Академический Документы

Профессиональный Документы

Культура Документы

Principal Integrity Engineer: Summary of Role

Загружено:

wahИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Principal Integrity Engineer: Summary of Role

Загружено:

wahАвторское право:

Доступные форматы

Principal Integrity Engineer

Summary of Role:

The Principal Integrity Engineer will be responsible for update, assessment and analysis of

inspection and integrity management activities. The Principal Integrity Engineer will report

directly to the Technical Services Coordinator.

Responsibilities / Duties:

Responsible for the review, assessment and update of integrity management and

inspection data for pressure systems, pipelines and structures and the development of

project strategy documentation, risk assessments and Written Schemes of Examination.

Provide effective technical advice to the inspection team, ensuring threats are evaluated,

procedures are followed and work is completed in accordance with the company's

technical procedures.

Liaise and manage subcontractor's day-to-day activities.

Ensure that any actions arising from inspection activities are fully reported and

communicated with the Integrity Team Leader and Client.

Perform effective review of inspection data, results trending and remnant life assessments,

perform fitness-for-service assessments and provide recommendations for repair and

replacement methodologies.

Perform root cause analysis and failure investigation on systems and equipment, as

required.

Provide timely and accurate reports to the Integrity Team Leader and Client as required,

informing the Client of anomalies and recommend actions to be taken.

Ensure project activities are performed in accordance with accreditation schemes,

legislation and industry standards and that project activities are performed in accordance

with the health, safety and environmental policy.

Audit the inspection team on compliance to international standards and procedures.

Act as focal point for corrosion management expertise and ensure that relevant reports

and data are reviewed and communicated accordingly.

Co-ordinate and participate in periodic plant and equipment history reviews in order to

maximise plant availability.

Assist the Integrity Team Leader in budget preparation, annual revenue forecasts and

monthly updates.

Co-ordinate and action results from associated failure investigations / significant

anomalies.

Ensure the effective application of new techniques, technologies and use of specialist NDT

contractor to limit intrusive inspection so to maximise inspection intervals.

Ensure onsite work activities are performed in accordance with the health, safety and

environmental policy, company SHE&Q manual and asset specific control of work

procedures and practices.

Skills / Qualifications:

A relevant engineering degree preferably in Corrosion Engineering, Mechanical

Engineering or Metallurgy.

Minimum 15 years of specific experience in Integrity Management, Risk Based Inspection

and In-Service Inspection (excluding purely NDT).

Experience and knowledge of integrity management software systems such as Credo,

RBMI, ACET, etc. is preferred.

Thorough understanding of NDT techniques and in-service application of NDT.

Thorough understanding of defect assessment techniques in accordance with relevant

codes / standards and API 579.

Thorough knowledge of pressure vessel and pipe work design and inspection codes of

practice.

Knowledge of related standards / regulatory requirements.

Plant inspection or API certification, with associated experience.

Versatile and flexible team player with good verbal and written communication skills.

Good command of English language.

Вам также может понравиться

- Role DescriptionДокумент7 страницRole Descriptionpersonalmail_20011078Оценок пока нет

- ITL Role ProfileДокумент2 страницыITL Role Profiledirectora.ceciliaavomoОценок пока нет

- Technical Integrity Engineering Is A Term Applied To The Engineering Disciplines Associated With TheДокумент5 страницTechnical Integrity Engineering Is A Term Applied To The Engineering Disciplines Associated With TheVenkatesh PethurajОценок пока нет

- ROLEsДокумент4 страницыROLEsfransiskaa hasibuanОценок пока нет

- Senior Instrument Engineer Key ResponsibilitiesДокумент2 страницыSenior Instrument Engineer Key ResponsibilitiesE.C.MADHUDUDHANA REDDYОценок пока нет

- RCM (Instrument) Engineer IMS One World - Jubail: Required SkillsДокумент4 страницыRCM (Instrument) Engineer IMS One World - Jubail: Required SkillsadibОценок пока нет

- Engineering Manager - Pham NguyenДокумент5 страницEngineering Manager - Pham NguyenYen NguyenОценок пока нет

- Asset Management Specialist - MidrandДокумент3 страницыAsset Management Specialist - MidrandLindaniОценок пока нет

- Maintain CeДокумент3 страницыMaintain Cemuhammad raheelОценок пока нет

- Corrosion Inspector Job PurposeДокумент2 страницыCorrosion Inspector Job PurposeYoucef ChorfaОценок пока нет

- Reliability Engineer JDДокумент3 страницыReliability Engineer JDqaisarabbas9002Оценок пока нет

- QA Manager YogeshДокумент4 страницыQA Manager YogeshParag WadekarОценок пока нет

- Job Assessment Report: Mahmudul HasnerДокумент9 страницJob Assessment Report: Mahmudul HasnerMahmudul HasnerОценок пока нет

