Академический Документы

Профессиональный Документы

Культура Документы

12-SAMSS-007 Fabrication Structural Miscellaneous Steel 2006

Загружено:

ymasedaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

12-SAMSS-007 Fabrication Structural Miscellaneous Steel 2006

Загружено:

ymasedaАвторское право:

Доступные форматы

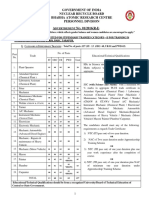

Materials System Specification

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Onshore Structures Standards Committee Members

3 September 2006

Baldwin, Charles Cummins, Chairman

Sheref, Khaled Mohammad, Vice Chairman

Hemler, Steven R.

Henry, Michael Patrick

Marhoon, Saeed Ahmed

Mohammed, Ammar Khalil

Utaibi, Abdul Aziz Saud

Abu-Adas, Hisham A.W.

Saleh, Loay Abdullah

Abulhamayel, Ismat Abdulkader

Dakhil, Osamah Ali

Mohammed, Jamal Sadeq

Grosch, Jonathan Joseph

Kim, Steve Un

Stark, Gregory Dalton

Thompson, Scott Burnett

Saudi Aramco DeskTop Standards

Table of Contents

1

2

3

4

5

6

7

Scope............................................................. 2

Conflicts and Deviations................................. 2

References..................................................... 2

Products and Materials.................................. 7

Galvanizing, Painting and Coating............... 10

Fabrication.................................................... 14

Inspection and Testing................................. 26

Appendix 1 ASTM Material Equivalency......... 28

Previous Issue: 7 May 2006 Next Planned Update: 1 May 2009

Revised paragraphs are indicated in the right margin

Primary contact: Baldwin, Charles Cummins on 966-3-8746149

CopyrightSaudi Aramco 2005. All rights reserved.

Page 1 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Scope

This Specification defines the requirements for material selection, connections,

detailing, fabrication, galvanizing, painting and coatings, marking for erection and

delivery of structural and miscellaneous steel. Erection of structural steel shall be per

12-SAMSS-008. Offshore structures and pre-engineered metal buildings are excluded

from this specification.

Conflicts and Deviations

2.1

Any conflicts between this Specification and other applicable Saudi Aramco

Materials System Specifications (SAMSSs), Engineering Standards (SAESs),

Standard Drawings (SASDs) or industry standards, codes, and forms shall be

resolved in writing by the Company or Buyer Representative through the

Manager, Consulting Services Department.

2.2

Direct all requests to deviate from this Specification in writing to the Company or

Buyer Representative, who shall follow internal company procedure SAEP-302

and forward such requests to the Manager, Consulting Services Department of

Saudi Aramco, Dhahran.

References

The selection of material and equipment, and the design, construction, maintenance, and

repair of equipment and facilities covered by this Specification shall comply with the

latest edition of the references listed below, unless otherwise noted.

3.1

Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302

Instructions for Obtaining a Waiver of a

Mandatory Saudi Aramco Engineering

Requirement

Saudi Aramco Engineering Standards

SAES-H-001

Selection Requirements for Industrial Coatings

SAES-H-100

Painting Requirements for Industrial Facilities

SAES-H-101

Approved Protective Coating Systems

Saudi Aramco Materials System Specification

12-SAMSS-008

Erection of Structural and Miscellaneous Steel

Page 2 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Saudi Aramco Standard Drawing

AB-036322-001

Anchor Bolt Details Inch and Metric Sizes

Saudi Aramco Inspection Requirements

Form 175-120100

Steel Structures

Form 175-120500

Tower: Communication

Saudi Aramco Forms and Data Sheets

NMR-7927

3.2

Non-Material Requirements for Fabricated

Structural Steel

Industry Codes and Standards

American Institute of Steel Construction (AISC)

AISC

Detailing for Steel Construction

AISC

Manual of Steel Construction: Allowable Stress

Design (ASD), 9th Edition

AISC

Manual of Steel Construction: Volume II

Connections (ASD/LRFD)

AISC

Specification for Structural Steel Buildings:

Allowable Stress Design and Plastic Design

AISC

Specification for Structural Joints Using

ASTM A325 or ASTM A490 Bolts

AISC

Code of Standard Practice for Steel Buildings and

Bridges

AISC

Allowable Stress Design (ASD) of Simple Shear

Connections

AISC

Load and Resistance Factor Design (LRFD) of

Simple Shear Connections

AISC

Load and Resistance Factor Design (LRFD)

Specification for Structural Joints Using ASTM

A325 or ASTM A490 Bolts

AISC

Load and Resistance Factor Design (LRFD)

Specification for Structural Steel Buildings

AISC

Manual of Steel Construction, Load and

Resistance Factor Design (LRFD)

Page 3 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

American Society for Testing and Materials (ASTM)

ASTM A1

Standard Specification for Carbon Steel Tee Rails

ASTM A6/A6M

Standard Specification for General Requirements

for Rolled Structural Steel Bars, Plates,

Shapes, and Sheet Piling

ASTM A36/A36M

Standard Specification for Carbon Structural Steel

ASTM A53/A53M

Standard Specification for Pipe, Steel, Black and

Hot-Dipped, Zinc-Coated, Welded and

Seamless

ASTM A106

Standard Specification for Seamless carbon Steel

Pipe for High-Temperature Service

ASTM A108

Standard Specification for Steel Bars, Carbon,

and Alloy, Cold Finished

ASTM A123/A123M

Standard Specification for Zinc (Hot-Dip

Galvanized) Coatings on Iron and Steel

Products

ASTM A143/A143M

Standard Specification for Safeguarding Against

Embrittlement of Hot-Dip Galvanized

Structural Steel Products and Procedure for

Detecting Embrittlement

ASTM A153/A153M

Standard Specification for Zinc Coating (Hot-Dip)

on Iron and Steel Hardware

ASTM A193/A193M

Standard Specification for Alloy-Steel and

Stainless Steel Bolting Materials for HighTemperature Service

ASTM A194/A194M

Standard Specification for Carbon and Alloy Steel

Nuts for Bolts for High-Pressure or HighTemperature Service, or Both

ASTM A307

Standard Specification for Carbon Steel Bolts and

Studs, 60,000 psi Tensile Strength

ASTM A325

Standard Specification for Structural Bolts, Steel,

Heat Treated, 120/105 ksi Minimum Tensile

Strength

ASTM A325M

Standard Specification for High-Strength Bolts,

Steel, Heat Treated 830 MPa Minimum Tensile

Strength [Metric]

Page 4 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

ASTM A384/A384M

Standard Practice for Safeguarding Against

Warpage and Distortion during Hot-Dip

Galvanizing of Steel Assemblies

ASTM A385

Standard Practice for Providing High-Quality

Zinc Coatings (Hot-Dip)

ASTM A490

Standard Specification for Heat-Treated Steel

Structural Bolts, 150 ksi Minimum Tensile

Strength

ASTM A490M

High Strength Steel Bolts, Classes 10.9 and

10.9.3, for Structural Steel Joints (Metric)

ASTM A500

Standard Specification for Cold-Formed Welded

and Seamless Carbon Steel Structural Tubing

in Rounds and Shapes

ASTM A501

Standard Specification for Hot-Formed, Welded

and Seamless Carbon Steel Structural Tubing

ASTM A563

Standard Specification for Carbon and Alloy Steel

Nuts

ASTM A563M

Standard Specification for Carbon and Alloy Steel

Nuts [Metric]

ASTM A572/A572M

Standard Specification for High-Strength LowAlloy Columbium-Vanadium Structural Steel

ASTM A653/A653M

Standard Specification for Steel Sheet, ZincCoated (Galvanized) or Zinc-Iron Alloy-Coated

(Galvannealed) by the Hot-Dip Process

ASTM A759

Standard Specification for Carbon Steel Crane

Rails

ASTM A780

Standard Practice for Repair of Damaged and

Uncoated Areas of Hot-Dip Galvanized

Coatings

ASTM A786/A786M

Standard Specification for Hot-Rolled Carbon,

Low-Alloy, High-Strength Low-Alloy, and Alloy

Steel Floor Plates

ASTM A992/A992M

Standard Specification for Structural Steel Shapes

ASTM A1008/A1008M

Standard Specification for Steel, Sheet, ColdRolled, Carbon, Structural, High-Strength

