Академический Документы

Профессиональный Документы

Культура Документы

(D-303) Installation of Vessel Heat Exchanger - Rev.3 PDF

Загружено:

mihir_jha2Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

(D-303) Installation of Vessel Heat Exchanger - Rev.3 PDF

Загружено:

mihir_jha2Авторское право:

Доступные форматы

S-OIL REFINERY

EXPANSION PROJECT

ENGINEERING SPECIFICATION

FOR

INSTALLATION OF VESSEL & HEAT EXCHANGER

ES No.

D-303

Revision

PAGE 1 OF 1

*REVISION HISTORY SHEET*

REV.NO.

DATE

Jul /24/2008

Oct/16/2008

DESCRIPTION

Newly Issued For Approval

(All)

Revise the project name in cover and contents.

(1.1)

The word "Bunker-C Cracking Center" was deleted

(1.1)

The word "Ssangyong Oil Refining Co., Ltd" was

changed to "S-OIL Corporation"

Nov/07/2008

Issued as approved (no comment)

Dec/09/2008

The revision history sheet was added

S-OIL ONSAN REFINERY

EXPANSION PROJECT

ENGINEERING SPECIFICATION

FOR

INSTALLATION OF VESSEL & HEAT EXCHANGER

ES No.

D-303

Revision

PAGE 1 OF 7

*CONTENTS*

1. GENERAL................................................................................................................................................................2

1.1 Scope...............................................................................................................................................................2

1.2 Related Engineering Specifications..................................................................................................................2

2. INSTALLATION WORKS.........................................................................................................................................2

3. IN-PROCESS CHECK.............................................................................................................................................3

3.1 Preparation of Foundation................................................................................................................................3

3.2 Setting of Liners or Mortar Pad........................................................................................................................3

3.3 Anchor Bolts Setting.........................................................................................................................................3

3.4 Setting of Equipment........................................................................................................................................3

3.5 Grouting of Anchor Pocket...............................................................................................................................4

3.6 Alignment.........................................................................................................................................................4

3.7 Grouting of Base..............................................................................................................................................4

4. ALIGNMENT.............................................................................................................................................................4

4.1 Tolerance..........................................................................................................................................................4

4.2 Priority Criteria.................................................................................................................................................5

4.3 Alignment of Vertical Equipment......................................................................................................................5

4.4 Alignment of Skid-mounted Equipment............................................................................................................6

4.5 Alignment of Stacking-type Equipment............................................................................................................6

5. ASSEMBLING OF ACCESSORIES.........................................................................................................................6

5.1 Internal Parts....................................................................................................................................................6

5.2 Platform and Ladder.........................................................................................................................................7

5.3 Davit.................................................................................................................................................................7

S-OIL ONSAN REFINERY

EXPANSION PROJECT

ENGINEERING SPECIFICATION

FOR

INSTALLATION OF VESSEL & HEAT EXCHANGER

ES No.

D-303

Revision

PAGE 2 OF 7

1. GENERAL

1.1 Scope

1.1.1 This specification covers the general requirements for the installation and inspection of vessels and

heat exchangers (Hereinafter collectively referred to as equipment), which may be included in S-OIL

ONSAN REFINERY EXPANSION PROJECT to be constructed by S-OIL Corporation. (Hereinafter

referred to as S-OIL) at Onsan, Korea.

1.1.2 This specification covers the general requirements for other similar type of static equipment, such as

silencers, filters, etc.

1.1.3 Vessels, heat exchangers, or tanks to be fabricated at site are not covered by this specification.

1.2 Related Engineering Specifications

The related Engineering Specification to supplement this specification are as follows:

D-301 "General Requirements in Equipment Installation"

2. INSTALLATION WORKS

Equipment shall be installed in correct position and orientation. Due care shall be paid to the following points

during the work.

(1) Prevention of damage to foundation, foundation bolts, equipment, adjacent structures, etc.