- Static Equipment EngineerДокумент2 страницыStatic Equipment EngineerMEDHAT HASSAN SHALABYОценок пока нет

- Manager Inspection & Reliability / MaintenanceДокумент9 страницManager Inspection & Reliability / MaintenanceLIAQATОценок пока нет

- Lafarge - Reliability JobДокумент9 страницLafarge - Reliability JobsatfasОценок пока нет

- Resume For QC JobДокумент7 страницResume For QC Jobtcrmvpdkg100% (1)

- Job Description: Roles and ResponsibilitiesДокумент3 страницыJob Description: Roles and ResponsibilitiesbhushanОценок пока нет

- Inspection and Testing To Ensure The Quality of End Product in Construction WorksДокумент5 страницInspection and Testing To Ensure The Quality of End Product in Construction WorksensafepsОценок пока нет

- Director of EngineeringДокумент3 страницыDirector of EngineeringPhươngNghiОценок пока нет

- HotelДокумент9 страницHotelZaffar NoorОценок пока нет

- JD SR - Civil EngineerДокумент3 страницыJD SR - Civil EngineerAlexandru IonescuОценок пока нет

- Asset Management Engineer - NetcareДокумент4 страницыAsset Management Engineer - NetcareLindaniОценок пока нет

- Job Class - Senior Mechanical Maintenance TechnicianДокумент7 страницJob Class - Senior Mechanical Maintenance TechnicianAvina NigОценок пока нет

- Roles & Responsibilities of Construction ProfessionalsДокумент6 страницRoles & Responsibilities of Construction Professionalsabhayavhad51100% (1)

- Senior Engineer, Reliability in Abu Dhabi, United Arab Emirates Projects, Engineering & Operations at ADNOC GroupДокумент1 страницаSenior Engineer, Reliability in Abu Dhabi, United Arab Emirates Projects, Engineering & Operations at ADNOC Groupmmkhalil1990Оценок пока нет

- 1.engineering & Commissioning Manager (ECM)Документ7 страниц1.engineering & Commissioning Manager (ECM)harrisvasОценок пока нет

- Witness InspectionДокумент2 страницыWitness InspectionJlkKumarОценок пока нет

- CC Instrument and Control Maintenance Role Profile With Supporting Notes 2021Документ3 страницыCC Instrument and Control Maintenance Role Profile With Supporting Notes 2021hariharan.ece88Оценок пока нет

- Ishtiaq Mechanical Eng CVДокумент9 страницIshtiaq Mechanical Eng CVmohammedОценок пока нет

- Job DescriptionДокумент3 страницыJob Descriptionairsys7projecОценок пока нет

- Mechanical Design Engineer2Документ8 страницMechanical Design Engineer2Arnold LicayanОценок пока нет

- Shahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Документ7 страницShahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Sikander GirgoukarОценок пока нет

- MepДокумент4 страницыMepMohsin MapariОценок пока нет

- Maintenance Planner/Scheduler: Distinguishing Features of The ClassДокумент4 страницыMaintenance Planner/Scheduler: Distinguishing Features of The ClassbabaОценок пока нет

- Resume Examples For Maintenance TechnicianДокумент5 страницResume Examples For Maintenance Technicianbcqv1trr100% (2)

- MEP Engineer Job ResponsibilitiesДокумент9 страницMEP Engineer Job ResponsibilitiesRamy MahmoudОценок пока нет

- Job SummaryДокумент4 страницыJob Summaryabeer789Оценок пока нет

- CV - Asset IntegrityДокумент4 страницыCV - Asset IntegritySyed Shiraz Ali100% (1)

- Qa - QC ManagerДокумент14 страницQa - QC Managermunawar hussainОценок пока нет

- ExperiencesДокумент3 страницыExperiencesAzzeddine BoukebireОценок пока нет

- Job Description-Instrument EngineerДокумент1 страницаJob Description-Instrument EngineerpayamОценок пока нет

- JD Mechanical ENДокумент3 страницыJD Mechanical ENCertified Rabbits LoverОценок пока нет

- Fire and Gas Technician: EducationДокумент3 страницыFire and Gas Technician: Educationjohn M100% (1)

- SM QhseДокумент10 страницSM QhsekoralbiruОценок пока нет

- Reliability Engineer: Organizational RelationshipsДокумент6 страницReliability Engineer: Organizational RelationshipsJosé David Cruz MahechaОценок пока нет

- GasДокумент18 страницGassojeck0% (1)

- Resume Sample For Quality Control InspectorДокумент7 страницResume Sample For Quality Control Inspectorc2yyr2c3100% (1)

- Shift Charge Engineer: Rajahmundry, Andhra PradeshДокумент2 страницыShift Charge Engineer: Rajahmundry, Andhra PradeshBv RaoОценок пока нет

