Академический Документы

Профессиональный Документы

Культура Документы

Tuned LCST Thermo-Responsive PNIPAAm Copolymers With Hydrophobic Spacers

Загружено:

Noor FaizahАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tuned LCST Thermo-Responsive PNIPAAm Copolymers With Hydrophobic Spacers

Загружено:

Noor FaizahАвторское право:

Доступные форматы

Macromol. Symp.

2007, 251, 3340

DOI: 10.1002/masy.200750505

Thermo-Responsive PNIPAAm Copolymers with

Hydrophobic Spacers

Florentina Stoica,1 Aline F. Miller,1 Cameron Alexander,2 Alberto Saiani*1,3

Summary: We have synthesised and characterised three sets of acryloyl(amino-acid)/

NIPAAm co-polymers. Three different co-monomers were synthesised and copolymerized with N-isopropylacrylamide (NIPAAm) by free radical polymerization in

different molar ratios (12:1, 9:1, and 6:1). All series contain aliphatic spacers and

are carboxylic terminated. The effect of co-monomer nature and content on the glass

transition and the LCST transition in solution has been investigated. The main factor

affecting the glass transition and the LCST of the polymer was found to be the side

chain length of the co-monomer. The introduction of the co-monomer resulted in an

overall increase in the polymer hydrophobicity which led to a decrease of both the

polymer glass transition and the LCST transition observed in solution.

Keywords: copolymer; PNIPAAm; thermo-responsive

Introduction

Polymers displaying phase transitions in

aqueous solution from a hydrophilic to

hydrophobic state are of widespread interest as smart biomedical materials.[1]

The prototypical polymer in this class is

poly(N-isopropylacrylamide) (PNIPAAm)

and co-polymers derived from this basic

material. One interesting feature of these

polymers is that the lower critical solution

transition (LCST) is observed in water

around body temperature[2] i.e. 37 8C.

These materials are currently being used

in a variety of applications including cell

attachment, drug release, separation membranes and tissue engineering.[36]

The LCST transition in PNIPAAm can

be triggered using a variety of external

stimuli such as temperature, pH and solvent

composition. The two main effects responsible for the LCST are hydrophobic and

1

School of Chemical Engineering and Analytical

Science, The University of Manchester, Sackville

Street, PO Box 88, Manchester, M60 1QD, UK

E-mail: A.Saiani@manchester.ac.uk

School of Pharmacy, University of Nottingham, University Park, Nottingham, NG7 2RD, UK

School of Materials, The University of Manchester,

Grosvenor Street, Manchester, M1 7HS, UK

hydrogen-bonding interactions. The exact

mechanism and the role of each type of

interaction are still debated in the literature.[13] The introduction of co-monomers

in the polymer chain has a significant effect

on the LCST; hydrophobic co-monomers

lower the LCST while hydrophilic comonomers increasing it.ref

In this work we have investigated the

influence of hydrophobicity and co-monomer content on the LCST behaviour of a set

of PNIPAAm based co-polymers. The

generic chemical structures of NIPAAm

and the co-monomers used are presented in

Figure 1.

The co-monomers used are acidic and

have hydrophobic spacer of varying length.

Their hydrophobicity increases with increasing spacer length.

Experimental Part

Reagents and Solvents

All the reagents and solvents used for the

synthesis and the characterisation of the

co-monomers and co-polymers were purchased from Sigma Aldrich and used as

received except for N-isopropylacrylamide

(NIPAAm) and 4,40 -azoisobutyronitrile

Copyright ! 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

33

34

Macromol. Symp. 2007, 251, 3340

H 2C

CH

H2C

NH

H3C

CH

NH

CH2 n

CH3

O

OH

n = 3 : -acryloylaminobutyric acid

n = 5 : 6-acryloylaminohexanoic acid

n = 10 : 11-acryloylaminoundecanoic acid

N-isopropylacrylamide

Figure 1.

Chemical structure of monomer and co-monomers used for the polymer synthesis.

(AIBN) which were purified by re-crystallisation from hexane and methanol respectively.