Low-Alloy and High-Strength Low-Alloy with

Improved Formability

Page 5 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

ASTM A1011

Standard Specification for Steel, Sheet and Strip,

Hot-Rolled, Carbon, Structural, High-Strength

Low-Alloy and High-Strength Low-Alloy with

Improved Formability

ASTM B695

Standard Specification for Coatings of Zinc

Mechanically Deposited on Iron and Steel

ASTM E376

Measuring Coating Thickness by Magnetic-Field

or Eddy-Current (Electromagnetic)

Examination Methods

ASTM F436

Standard Specification for Hardened Steel

Washers

ASTM F436M

Standard Specification for Hardened Steel

Washers [Metric]

ASTM F606

Standard Test Methods for Determining the

Mechanical Properties of Externally and

Internally Threaded Fasteners, Washers, and

Rivets

ASTM F606M

Standard Test Methods for Determining the

Mechanical Properties of Externally and

Internally Threaded Fasteners, Washers, and

Rivets [Metric]

ASTM F959

Standard Specification for Compressible-WasherType Direct Tension Indicators for Use with

Structural Fasteners

ASTM F959M

Standard Specification for Compressible-WasherType Direct Tension Indicators for Use with

Structural Fasteners [Metric]

ASTM F1554

Standard Specification for Anchor Bolts, Steel, 36,

55 and 105-ksi Yield Strength

American Petroleum Institute (API)

API SPEC 5L

Specification for Line Pipe

American Welding Society (AWS)

ANSI/AWS D1.1/ D1.1M

Structural Welding Code Steel

ANSI/AWS D1.3/ D1.3M

Structural Welding Code Steel Sheet

European Standards

EN 10204

BS EN 10204: Metallic Products

Page 6 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

BS EN 10025-2

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Hot Rolled Products of Structural Steel

National Association of Architectural Metals Manufacturers (NAAMM)

NAAMM MBG 531

Metal Bar Grating Manual

NAAMM MBG 532

Heavy Duty Metal Bar Grating Manual

Process Industry Practices (PIP)

STF05501

Fixed Ladders and Cages

STF05511

Fixed Industrial Stairs

STF05520

Pipe Railing for Walkway and Working Surface

Details

STF05530

Grating Details

Steel Deck Institute (SDI)

SDI Design Manual for Composite Decks, Form Decks and Roof Decks

No. 30

Steel Joist Institute (SJI)

SJI Standard Specifications and Load Tables

U.S. Federal Communications Commission (FCC)

U.S. FCC

Rules and Regulations, Part 17

U.S. Department of labor, Occupational Safety and Health Administration

(OSHA)

OSHA 29 CFR Part 1926

4

Products and Materials

4.1

4.2

Material Requirements

4.1.1

All material shall be of new stock.

4.1.2

The minimum thickness of any part of a structural shape shall be 5 mm.

4.1.3

Where contact of dissimilar metals will cause galvanic corrosion, a

suitable insulating material shall be provided between the metals.

Structural Shapes, Plates & Bars

ASTM A36 / ASTM A36M (for plates, bars, M, S, HP, C, M, C and L-shapes);

Page 7 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

ASTM A572 / ASTM A572M, or ASTM A992 / ASTM A992M (for WT and

Wshapes). Commonly accepted structural steel materials and shapes other than

ASTM may be used in accordance with Appendix 1 of this specification. Any

difference(s) in the material dimensions, section properties, yield strength or

tensile strength shall be accounted for in the design calculations.

Commentary Note:

Universal Beams and Universal Columns (UB & UC) and split tees rolled to BS

EN 10025-2 S355JR/JO may be used as substitutes for W & WT shapes.

Commonly accepted shapes include shapes specified to Japanese Standards

(JS), British Standards (BS), European Standards (EuroNorm) and German

Standards (DIN).

4.3

Pipe Columns & Handrail

Pipe for columns or handrail shall be per ASTM A53 Type E or S, Grade B,

ASTM A106 Grade B or API SPEC 5L, Grade B.

4.4

Structural Tubing

Structural tubing shall be per ASTM A501 or ASTM A500 Grade B.

4.5

Metal Decking

Floor and Roof metal deck shall be cold-formed steel sheets conforming to

ASTM A653/A653M or ASTM A1008/A1008M or equal having a minimum

yield strength of 228 N/mm (33,000 psi). The metal deck shall be galvanized

and receive a protective coating of zinc conforming to ASTM A653, G90

Coating Designation. Design shall be in accordance with "SDI Design Manual

for Composite Decks, Form Decks and Roof Decks, No. 30."

4.6

High Strength Bolt Assemblies

Bolt - ASTM A325/A325M Type I or ASTM A490/A490M, if specified on the

design drawings

Washer - ASTM F436/F436M

Direct Tension Indicator (D.T.I.) Washers - ASTM F959/F959M, when

specified on the design drawings

Heavy Hex Nut - ASTM A563 Grade DH or ASTM A563M Grade 10S

4.7

Standard Bolt Assemblies

Bolt - ASTM A307 Grade A, (Hex " - 1" diameter)

Page 8 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Washer - ASTM F436/F436M

Nut - ASTM A563/A563M Grade A, Heavy Hex

4.8

Anchor Bolt Assemblies shall be in accordance with Standard Drawing

AB-036322 Sht. No. 001 (Rev. No. 07 or later) and the following material

specifications:

Threaded Anchor Bolts - ASTM A36 / ASTM A36M or ASTM F1554, Gr. 36

Headed Bolts - ASTM A307 Grade A (Hex " - 1" diameter, Heavy Hex over

1" diameter)

Washers - ASTM F436 or ASTM F436M

Plate Washers - ASTM A36 / ASTM A36M

Nuts - ASTM A563 Grade A, Heavy Hex or ASTM A563M

4.9

High Strength Anchor Bolt Assemblies shall be in accordance with Standard

Drawing AB-036322 Sht. No. 001 (Rev. No. 07 or later) and the following

material specifications:

Anchor Bolts - ASTM A193 / ASTM A193M Gr. B7 or ASTM F1554, Gr. 105

Heavy Hex Nuts - ASTM A194 or ASTM A194M or ASTM A563, DH

Washers - ASTM F436 or ASTM F436M

Plate Washers - ASTM A36 / ASTM A36M

4.10

Shear Connectors (for composite construction) - Headed Studs

ASTM A108 Grade 1010 through 1020, ANSI/AWS D1.1 Section 7, Type B

4.11

Welding Filler Metal

Welding filler metal shall be per ANSI/AWS D1.1, Section 3.3 (including Table

3.1) low hydrogen with an electrode strength of 58 ksi (400 MPa) minimum

yield strength and 70 ksi (480 MPa) minimum tensile strength. (For example,

use E70XX for SMAW, F7XX-EXXX for SAW, ER70S-X for GMAW, and

E7XT-X for FCAW.) However, E60XX (410 MPa) electrodes may be used for

tack welding.

4.12

Crane Rails

Rails 60 lb/yd to 84 lb/yd (30 kg/m to 42 kg/m) ASTM A1

Page 9 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Rails 104 lb/yd to 175 lb/yd (52 kg/m to 88 kg/m) ASTM A759

4.13

Checkered Floor Plates

ASTM A786 / ASTM A786M Pattern 2 or 4 and ASTM A36/A36M

4.14

Steel Bar Grating and Grating Stair Treads

Steel Bar Grating and Grating Stair Treads shall be per ASTM A1011/A1011M,

galvanized per ASTM A123 and comply with NAAMM MBG 531 & MBG 532.

Steel grating shall be rectangular type, with plain 3/16-inch x 1-1/4-inch (5-mm

x 32-mm bearing bars on 1-3/16-inch (30-mm) spacing with cross bars on 4-inch

(100-mm) spacing. Grating stair treads shall have abrasive or checkered plate

nosing.

4.15

Grating Fasteners

Grating shall be securely fastened to the supporting members as shown in

NAAMM MBG531 and PIP STF05530. When grating clips are used, they shall

be from a recognized manufacturer with a published datasheet and written

installation procedures including tightening criteria. The grating fasteners shall

be of a design that permits installation by a single worker without requiring

access to the underside of the grating. The grating clips shall be stainless steel

or shall be galvanized per ASTM A153 / ASTM A153M or ASTM B695.