(2) Where the equipment having conical skirt or flat bottom support is directly placed on the foundation, the

vessel shall be installed without excessive concentrated force against bottom plate.

(3) For horizontal equipment which are subject to expansion/contraction, the relative position between foundation

bolts and bolt holes shall be set to allow free movement of the equipment in the correct direction of

expansion/contraction.

(4) Where sliding plates are used, no liners shall be applied between base plate and sliding plate. Contact

surfaces shall be cleaned and metal to metal coated with grease or graphite. After completion of installation

S-OIL ONSAN REFINERY

EXPANSION PROJECT

ENGINEERING SPECIFICATION

FOR

INSTALLATION OF VESSEL & HEAT EXCHANGER

ES No.

D-303

Revision

PAGE 3 OF 7

of the equipment and connection with piping, the nuts of the anchor bolts at sliding side shall be loosened to

give 1 to 2 mm of clearance, and then tightened with lock nuts leaving this clearance.

(5) Welding of liners shall be carried out after completion of final alignment inspection. In general, no welding

shall be permitted between base plate and liners.

(6) Where wooden pillows are used, setting and tightening of anchor bolts shall be in accordance with drawings

and manufacturer's installation manual.

3. IN-PROCESS CHECK

3.1 Preparation of Foundation

(1) Cleanliness of foundation surface and anchor bolt pockets

(2) Flatness of foundation surface where chipped

3.2 Setting of Liners or Mortar Pad

(1) Numbers and size of liners or mortar pads

(2) Uniform contact of liners with foundation surface

(3) Surface of liner plates

(4) Mixing ratio and condition of mortar in the case of mortar pads

(5) Elevation and level

(6) Position

3.3 Anchor Bolt Setting

(1) Size and setting position for projection and center

(2) Perpendicularity

(3) Free from oil and damage

(4) Thread lubrication

3.4 Setting of Equipment

(1) Cleanliness and smoothness of mounting face(s)

(2) Damage and foreign matter on the surface

S-OIL ONSAN REFINERY

EXPANSION PROJECT

ENGINEERING SPECIFICATION

FOR

INSTALLATION OF VESSEL & HEAT EXCHANGER

ES No.

D-303

Revision

PAGE 4 OF 7

3.5 Grouting of Anchor Pocket

(1) Mixing ratio and condition of grouting mortar

(2) Filling method and complete penetration

(3) Curing period

(4) After curing, check for cracks, peeling-off and cavities

3.6 Alignment

(1) Elevation

(2) Position

(3) Perpendicularity or level

3.7 Grouting of Base

(1) Mixing ratio and condition of grouting mortar

(2) Filling method and complete penetration

4. ALIGNMENT

4.1 Tolerance

Alignment of the equipment shall be carried out as follows, unless otherwise specified

(1) Tolerance shall be as in the following table.

Unit : mm

Type

Item

Vertical

Horizontal

Elevation

3.0

Position

3.0

Perpendicularity

Level

0.8 / 1,000

(And not more than 19mm)

0.8 / 1,000

(And not more than 19mm)

S-OIL ONSAN REFINERY

EXPANSION PROJECT

ENGINEERING SPECIFICATION

FOR

INSTALLATION OF VESSEL & HEAT EXCHANGER

ES No.

D-303

Revision

PAGE 5 OF 7

(2) Elevation shall be measured on the basis of level marking on the foundation.

(3) Position shall be measured on the basis of center marking of the foundation.

4.2 Priority Criteria

4.2.1 When the criteria stipulated in Para. 4.1 above interfere each other, the following order of priority may

be given:

(1) Vertical equipment

(a) Perpendicularity

(b) Position

(c) Elevation

(2) Horizontal equipment

(a) Horizontality

(b) Position

(c) Elevation

4.2.2 Regardless of the above priority, where an equipment is connected directly to special piping or another

equipment, relative position and elevation shall be given the priority.

4.3 Alignment to vertical Equipment

In general, alignment of vertical equipment shall be performed on 3 points from top to bottom of each

orientation and at two orientation of right angle to each other.