Synthesis of Co- Monomers

The co-monomers where synthesised as

described by Kuckling et al.[7] following the

synthetic route shown in Figure 2. The

synthesis was carried out in a two-neck

vessel under nitrogen atmosphere using the

Schotten-Baumann reaction conditions.[8]

The amino acids were first added to a

NaOH water or ethanol solution depending

on the amino acid used. The vessel was then

cooled to 0 8C in an ice bath and acryloyl

chloride added drop-wise while the suspension was stirred. The reaction mixture was

further stirred for two hours. The residual

solid phase was then removed by filtration

and the solution acidified to pH ! 1.5 by

adding drop-wise concentrated HCl. The

aqueous phase was extracted three times

using ethyl acetate and the resulting organic

phase was washed with deionised water in

order to eliminate the salt that formed as a

secondary product of the reaction. Water

was then removed from the system using

anhydrous calcium chloride, CaCl2. The

solution was filtered and the solvent finally

removed using a rotary evaporator while

the vessel was cooled in ice-cold water. The

co-monomers were obtained in the form of

white-yellow powders. The reaction conversion rates ranged between 56 and 72% (wt.)

depending on the amino acid used.

Infrared spectroscopy was used to characterise the co-monomers. The experiments were carried out on the powder

samples by ATR using a Thermo Nicolet

FTIR spectrometer. Absorption bands

characteristic of the COOH terminal group

of the co-monomers were observed around

9001000 cm"1. The presence of the CC

was confirmed by the presence of absorption bands at 900, 1200 and 1600 cm"1. The

co-monomers were used as obtained for the

synthesis of the co-polymers.

H2C

H2C

NH2

CH

CH2 n

+

O

CH

Schotten-Baumann

NH

CH2 n

conditions

Cl

O

HCl

OH

O

acryloyl chloride

amino acid

OH

co-monomer

Figure 2.

Scheme of the route used for the synthesis of the co-monomers.

Copyright ! 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.ms-journal.de

Macromol. Symp. 2007, 251, 3340

35

Synthesis of PNIPAAm and Co-Polymers

PNIPAAm and its co-polymers were synthesised by solution free radical polymerization as described by Alarcon et al.[9]

(Figure 3). The same reaction conditions

were used to synthesise all our polymers.

The desired quantity of monomers and

co-monomers were first dissolved in isopropanol in a Schlenk vessel. Subsequently

the initiator (AIBN) was added to the

solution. In order the remove the oxygen

from the solution three freeze-thaw cycles

were performed. The vessel was then

placed in a thermostated oil-bath at 65 8C

for 24 hours in order for the reaction to

occur. The polymers were recovered

by precipitation in diethyl ether and

purified by dissolution and precipitation

in deionised water at 50 8C. The solid

precipitate was separated from the liquid

phase by centrifugation at 6000 rpm for

15 minutes. The washing-centrifugation

process was carried out three times. Finally

the samples were freeze-dried for 2 days.

The polymers were obtained in a white

powder form.

Three sets of co-polymers were synthesised using the 3 co-monomers shown in

figure 1. For each set three NIPAAm/comonomer molar ratios were used: 6:1, 9:1

and 12:1. The nomenclature used to name

the co-polymers is presented in Table 1.

The exact composition of the co-polymer

was measured using 1H NMR. For this

purpose the sample were dissolved in

deuterated chloroform at 200 mg ml"1

and measurements were performed at

H2C

H2C

CH

NH

H3C

NIPAAm

+

CH3

25 8C on a Bruker RDV500 spectrometer

(500 MHz). To confirm the structure of

samples the following peaks were used:

11.5 ppm (CH3, NIPAAm only), 1.8

2 ppm (CH, polymer backbone), 1.53.5

ppm (CH2, co-monomers side chains), 3.5

4 ppm (NH, side chains), 44.5 ppm (CH,

neighboring CH3 NIPAAm only) and

1112 ppm (COOH, co-monomers side

chains and end groups). In order to calculate the real NIPAAm/co-monomer molar

ratio of each co-polymer the following

peaks at 1.53.5 ppm, 44.5 ppm and

11.5 ppm were used. As can be seen

from Table 1 the measured molar ratios

are in very good agreement with the feed

ratios used.

Number and mass-average molecular

weights (Mn and Mw) and the polydispersities (Mw/Mn) of the polymers were determined by gel permeation chromatography

(GPC) and are listed in Table 1. A PLGel

column (300 $ 10 mm) was used with tetrahydrofuran (THF) (1 ml min"1) as the

mobile phase and dodecane as internal

marker. The injection concentration was

typically 0.2% of polymer in 0.1 ml THF.