4.16

Steel Joists

SJI Standard Specifications and Load Tables

Galvanizing, Painting and Coating

5.1

Fireproofed Steel

5.1.1

Galvanized steel is acceptable under cementatious fireproofing.

Galvanized steel that will receive intumescent fireproofing materials

must be brush-off blasted (sweep blast) and then receive an APCS-1B

primer prior to the application of the intumescent fireproofing.

5.1.2

Bare carbon steel that will receive fireproofed shall be prepared as

follows:

a)

A full APCS-1B system (primer and top coat(s)) shall be applied

under cementatious fireproofing materials.

b)

APCS-1B primer shall be applied prior to the application of the

intumescent fireproof materials.

Page 10 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

5.2

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Galvanizing

5.2.1

All materials, except ASTM A193, ASTM A194, ASTM A490 or

ASTM A490M bolts, and crane rails, shall be galvanized. Steel

embedded in concrete (including ASTM A36, ASTM A307 and ASTM

F1554 anchor bolts) shall be hot-dip galvanized.

5.2.2

Galvanizing of steel shapes, plates and hardware shall be in accordance

with the following ASTM specifications:

5.2.3

5.2.4

a)

Steel shapes and plates - ASTM A123

b)

ASTM A325 Type 1 or ASTM A325M Type 1 bolts and

corresponding nuts and washers -ASTM B695 or ASTM A153 /

ASTM A153M.

c)

ASTM A36 / ASTM A36M threaded bar or ASTM A307 bolts

and corresponding nuts and washers - ASTM A153 / ASTM

A153M or ASTM B695

d)

All bolts, nuts, and washers shall meet required mechanical

properties after galvanizing.

General Fabrication

5.2.3.1

It shall be the Fabricator's responsibility to safeguard

against embrittlement and warpage per ASTM A143 and

ASTM A384. Fabrication details shall meet the

requirements of ASTM A385 to allow for the creation of

high quality zinc coatings.

5.2.3.2

Whenever practical, cutting, drilling and welding shall be

performed before galvanizing. The Fabricator shall remove

weld slag before galvanizing.

5.2.3.3

The edges of tightly contacting surfaces shall be completely

seal welded.

5.2.3.4

Vent holes shall be provided for piping or tubular

assemblies as required by ASTM A385. The vent holes

shall be located in the bottom side to prevent rainwater

accumulation.

5.2.3.5

The Fabricator before proceeding shall bring potential

problems that require a modification in design to the

attention of the Buyer.

Galvanizing of Steel Hardware

Page 11 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

5.2.5

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

5.2.4.1

Nuts shall be tapped oversize in accordance with ASTM

A563/A563M.

5.2.4.2

Nut threads shall be retapped after hot-dip galvanizing to

provide proper fit.

5.2.4.3

Direct tension indicators, if used, shall be mechanically

galvanized by the manufacturer according to the

requirements of Class 50 of ASTM B695.

5.2.4.4

Anchor bolt coatings shall be in accordance with Standard

Drawing AB-036322 Sht. No. 001 (Rev. No. 07 or later).

Inspection of Galvanized Steel

The Buyer reserves the right to inspect and reject all galvanized steel in

accordance with the provisions of ASTM A123 and ASTM E376.

5.2.6

Repair of Galvanized Steel

5.2.6.1

Any damage to galvanizing shall be repaired in accordance

with ASTM A780.

5.2.6.2

Before repair of damaged galvanized coating, exposed

substrate metal shall be cleaned to bright metal and free of

all visual rust, oil, or grease. Any non-adhering galvanizing

shall be removed to the extent that the surrounding

galvanizing is integral and adherent.

5.2.6.3

When surface defects exceed 2% of a member's area, the

defects shall be repaired by redipping the member in the

zinc bath.

5.2.6.4

Cold repair using an organic zinc rich coating (primer in

APCS-1C) is allowed if the total damaged area is less than

1% of the total coated area of the member being repaired

and no single repair is greater than 1300 mm or 300 mm

long. The dry film thickness shall be 0.05 to 0.08 mm (2 to

3 mils) and contain a minimum of 65% zinc dust by weight.

5.2.6.5

Hot repairs shall be made in the shop if any of the following

conditions exist:

a.

Total damaged area is greater than 1% but less than

2% of the total coated area of the member being

repaired

Page 12 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

5.3

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

b.

Any single repair is at least 2 in (1,300 mm) in area

c.

Any single repair is 12-inches (300 mm) long or more

5.2.6.6

Hot repair shall be made using zinc alloy rod or powder

manufactured for the repair of galvanized steel.

5.2.6.7

Flux, heavy ash, or heavy dross inclusions shall be removed

by brushing, grinding, or filing as required.

5.2.6.8

Galvanized steel which has been rejected shall be stripped,

regalvanized, and submitted again for inspection.

5.2.6.9

Correction of excessive warpage that exceeds ASTM

A6/A6M criteria, shall be by press straightening when

possible. The application of localized heating to straighten

must be approved by the Chairman of the Onshore

Structures Standards Committee.

5.2.6.10

If galvanized tension control bolts are used, all bare steel

surfaces (i.e., bolt ends) shall be repair galvanized per this

section.

Painting and Coatings

5.3.1

Where hot-dip galvanizing cannot be done after fabrication, uncoated

locations shall be painted in accordance with the Saudi Aramco

Engineering Standards SAES-H-001, SAES-H-100 and SAES-H-101.

5.3.2

Where fireproofing of structural steel is specified, the steel shall be

coated with materials that are qualified and approved in accordance

with SAES-H-001, APCS-1B, Epoxy Coated System with Epoxy

Primer.

5.3.3

Shop painting is not required unless specified in the Purchase Order,

except for communication towers, which require painting, aviation

marking and lighting as follows:

a)

Surface preparation and dry film thickness requirements shall be

in accordance with SAES-H-101, APCS-1E.

b)

Minimum and maximum overcoating times must be in strict

accordance with the Manufacturer's Product Data Sheet, and all

coatings must be qualified and approved in accordance with

SAES-H-101, APCS-1E.

Page 13 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

c)

5.4

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Aviation Marking: Colors for the two cover coats shall meet the

requirements specified in the U.S. Federal Communications

Commission, U.S. FCC Rules and Regulations, Part 17.

5.3.4

Floor plate shall be coated with an anti-skid paint per SAES-H-101,

APCS-12, when required to be shop applied in the contract documents.

5.3.5

High-strength anchor bolts shall be coated in accordance with Standard

Drawing AB-036322 Sht. No. 001 (Rev. No. 07 or later).

Fixed Ladders and Cages

For Fixed Ladders and Cages details refer to drawings as per PIP STF05501.

5.5

Fixed Industrial Stairs

For fixed industrial stairs, refer to drawings as per PIP STF05511.

5.6

Pipe Railing for Walkway and Working Surfaces

For pipe railing for walkway and working surfaces details, refer to drawings as

per PIP Standard STF05520. Angle railing shall not be used.

5.7

Grating Details

For grating details refer to PIP STF05530.

Fabrication

6.1

General

6.1.1

All fabrication shall be in accordance with the AISC Code of Standard

Practice for Steel Buildings and Bridges and either the AISC

Specification for Structural Steel Buildings: Allowable Stress Design

and Plastic Design or the AISC LRFD Specification for Structural

Steel Buildings, as applicable, subject to modification by the contract

documents.

6.1.2

All structural steel shall be made by open hearth, basic oxygen or

electric furnace process. Bessemer steel is not acceptable.

6.1.3

No rimmed or capped steel shall be used.

6.1.4

Structural steel pipe shall be limited to seamless or electric-welded,

straight-seam pipe. Where steel pipes or tubing are used, all open ends

shall be sealed to prevent internal corrosion.

Page 14 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

6.1.5

The welding symbols used on plans and shop drawings shall be per the

American Welding Society (AWS). The field connection symbols

shall distinguish between assembly yard and erection site connections.

6.1.6

All welding shall be in accordance with ANSI/AWS D1.1/D1.1M,

Structural Welding Code Steel or ANSI/AWS D.1.3, Structural

Welding Code Sheet Steel, as appropriate.

6.1.7

Shop splices, substitutions of member sizes, or changes in details or

dimensions shall not be permitted without written authorization from

the Chairman of the Onshore Structures Standards Committee.