S-OIL ONSAN REFINERY

EXPANSION PROJECT

ENGINEERING SPECIFICATION

FOR

INSTALLATION OF VESSEL & HEAT EXCHANGER

ES No.

D-303

Revision

PAGE 6 OF 7

4.4 Alignment of Skid-mounted Equipment

Alignment of skid-mounted equipment shall be performed for horizontality, position and elevation of skid-base.

Alignment check for each component is not required.

4.5 Alignment of Stacking-type Equipment

4.5.1 Alignment of stacking-type equipment shall be performed based on relative position and elevation of

connecting nozzles, adjusting by placing shim plates between base plates of lower equipment and

upper equipment.

4.5.2 In the case of flange connection, applying paste on gaskets, inserting gaskets and bolt tightening shall

be confirmed.

5. ASSEMBLING OF ACCESSORIES

5.1 Internal Parts

Installation of internal parts such as, main beam, distributor, demister, grating, etc. shall be performed in

accordance with drawing, with consideration of work sequence for catalyst/packing loading or tray assembly

work.

S-OIL ONSAN REFINERY

EXPANSION PROJECT

ENGINEERING SPECIFICATION

FOR

INSTALLATION OF VESSEL & HEAT EXCHANGER

ES No.

D-303

Revision

PAGE 7 OF 7

5.2 Platform and Ladder

5.2.1 Platforms and ladders may be mounted any time before or after the installation of the equipment.

However, when mounted before installation, it shall be confirmed that those will not affect the erection

work of equipment.

5.2.2 When platforms and ladders are fixed to vertical towers and vessels subject to expansion/contraction,

slot holes of platforms, ladders, or lugs and loosening of nuts shall be confirmed.

5.2.4 When deformation of checker plates of platform floor is found, repair shall be carried out by heating or

reinforcing.

5.2.5 Welding slag of platform and ladders shall be completely removed by hammer.

5.2.6 When handrails are assembled by welding at site, the weld bead shall be finished flush by grinding.

5.2.7 Smooth movement and correct position of safety gate (bar) shall be checked.

5.3 Davit

5.3.1 Davits shall be mounted in accordance with drawings.

5.3.2 After mounting of davits, free movement shall be checked.

Вам также может понравиться

- BN-MLS-21-PTSC-307302 - Rev02 UFD - Vent and Drains System - Code 2Документ2 страницыBN-MLS-21-PTSC-307302 - Rev02 UFD - Vent and Drains System - Code 2citramuaraОценок пока нет

- Sample2 DrawingДокумент1 страницаSample2 DrawingSourav HaitОценок пока нет

- Guideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling FacilityДокумент117 страницGuideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling Facilityshahjada100% (1)

- Project Standards and Specifications Piping Design Criteria Rev1.0Документ15 страницProject Standards and Specifications Piping Design Criteria Rev1.0Alejandro AguanteОценок пока нет

- EGP3-01.16 Welding For Skids and Miscellaneous SteelДокумент10 страницEGP3-01.16 Welding For Skids and Miscellaneous SteelMathias OnosemuodeОценок пока нет

- Piping Scope of Work FEEDДокумент2 страницыPiping Scope of Work FEEDAfolabi OlaniyiОценок пока нет

- Water SoftenersДокумент11 страницWater Softenersadel rihanaОценок пока нет

- Nawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFДокумент29 страницNawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFAhmed AbidОценок пока нет

- AL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCДокумент5 страницAL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCCaptainToniesОценок пока нет

- TGE Brochure 2010Документ12 страницTGE Brochure 2010ankeshkatochОценок пока нет

- MWP-C-CS-PC-0009 Tank Erection Procedure-BДокумент16 страницMWP-C-CS-PC-0009 Tank Erection Procedure-BKing王Оценок пока нет

- Catalog Swivel Joints PDFДокумент24 страницыCatalog Swivel Joints PDFhantaodulutОценок пока нет