The eluents were monitored using a Gilson

Model 132 detector. Polystyrene was used

as calibration standard and therefore all the

results are given in polystyrene equivalent

molecular weight.

PNIPAAm was synthesised and characterised using the same procedures as described for the co-polymers. The weight-average

molecular weight of the PNIPAAm used was

8100 Da.

CH

*

isopropanol

NH

CH2 n

CH

NH

CH

OH

co-monomer

NH

AIBN

CH2

H3C

O

CH3

O

OH

co-polymer

Figure 3.

Scheme of the route used to synthesise the co-polymers.

Copyright ! 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.ms-journal.de

36

Macromol. Symp. 2007, 251, 3340

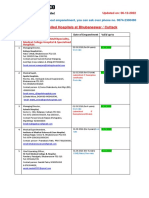

Table 1.

Structure nomenclature, composition, weight-average molecular weight and polydispersity of the copolymers

synthesised.

NIPAAM/co-monomer

feed molar ratio

n=3

*

CH

NH

n=5

CH

NH

CH3

O

CH

CH2

H3C

n = 10

CH

NH

CH3

OH

CH

CH

NH

OH

CH2

H3C

CH3

10

OH

CP(n 3)-9-COOH

CP(n 3)-12-COOH

CP(n 5)-6-COOH

CP(n 5)-9-COOH

CP(n 5)-12-COOH

CP(n 10)-6-COOH

CP(n 10)-9-COOH

CP(n 10)-12-COOH

8.9:1

11.6:1

5.6:1

9.2:1

11.3:1

6.2:1

9.1:1

11.5:1

6200

3800

2400

5700

3500

7900

6500

10100

2.2

1.2

1.8

1.4

1.3

1.4

2.4

1.7

Differential Scanning Calorimetry (DSC)

DSC experiments were performed using a

DSC Q100 from TA Instruments equipped

with an autosampler and a RCS cooling

system. 2.5 to 3 mg of powder samples were

placed in a standard aluminum pan that was

not hermetically sealed. The samples were

subjected to 3 heating-cooling cycles from

10 to 200 8C at 10 8C min"1 under dry

nitrogen atmosphere. The glass transition

were measured during the 2nd and 3rd

heating scan.

UV/Vis Spectrometry

UV/Vis spectrometric measurements were

performed using a Perkin-Elmer Lambda

40 spectrometer at a fixed wavelength of

600 nm. Solutions were prepared in deionised water at 3 different concentrations: 1,

5 and 10 mg ml"1.

Microcalorimetry

Microcalorimetric measurements were performed using a Setaram DSC III microcalorimeter. Solutions were prepared using

NH

Nomenclature

6:1

9:1

12:1

NIPAAm/co-monomer

molar composition

6:1

9:1

12:1

Molecular weight (Mw)/Da

6:1

9:1

12:1

Polydispersity (Mw/Mn)

6:1

9:1

12:1

NH

CH2

H3C

deionised water at 20 mg ml"1 concentration. Standard stainless steel pans were

used and deionised water was used as reference. For each sample 4 heating-cooling

cycles from 5 to 60 8C at 1 8C min"1 were

performed. The LCST temperature was

recorded as the maximum of the transition

peak.

Results and Discussion

In Figure 4 the Tg versus the co-monomer

chain length is presented for each NIPAAm

co-polymer. The glass transition for pure

PNIPAAm was found to be !130 8C.[12]

As can be seen from Figure 4 for n 3

and n 5 the polymer glass transition is

weakly affected by the presence of comonomers. For n 5 and a NIPAAm/

co-monomer ratio of 6:1 the glass transition

is found to decrease by only 4 8C. When

the side chain length is increased to n 10

the polymer glass transition is found

to decrease significantly by 20 to 30 8C

Copyright ! 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.ms-journal.de

Tg [C]

Macromol. Symp. 2007, 251, 3340

37

molar ratio [12:1]

molar ratio [9:1]

molar ratio [6:1]

135

130

125

120

115

110

105

100

95

0

10

chain length [no.CH 2]

Figure 4.