6.1.8

In order to reduce field connections to a minimum, shop assembly shall

be as complete as possible, consistent with the feasibility and economy

of the handling and shipping of the assembled units. Sections or

assemblies too long for shipment shall be provided with field joints of

the same member strength. Lifting lugs for lifting of fully assembled

structural units shall be designed for attachment to primary structural

members only. Lifting lugs shall be attached by means of a complete

joint-penetration groove weld when the assembly weight exceeds 3000

kg (see paragraph 7.5.e).

6.1.9

All beams, except cantilevers, shall be fabricated with natural mill

camber in the up position.

6.1.10

All re-entrant corners shall be shaped, notched-free, to a radius.

6.1.11

Fabricator, when performing shop assembly work, shall not exceed the

tolerances specified in AISC Code of Standard Practice for Steel

Buildings and Bridges, Section 7.11.

6.1.12

Base plate hole sizes for structural steel columns shall be as follows:

Anchor bolts to 1 inch (20-24 mm) 5/16 inch (8 mm) oversize

Anchor bolts 1 to 2 inch (25-50 mm) inch (12 mm) oversize

Anchor bolts over 2 inch (50 mm)

1 inch (25 mm) oversize

6.1.13

All pieces shall be clearly marked with permanent identifying erection

mark number. Method and location of marking shall be approved by

Buyer.

6.1.14

Before surface preparation, the Fabricator shall remove all sharp

corners, burrs (including bolt hole burrs), weld spatter, slag, weld flux,

loose mill scale and other foreign matter.

Page 15 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

6.2

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

6.1.15

Exposed corners, edges, burrs or rough spots on handrails, guards,

ladders, platforms and stairs, which might cause injury to personnel

using the assembled structure, shall be ground or filed smooth.

6.1.16

Platforms, stairways and handrails shall be shop-assembled in the

largest units suitable for handling and shipping. Ladder cages shall be

shop assembled on ladders.

6.1.17

The method for fastening grating shall be as specified on the design

drawings. A minimum of two fasteners per panel shall be used at each

support, with a minimum of four fasteners per panel. The fasteners

shall be supplied by the Fabricator with 5% extra to cover losses.

6.1.18

Grating / checkered plate openings dimensioned on the design

drawings shall be cut and banded in the shop as shown on the design

drawing. Un-dimensioned grating/checkered plate openings will be cut

in the field by others.

6.1.19

Joints perpendicular to the span of grating and checkered plate flooring

shall occur only over support members.

6.1.20

Checkered plate shall have inch (12 mm) diameter drain holes (when

specified on contract drawings) provided for each 20 ft (2 m) of area,

with a minimum of one hole per panel.

Connections

All connections shall be either engineer-designed, fabricator-selected, or

fabricator-designed. Unless otherwise noted on the design drawings, all

connections not fully detailed on the design drawings shall be fabricatordesigned.

6.2.1

Engineer-Designed Connections

6.2.1.1

Engineer-designed connections will be fully designed and

detailed on the design drawings and shall be furnished as

shown.

6.2.1.2

Engineer-designed connections shall be only those

connections fully detailed on the design drawings, showing

all fastener sizes, arrangement, dimensions, and all

connection material, and weld types and sizes. The

fabricator shall reflect this information on shop drawings.

Page 16 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

6.2.1.3

6.2.2

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Requests to deviate from the specific details of any

engineer-designed connection by the Fabricator must be in

writing, with written approval from Saudi Aramco.

Fabricator-Selected Connections

Fabricator-selected connections are usually simple connections (shear

only). The Fabricator shall detail these connections by selecting

Standard details from the AISC Allowable Stress Design Manual Part

4, Table II or Table III.

6.2.3

Fabricator-Designed Connections

6.2.3.1

Fabricator-Designed connections shall be designed and

detailed by the Fabricator to carry all loads shown on the

design drawings or as specified in the contract documents.

6.2.3.2

The Fabricator shall have an experienced Structural

Engineer design or supervise the design of all fabricatordesigned connections.

6.2.3.3

Fabricator-designed connections shall meet all requirements

of the contract documents. In all cases, design shall

consider the entire joint (including beams, girders, columns,

and bracing) and shall take into account bolt shear,

combined bolt tension and shear, prying action, local

bending, coped beam capacities, block shear, web buckling,

etc. The Fabricator shall design and furnish stiffeners for

column webs, column flanges and elements of other

members involved as determined by analysis.

6.2.3.4

If transfer forces (axial forces at ends of beams and girders)

are shown on the design drawings, framed beam

connections shall be designed to carry the transfer forces in

combination with the beam end reactions.

6.2.3.5

Sample engineering calculations for each type of

Fabricator-designed connection shall be sealed and signed

by the responsible Structural Engineer who designed or

supervised the design of the connections. Additionally,

where required by the Contract Documents, all shop

drawings containing Fabricator-designed connections shall

be sealed and signed by the responsible Structural Engineer

and shall be submitted to the Saudi Aramco Representative

for review.

Page 17 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

6.2.3.6

6.2.4

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Review of shop drawings detailing Fabricator-Designed

connections and engineering calculation sheets by the Saudi

Aramco Representative does not relieve the Fabricator of

the responsibility for both the design adequacy and

detailing of connections designed by the Fabricator.

Allowable Stress Increase

The Fabricator shall not increase allowable stresses in the design of

connections (i.e., no one-third increase for wind and seismic as

required by ASD), unless noted otherwise on the design drawings (if

LRFD design is used).

6.2.5

Bolted Connections

6.2.5.1

Design, detailing, and fabrication of bolted connections

shall be in accordance with either the AISC Allowable

Stress Design (ASD) or Load and Resistance Factor Design

(LRFD) method, as noted in the contract documents.

6.2.5.2

Connection design shall conform to the following

standards:

a)

AISC Specification for Structural Joints Using ASTM

A325 or A490 Bolts

b)

AISC Manual of Steel Construction (ASD) or AISC

Manual of Steel Construction (LRFD)

c)

AISC Manual of Steel Construction: Volume II,

(ASD/LRFD)

d)

AISC Detailing for Steel Construction

6.2.5.3

ASTM A325/A325M high-strength bolts, inch (20 mm)

in diameter, shall be used in all bolted structural

connections, unless otherwise noted in the contract

documents. However, larger ASTM A325/A325M bolts

may be used when required to meet connection capacity

requirements and shall be clearly flagged on the erection

drawings.

6.2.5.4

All ASTM A325 or ASTM A325M high-strength bolts,

shall be Type 1, galvanized. Galvanized washers and nuts

shall be furnished for galvanized bolts.

Page 18 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

6.2.5.5

All bolts, nuts, and washers shall be properly identified and

marked with the material grade and manufacturer's logo if

required by respective ASTM standard. All fasteners not so

marked shall be rejected. Should any unmarked fasteners

be installed, they shall be removed. Mechanical testing of

unmarked fasteners shall not constitute justification for their

use.

6.2.5.6

The minimum design capacity of all bolted, or mixed bolted

and welded, framed-beam connections shall be the member

end reaction shown on the design drawings. When the

member end reaction is not shown, the minimum design

capacity shall be one-half of the total uniform load capacity

as shown in the Allowable Uniform Load Tables in Part 2

of the AISC Manual of Steel Construction (ASD) for the

given beam size, span and grade of material. Unless

otherwise specified in the contract documents.

6.2.5.7

The minimum number of bolts in a framed beam connection

shall be two bolts.

6.2.5.8

High-strength bolted connections shall be bearing-type with

threads included in the shear plane (A325-N). Slip-critical

connections (A325-SC) shall be used when noted on the

contract documents. All high-strength bolts shall be fully

tightened as per paragraph 6.2.5.18, unless they are clearly

identified on the design drawings to be tightened only to a

snug-tight condition.

6.2.5.9

Ladder, stair tread, purlin, girt, doorframe and handrail

connections may be made with standard machine bolts,

conforming to ASTM A307.

6.2.5.10

ASTM A307 bolts, when used, shall be limited in size to

5 inch (16 mm) diameter and smaller.

8

6.2.5.11

All bolt holes shall be standard holes with a diameter

1 inch (1 mm) larger than the nominal bolt diameter,

16

unless otherwise specified on the design drawings or noted

in the following subsections.