- Hydrostatic Test ChartДокумент10 страницHydrostatic Test ChartAnanda ShofwanОценок пока нет

- SVDN-CPP-M-0017-D01-0007-Rev.01-GA Drawing For MP Gas Suction Scrubber - PTC Code 2Документ9 страницSVDN-CPP-M-0017-D01-0007-Rev.01-GA Drawing For MP Gas Suction Scrubber - PTC Code 2123aefОценок пока нет

- (D-121) Pressure Vessels of Low Alloy Steel - Rev.1 PDFДокумент8 страниц(D-121) Pressure Vessels of Low Alloy Steel - Rev.1 PDFmihir_jha2Оценок пока нет

- B313 Mitre Ver 1.1Документ5 страницB313 Mitre Ver 1.1nizardsouissiОценок пока нет

- Spherical Tank Cap. 2 X 3000 MTДокумент2 страницыSpherical Tank Cap. 2 X 3000 MTNofrizal HasanОценок пока нет

- Step 7 De-Watering & DryingДокумент1 страницаStep 7 De-Watering & Dryingmansih457Оценок пока нет

- TQ - Air Fin Cooler (CS) - ModificationДокумент6 страницTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaОценок пока нет

- Installation Procedure For Air Heater CoolerДокумент4 страницыInstallation Procedure For Air Heater CoolerRachel FloresОценок пока нет

- PE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - BДокумент7 страницPE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - B7radu7Оценок пока нет

- Prepared By: Ahmed Mohamed Elshora Under The Supervision Of: U-104 Process TeamДокумент38 страницPrepared By: Ahmed Mohamed Elshora Under The Supervision Of: U-104 Process TeamAhmed ElShoraОценок пока нет

- ENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - AДокумент9 страницENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - AyoeyОценок пока нет

- 15-Chapitre - 10-Heat ExchangersДокумент25 страниц15-Chapitre - 10-Heat ExchangersTaki Goumri100% (1)

- 31 1 Static Equipment Vertical ErectionДокумент2 страницы31 1 Static Equipment Vertical Erectionpunitg_2Оценок пока нет

- Shell & Tube Installation, Operation & Maintenance ManualДокумент14 страницShell & Tube Installation, Operation & Maintenance Manualnidhul07Оценок пока нет

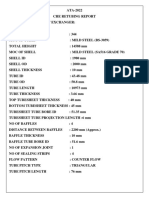

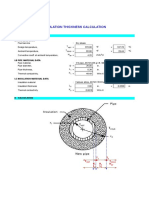

- CHE Retubing ReportДокумент29 страницCHE Retubing ReportRajesh KtrОценок пока нет

- Nioec SP-50-05Документ47 страницNioec SP-50-05er534ytОценок пока нет

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Документ5 страниц18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaОценок пока нет

- Insulation Calculation For 36 inДокумент18 страницInsulation Calculation For 36 inSaepul RochmanОценок пока нет

- Aromatic Heater Erection Spa 20 01Документ65 страницAromatic Heater Erection Spa 20 01Vinod Soman100% (3)

- Jms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0013Документ11 страницJms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0013amir hakimОценок пока нет

- TIMAS-PR-PI-001 - Hot Tapping ProcedureДокумент11 страницTIMAS-PR-PI-001 - Hot Tapping ProcedureMechanical Static WRKОценок пока нет

- Installation of Columns: Installation Recommendations For Precast Reinforced Concrete Production Edition 1 September 2008Документ14 страницInstallation of Columns: Installation Recommendations For Precast Reinforced Concrete Production Edition 1 September 2008j_herndz100% (1)

- Specialty Items PDFДокумент27 страницSpecialty Items PDFHussein OthmanОценок пока нет

- 20130429-Erection Procedure of Condenser (Mr. Tam)Документ56 страниц20130429-Erection Procedure of Condenser (Mr. Tam)Huynh Thanh Tam100% (1)