- Process Engineer III - V Basic FunctionДокумент4 страницыProcess Engineer III - V Basic FunctionmessiОценок пока нет

- Senior Process Engineer (External)Документ3 страницыSenior Process Engineer (External)kebiskygmailОценок пока нет

- JD QAQC Engineer Mech 2016Документ2 страницыJD QAQC Engineer Mech 2016Sebastian Rajesh100% (1)

- Pipesim User GuideДокумент3 страницыPipesim User GuideVangapanduSrinivasaraoОценок пока нет

- Desired Skills and ExperienceДокумент3 страницыDesired Skills and ExperienceSyed Mujtaba Ali BukhariОценок пока нет

- Novo Documento RTF (Recuperação Automática)Документ27 страницNovo Documento RTF (Recuperação Automática)Certified Rabbits LoverОценок пока нет

- Curriculum Vitae Of: Correspondence/Permanent Address: EmailДокумент19 страницCurriculum Vitae Of: Correspondence/Permanent Address: EmailsojeckОценок пока нет

- QAQCДокумент1 страницаQAQCashfaqОценок пока нет

- Irshad Ahmad Makroo: Post Applied - Mechanical EngineerДокумент3 страницыIrshad Ahmad Makroo: Post Applied - Mechanical EngineerInnocent DemonОценок пока нет

- Build ThermitДокумент1 страницаBuild ThermitwahОценок пока нет

- DrumsДокумент2 страницыDrumswahОценок пока нет

- B Gas Q-2Документ2 страницыB Gas Q-2wahОценок пока нет

- Stress 1Документ39 страницStress 1wahОценок пока нет

- Bristle Blaster English - P 033 En.1Документ4 страницыBristle Blaster English - P 033 En.1egomoОценок пока нет

- Stress, Strain and Young's ModulusДокумент2 страницыStress, Strain and Young's ModuluswahОценок пока нет

- Sample of My Daughter's Hand WritingДокумент1 страницаSample of My Daughter's Hand WritingwahОценок пока нет

- ASME ANSI B16 Series StandardsДокумент6 страницASME ANSI B16 Series StandardswahОценок пока нет

- Concrete Defects Causes and Remedies Seg4 BДокумент23 страницыConcrete Defects Causes and Remedies Seg4 BJeremy Chow100% (2)

- Lube Oil System AccumulatorsДокумент2 страницыLube Oil System AccumulatorswahОценок пока нет

- BpweldtiДокумент36 страницBpweldtiBivashОценок пока нет

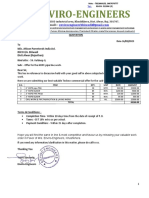

- No. Count Count %: Monthly KpisДокумент4 страницыNo. Count Count %: Monthly KpiswahОценок пока нет

- API 5L Line Pipe Physical PropertiesДокумент1 страницаAPI 5L Line Pipe Physical PropertieswahОценок пока нет

- Bolt Damage, RustДокумент1 страницаBolt Damage, RustwahОценок пока нет

- Asset Integrity Management (AIM) : Health, Safety, and Environment Construction InspectionДокумент1 страницаAsset Integrity Management (AIM) : Health, Safety, and Environment Construction InspectionwahОценок пока нет

- Auto-Oxidative Corsslinked ResinsДокумент5 страницAuto-Oxidative Corsslinked ResinswahОценок пока нет

- Coating DefectsДокумент13 страницCoating DefectswahОценок пока нет

- Fastener Technical GuideДокумент69 страницFastener Technical Guidewah100% (2)

- I Am Study in ALMOTTASSEM Inter National SchoolДокумент1 страницаI Am Study in ALMOTTASSEM Inter National SchoolwahОценок пока нет

- KPIs in ServiceДокумент19 страницKPIs in ServicevelusnОценок пока нет

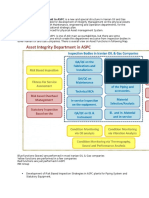

- Asset Integrity Department in ASPC Is A New and Special Structure in Iranian Oil and GasДокумент5 страницAsset Integrity Department in ASPC Is A New and Special Structure in Iranian Oil and GaswahОценок пока нет

- Accelerated Aging TestДокумент3 страницыAccelerated Aging TestwahОценок пока нет

- Tank Inspection ChecklistДокумент2 страницыTank Inspection ChecklistwahОценок пока нет

- Useful Phrases For Discussions: 1. Asking About or For An OpinionДокумент4 страницыUseful Phrases For Discussions: 1. Asking About or For An OpinionwahОценок пока нет

- BooksДокумент1 страницаBookswahОценок пока нет

- Moving and GrawingДокумент2 страницыMoving and GrawingwahОценок пока нет

- 2 - Ashby Method: 2.1 - Introduction To Materials SelectionДокумент25 страниц2 - Ashby Method: 2.1 - Introduction To Materials Selectionsgr_kansagraОценок пока нет