Co-polymers Tg vs. co-monomer chain length for different NIPAAm/co-monomer molar ratios.

depending on the NIPAAm:co-monomer

molar ratio. For all chain lengths investigated the glass transition is found to

decrease with increasing co-monomer content. It is well known that the glass

transition of polymers is affected by the

presence of flexible side chains along their

backbone.[10,11] These side chains increase

the overall polymer chain mobility resulting

in a decrease of the glass transition. For the

set of polymers investigated here it is

interesting to note that the effect of the

presence of co- monomer with flexible side

chains on the polymer glass transition only

becomes significant for the co-monomer

with the longest side chain i.e.: n 10. The

effect of the co-monomer on the polymer

glass transition is also more pronounced for

higher co-monomer content.

PNIPAAm and their co-polymers are

known to have a LCST transition around

body temperature. Below the LCST the

polymer is soluble and clear transparent

solutions are formed. When the temperature is increased above the LCST the polymer precipitates out of solution resulting in

the solution becoming cloudy. The polymer

through the LCST goes from an extended

to a globular conformation. This transition is driven mainly by hydrophobic and

3.5

Absorbance [a.u.]

3

2.5

2

cooling

heating

1.5

1

0.5

0

20

23

26

29

32

35

38

41

44

47

50

Temperature [C]

Figure 5.

UV/Vis absorbance spectra (600 nm) of a PNIPAAm solution (10 mg ml"1) during a heating/cooling cycle (1 8C

min"1) from room temperature to 50 8C.

Copyright ! 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.ms-journal.de

Macromol. Symp. 2007, 251, 3340

cooling

5

4

3

Heat Flow [mW]

38

2

1

0

-1 20

23

26

29

32

35

38

41

44

47

50

-2

-3

-4

-5

heating

Temperature [ C]

Figure 6.

Microcalorimetry curve of a PNIPAAm solution (10 mg ml"1) during a heating/cooling cycle (1 8C min"1) from

room temperature to 50 8C.

hydrogen-bonding interactions between

polymer chains. Above the LCST interand intra- polymer interactions become

predominant resulting in the polymer falling out of solution. The transition can be

followed using a UV/Vis spectrometer as

shown in Figure 5 for a PNIPAAm solution

at 10 mg ml"1. At the LCST a step change in

the absorbance of the solution is observed.

As can be seen from Figure 5 the LCST

transition if fully reversible. On heating

the LCST transition is usually observed at

a slightly higher temperature (2 to 4 8C

higher) than on cooling.

Figure 6 shows the microcalorimetry

curves obtained for the same PNIPAAm

solution when heated from room temperature to 50 8C and then cooled. A clear

endotherm on heating and an exotherm on

cooling can be observed. This suggests that

at least part of the LCST process is a 1st

order transition.

UV/Vis and microcalorimetry were used

to measure the LCST temperatures for

20 mg ml"1 solutions of all our polymers.

The results are summarised in Table 2.

The two techniques give identical values

for the LCST temperatures. The LCST

of PNIPAAm is found to be around 37 8C

as expected. In Figure 7 and 8 the LCST

temperatures are plotted as a function

of the co-monomer content and the comonomer chain length respectively.

As can be seen from Figure 8 for identical co-monomer content the LCST temperature decreases with increasing comonomer chain length. As said in the

introduction the longer the methylene

spacer the more hydrophobic the comonomer. Increasing the hydrophobicity

of the co-monomer used results in an

increase in the overall polymer hydrophobicity. Figure 8 clearly shows that the LCST

is a function of the hydrophobicity of the

polymer. Another effect that could be at

the origin of the decrease in the LCST is the

presence of acidic end groups on the

co-monomers that can hydrogen bond with

Table 2.

LCSTs in heating/cooling.

LCST temperatures (heating/cooling)/8C

Molar ratio

12:1

9:1

6:1

n3

34.9/33.3

34.5/33.2

n5

30.1/27.5

28.6/26.0

27.8/23.0

Copyright ! 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

n 10

19.0/17.8

16.5/16.8

12.3/11.5

PNIPAAm

38.9/36.6

www.ms-journal.de

Macromol. Symp. 2007, 251, 3340

39

no.CH2=10

no. CH2=5

no. CH2=3

40

35

LCST [C]

30

25

20

15

10

0

10 11 12 13 14 15 16 17

co-monomer content [mol%]

Figure 7.