- Hottaping FURMANITEДокумент85 страницHottaping FURMANITEAriz Joelee ArthaОценок пока нет

- Gangway Tower Preservation Procedure On SiteДокумент4 страницыGangway Tower Preservation Procedure On SiteSalim Mohd RazОценок пока нет

- Heat Shrink CoatingДокумент5 страницHeat Shrink CoatingMekhmanОценок пока нет

- D0307 (MECH) Painting Procedure For Boiler Steel Structure - Rev 0Документ18 страницD0307 (MECH) Painting Procedure For Boiler Steel Structure - Rev 0Surya Darma100% (1)

- Tank Erection JackДокумент2 страницыTank Erection JackardaneОценок пока нет

- Jsa For Roof Air LiftДокумент2 страницыJsa For Roof Air LiftKoshy Thankachen100% (1)

- Shore ApproachДокумент12 страницShore ApproachafifahrashidОценок пока нет

- Post Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12Документ18 страницPost Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12mohd as shahiddin jafriОценок пока нет

- Scissor Shoe Installation Guide Jan 2005 PDFДокумент32 страницыScissor Shoe Installation Guide Jan 2005 PDFMohsen Halweni50% (2)

- Sichuan Air SeparationДокумент25 страницSichuan Air SeparationFarshad Asgari0% (1)

- AB-507 Installed Fired Heaters GuidelineДокумент36 страницAB-507 Installed Fired Heaters GuidelineRosa galindoОценок пока нет

- Procedure For Instalattion of VesselДокумент6 страницProcedure For Instalattion of Vesselyayan hОценок пока нет

- Isometric Piping SymbolsДокумент21 страницаIsometric Piping SymbolsDanish_TalhaОценок пока нет

- Bolt Torquing Tensioning Procedure PDFДокумент29 страницBolt Torquing Tensioning Procedure PDFric leonisoОценок пока нет

- KLM - PROJECT - STANDARD - AND - SPECIFICATIONS - Plant - Operating - Manuals - Rev01 PDFДокумент10 страницKLM - PROJECT - STANDARD - AND - SPECIFICATIONS - Plant - Operating - Manuals - Rev01 PDFLenaldy Nuari GarnokoОценок пока нет

- Air Separator PDFДокумент2 страницыAir Separator PDFIlyas AhmedОценок пока нет

- Tube To Tube SheetДокумент9 страницTube To Tube Sheetcmpatel_00100% (2)

- Leak Testing & Plugging Procedure For SYN. Loop Waste Heat BoilerДокумент3 страницыLeak Testing & Plugging Procedure For SYN. Loop Waste Heat BoilerBESTINОценок пока нет

- (D-301) General Requirement in Equipment Installation - Rev.4 PDFДокумент11 страниц(D-301) General Requirement in Equipment Installation - Rev.4 PDFmihir_jha2Оценок пока нет

- Checklist For Transformer Burnt Oil Tank Design & DrawingДокумент3 страницыChecklist For Transformer Burnt Oil Tank Design & DrawingRupesh KhandekarОценок пока нет

- D 103eДокумент19 страницD 103eCivil FriendОценок пока нет

- Design Criteria StructuralДокумент56 страницDesign Criteria Structuralvenkiee100% (1)

- FW Pipe Rack DocumentДокумент38 страницFW Pipe Rack DocumentSumanthОценок пока нет

- General Notes 1 Steel WorkДокумент18 страницGeneral Notes 1 Steel Workmaga2292Оценок пока нет

- (E-104) Air Cooled Heat Exchangers - Rev1 PDFДокумент13 страниц(E-104) Air Cooled Heat Exchangers - Rev1 PDFmihir_jha2Оценок пока нет

- Ullmann Filtration FundamentalsДокумент33 страницыUllmann Filtration FundamentalspastorgeeОценок пока нет

- (FB-101) Spec For Atmospheric Storage Tanks - Rev.4 PDFДокумент31 страница(FB-101) Spec For Atmospheric Storage Tanks - Rev.4 PDFmihir_jha2Оценок пока нет