6.2.5.12

For framed-beam bearing connections, horizontal shortslotted holes are permitted in the outstanding leg of clip

angles.

Page 19 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

6.2.5.13

For framed-beam slip-critical connections, oversized or

horizontal short-slotted holes may be used in the

outstanding legs of clip angles. However, in both these

cases bolt shear allowable loads are reduced, as shown in

Table I-D, Part 4, of the AISC Allowable Stress Design

Manual.

6.2.5.14

For slotted holes, the long direction of the slot shall be

perpendicular to the load direction. All slotted or oversize

hole dimensions shall be per Table 1 of the AISC ASD

Specification for Structural Joints Using ASTM A325 or

ASTM A490 Bolts or AISC LRFD Specification for

Structural Joints Using ASTM A325 or ASTM A490 Bolts

6.2.5.15

Hardened washers shall be provided under all bolt heads

and/or nuts adjacent to any ply with oversized or slotted

holes. For standard holes, a minimum of one hardened

washer shall be supplied with each bolt.

6.2.5.16

If direct tension indicator washers are used, they shall

conform to ASTM F959/F959M, and shall be installed

according to the manufacturer's published specifications.

6.2.5.17

Where high-strength bolts are used, "turn-of-nut" or "load

indicating washer" methods may be used for bolt

tightening. Temporary shop erection bolts must be removed

and replaced with high-strength bolts. A marking system

shall be used to mark high-strength bolted connections after

tightening is completed.

6.2.5.18

All bolt lengths shall be determined from the Commentary

on Specifications for Structural Joints Using ASTM A325

or ASTM A490 Bolts, Table C2.

6.2.5.19

A minimum of 5% extra quantities of each bolt size and

length, including nuts and washers, shall be furnished by

the fabricator for field erection.

6.2.5.20

All column splices shall be field-bolted and conform to

AISC Detailing for Steel Construction, Appendix D.

6.2.5.21

A washer shall be furnished with each anchor bolt. Plate

washer thicknesses shall be as shown on the design

drawings.

Page 20 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

6.2.6

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

6.2.5.22

All nuts for high-strength bolts shall be wax-dipped to

reduce torque during installation.

6.2.5.23

As required by OSHA 29 CFR 1926 Subpart R, when two

structural members on opposite sides of a column web, or a

beam web over a column, are connected sharing common

connection holes, the fabricator shall provide means of

supporting one member while erecting the other member.

Unless the means of support is indicated in the contract

documents, the fabricator may provide one additional row

of bolts in the member to be erected first, an erection seat

for the member to be erected first, or other suitable means.

Unless additional loading is indicated, the erection seat

shall be sized and attached to the column or supporting

beam web with sufficient bolts to support the dead weight

of the member. See the OSHA document for additional

information.

Welded Connections

6.2.6.1

Design, detailing, and fabrication of all welded connections

shall be in accordance with either AISC's Allowable Stress

Design (ASD) or Load and Resistance Factor Design

(LRFD) method, as noted in the Contract Documents.

6.2.6.2

ASD based welded connection design shall conform to

ANSI/AWS D1.1, AISC Manual of Steel Construction

(ASD), AISC Manual of Steel Construction: Volume II

Connections (ASD/LRFD), and AISC Detailing for Steel

Construction.

6.2.6.3

LRFD based welded connection design shall conform to

ANSI/AWS D1.1, AISC Manual of Steel Construction

(LRFD), and AISC Detailing for Steel Construction.

6.2.6.4

The minimum design capacity of all welded framed beam

connections shall be the member end reaction shown on the

design drawings. When the member end reaction is not

shown on the design drawings, the minimum design

capacity shall be one-half of the total uniform load capacity

as shown in the Allowable Uniform Load Tables in Part 2

of the AISC Manual of Steel Construction (ASD) for the

given beam size, span and grade of material, unless

otherwise specified in the Contract Documents.

Page 21 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

6.2.7

6.2.8

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

6.2.6.5

The minimum fillet weld size is 3/16 inch (5 mm) for

structural welds. Seal welds may be 1/8 inch (3 mm)

minimum fillet weld.

6.2.6.6

All structural strength welding shall be continuous, unless

alternate procedures are approved by the Chairman of the

Onshore Structures Standards Committee.

6.2.6.7

The Fabricator shall design and install erection clips for

field-welded connections.

6.2.6.8

Field connections for random-length materials of handrail

and ladder cage assemblies shall be welded.

6.2.6.9

Continuous seal-welding shall be used in places that are not

self-draining or where crevice corrosion is likely to occur.

If seal-welding is not practical, alternative methods of

sealing shall be used with the approval of the Saudi Aramco

Representative.

6.2.6.10

Fabricator shall remove all run-off bars and extension tabs.

Shop and Field Connections

6.2.7.1

All field connections shall be bolted and all shop

connections shall be either bolted or welded, unless

otherwise shown on the design drawings.

6.2.7.2

Single-angle shear connections shall not be used.

6.2.7.3

To ensure electrical continuity when shop-applying nonconductive coatings (i.e., epoxies), all contact surfaces shall

be masked unless otherwise noted in the contract

documents. All locations of no-paint or areas requiring full

masking or strip masking shall be noted on the shop

drawings

Bracing Connections

6.2.8.1

Unless otherwise noted on the design drawings, connections

for pre-assembled bracing and truss members shall be

designed for the forces shown on the design drawings,

however, not less than 50% of allowable tension capacity of

the members or 6 kips (27 Kn), whichever is greater. The

allowable tension capacity shall be calculated using the

Page 22 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

gross cross section of the member. A minimum of two

bolts per connection is required.

6.2.8.2

All cross-bracing shall be bolted at intersections, with one

bolt minimum for angles and two bolts minimum for tees.

6.2.8.3

All heavy bracing connections, including gusset plates,

shall be designed according to either the AISC Manual of

Steel Construction: Volume II Connections (ASD/LRFD),

Chapter 7 or the AISC Manual of Steel Construction

(LRFD): Volume II, Part II, as applicable.

6.2.8.4

All gusset and stiffener plates shall be 3/8 inch (10 mm)

minimum thickness. For minor structures such as platforms

and miscellaneous structures, inch (6 mm) thick gusset

and stiffener plates may be used. The minimum thickness

for connection plates in electrical transmission towers or

communication towers shall be inch (6 mm).

6.2.8.5

All vertical bracing and knee bracing shall have gusset

plates on column centerlines, unless otherwise noted on the

design drawings.

6.2.8.6

Unless otherwise noted on the design drawings, the

following working points shall be used:

a)

For vertical bracing at the intersection of a column,

beam and brace, the gusset plate shall be connected to

both beam and column. The work point shall be the

point at which the beam and column centerlines

intersect.

b)

For the connection of K-braces to nominal beams 10

inches (250 mm) or smaller, the working point shall

be the intersection of the horizontal centerline of the

beam and the centerline of the bay.

c)

For the connection of K-braces to nominal beams 12

inches (300 mm) or larger, the working point shall be

the intersection of a horizontal line 5-inches (125 mm)

below the top flange when the brace is above the

beam, or 5-inches (125 mm) above the bottom flange

when the brace is below the beam, and the centerline

of the bay.

Page 23 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

6.2.9

6.3

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Connections for Concrete Fireproofed Members

6.2.9.1

Connections for members fireproofed with concrete shall be

detailed to minimize blockouts in shop applied fireproofing.

6.2.9.2

Gusset plates for vertical or horizontal bracing members

and single-plate shear connections for beams shall extend

outside fireproofing a sufficient length to make the

connection with the fireproofing in place.

6.2.9.3

Handrails shall not be connected to fireproofed columns.

Handling, Shipping, and Delivery

6.3.1

Handling and Shipping

6.3.1.1

Delivery of steel shall be in the order needed for erection.

The delivery sequence for the fabricated steel, unless

otherwise noted in the contract documents or arranged by

Saudi Aramco, shall be as follows: anchor bolts, loose base

plates, steel embedded in concrete, erection bolts, first tier

columns and framing for all its levels (including stairs and

handrail), second tier columns and its framing, etc.

6.3.1.2

All bolts, washers and nuts shall be packaged and delivered

in rigid, weatherproof containers. Cardboard containers are

not acceptable.

6.3.1.3

Railcars and/or trucks shall be loaded and cribbed so that

they can be readily unloaded by others. Load in such a

manner that continuous drainage will occur.