LCST temperature vs. co-monomer content.

the NH groups on the PNIPAAm. This

increases the probability of inter- and intrapolymer interactions stabilising the coil

conformation.

For n 3 and n 5 in the NIPAAM/

co-monomer molar ratio range the LCST

seem very little affected by the increase

in co-monomer content (Figure 7 and 8).

On the other hand for n 10 the doubling

of co-monomer results in a significant

decrease of the LCST by 10 8C.

Conclusions

The synthesis of acrylic acid derivate

co-monomers with aliphatic spacers was

successfully achieved with good yields

(6080%). Temperature sensitive co-polymers were prepared by the copolymerization

of N- isopropylacrylamide (NIPAAm) with

varying amounts of acrylamide derivates

bearing carboxylic groups attached to

spacers with different chain length. We have

molar ratio [12:1]

molar ratio [9:1]

molar ratio [6:1]

45

40

35

LCST [C]

30

25

20

15

10

5

0

0

10

length [CH2 units]

Figure 8.

LCST temperature vs. co-monomer chain length.

Copyright ! 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.ms-journal.de

40

Macromol. Symp. 2007, 251, 3340

shown that the glass transitions as well as

the LCST transition in solutions are affected

by the presence of the co-monomer.

The glass transition was shown to be reduced

significantly for n 10 only, while the

LCST decreased continuously with increasing co- monomer chain length.

Our results clearly indicate the role

played by the polymer hydrophobicity on

the LCST transition. The main factor

affecting the glass transition and the LCST

of the polymer was found to be the side

chain length of the co-monomers. In

the NIPAAm/co-monomer molar ration

investigated the co-monomer content was

found to have an significant effect on the

glass transition and the LCST only for the

co-monomer with the longest methylene

spacer i.e.: n 10.

Acknowledgements: The financial support of

the Marie Curie 6th Framework is gratefully acknowledged. We thank specially to

Drs. Frank Heatley (NMR), Geoffrey Dent

(FTIR) and Keith Nixon (GPC) for their

technical support.

[1] T. Okano, A. Kikuchi, Y. Sakurai, Y. Takei, N. Ogata,

J. Control Rel. 1995, 36, 125.

[2] H. Schild, D. Tirrell, Polym. Prepr. 1989, 30, 342.

[3] G. Chen, A. S. Hoffamn, Macromol. Chem. Phys.

1995, 196, 1251.

[4] E. Ayano, H. Kanazawa, J. Sep. Sci. 2006, 29, 738 749.

[5] T. F. D. J. Tanaka, T. Sun, I. Nishio, G. Swislow, A.

Shah, Phys. Rev. Lett. 1980, 45, 1636.

[6] C. d. l. H. Alarcon, S. Pennadam, C. Alexander,

Chem. Soc. Rev. 2005, 34, 276285.

[7] D. Kuckling, H. J. P. Adler, K. F. Arndt, L. Ling,

W. D. Habicher, Macromol. Chem. Phys. 2000, 201, 273.

[8] D. E. Frantz, D. G. Weaver, J. P. Carey, M. H. Kress,

U. H. Dolling, Org. Lett. 2002, 4, 47174718.

[9] C. d. l. H. Alarcon, Vol. PhD, University of Portsmouth, 2004.

[10] S. Kasapis, Food Hydrocoll. 2006, 20, 218228.

[11] G. Dlubek, D. Bamford, A. Rodriguez-Gonzales,

S. Bornemann, J. Stejny, B. Schade, M. A. Alam, M.

Arnold, J. Polym. Sci. : Part B: Polymer Physics 2002, 40,

434453.

[12] J. Brandrup, E. H. Immergut, Polymer Handbook

1989.

[13] G. H. Schild, Prog. Polym. Sci. 1992, 17, 163.