- Chemical Plant Inspection Grouping Per Unit Each Group Doing PPM Inspection Planned and Unplanned Inspection Project ExecutionДокумент1 страницаChemical Plant Inspection Grouping Per Unit Each Group Doing PPM Inspection Planned and Unplanned Inspection Project ExecutionwahОценок пока нет

- UPI Is The Utility Plant Provide Steam Water Etc To Other Plant Units Corrosive in NatureДокумент1 страницаUPI Is The Utility Plant Provide Steam Water Etc To Other Plant Units Corrosive in NaturewahОценок пока нет

- Hudrocarbons and Utility vs. Chemical PlantsДокумент1 страницаHudrocarbons and Utility vs. Chemical PlantswahОценок пока нет

- Profession: Mushrab Abulrazzaq 050-6822072 0556135698Документ4 страницыProfession: Mushrab Abulrazzaq 050-6822072 0556135698Huda AbdulKaderОценок пока нет

- 5 Star Rated ACДокумент3 страницы5 Star Rated ACavr8784Оценок пока нет

- EV Connect What Is EVSE White PaperДокумент13 страницEV Connect What Is EVSE White PaperEV ConnectОценок пока нет

- SprinkCAD FlyerДокумент2 страницыSprinkCAD FlyerGerardo ClementeОценок пока нет

- Sap Hana Attribute ViewsДокумент15 страницSap Hana Attribute ViewskhanmdОценок пока нет

- A001-MNC Siemens ChillerДокумент24 страницыA001-MNC Siemens ChillerLuis Yama0% (1)

- Piping Insulation Project Planned Schedule-Rev1Документ1 страницаPiping Insulation Project Planned Schedule-Rev1Anene EmmanuelОценок пока нет

- Invitation To Bid-Kalibo and Laguindingan Airport 01.2018Документ2 страницыInvitation To Bid-Kalibo and Laguindingan Airport 01.2018zaccОценок пока нет

- Manufacturing Systems EmergenceДокумент15 страницManufacturing Systems EmergenceArvind ARОценок пока нет

- Logistics OperationДокумент21 страницаLogistics OperationCJ David100% (1)

- AmphiMaster LiteratureДокумент6 страницAmphiMaster LiteratureAlcatrazIIОценок пока нет

- SatelliteДокумент37 страницSatelliteusama basionyОценок пока нет

- Plan de Trabajos: Cash FlowДокумент3 страницыPlan de Trabajos: Cash FlowAriel IsaackОценок пока нет

- Cross Cultural Issues in International BusinessДокумент25 страницCross Cultural Issues in International BusinessSharron Michelle BharathОценок пока нет

- Gasm İngilizceДокумент84 страницыGasm İngilizceozveoz100% (2)

- Honda Accessory Warranty MessageДокумент1 страницаHonda Accessory Warranty MessageMonkees LabsОценок пока нет

- Material Inspection ProcedureДокумент16 страницMaterial Inspection ProcedureImtiyaz Akhtar100% (2)

- Sap Fico ConsultantДокумент3 страницыSap Fico ConsultantNanda AmbatiОценок пока нет

- Double Surface TreatmentДокумент9 страницDouble Surface TreatmentAdrian FrantescuОценок пока нет

- Warehouse and StorageДокумент3 страницыWarehouse and StorageAnonymous mO72yqNcОценок пока нет

- Ahlcon - Hdpe Pipe Line WorkДокумент1 страницаAhlcon - Hdpe Pipe Line WorkPrashant YadavОценок пока нет

- SEO Proposal For AidanДокумент4 страницыSEO Proposal For AidanRitu BansalОценок пока нет

- G.O.Ms - No.20 Dated:19.11.2014Документ106 страницG.O.Ms - No.20 Dated:19.11.2014Srinivas PОценок пока нет

- Vertical Turbine Pump InformationДокумент10 страницVertical Turbine Pump Informationraghu_mn100% (1)

- QSP 7.1-03 Control of Organizational Knowledge (Preview)Документ4 страницыQSP 7.1-03 Control of Organizational Knowledge (Preview)Centauri Business Group Inc.100% (1)

- Jira Tutorial PDFДокумент20 страницJira Tutorial PDFregiane100% (5)

- Dooya 1Документ204 страницыDooya 1Prakash SheОценок пока нет

- GP Standard Shackles Brochure enДокумент2 страницыGP Standard Shackles Brochure enInhake AutechreОценок пока нет

- Abhishek Gupta JBM AutoДокумент26 страницAbhishek Gupta JBM AutoRashmi SinghОценок пока нет

- How To Gambas - Building GUI Applications-0.0.1Документ177 страницHow To Gambas - Building GUI Applications-0.0.1Ahmad MuaazОценок пока нет