- A9R1m27qv2 n1gwh0 860 PDFДокумент1 страницаA9R1m27qv2 n1gwh0 860 PDFmihir_jha2Оценок пока нет

- (D-112) Marking For Vessels Heat Exchangers - Rev.3 PDFДокумент8 страниц(D-112) Marking For Vessels Heat Exchangers - Rev.3 PDFmihir_jha2Оценок пока нет

- (K-101X) Eng'g Spec For Instrumentation For Package Equipment - Rev.4 PDFДокумент46 страниц(K-101X) Eng'g Spec For Instrumentation For Package Equipment - Rev.4 PDFmihir_jha2100% (1)

- (D-121) Pressure Vessels of Low Alloy Steel - Rev.1 PDFДокумент8 страниц(D-121) Pressure Vessels of Low Alloy Steel - Rev.1 PDFmihir_jha2Оценок пока нет

- (D-307) Tray Assembling Work - Rev.2 PDFДокумент15 страниц(D-307) Tray Assembling Work - Rev.2 PDFmihir_jha2Оценок пока нет

- (FB-102) Spec For Spheres Fabrication - Rev.3 PDFДокумент8 страниц(FB-102) Spec For Spheres Fabrication - Rev.3 PDFmihir_jha2Оценок пока нет

- (E-101) Heat Exchangers - Rev.4 PDFДокумент32 страницы(E-101) Heat Exchangers - Rev.4 PDFmihir_jha2Оценок пока нет

- (E-111) Steam Surface Condenser - Rev.2 PDFДокумент17 страниц(E-111) Steam Surface Condenser - Rev.2 PDFmihir_jha2Оценок пока нет

- Karamchandani Gupta Amortiguamiento en Torres de ProcesoДокумент4 страницыKaramchandani Gupta Amortiguamiento en Torres de ProcesocorneliortizОценок пока нет

- (D-101) Pressure Vessels - Rev2 PDFДокумент30 страниц(D-101) Pressure Vessels - Rev2 PDFmihir_jha2Оценок пока нет

- (D-311) Filling Work For Vessel - Rev.3 PDFДокумент8 страниц(D-311) Filling Work For Vessel - Rev.3 PDFmihir_jha2Оценок пока нет

- Flexitallic Spiral Wound Gasket MaterialsДокумент1 страницаFlexitallic Spiral Wound Gasket Materialsmihir_jha2Оценок пока нет

- (D-202) Inspection and Tests of Vessels and Heat Exchangers - Rev.4 PDFДокумент22 страницы(D-202) Inspection and Tests of Vessels and Heat Exchangers - Rev.4 PDFmihir_jha2Оценок пока нет

- (D-301) General Requirement in Equipment Installation - Rev.4 PDFДокумент11 страниц(D-301) General Requirement in Equipment Installation - Rev.4 PDFmihir_jha2Оценок пока нет

- KST GasketsДокумент42 страницыKST Gasketsmihir_jha2Оценок пока нет

- (A-165-EL) Eng'g Spec For Design Loads - Rev.3 PDFДокумент25 страниц(A-165-EL) Eng'g Spec For Design Loads - Rev.3 PDFmihir_jha2Оценок пока нет

- (D-103) Fractionating Trays - Rev1 PDFДокумент10 страниц(D-103) Fractionating Trays - Rev1 PDFmihir_jha2Оценок пока нет

- Design Calculation 024-C-003Документ605 страницDesign Calculation 024-C-003mihir_jha2Оценок пока нет

- Insulation & FireproofingДокумент1 страницаInsulation & Fireproofingmihir_jha2Оценок пока нет

- Mihirjha LatestДокумент3 страницыMihirjha Latestmihir_jha2Оценок пока нет

- M&Y Values 1-2010Документ7 страницM&Y Values 1-2010mihir_jha2Оценок пока нет

- Spa ClaimsДокумент1 страницаSpa ClaimsJosephine Berces100% (1)