Copyright ! 2007 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

www.ms-journal.de

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Switching Lab-05b Configuring InterVLAN RoutingДокумент2 страницыSwitching Lab-05b Configuring InterVLAN RoutingHernan E. SalvatoriОценок пока нет

- Epistemology and OntologyДокумент6 страницEpistemology and OntologyPriyankaОценок пока нет

- Shaker ScreenДокумент2 страницыShaker ScreenRiaz EbrahimОценок пока нет

- Forces L2 Measuring Forces WSДокумент4 страницыForces L2 Measuring Forces WSAarav KapoorОценок пока нет

- BSDДокумент26 страницBSDEunnicePanaliganОценок пока нет

- Medabots-Rokusho Version (European) - Medal Codes (Part 1) (GBA Cheats) - CodeTwink ForumsДокумент5 страницMedabots-Rokusho Version (European) - Medal Codes (Part 1) (GBA Cheats) - CodeTwink Forumsdegraded 4resterОценок пока нет

- University Fees Structure (Himalayan Garhwal University) - UttarakhandДокумент1 страницаUniversity Fees Structure (Himalayan Garhwal University) - UttarakhandabhaybaranwalОценок пока нет

- Community Resource MobilizationДокумент17 страницCommunity Resource Mobilizationerikka june forosueloОценок пока нет

- Micro - Systemic Bacteriology Questions PDFДокумент79 страницMicro - Systemic Bacteriology Questions PDFShashipriya AgressОценок пока нет

- Channel & Lomolino 2000 Ranges and ExtinctionДокумент3 страницыChannel & Lomolino 2000 Ranges and ExtinctionKellyta RodriguezОценок пока нет

- Module 2Документ7 страницModule 2karthik karti100% (1)

- Rin Case StudyДокумент4 страницыRin Case StudyReha Nayyar100% (1)

- SRS Document Battle Royale Origins - V2Документ36 страницSRS Document Battle Royale Origins - V2Talha SajjadОценок пока нет

- Empanelled Hospitals List Updated - 06-12-2022 - 1670482933145Документ19 страницEmpanelled Hospitals List Updated - 06-12-2022 - 1670482933145mechmaster4uОценок пока нет

- Ose Sample QuotationДокумент37 страницOse Sample Quotationrj medelОценок пока нет

- Revised Corporation Code - Non Stock Close and Special CorporationsДокумент19 страницRevised Corporation Code - Non Stock Close and Special CorporationsVenziel PedrosaОценок пока нет

- Ged 102 Mathematics in The Modern WorldДокумент84 страницыGed 102 Mathematics in The Modern WorldKier FormelozaОценок пока нет

- Effect of Plant Growth RegulatorsДокумент17 страницEffect of Plant Growth RegulatorsSharmilla AshokhanОценок пока нет

- Atlascopco XAHS 175 DD ASL Parts ListДокумент141 страницаAtlascopco XAHS 175 DD ASL Parts ListMoataz SamiОценок пока нет

- How To Be A Better StudentДокумент2 страницыHow To Be A Better Studentct fatima100% (1)

- Controlled DemolitionДокумент3 страницыControlled DemolitionJim FrancoОценок пока нет

- APA Citation Method For ERLACS: Reference Citations in TextДокумент8 страницAPA Citation Method For ERLACS: Reference Citations in Textdanny_alfaro_8Оценок пока нет

- Jota - EtchДокумент3 страницыJota - EtchRidwan BaharumОценок пока нет

- 2 - Sample Kids Can Read and Write 2 and 3 Letter Words - Step 2 Final Downloadable Version For Website PDFДокумент18 страниц2 - Sample Kids Can Read and Write 2 and 3 Letter Words - Step 2 Final Downloadable Version For Website PDFsantoshiОценок пока нет

- Assessing The Marks and Spencers Retail ChainДокумент10 страницAssessing The Marks and Spencers Retail ChainHND Assignment Help100% (1)

- Research Methods in Developmental PsychologyДокумент9 страницResearch Methods in Developmental PsychologyHugoОценок пока нет

- GA Power Capsule For SBI Clerk Mains 2024 (Part-2)Документ82 страницыGA Power Capsule For SBI Clerk Mains 2024 (Part-2)aa1904bbОценок пока нет

- Module 2 TechnologyДокумент20 страницModule 2 Technologybenitez1Оценок пока нет

- Furnace Temperature & PCE ConesДокумент3 страницыFurnace Temperature & PCE ConesAbdullrahman Alzahrani100% (1)

- Steel Price Index PresentationДокумент12 страницSteel Price Index PresentationAnuj SinghОценок пока нет