6.3.1.4

The Fabricator shall ensure that all steel and its coatings are

protected from any damage caused by handling, storage or

shipping prior to receipt by the Buyer.

6.3.1.5

The Fabricator shall ensure that adequate protection is

provided for threads on sag rods, anchor bolts, and any

other threaded components so as to prevent damage during

shipping and handling. Care shall be taken that holes and

surfaces prepared for connection and the threads of bolts,

anchors, mortises, etc., stay clean and undamaged.

6.3.1.6

The bottom of base plates shall be clean and free of any rust

or corrosion.

Page 24 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

6.3.2

6.4

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Delivery

6.3.2.1

The Fabricator is responsible for delivering all materials

and documentation to the job site in good condition. All

material and documentation will be inspected immediately

upon receipt by Buyer to determine that all items included

in the Bill of Materials have been supplied, to assure that all

documentation has been received, and to check for any

damage.

6.3.2.2

All materials designated for the care, custody and control of

the Erector shall be received, unloaded, stored, and

otherwise handled in a manner that will prevent distortion,

deterioration, or damage.

6.3.2.3

Saudi Aramco reserves the right to reject all damaged or

substandard material or documentation.

Erection and Shop Drawings

6.4.1

Shop drawings and erection drawings shall be prepared in accordance

with the AISC documents listed in this specification.

6.4.2

Erection drawings shall reference the corresponding design drawings.

Every steel piece on the shop drawings shall reference the appropriate

erection drawing.

6.4.3

Erection and shop drawings shall be grouped in sets and identified

separately for each structure or yard area.

6.4.4

Erection drawings shall clearly show the mark number and position for

each member.

6.4.5

All fabricated steel sections shall be match-marked for field assembly

with designating numbers or letters corresponding to the field erection

drawings. Match-marking of steel shall be done with suitable paint,

waterproof ink or with pressed metal tags.

6.4.6

In addition to the Fabricator's identification marks, each item or bundle

of walkways and platforms shall be marked with a unique tag number

to clearly indicate its associated equipment. Each item or bundle of

walkways and platforms shall also be indicated on the erection

drawings.

6.4.7

Shop drawings shall state the welding procedure to be used.

Page 25 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

6.5

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

6.4.8

Shop drawings shall clearly show the specification and grade of steel to

be used.

6.4.9

The buyer's purchase order number shall be shown on all erection and

shop drawings.

6.4.10

Surface preparation and shop-applied coatings, including areas to be

masked, shall be noted on the shop drawings.

6.4.11

The Fabricator shall provide a bolt list and a list of other fasteners

showing the number, grade, size, and length of field bolts for each

connection. These lists may be shown on either the shop drawings or

on separate sheets.

6.4.12

In the event that drawing revisions are necessary, the Fabricator shall

clearly flag on the shop drawings all changes showing the latest

revisions.

Drawings Submittals

6.5.1

A Shipping List (including total weight), a Bolt List, and a minimum

of two sets of final erection and shop drawings shall accompany the

first shipment of each release.

6.5.2

Design drawings including foundation loading diagrams shall be

provided for approval of the Buyer as specified in the Non-Material

Requirements, Form NMR-7927 attached to the Purchase Order.

6.5.3

The foundation loading diagram to be provided by the Vendor shall

show the type, size, location and projection of all anchor bolts for the

metal system components, and the minimum length and width of the

foundation required. Column reactions (magnitude and direction) and

minimum base plate dimensions shall also be included.

Inspection and Testing

7.1

All NDT procedures shall be submitted to the Inspection Department /

Operations Inspection Division (OID) ASNT Level-III for acceptance prior to

work commencing.

7.2

The Buyer has the Right to inspect all materials and workmanship, and shall have

unrestricted entry to the shop of the Fabricator at all times while work is being

performed. The Buyer may reject improper, inferior, defective, or unsuitable

materials and workmanship. All materials and workmanship rejected shall be

repaired or replaced by the Fabricator as directed by the Buyer. The company

Page 26 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

inspector shall have access to the vendor's facilities to see that SAES-H-100

quality elements are in place prior to and during blasting, priming and coating

operations.

7.3

The Inspection Test Plan (ITP) shall be provided for review and approval by the

company inspector.

7.4

Inspection and testing shall conform to this Specification and Saudi Aramco

Inspection Requirements Forms 175-120100 or 175-120500 attached to the

Purchase Order.

7.5

Welding procedures and individual welders shall be qualified in accordance with

the requirements of ANSI/AWS D1.1/D1.1M or ANSI/AWS D1.3 as

appropriate. All welding procedures and welding performance qualification

records shall be made available to the Buyer's Inspector for review.

7.6

Inspection of welding shall be performed in accordance with the Structural

Welding Code, ANSI/AWS D1.1/D1.1M. Ultrasonic testing may be substituted

for radiography if approved by Saudi Aramco Inspection.

a)

All welds shall have 100% visual inspection performed per ANSI/AWS

D1.1. In addition, any strikes, gouges, and other indications of careless

workmanship (such as surface porosity) shall be removed by grinding.

b)

Pipes used as piling (circumferential welds) and tubular structures shall be

randomly radiographed at the rate of 10% [one weld of each ten (10) welds

shall be 100% radiographed]. The specified amount of random

radiography shall include X-ray samples from each welder's daily

production.

c)

The butt-welded flange sections for all primary load-bearing members

shall be 100% radiographed at the weld. Primary load-bearing members

shall be defined as the main frames and any members that are part of the

lateral load carrying system.

d)

Secondary members such as purlins, girts or rafters that are not part of the

main sway frame, the butt-welds can be tested as follows; 10% of the buttwelds of each days production (randomly selected) shall have radiographic

tests performed on the welds.

e)

All lifting lug connections shall be 100% radiographed. Procedures and

operator qualifications shall meet ANSI/AWS D1.1 and be submitted to

the Company Inspector for review and approval. For Skid-mounted

equipment with a total lift weight of less than 3000 kg, it is acceptable to

use fillet-welded lugs with dye penetrant inspection.

f)

The minimum percent coverage of the specified NDT method may be

increased (at any level up to 100%) if, in the opinion of the Company

Page 27 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

Inspector, the welds are of questionable workmanship or NDT indicates an

excessive number of defects. Additional or alternative NDT methods may

be used at the discretion of the Company Inspector in order to assist in

determining the type or extent of defects.

7.7

Material test reports for each heat of structural steel, each lot of high-strength

and ASTM A307 bolts shall be available for review by the Buyer. Material test

reports shall conform to EN 10204, Type 3.1.

7.8

The Buyer may require a quantity of representative samples of bolt assemblies

which the Fabricator shall supply to the Buyer for testing. Testing in accordance

with ASTM F606 or ASTM F606M will be at the Buyer's expense.

7.9

If any damage is discovered, or any parts, components, or documentation are

missing or otherwise defective, the occurrence shall be immediately reported to

the Buyer in writing.

7.10

Shop inspection may include, but not be limited to the following:

Verification of conformance of materials with this Specification and the

drawings. The limits of acceptability and repair of surface imperfections for

structural steel shall be in accordance with ASTM A6 / ASTM A6M.

7.11

Inspection of high-strength bolted connections shall be in accordance with AISC

Specification for Structural Joints Using ASTM A325 or ASTM A490 Bolts.

7.12

The buyer reserves the right to inspect and reject all galvanized steel in

accordance with ASTM A123 and ASTM E376.

28 April 2004

30 April 2005

7 May 2006

3 September 2006

Revision Summary

Major revision.

Editorial revision; added requirements for fireproofed steel in Section 5.1 and updated

Appendix 1 with revised ASTM Material Equivalency.

Editorial revision as marked.

Editorial revision as marked.