- Dreamfoil Creations & Nemeth DesignsДокумент22 страницыDreamfoil Creations & Nemeth DesignsManoel ValentimОценок пока нет

- Dbms UPDATED MANUAL EWITДокумент75 страницDbms UPDATED MANUAL EWITMadhukesh .kОценок пока нет

- SOP No. 6Документ22 страницыSOP No. 6Eli CohenОценок пока нет

- MPPWD 2014 SOR CH 1 To 5 in ExcelДокумент66 страницMPPWD 2014 SOR CH 1 To 5 in ExcelElvis GrayОценок пока нет

- Completed NGC3 ReportДокумент4 страницыCompleted NGC3 ReportTiCu Constantin100% (1)

- ACC403 Week 10 Assignment Rebecca MillerДокумент7 страницACC403 Week 10 Assignment Rebecca MillerRebecca Miller HorneОценок пока нет

- Freqinv 3g3fv Ds 01oct2000Документ20 страницFreqinv 3g3fv Ds 01oct2000Mohd Abu AjajОценок пока нет

- Certification DSWD Educational AssistanceДокумент3 страницыCertification DSWD Educational AssistancePatoc Stand Alone Senior High School (Region VIII - Leyte)Оценок пока нет

- Catalogue of The Herbert Allen Collection of English PorcelainДокумент298 страницCatalogue of The Herbert Allen Collection of English PorcelainPuiu Vasile ChiojdoiuОценок пока нет

- Mutual Fund Insight Nov 2022Документ214 страницMutual Fund Insight Nov 2022Sonic LabelsОценок пока нет

- TRX Documentation20130403 PDFДокумент49 страницTRX Documentation20130403 PDFakasameОценок пока нет

- Reflection Paper 1Документ5 страницReflection Paper 1Juliean Torres AkiatanОценок пока нет

- Immovable Sale-Purchase (Land) ContractДокумент6 страницImmovable Sale-Purchase (Land) ContractMeta GoОценок пока нет

- BBCVДокумент6 страницBBCVSanthosh PgОценок пока нет

- Summary - A Short Course On Swing TradingДокумент2 страницыSummary - A Short Course On Swing TradingsumonОценок пока нет

- scx4521f SeriesДокумент173 страницыscx4521f SeriesVuleticJovanОценок пока нет

- RFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonДокумент8 страницRFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonSteven MoietОценок пока нет

- Permit To Work Audit Checklist OctoberДокумент3 страницыPermit To Work Audit Checklist OctoberefeОценок пока нет

- The April Fair in Seville: Word FormationДокумент2 страницыThe April Fair in Seville: Word FormationДархан МакыжанОценок пока нет

- Fire and Life Safety Assessment ReportДокумент5 страницFire and Life Safety Assessment ReportJune CostalesОценок пока нет

- Black BookДокумент28 страницBlack Bookshubham50% (2)

- 19-2 Clericis LaicosДокумент3 страницы19-2 Clericis LaicosC C Bờm BờmОценок пока нет

- 1.6 Program AdministrationДокумент56 страниц1.6 Program Administration'JeoffreyLaycoОценок пока нет

- Jainithesh - Docx CorrectedДокумент54 страницыJainithesh - Docx CorrectedBala MuruganОценок пока нет

- Pyro ShieldДокумент6 страницPyro Shieldmunim87Оценок пока нет

- Dunham Bush Midwall Split R410a InverterДокумент2 страницыDunham Bush Midwall Split R410a InverterAgnaldo Caetano100% (1)

- Sem 4 - Minor 2Документ6 страницSem 4 - Minor 2Shashank Mani TripathiОценок пока нет

- GSMДокумент11 страницGSMLinduxОценок пока нет

- Woodward GCP30 Configuration 37278 - BДокумент174 страницыWoodward GCP30 Configuration 37278 - BDave Potter100% (1)