driving - Defensive Drivingfaik395Оценок пока нет

- TOPIC: Demolition SafetyДокумент1 страницаTOPIC: Demolition SafetyMohamed HamdallahОценок пока нет

- Safety - Preventing Serious Injury and Fatalities - Chevrons Field Guide - Part 1Документ12 страницSafety - Preventing Serious Injury and Fatalities - Chevrons Field Guide - Part 1Priyo DjatmikoОценок пока нет

- 5 PSI Questions: Ask Isk Dentification ArdДокумент2 страницы5 PSI Questions: Ask Isk Dentification ArdZaki ChaabnaОценок пока нет

- Unloading of EWPs From ContainersДокумент10 страницUnloading of EWPs From ContainersPirashanth SathananthanОценок пока нет

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Документ6 страницRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008Оценок пока нет

- Erction and Dismantle ScaffoldingДокумент4 страницыErction and Dismantle Scaffoldingdownload dokumenОценок пока нет

- Yorkville AM100 Service ManualДокумент10 страницYorkville AM100 Service Manualcaimanater100% (1)

- Control of Hazardous Energy by Means of LOTO (Lock Out - Tag Out)Документ20 страницControl of Hazardous Energy by Means of LOTO (Lock Out - Tag Out)Huzaifa SafdarОценок пока нет

- DC REGULATED POWER SUPPLY NP-9912 - Service - Manual PDFДокумент12 страницDC REGULATED POWER SUPPLY NP-9912 - Service - Manual PDFDa ElОценок пока нет

- DIY UX AuditДокумент28 страницDIY UX Auditmerdy100% (1)

- Learn Applications For Crow (Amsaa), Power Law and Other Rga Models Using Reliasoft RgaДокумент1 страницаLearn Applications For Crow (Amsaa), Power Law and Other Rga Models Using Reliasoft RgaTomi RizkiОценок пока нет

- Monthly Planning SheetДокумент1 страницаMonthly Planning SheetPawan ChaturvediОценок пока нет

- Quality Assurance Specialist in NJ NY Resume Fred PuchalaДокумент2 страницыQuality Assurance Specialist in NJ NY Resume Fred PuchalaFredPuchalaОценок пока нет

- Qlight Total Catalogue (En)Документ446 страницQlight Total Catalogue (En)Anonymous MDkp0hnb3lОценок пока нет

- Fleet Parts StorekeeperДокумент2 страницыFleet Parts StorekeeperBright Edward NasamuОценок пока нет

- Beams & LintelsДокумент29 страницBeams & LintelsPWQGroupОценок пока нет

- Sage X3 Positioning and MessagingДокумент23 страницыSage X3 Positioning and MessagingMiguel FelicioОценок пока нет

- Ground Fault Neutralizer (GFN) Questions & Answers: RD TH THДокумент5 страницGround Fault Neutralizer (GFN) Questions & Answers: RD TH THDolyОценок пока нет

- SmartSense BrochureДокумент6 страницSmartSense BrochuremrsrinathОценок пока нет

- MIF Int ControlsДокумент15 страницMIF Int ControlsjefrsnОценок пока нет

- Final Project - Mayela Gonzalez PDFДокумент120 страницFinal Project - Mayela Gonzalez PDFRuaa safi gmail.com 1991 R4Оценок пока нет

- Audit SkillsДокумент36 страницAudit SkillsSudhagarОценок пока нет

- The Nature of Industrial BuyingДокумент40 страницThe Nature of Industrial Buying99862123780% (1)

- Cameron - Orbid Valves - AD01201VДокумент28 страницCameron - Orbid Valves - AD01201VmubeennavazОценок пока нет

- LikithДокумент6 страницLikithBhaskar Rao PОценок пока нет

- Global Partner Program - Training and Certification - Learning Path OptionsДокумент51 страницаGlobal Partner Program - Training and Certification - Learning Path OptionsFabioОценок пока нет

- SOP For Breakdown of Vehicle - 17. Rev-2Документ3 страницыSOP For Breakdown of Vehicle - 17. Rev-2syed aquibОценок пока нет

- Air Line Pilot January 2013Документ56 страницAir Line Pilot January 2013kfcarp29030% (1)

- NCR Tracking Log AAILДокумент5 страницNCR Tracking Log AAILssenthil04Оценок пока нет

- Previews 1870537 Pre PDFДокумент9 страницPreviews 1870537 Pre PDFHedi Ben MohamedОценок пока нет

- The Link Between Business Strategy and InformationДокумент20 страницThe Link Between Business Strategy and InformationjlobovargasОценок пока нет

- WPS& WQRДокумент132 страницыWPS& WQRAby Jacob Mathews100% (3)

- Technical AnalysisДокумент16 страницTechnical Analysismanju09535Оценок пока нет

- Cloud ComputingДокумент29 страницCloud Computingtanishq_5774371100% (2)

- DME Mould Cooling Catalogue CompleteДокумент84 страницыDME Mould Cooling Catalogue CompleteSergio Osorio0% (1)

- Credit Best CompaniesДокумент157 страницCredit Best CompaniessureshОценок пока нет

- Assignment 2.1 ACCTG020 (Accounting For Scrap, Goods, and Defective Goods)Документ6 страницAssignment 2.1 ACCTG020 (Accounting For Scrap, Goods, and Defective Goods)Xyra ArsolerОценок пока нет

- JDNFKДокумент1 страницаJDNFKCathy OraldeОценок пока нет