Page 28 of 29

Document Responsibility: Onshore Structures

Issue Date: 3 September 2006

Next Planned Update: 1 May 2009

12-SAMSS-007

Fabrication of Structural

and Miscellaneous Steel

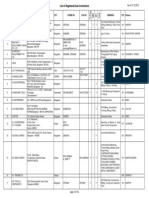

Appendix 1 ASTM Material Equivalency

ASTM Materials

ASTM A36/A36M

EN Materials

EN 10025-2, Gr S275J0

ISO Materials

JIS Materials

ISO 630-95, E275 C

G3106-95, SM490A

ISO 9329-1, TS430

G3454-88, STPG 410

EN 10025-2, Gr S275JR

ASTM A53

ISO 9330-1, TW430

ASTM A108, G1010

EN 10016-2, C10D

ISO 4954, CC 11 X

G1015

EN 10016-2, C15D

ISO 4954, CC 15 K

G1020

EN 10016-2, C20D

ISO 4954, CC 21 K

ASTM A307

No Substitute

No Substitute

No Substitute

ASTM A325

No Substitute

No Substitute

No Substitute

ASTM A325M

No Substitute

ISO 7412 per ASTM A325M

No Substitute

ASTM A500

EN 10219-1, S355J0H

G3444-94, STK490

G3466-88, STKR490

ASTM A501

EN 10210-1, S275J0H

G3444-94, STK490

G3466-88, STKR490

ASTM A563

No Substitute

No Substitute

No Substitute

ASTM A563M

No Substitute

ISO 4775 per ASTM A563M

No Substitute

ASTM A1011/A1011M

EN 10025-2, Gr S235JR

ISO 3573, HR1

G3131, SPHC

ASTM A572/A572M, G50

EN 10025-2, Gr S355JR

ISO 4950-2, E355DD

G3106, SM490YA

G65

EN 10025-2, Gr S450JO

ISO 4950-2, E460CC

G3106, SM570

ASTM A759

None

ISO 5003

E1101, E1103

ASTM A992/A992M

EN 10025-2, Gr S355JR

ISO 630-95, E355 C

G3106, SM490YA

EN 10025-2, Gr S355J0

G3106, SM570

G3136

Note: The minimum published yield strength may vary based on the material thickness. Refer to the appropriate

material specification.

Page 29 of 29

Вам также может понравиться

- Materials System SpecificationДокумент23 страницыMaterials System SpecificationFAPM1285Оценок пока нет

- 20 TMSS 02 R0Документ0 страниц20 TMSS 02 R0renjithas2005Оценок пока нет

- Structural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaДокумент10 страницStructural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaAnonymous nABFA4lОценок пока нет

- Suggested Specifications For Hot-Dip GalvanizingДокумент11 страницSuggested Specifications For Hot-Dip GalvanizingSreedhar Patnaik.M100% (1)

- C12632-QM-WPS-S-0001 R.1 PDFДокумент373 страницыC12632-QM-WPS-S-0001 R.1 PDFErick HoganОценок пока нет

- SAES-T-744 Design Criteria and Installation of Communication TowersДокумент7 страницSAES-T-744 Design Criteria and Installation of Communication TowersAbdul Rahim ShaikhОценок пока нет

- Saes A 206Документ16 страницSaes A 206Malcolm F Beall100% (1)

- Pip-001 Rev. A6Документ8 страницPip-001 Rev. A6anisaanОценок пока нет

- Saer 5974 PDFДокумент31 страницаSaer 5974 PDFZhiguo YangОценок пока нет

- Tes-W-109.01-R0-General Welding CriteriaДокумент23 страницыTes-W-109.01-R0-General Welding CriteriaUtkucan KILIÇОценок пока нет

- Corrosion Roche Arkhangelsk Part 4 CP2 CoatingsДокумент71 страницаCorrosion Roche Arkhangelsk Part 4 CP2 CoatingsAdel ChelbaОценок пока нет

- Saep 311Документ30 страницSaep 311GulfamОценок пока нет

- 01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeДокумент4 страницы01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeZahidRafiqueОценок пока нет

- Foundation Design - Day 1-Day 2Документ86 страницFoundation Design - Day 1-Day 2ochukoikogho0% (1)

- Hot Dip GalvanizingДокумент3 страницыHot Dip Galvanizingapply19842371Оценок пока нет

- Cable TrayДокумент5 страницCable Traykxalxo7637Оценок пока нет

- Asme+b31 4 PDFДокумент16 страницAsme+b31 4 PDFvin_omloveОценок пока нет

- Galvanizing ProcedureДокумент11 страницGalvanizing ProcedureMcmiltondmordomОценок пока нет

- Pip SupportДокумент167 страницPip SupportCristian DehnОценок пока нет

- Astm 890Документ3 страницыAstm 890bsnegi111Оценок пока нет

- Section 05120 Structural Steel Part 1Документ43 страницыSection 05120 Structural Steel Part 1jacksondcplОценок пока нет

- 01-SAMSS-044 PDF Download - CRA Clad Pipe SpoolsДокумент4 страницы01-SAMSS-044 PDF Download - CRA Clad Pipe SpoolsZahidRafiqueОценок пока нет

- Experience With Lined and Clad PipelinesДокумент17 страницExperience With Lined and Clad Pipelinesjoni Mart Sitio100% (1)

- 5 DCN - Design Change NoticeДокумент3 страницы5 DCN - Design Change Noticearif99pakОценок пока нет

- AZZ Galv Fab BookДокумент27 страницAZZ Galv Fab BookDaren NeradОценок пока нет

- Products Presentation MajorДокумент47 страницProducts Presentation MajorJuanita AndrewsОценок пока нет

- NL-WI-236-04 Nozzle Loads EquipmentДокумент3 страницыNL-WI-236-04 Nozzle Loads EquipmentChirag ShahОценок пока нет

- 583-9738 Procedure For Piping 00Документ22 страницы583-9738 Procedure For Piping 00sivaramОценок пока нет

- 6001F Rev 07 Material, Fabrication and Installation StructureДокумент83 страницы6001F Rev 07 Material, Fabrication and Installation StructurePatrickioОценок пока нет

- Ad-Cdzzzz-Cv-Spe-0032-000 Specification For Structural and Miscellaneous Materials and FabricationДокумент19 страницAd-Cdzzzz-Cv-Spe-0032-000 Specification For Structural and Miscellaneous Materials and FabricationMehman NasibovОценок пока нет

- A FEDS Structural BoltsДокумент6 страницA FEDS Structural BoltsCrimsonPoshОценок пока нет

- Hydrotest ProcedureДокумент3 страницыHydrotest Procedureaman131100% (2)

- RFI-3410 - Daily Fit Up Inspection Report-OKДокумент92 страницыRFI-3410 - Daily Fit Up Inspection Report-OKnguyennamxmОценок пока нет

- WELDABILITY of SteelДокумент41 страницаWELDABILITY of Steel0502ravi100% (1)

- Post Weld Heat TreatmentДокумент10 страницPost Weld Heat Treatmentcristian291011Оценок пока нет

- 1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1Документ4 страницы1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1JithuJohnОценок пока нет

- Welding Duplex Stainless Steel Piping SpecДокумент44 страницыWelding Duplex Stainless Steel Piping SpecAlaa100% (1)

- Saes B 054Документ14 страницSaes B 054Tarek Mustafa100% (1)

- A-320 - Fire Proofing of Steel StructureДокумент11 страницA-320 - Fire Proofing of Steel StructurePoorvi Bhave75% (4)

- Korean StandardДокумент1 страницаKorean StandardbayuОценок пока нет

- 4.4 Technical Specification For Structural SteelworkДокумент11 страниц4.4 Technical Specification For Structural SteelworkHazim HaОценок пока нет

- 01-SAMSS-333-HF Welded Line Pipe PDFДокумент35 страниц01-SAMSS-333-HF Welded Line Pipe PDFmunnaОценок пока нет

- Repair Welding Temper BeadДокумент9 страницRepair Welding Temper BeadwilliamjdtОценок пока нет

- Cathodic Protection ProjectДокумент6 страницCathodic Protection Projectjamal AlawsuОценок пока нет

- Technical Specification Index of Piping Material ClassДокумент3 страницыTechnical Specification Index of Piping Material ClassZvonko Bešlić100% (1)

- WeldPulse - Welding Software BrochureДокумент13 страницWeldPulse - Welding Software BrochureWeldPulse100% (1)

- Sts 02360Документ22 страницыSts 02360Sowjanya VenigallaОценок пока нет

- Inspection General for Plant's Equipment-R0-나규홍Документ25 страницInspection General for Plant's Equipment-R0-나규홍Rjeb mohamedОценок пока нет

- CWB - Welding Requirements Csa-S6 Canadian Highway Bridge Design Code Welding RequirementsДокумент2 страницыCWB - Welding Requirements Csa-S6 Canadian Highway Bridge Design Code Welding RequirementsStephen TilleyОценок пока нет

- Design Basis Report FOR Cable Tray: Document No. RINFRA-KUMPP-NEE-220-R-0001-R00Документ6 страницDesign Basis Report FOR Cable Tray: Document No. RINFRA-KUMPP-NEE-220-R-0001-R00pulasta109Оценок пока нет

- (Compare Report) SAES-B-005Документ14 страниц(Compare Report) SAES-B-005kartik_harwani4387Оценок пока нет

- Steel StructureДокумент6 страницSteel StructureONG VОценок пока нет

- Sabp P 004Документ17 страницSabp P 004Hassan MokhtarОценок пока нет

- WPS 03 GtawДокумент3 страницыWPS 03 GtawBiswajit DeyОценок пока нет

- Technical Proposal Blast DoorsДокумент17 страницTechnical Proposal Blast DoorsnpwalОценок пока нет

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsДокумент6 страницOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketОценок пока нет

- 20-SDMS-01 R3 FinalДокумент30 страниц20-SDMS-01 R3 FinalFayyaz Ahmad KhanОценок пока нет

- Section 05505 METAL FABRICATIONS PDFДокумент13 страницSection 05505 METAL FABRICATIONS PDFIm ChinithОценок пока нет

- Sdcs-03 Part 1 (Distribution Network Grounding) Rev01Документ107 страницSdcs-03 Part 1 (Distribution Network Grounding) Rev01Haytham BafoОценок пока нет

- American Concrete Pavement Association Design and Construction GuideДокумент12 страницAmerican Concrete Pavement Association Design and Construction GuideluftwachОценок пока нет

- Glosario de Terminos en Ingenieria de PuentesДокумент99 страницGlosario de Terminos en Ingenieria de Puentesymaseda100% (1)

- Glosario de Terminos en Ingenieria de PuentesДокумент99 страницGlosario de Terminos en Ingenieria de Puentesymaseda100% (1)

- SAES-M-009 Design Criteria For Blast Resistant 2005Документ55 страницSAES-M-009 Design Criteria For Blast Resistant 2005ymasedaОценок пока нет

- SAES-Q-009 Concrete Retaining Walls 2008Документ5 страницSAES-Q-009 Concrete Retaining Walls 2008ymasedaОценок пока нет

- Saes Q 007Документ20 страницSaes Q 007noorggggg100% (1)

- SAES-Q-012 Criteria Design Construction Precast Prestressed Concrete Structures 2006Документ15 страницSAES-Q-012 Criteria Design Construction Precast Prestressed Concrete Structures 2006ymaseda100% (3)

- Ring Wall Foundation PDFДокумент18 страницRing Wall Foundation PDFAbhaysinh Shinde85% (13)

- SAES-Q-004 Installation Piles Offshore Structures 2004Документ22 страницыSAES-Q-004 Installation Piles Offshore Structures 2004ymaseda100% (2)

- SAES-M-005 Design and Construction Fixed Offshore Platforms 2008Документ24 страницыSAES-M-005 Design and Construction Fixed Offshore Platforms 2008ymaseda100% (2)

- SAES-L-440 Anchors Buried Pipelines 2005Документ6 страницSAES-L-440 Anchors Buried Pipelines 2005ymasedaОценок пока нет

- 12-SAMSS-014 Pre-Engineered Metal Buildings 2008Документ31 страница12-SAMSS-014 Pre-Engineered Metal Buildings 2008ymasedaОценок пока нет

- 124 1r 92-Esthetics in ConcreteДокумент1 страница124 1r 92-Esthetics in ConcreteymasedaОценок пока нет

- 12-SAMSS-008 Erection Structural Miscellaneous Steel 2011Документ4 страницы12-SAMSS-008 Erection Structural Miscellaneous Steel 2011ymasedaОценок пока нет

- 124 2R-94 PDFДокумент1 страница124 2R-94 PDFfarhadamОценок пока нет

- Company Profile ConДокумент4 страницыCompany Profile ConSudipThapaОценок пока нет

- TMAC Quality Management Systems CertificationsДокумент2 страницыTMAC Quality Management Systems CertificationsGuzman ManufacturingОценок пока нет

- Data Rates-CD Works Part 1Документ20 страницData Rates-CD Works Part 1vpmohammedОценок пока нет

- WP001Документ37 страницWP001jfl2096Оценок пока нет

- IS 802 Part-2:1978Документ13 страницIS 802 Part-2:1978Sardar. Vikramjit Singh RandhawaОценок пока нет

- Section 05120 Structural SteelДокумент9 страницSection 05120 Structural SteelMØhãmmed ØwięsОценок пока нет

- Hot TappingДокумент15 страницHot Tappingghkashyap150% (2)

- Ch13 - Steel Fabrication WorkДокумент54 страницыCh13 - Steel Fabrication Workwhyme_bОценок пока нет

- Automated Drain Cleaner Design and Progress ReportДокумент12 страницAutomated Drain Cleaner Design and Progress ReportMohd Anwar83% (6)

- Oilgasengineering 131129020341 Phpapp02Документ231 страницаOilgasengineering 131129020341 Phpapp02sj_scribd100% (5)

- Case Study of Fabtrol PDFДокумент8 страницCase Study of Fabtrol PDFtanvirОценок пока нет

- Structural Steel Specification for Civil Engineering ProjectsДокумент6 страницStructural Steel Specification for Civil Engineering Projectsfernanda rojasОценок пока нет

- Resume Mitesh Suneriya W CTCДокумент3 страницыResume Mitesh Suneriya W CTCMiteshSuneriyaОценок пока нет

- Government of India Nuclear Recycle Board Bhabha Atomic Research Centre Personnel Division A N - 01/2016 (R-I)Документ7 страницGovernment of India Nuclear Recycle Board Bhabha Atomic Research Centre Personnel Division A N - 01/2016 (R-I)Śáńtőśh MőkáśhíОценок пока нет

- Udated Final SCVD-As of 31.12.2012Документ142 страницыUdated Final SCVD-As of 31.12.2012ArunkumarОценок пока нет

- Mechanized Vegetable Slicer Proposal - Technical - RuTAG FinalДокумент15 страницMechanized Vegetable Slicer Proposal - Technical - RuTAG Finalsathiscad123Оценок пока нет

- Design of a Manually Operated Rice TransplanterДокумент45 страницDesign of a Manually Operated Rice TransplanterJaja Gallardo BonafeОценок пока нет

- PSP-06 (Blasting & Painting Procedure)Документ6 страницPSP-06 (Blasting & Painting Procedure)beruslee82% (11)

- DMCI Steel Railing Fabrication MethodДокумент15 страницDMCI Steel Railing Fabrication MethodNanette LagundayОценок пока нет

- Costing of PipelinesДокумент18 страницCosting of Pipelinesbjtiew100% (3)

- Basic Fabrication Process FlowchartДокумент1 страницаBasic Fabrication Process FlowchartMorjhan MJ86% (29)

- SECTION 05530 Gratings Rev 1Документ17 страницSECTION 05530 Gratings Rev 1Mohsin ShaikhОценок пока нет

- Fabricatin Inspection Testing of Structural ProductДокумент44 страницыFabricatin Inspection Testing of Structural ProductwalitedisonОценок пока нет

- SECTION 05091 Rail W Elding: (Latest Addition)Документ232 страницыSECTION 05091 Rail W Elding: (Latest Addition)Giovanni-DuránОценок пока нет

- Prospectus 2013 14Документ165 страницProspectus 2013 14Bench AminОценок пока нет

- Lincoln Notes On Weld DistortionДокумент5 страницLincoln Notes On Weld DistortionansarALLAAHОценок пока нет

- Ptechnologies Industries Corp Company ProfileДокумент27 страницPtechnologies Industries Corp Company Profilejhay lagmanОценок пока нет

- Anclas Placas Base para Columnas Thomas MurrayДокумент89 страницAnclas Placas Base para Columnas Thomas MurrayMariano DiazОценок пока нет

- Hot Dip Galvanized SectionsДокумент5 страницHot Dip Galvanized SectionsFULIMA Steel StructureОценок пока нет

- Wtia Training Program 2014Документ6 страницWtia Training Program 2014Syed Mahmud Habibur RahmanОценок пока нет